Views

By weight

The wide range of applications of jackhammers is achieved due to the specific differences between the individual models. So, the lightest devices (weighing less than 6 kg) are used mainly for domestic purposes. They can confidently cope with crushing tiles, plaster, relatively thin cement floors. Devices of the middle weight category are widely demanded by builders, they are used to break asphalt. The most powerful devices weigh up to 30 kg and are needed mainly in large-scale construction work.

By drive type

Air-powered jackhammers are the most commonly used options. Compressed air is produced using a compressor. The chisel moves under the action of the air flow. Air-driven household appliances must strike with a force of at least 5 J. For industrial units, the bar is twice as high. Such characteristics make it possible to:

- destroy sidewalks;

- demolish buildings made of natural or artificial stone;

- breaking through concrete and so on.

Electric hammers are equipped with special internal strikers. The strikers are driven by rotating parts. Motorized units can easily break a wall or covering

But it is important to understand that the high power of the force generated by an electric motor is not always good. This property makes it difficult to fully drill and cut materials.

Problems can also be associated with the appearance of sparks. They are found even in the most reliable models. Due to this feature, electrical devices cannot be used in places with high fire risks. Conventional models are not capable of operating disconnected from the mains. Battery versions can be considered an exception, but they are heavier than analogue plugged into an outlet.

Hourly current consumption (in terms of continuous operation) reaches 1.7 kW. Each blow has a force of 45 J, and such blows are delivered 2000 times per minute.

Important: all modern models of fenders with an electric motor are equipped with double insulation, so you can connect the device to a home outlet without any fear. The gasoline (aka gasoline breaker) hammer is easy to use

Such mechanisms can work even where there is no electricity and it is not very convenient to use compressors. Versions with internal combustion engines, in addition, are safer than electric or pneumatic deflector systems. But it must be borne in mind that the heat engine creates a lot of noise. And you also have to constantly pour fuel into the tank, that is, the continuity of work is a big question.

Gasoline powered jackhammers perform well:

- when rocky and icy soil is destroyed;

- when dismantling asphalt and concrete;

- in the process of extracting resources.

Chippers with internal combustion engines help in a short time to break materials of different hardness. The size of the processed blocks does not play a special role either. Hydraulic devices deservedly stand out in a separate group. There are various devices for them. Basically, the hydraulic chipper, due to its versatility and high performance, is used by rescue teams.

DIY electric jackhammer repair

Repairing an electric jackhammer is not an easy task. In order to perform it, you need to understand: as a rule, hammer repair consists of two main stages:

- Fault detection - identification of a problem node that has already failed or its resource is close to zero.

- Replacement of defective parts.

Of course, it would be more correct to repair the electric hammer that needs it and contains a certain supply of working life. It is necessary to determine this so that the repair does not turn into a useless waste of time, effort, money, and the tool after the repair has worked for a certain period.

Important! If the jackhammer is in poor condition, then repairing it is extremely unprofitable. The prices for spare parts (spare parts) are quite high, and spending on them will call the profitability of repairs into question.

Remember! In order for the tool not to remind of itself of breakdowns as long as possible, its maintenance must be carried out regularly.

This does not require the presence of special devices. As a rule, disassembly of the jackhammer is possible with a rather limited number of tools.

The market provides a limited list of spare parts. As a rule, these are springs, valves, air distribution units, strikers. Therefore, not every breakdown can be eliminated without contacting a service. Nevertheless, it makes sense to consider some problems that can still be solved with your own hands.

Interesting! A positive point. Many spare parts for demolition hammers that can be found on the market are universal. That is, one spare part is suitable for several hammer models that differ from each other not only in power, but even in the manufacturer.

It will be correct to note that if we take into account the Chinese electric hammer, then in the event of a breakdown, one should not count on successful repairs. They are often disposable due to the poor quality of the materials used in the manufacture.

Consider a classic renovation plan:

- Disassembly and cleaning of dirt from a jackhammer.

- Defect detection (if it is not obvious).

- Repair or replacement of damaged parts.

- Assembling the tool.

- Functional check.

As a rule, such a plan is used by highly qualified service employees who do this professionally. We are considering the possibility of repair with our own hands, and, as a rule, this moment comes when the problem is obvious and requires an immediate solution. So, let's look at some of the most common breakdowns of electric jackhammers for models from the giants Makita and Hitachi, which you can do yourself.

Repair of jackhammers "Hitachi"

One of the most common problems with the Makita bump stop is the pinching of the lance in the barrel. As a rule, the reason is the wear of the retaining bodies, but a banal defect of the peak is also possible.

In order to fix the problem, you must act according to the following algorithm:

- The top cover (protection) is removed.

- The retaining ring is removed.

- Dirt accumulations are removed.

- The oil seal is removed (at this stage, the peak will fall out of the barrel).

Identifying the problem:

- The locking body is inspected. If it shows obvious signs of wear (rounded edges), then it must be replaced.

- Inspection of the splines of the barrel. They are normally square in shape. If they have a sharp shape, then the barrel needs to be replaced.

- Replacement of a worn-out element and assembly.

- Blockage in the hose. As a rule, it occurs due to a fracture. Fixing the problem won't be a big problem. You just need to find the damaged area and remove it. Unfortunately, if the removal of a part would result in unnecessary shortening of the hose, it will have to be replaced completely. The list of tools to fix this problem is minimal:

- knife;

- clamps of the appropriate size.

Repair of jackhammers "Makita"

There is often a problem of increased frequency of impacts with a weak single impact.

Reason: Excessive clearance between the barrel receiver and the distributor.

To fix the problem, you must:

- Disconnect hammer and muffler.

- Remove the retaining ring and retainer.

- Tighten the link to the "dead" point.

- Despite the reliability of the tool and the efforts of the manufacturer, there is often a problem with the point of contact between the end of the barrel and the valve box. The problem is eliminated if the assembly is cleaned in time.

The path from pick to bump

When stone caves were the predominant human habitation, then the first signs in history of the use of devices to facilitate the processing of hard rocks appeared. Most likely, these were stone chisels and axes.

Over the course of tens of millennia, nothing has fundamentally changed in this area of human activity. As blocks for the construction of pyramids were cut by hand in antiquity, until the end of the 19th century, the technologies of breaking stone, mining coal and salt remained at the level of a hand pick.

The invention of electric motors and internal combustion engines revolutionized this business. The simplicity of converting rotary motion into translational motion with a periodic impact on the pickaxe led to the appearance of mechanical jackhammers, without which it is impossible to imagine neither the construction of roads, nor mining, nor rescue operations after an earthquake.

Criterias of choice

There are three main criteria that are taken into account when choosing an electric jackhammer:

- The weight.

- Power.

Expert opinion

Dmitry Levin

These parameters will seem familiar to those craftsmen who previously bought rotary hammers. The principles of these tools are similar to each other. The only difference is that the bumpers do not have a drilling option.

The weight

Demolition hammers are presented in stores in three weight categories:

- Lungs (up to 5 kilograms). Designed for simple work and materials of small strength. Due to their weight, they are suitable for dismantling horizontal surfaces. Such tools are taken for construction work that requires long-term involvement. The hands of the master do not have time to get tired.

- Medium (from 5 to 10 kilograms). Both household and professional tools fall into this category. They are used for the treatment of hard surfaces - concrete, brick, asphalt, etc.

- Heavy (from 10 kilograms). Devices of this group are often called concrete breakers. But in practice, these hammers are universal - their wide functionality allows you to perform tasks of all levels of complexity.

It is inexpedient to be guided by the idea that the greater the weight of the device, the more reliable it is. It is necessary to select a hammer by weight in such a way that the device is suitable for the working conditions. For example, a heavy and oversized bumper is not suitable for work in a narrow inter-door space. It is also not suitable for working in a horizontal position.

Power

The performance of an electric jackhammer is determined by three interrelated parameters:

- Power.

- Impact force.

The power of a tool affects how long it will run continuously and the size of the tooling that the tool supports. Increasing power leads to higher productivity and vice versa. The jackhammer market offers different models with a range of powers from 500 to 2,000 watts.

Each material implies its own mode of operation and its own power. Household electric hammers do not need more than 1000 watts of power.

Impact force

The impact force is indicated for each model in Joules. As the force increases, the range of materials that the hammer can handle expands. High values of this criterion are typical for instruments from the heavy category. Lightweight hammers will not handle a lot of power out of proportion to their equipment.

For heavyweight jackhammers, the force of a single blow reaches 60 J (in the most advanced models).For light models, these indicators decrease significantly and are cut to the level of 3 - 8 J.

Additional functions

What weight category do you work with an electric jackhammer?

Light Medium

Electric breakers are not only selected based on performance. The secondary technologies that accompany the operation of the device are also important.

These technologies include:

- Beat frequency controller. The system is responsible for switching hammer modes based on momentary tasks. Usually regulation is carried out using a button or a wheel.

- Power button lock. The mechanism does not allow the device to be unauthorizedly included in the process of crushing materials. With this function, the technician does not need to constantly keep his finger on the button. On some models, the button is replaced by a slider.

- Inrush current limiter. Installed on high-power devices. The purpose of the system is to prevent power surges when the equipment is turned on.

- Anti-vibration system. Prevents vibrations of the tool in the hands of the master using dynamic counterweights. For the same purposes, hammers are supplied with rubberized handles, inserts and linings.

- Monitoring the wear of carbon brushes. The indicator is installed on selective models and keeps the owner of the hammer informed of the condition of the brushes. When wear becomes critical, the tool shuts down automatically, protecting the engine.

- Control panel. Contains indicators that inform the wizard about the quality of the machine. The panel notifies the owner in cases when the tool is worn out, needs repair or maintenance.

Expert opinion

Dmitry Levin

Electric breaker bodies are made of metal or plastic. The latter option is used more often due to its lightness and low cost.

When choosing a plastic model, it is important to make sure that it was made from a high-strength variety of material.

How to repair Makita products

Makita bumpers are most often damaged by pinching the lance. There are only two reasons: wear of the locking element or deformation of the part itself. You can fix the problem with your own hands like this:

- remove the upper protective cover;

- take out the stopper ring;

- clean all surfaces and parts;

- take out the oil seal;

- inspect the locking element;

- if necessary, change it to a spare.

If everything is in order with the locking element, check the splines of the barrel. If they have lost their square shape, they change the entire trunk. It is useful to be able to deal with the blockage of the hose. There is nothing complicated in this: all the work comes down to finding a deformed place and cutting it out. But if the hose is shortened to inconvenient limits, it will need to be replaced.

Owners of Makita air hammers often complain of very frequent blows, each of which is very weak. This problem appears due to too much clearance separating the air receiver from its distributor. As a result, part of the air stream goes to the side. Therefore, the impulse is transmitted only partially. The repair is carried out as follows:

- dismantle the muffler;

- take out the stopper ring;

- take out the retainer;

- twist the link until it reaches the "dead" position;

- collect everything in reverse order.

Now let's look at the repair of electrical fenders. The most important component of this repair is the replacement of the lubricating oil in the event of a leak or depletion of a resource. The work is carried out as follows:

- check if the instrument is connected to the network;

- remove the crank mechanism;

- remove the remnants of the grease;

- put a new portion (300 grams exactly).

This moment is typical not only for Makita products, but also for products from other manufacturers. Troubleshooting the bulk of problems, as you can easily understand, is no more difficult than with any other technically uncomplicated tool.

Specifications

A jackhammer is a tool designed to break a hard surface.The use of Makita breaker equipment allows you to remove tiles, destroy a partition made of bricks, concrete, remove asphalt, clean up the plaster and concrete layer, make niches and holes in walls, hammer frozen soil and ice, disassemble metal structures.

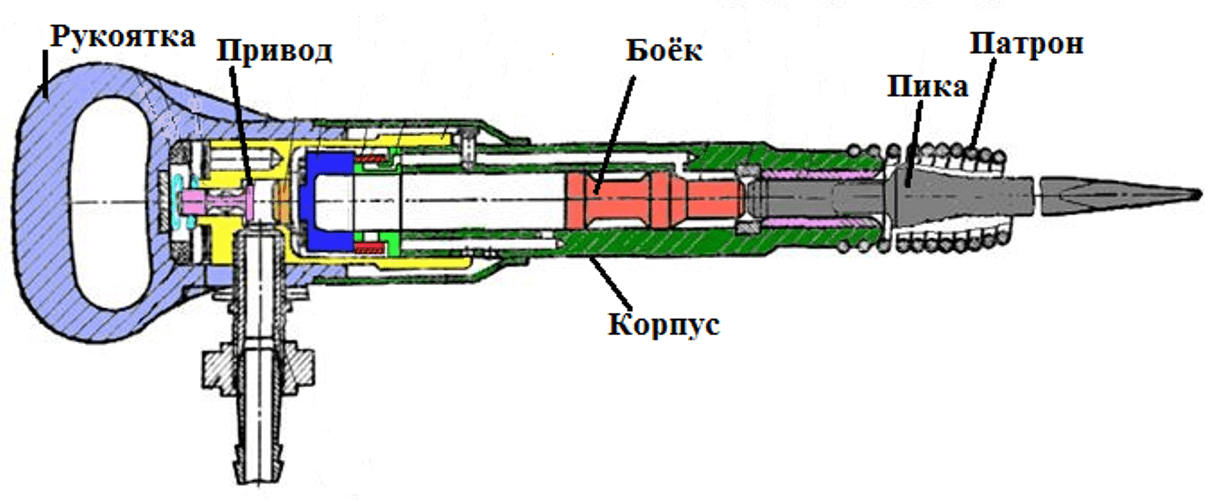

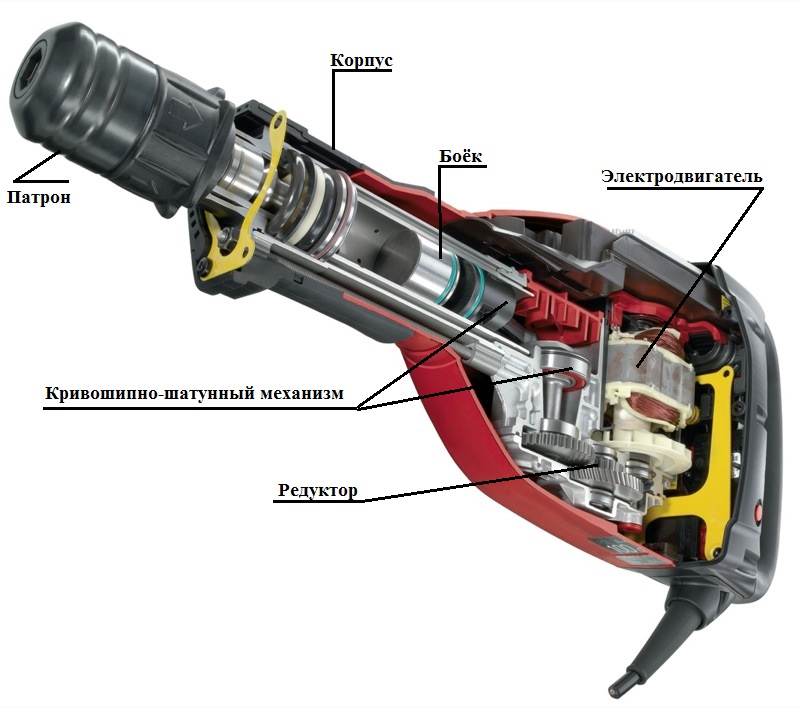

Anyone the jackhammer has powerful force impact, for which the striker, lance, drive are responsible. The tool is not characterized by a complex internal structure, as well as a scheme of work. Inside the electric hammer there is a striker that drives the drive. The latter transmits a mechanical impulse to the peak, that is, the percussion mechanism. Depending on the performance, it weighs from 3 to 32 kilograms.

The task facing the bump stop is determined by the peculiarity of its executive part - the peaks. The latter can be of the following varieties:

- crowbar;

- scapula;

- chisel;

- ramming.

General criteria and characteristics of demolition hammers

Technical characteristics of the electric jackhammer.

Now you know the features of the device of electric and pneumatic breakers. To complete the picture, you need to familiarize yourself with the main characteristics of such tools, which will allow you to choose the most suitable model.

The most important characteristics of any bump stop is the number of blows and their strength. It is these parameters that directly affect the efficiency of the bump stop.

In the case of an electric model, it is imperative to take into account such a moment as engine power.

Pay attention to the weight of the tool. This has already been mentioned earlier.

If the jackhammer weighs too much, it will create certain difficulties in its operation. It all very much depends on the nature of the upcoming work. For example, if you need to get rid of an old floor screed, a heavy jackhammer will come in handy. If it is necessary to destroy the walls, the weight of the unit will play against you.

The tool manufacturer should not be overlooked either. Extensive explanations are not needed here. Everyone knows that there are responsible manufacturers, under whose name truly high-quality goods are produced, and there are companies engaged in the production of so-called. consumer goods. If you are planning to buy a jackhammer, it is better to opt for a tool from a good brand. There are quite a few companies that are not yet very popular worldwide, but produce quality products.

Jackhammers are usually divided into professional and household. Professional-grade units have a higher power and, as a rule, allow you to cope with a wide range of tasks. Therefore, before buying, you must definitely plan the front of the upcoming work so as not to overpay for unnecessary functions.

In addition to the main characteristics considered, jackhammers also have additional features that must also be taken into account. First, make sure that the breaker, if it is an electric model, is equipped with a button lock, which will ensure uninterrupted and continuous operation of the unit.

This latch eliminates the need for the operator to constantly hold down the jackhammer start button.

First, make sure that the breaker, if it is an electric model, is equipped with a button lock, which will ensure uninterrupted and continuous operation of the unit. This retainer eliminates the need for the operator to constantly hold the trigger of the jackhammer.

Secondly, an addition such as an idle frequency limiter will be useful. This feature improves the performance of the bumper and provides longer tool life.The limiter works according to an extremely simple scheme: if a less intense load is applied to the tool, the engine speed is reduced in automatic mode. After the load increases again, the engine speed will also increase.

Thus, there is nothing complicated in the device of modern jackhammers. These are simple and functional tools that allow you to cope with a wide variety of renovation, decoration and construction work. Knowing the main features of the device and the most important characteristics of the jackhammer, you can easily choose and buy the most suitable tool for you.

Jackhammers seem to be familiar to all people. It is difficult to find those who have never seen how they smash asphalt or tiles, demolish walls. But not everything is so simple.