Specific versions

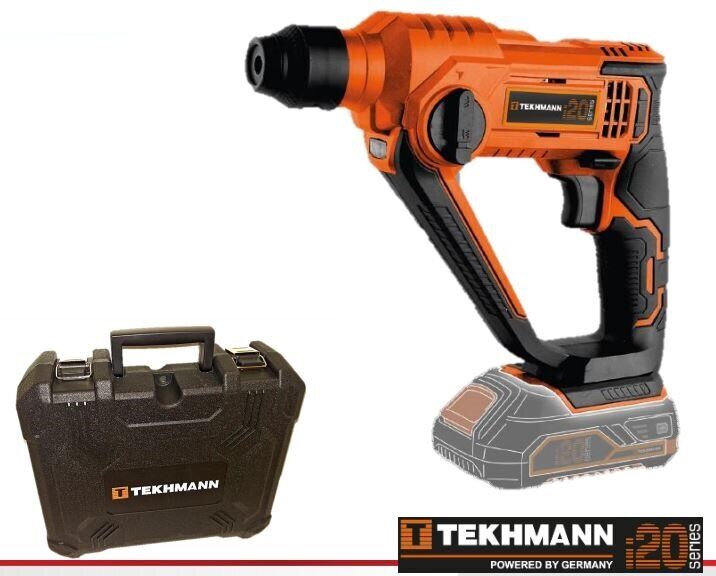

Among the battery modifications with attachment of additional attachments according to the SDS + system, the 18v BBH18 model stands out. The body of the hammer drill itself resembles the Latin letter L. It will help to punch holes up to 2.4 cm in size even in a concrete surface. The energy of each impact is sufficient for the device to work with high performance. Since the device has an option to suspend torsion, you can also gouge walls with it.

The bumpless mode is valuable when machining metal or wood structures. The body itself, made of strong steel, is almost indestructible. And the clutch gives additional protection to the internal components. At the same time, it protects the user. The battery is manufactured using a special technology to reduce the risk of overload.

The BBH 12 is deservedly considered an interesting battery model. The device is capable of making holes with a diameter of up to 1.3 cm. As in the previous case, a shockless mode is provided for normal work with wood and metal. Additionally, there is an adapter for bits and a battery charge indicator. The mass of the hammer drill is 2 kg, and during operation it emits 80 dB noise. This means that it is simply rash to use your device without ear protectors.

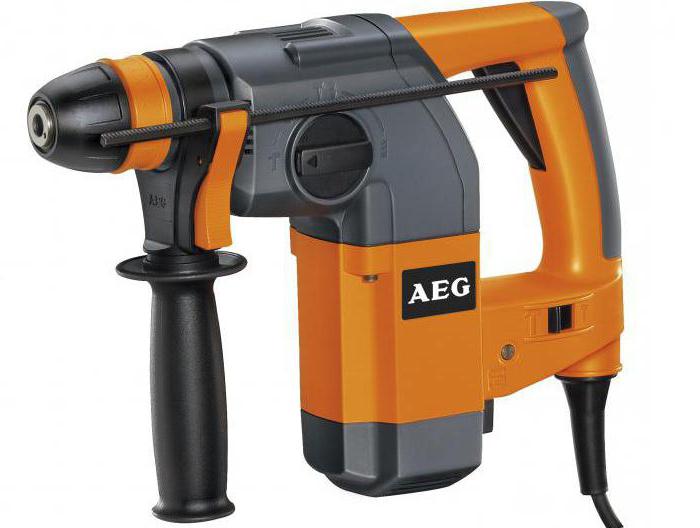

When you need the most convenient and productive device, you should give preference to the KH 24 IE model. It is a 3-mode, reversible hammer drill capable of punching holes from 1.3 cm (in tool steel) to 3 cm (in most types of wood). In addition to the clutch, the user is protected by a pair of non-slip handles. The SDS + chuck is designed in such a way that tool changes are easy. The perforator is appreciated by consumers as a solid device that allows them to confidently solve most of the tasks.

How to choose?

In order to contact specialized services for repairs as rarely as possible, it is necessary from the very beginning to choose exactly the hammer drill that meets the specific requirements. There are no special secrets for experienced craftsmen, but after all, not all are experienced craftsmen. The most important classification of drilling machines is according to the number of modes that they have. Single-mode devices do not find particular use in everyday life, they are needed mainly by professionals to solve a narrow range of tasks.

The two-mode models combine hammer drilling with conventional drilling or chiselling. Well, three-mode devices have maximum capabilities

Having dealt with the number of functions used, you need to pay attention to the level of power and strength. These figures should not be confused because the force of impact never absorbs all the power consumed.

The law of conservation of energy excludes the creation of devices where all the current would pass without loss into the movement of the working part of the tool.

But punching power and power are closely related. If there is more than one indicator, then the other is also more, you should not chase them once again, because a "stronger" device is always heavier. At home, not just a lightweight puncher is preferable. It is desirable that its cartridge is also fixed or removed without a key. Yes, this is somewhat less reliable, but the time savings justify the difference. In order not to delve into the distant technical and physical jungle, we list several criteria that a home punch must meet:

- power not less than 600 and not more than 900 W (it is this corridor that is optimal in the opinion of most experts);

- impact force from 1.2 J, but not more than 2.2 J (you still don't have to break through reinforced concrete walls again);

- the presence of all three main modes (since it is not known in advance what will have to be faced);

- adjustment of the twisting frequency (so that different surfaces can be processed);

- a sleeve that protects against jamming of the drill or drill.

How to repair?

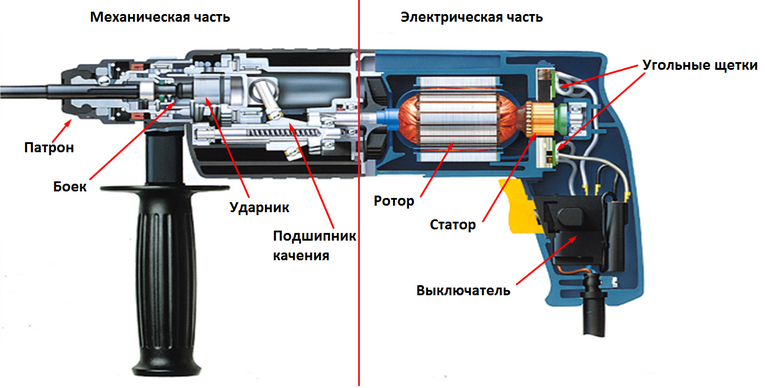

Even if the blue AEG brand is stuck on the device, this does not give a complete guarantee that it will not break. Problems can affect both the mechanical and electrical components of the rock drill. Both are arranged in much the same way as in an electric drill. But there is a difference in the method of transmission of effort. While drill makers prefer to equip them with a gear pair, drill makers use a full format gearbox. Regardless of what exactly broke, the first thing to do is clean the outside of the case. Then contamination will not get inside. A typical workflow is as follows:

- opening the case;

- parts washing;

- careful visual inspection;

- replacement of problem parts;

- if necessary, cover them with the grease specified in the instruction manual.

When the hammer drill bit does not want to be in the working position, there is no need to open the housing. It is enough to clean the cartridge from dirt. If this does not help, it will have to be changed. But in case of failures in the switch, you will still need to disassemble the device. But you can find the problem even without contacting specialists.

Let's say a puncher just doesn't work. The first step should always be to check for the presence of current in the network. Even if there is one, it is useful to check the health of the supply wire. For battery models, it is recommended to check the battery charge and the quality of the contacts.

Sometimes the hammer drill does not work simply because of the oxidized contacts of the start button. You can take a look at them by opening the back cover. Even if there are no visible signs of oxidation, the tester will say the final word. Contacts do not even need to be cleaned. Much more correct to change the entire punch.

The electric motor brushes can be replaced by hand. But the armature does not allow such treatment, like the stator and other parts of the engine. Only qualified specialists should work with it. If the speed regulator breaks down, it is best to change it entirely.