Device and characteristics

The structure of the overwhelming mass of optical-mechanical levels is similar and differs mainly in the presence or absence of a rotary flat metal ring (dial), which makes it possible to recognize angles on a horizontal surface with an accuracy of 50% and features in the design of some components. Let's analyze the structure and how the ordinary optical layer functions.

The basic element of the device is an optical (telescope) tube with a lens system, capable of showing objects of observation in an enlarged view with a magnification of 20 times or more. The pipe is fixed on a specialized rotating bed designed for the following:

- fixation on a tripod (tripod);

- setting the optical axis of the device in exactly horizontal position, for this purpose the bed is equipped with 3 vertically adjustable "legs" and one or 2 (in samples without auto-adjustment) bubble levels;

- accurate horizontal guidance, which is done by paired or single flywheels.

Adjustment to the user's vision is carried out by turning the adjusting ring on the eyepiece. If you look into the eyepiece of the telescope of the device, you can see that, in addition to enlarging the observed object, the device applies a scale of thin lines (reticle or reticle) to its image. It creates a cruciform pattern from horizontal and perpendicular lines.

How to choose?

The main step in buying an optical-mechanical level should be the study of the market for construction and geodetic devices that meet the required characteristics and working conditions. The following describes the main aspects of choosing the right device from the extensive assortment list available.

Often, the first aspect of the choice is not the functionality of the device, but its price. Focusing on the most budget-friendly modifications, the consumer runs the risk of purchasing a low-quality device with the smallest set of options and unreliable measurement accuracy. The optimal ratio of price and quality in most cases is acceptable.

Level configuration and the need for the presence of a compensator in it. The compensator is a free-hanging prism or mirror in the optical system to maintain the horizontal line of the hairline when the device is tilted within the specified range. The damper dampens accidental or externally initiated swinging of the compensator

When buying a device with a compensator, it is not so much the peculiarities of its structure, among which there are really original technical solutions, that the quality of their implementation by the manufacturer is of no small importance.

The quality of parts and workmanship. A feature of the optical-mechanical device is that there is especially nothing to break in its structure.

A manufacturing defect, if any, will be detected during the first measurements and the device will be replaced. Renowned companies guarantee the excellent quality of their own products, expressing this in the price of the product. When buying at a retail outlet, it is necessary to check the smoothness of the adjustment of the guide screws and immediately get the support of a highly qualified specialist.

Accuracy, multiplicity and other technical parameters again depend on the type of future work. Optical and mechanical levels with an integrated compensator and a magnetic vibration damping system are considered to be more accurate.

When buying a device, it is necessary to find out whether there is a verification certificate (when, in fact, it is required), since sometimes the price of the verification operation is included in the final price of the device, making it more expensive accordingly.

When buying a device from one of the popular brands, it will be useful to find out the location of the nearest organization that provides service support and maintenance services.

The availability of legible and detailed technical documents on the settings and does not cause problems in using the device.

How to use?

The work is performed by 2 people: one - specifically with the device, placing, pointing at the object - a ruler, reading and entering values, and the other with a measuring rod, dragging and placing it according to the instructions of the first, observing its perpendicularity. The first step is to find a place to install the device. The most suitable location is in the center of the area to be measured. A tripod is placed on the selected area. To obtain a level horizontal position, loosen the tripod leg clamps, mount the tripod head to the required height and tighten the screws.

The level is placed and fixed with a fixing screw on a tripod. Turning the lifting screws of the device, using the level, you need to achieve the horizontal positioning of the level. Now you need to focus on the object. To do this, the telescope must be aimed at the staff, turning the handwheel to make the image as sharp as possible, the sharpness of the reticle is adjusted with the adjusting ring on the eyepiece.

After installing and configuring the device, you can start exploring. The rod is placed on the starting point, the readings are carried out along the middle thread of the telescope mesh. The readings are recorded in the field book. Then the staff moves to the measured point, the process of reading the readings and registering the count is repeated. The difference between the readings of the initial and measured points will be the excess.

For information on how to use the optical level correctly, see the following video.

Popular models

This overview includes models that represent the most logical choice for a wide range of level users.

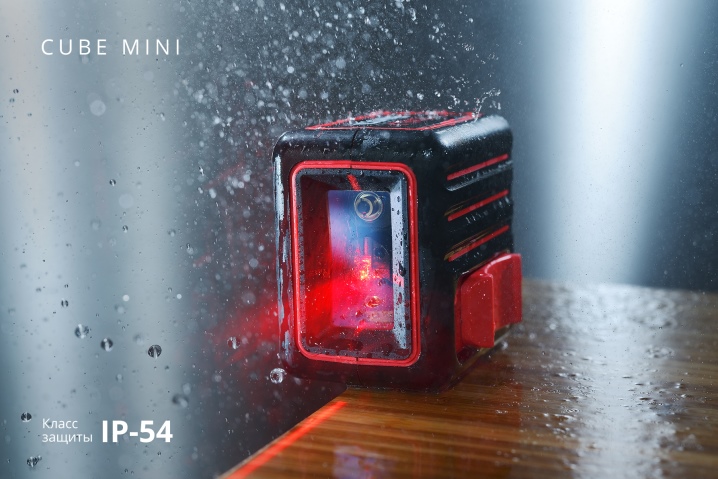

The Cube Mini Basic Edition belongs to the household Ada laser levels. They are great for leveling floors, parquet and tiles.

When installing furniture, this level is also very convenient to use. This model is also used for more complex tasks in the construction and installation of various structures and finishes. It has auto-leveling with a range of + -3 degrees, range - 20 m, accuracy - 0.2 mm / m.

Another budget option is 2D Basic Level, a model with two laser planes (horizontal has a scanning angle of 180 degrees, vertical - 160).

The Ada Cube 3D Professional Edition gives you more measurement and layout options by projecting one a horizontal line and two vertical... It has a battery saving mode, automatic leveling and simple one-button operation. There is a beep function that warns of excessive deviation from the horizon.

In the mode of operation with a radiation receiver, the operating range of this device can be increased to 70 m. The accuracy is the same as that of the previously considered models.

If you are looking for a more professional optical instrument, then the ADA Ruber-X32 model may be for you. It is more expensive than the ones described above, but provides higher accuracy. The level has a telescope with 32x magnification, which provides a high level of comfort when working

The device is unpretentious and can be used in any weather. The maximum deflection of the compensator is 0.3 degrees, the accuracy is 1.5 mm / km.

Operating tips

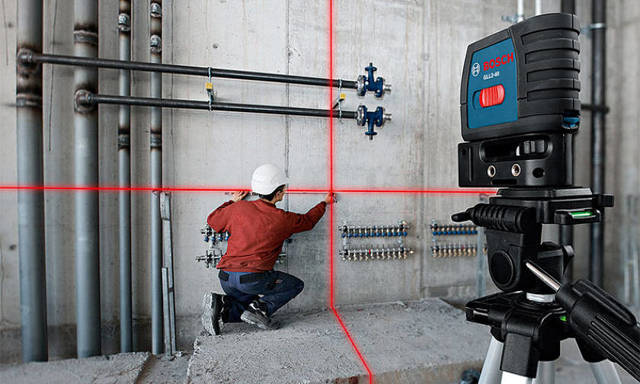

- When using devices with a laser, make sure that there are no objects in the path of the beam (so that the beam is not interrupted). It is recommended to choose the correct distance to the object corresponding to the declared range of the level. Otherwise, the level will be hard to see.

- Be sure to make sure that the level is leveled (installed on a horizontal plane or on a tripod). During shooting, the level is rigidly fixed.

- Before shooting, level the level on the horizon, focusing on the compensator signal, if there is such a function, or on the built-in bubble level.

- Laser devices can be hazardous to health. Avoid eye contact with the laser (both yourself and other people and animals).

- Laser models require timely battery replacement. In the case of long-term work, operation from the mains is allowed.

Laser levels of the CUBE series of the ADA Instruments trademark.

Auxiliary equipment and equipment

In addition to the device itself, for measurements we need the above tripod, as well as a specialized calibrated rod for measurements (measuring rod). The divisions are 10 mm wide stripes of alternating red and black. The numbers on the rail are located with a difference between 2 adjacent values of 10 centimeters, and the value from the zero mark to the end of the rail in decimeters, at the same time the numbers are shown in 2 digits. So, 50 centimeters is marked as 05, the number 09 means 90 centimeters, the number 12 is 120 centimeters, and so on.

For comfort, the 5-centimeter marks of each decimeter are also connected with a perpendicular strip, so that absolutely the entire rail is marked with symbols in the form of the letter "E", straight and mirrored. Old modifications of levels transfer an inverted picture, and a special rail is needed for them, where the numbers are inverted. The device is accompanied by a technical passport, which certainly indicates the year, month, the date of its last verification, calibration.

Manufacturing material

Tripods for instruments are made, as a rule, of aluminum, since this metal has a low mass, but at the same time has a high strength. These characteristics have a positive effect on the transport comfort of the equipment. In addition, wood serves as the material for the tripods, however, their price is higher, however, the stability is more reliable. Small mini tripods are made mainly of fiberglass. The devices themselves must be of high strength. In this regard, for the production of high-quality samples of the case, mainly metal or specialized plastic is used. Setting details, for example, screws can be made of plastic or metal.

About the company and products

ADA Instruments has been producing measuring instruments for engineers, surveyors and builders since 2008.

There are other useful tools in these areas, such as moisture meters, electronic levels, and calipers, which underscore ADA's vast experience in instrumentation design.

Production is located in Europe and Asia. The brand's products have European quality and the advantage of wide distribution in the world market, which makes them available for ordering or buying in any of the dealer stores, including in Russia.

If your goal is to choose a quality level, you will soon notice that customer reviews of ADA products are overwhelmingly positive. Levels and leveling rods supplied under this trademark, laser and optical levels, measuring devices (laser tape measures) and for marking are considered to be of the highest quality on the market.

Therefore, modern models of ADA instruments are in great demand.

Although only eleven years have passed since the registration of the brand, both amateurs and professionals alike note an important feature of ADA measuring instruments - their high accuracy. Decoding of the name ADA - Additional Accuracy, or additional accuracy. The quality of workmanship and the use of modern electronic reading devices allowed the developers to achieve the minimum error of the devices.

Of course, ADA products don't go on sale right away. Instruments that come off the assembly line must be tested and verified for calibration and accuracy, this applies to any production model, not just custom-made instruments. Thus, when buying a tool from an authorized dealer of this company, you can be sure that it complies with the current technical specifications, including Russian GOST standards.

Levels from this manufacturer are supplied in a wide variety of designs, configurations and meet various needs. For professional purposes, there are devices based on optical determination of heights, they have the highest accuracy. For less complex tasks, laser-type levels are offered, which are cheaper.