Rating of the best models

Today the motoblock market is rich in a wide range of offers. At the same time, from a rich list, several options can be distinguished that are most in demand among buyers, to which most hillers are suitable.

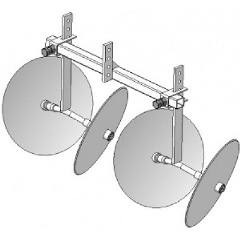

- "Type of. 2 "- a disc sliding model that fits" Celina MB "," Cascade "," Kadvi "," Neva ". Perfectly spuds, weeds, buries potatoes in the created in-depth strips. The model provides for the adjustment of discs in height, width and working angle. Needs a hitch.

- "Celina 010417" is suitable for motoblocks "Neva", "Celina", "Oka", "Favorit", "Salut" (including "Salyut 100"). This is a two-row tiller without a hitch, which must be purchased separately. An adjustable version of the plow, customizable based on the characteristics of the soil and its processing technology.

- Hillers for Kipor walk-behind tractors (including the diesel version of the Kipor KDT 610) are made to order. These models have an adjustable opening angle, the tiller itself has a wheel. In addition to Kipor KDT, they are suitable for KAMA walk-behind tractors.

- Forma 2/4 is a forming device with an adjustable row spacing, which can be 70 and 75 cm. Equipped with an adjustable tilt of the forming device. Provides for the processing of the soil after germination.

- The tiller "STV NPD" is intended for motor-blocks "VRMZ", "Neva", "Kaskad", "Oka". To achieve maximum efficiency, it requires preliminary loosening of the soil before cutting furrows. Single row model, without coupler, which must be purchased separately.

Which hiller is better for a walk-behind tractor

Lister (fixed width)

The equipment can be used on units with a capacity of up to 3.5 liters. with., it is suitable for processing narrow row spacings (width 25-30 cm). The design consists of two special wings, which are rigidly securely fixed. The stand of the model is very thin.

The disadvantage of this equipment can be called adhesion of the earth at its high humidity.

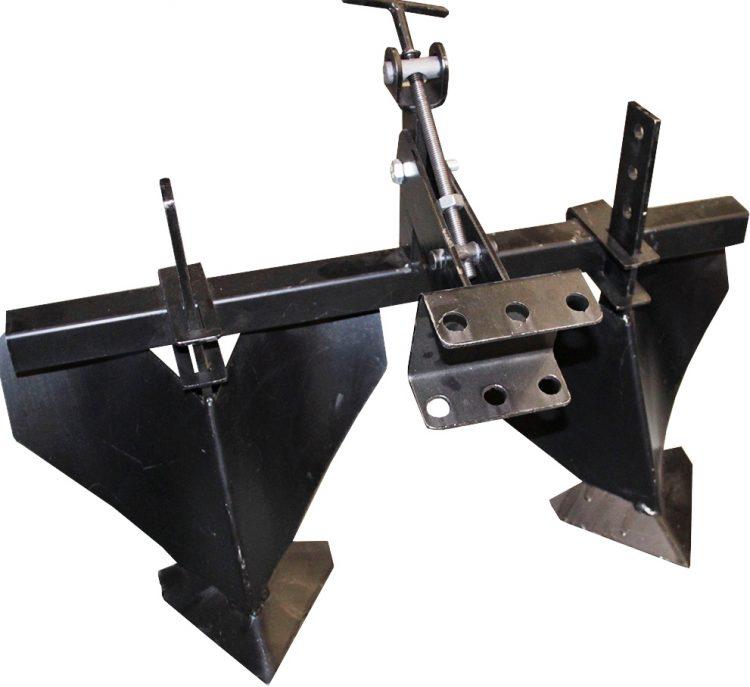

Variable width furrower

The equipment allows you to adjust the width of the row spacing, so it can be used to handle the beds, the sizes and widths of which are varied.

The hiller is suitable for different types of motoblocks, for example, for units Neva MB 2 and MB 1, Agro, and is also used for models with high power.

The disadvantage of the device is high energy consumption.

Today, this model is the most effective for hilling, but at the same time it has a high cost.

Dutch

In this hiller, the wings rotate in a vertical and horizontal plane, due to which the plowing of the land occurs more efficiently and without high energy consumption. Despite this efficiency, the cost of the hiller is affordable.

Rotary active hiller

The disadvantage of the model is that it is not suitable for all motoblocks, since it is possible to work with the equipment only in second gear, which not every unit has.

It cannot be said which hiller will be better for working on the site. The choice of equipment depends on the type of work, conditions and price. An alternative can be the use of homemade hillers, which can be attached to any walk-behind tractor.

Making a hiller of the lister type

A disc hiller for a walk-behind tractor or any other model can be made with your own hands. For the result to hit expectations, you need to follow the instructions below. For work, prepare sheets of metal, the thickness of which is not more than 3 mm; iron pipes with a cross section of 20x20 or 30x30mm; metal strips and hinges, the first 3 pieces are enough, the second 4.

Build process:

- On a metal sheet, they make outlines of the sidewalls of the plow - the ears. The greater their width, the more land they can capture. This will speed up the process of pouring under the bushes. The narrow part is responsible for cutting the soil.The ears should be no more than 7 cm in width, if the row spacing is smaller, then the parameter will be smaller.

- The elements are neatly cut out, leaving no chips or notches along the edges.

- The sides need to be bent, to give them a specific shape.

- Both parts must have the same bend radius. Otherwise, the quality of the work performed will be significantly reduced.

- The prepared parts are welded. The seam is carefully cleaned.

- There should be a metal strip between the ears. If the design is not adjustable, then the strips are welded to the sidewalls. Otherwise, loops are needed for fixing.

- The permissible angle between the stripes should be no more and no less than 90 degrees, and between the ears 120.

- The remaining ends of the strips are welded together.

A spout is installed on the narrow ends of the sidewalls. Welding is used. The angle from the stripes to the nose should be 150 degrees. As soon as the hiller is made, it is welded onto the bracket. The last part is needed in order to connect the object with a walk-behind tractor, tractor, cultivator.

How to make a hiller for a walk-behind tractor yourself

Attachments are not included with the walk-behind tractor. They are manufactured and sold separately. On the agricultural machinery market, for any type of cultivator, you can find a hiller designed for the draft power of your horse. But the problem is that a finished tool costs more than 10 thousand, and this is a significant amount for a villager in modern conditions. But at the dump or outside the outskirts, you can find everything you need to build a hiller for a walk-behind tractor.

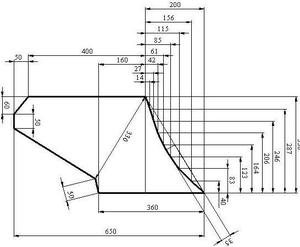

First you need to decide whether we will make a disk or lister hiller. A single row or double row tool will pull the cultivator. Do I need to provide sliding wings, an adjustable distance between the two tools. That is, before you build a do-it-yourself hiller for a walk-behind tractor, you need drawings and videos, for example, this:

Of course, it is necessary to have skills in working with metal. Not every villager in an abandoned barrel of a heater will see the nodes valuable for the economy. Therefore, they go to the craftsmen for advice, ask for help.

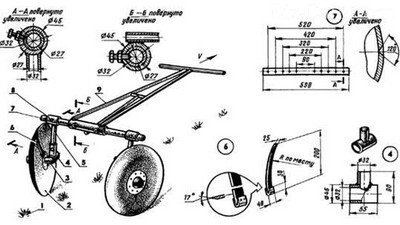

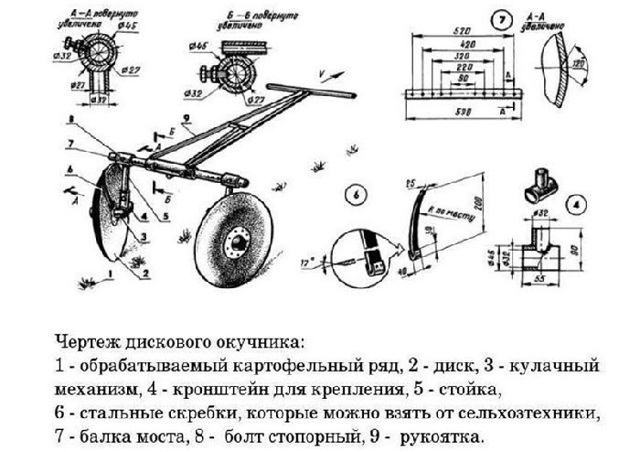

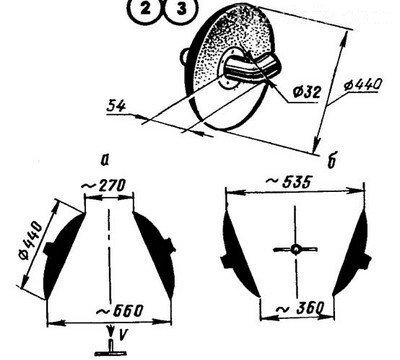

But not only disks, the device for attaching them must be thought out, and to help the master, drawings of a disc hiller for a walk-behind tractor are offered with his own hands.

On this topic:

BACK

FORWARD

1 of 3

Here, in addition to the disks, the dimensions and section of the most important units of the homemade hiller are given.

The design will undergo significant changes if you manage to find discs from decommissioned cultivators or other agricultural equipment. In any case, when making a frame, you will need to consider a disc adjustment system.

The wisdom of masters with golden hands is limitless. So if there are no discs, they can be replaced by a round blade from a circular saw. The steel is of high quality, the teeth additionally loosen the soil. You still have to create a bearing assembly, otherwise the saw blade will not rotate. But the steel is instrumental and in the hands of a craftsman, a disc hiller for a walk-behind tractor with their own hands will work effectively.

Features of operation and maintenance

Installing a hiller on a walk-behind tractor requires adherence to the rules for adjusting the angle of attack and depth of immersion, while it should be less than a plow. Wheels and a hitch are installed on the hiller, after which it is attached to the main unit. The tiller is installed on a flat surface, while the tiller is lowered and connected by means of a hitch.

When installing attachments, the operator tries to ensure that the tiller's stand is vertical. It is this position that is necessary for the correct setting of the optimal angle of attack. After that, the hitch is lowered to the ground or even deepened a little into it.

It is important that the equipment is positioned below the star support

Before starting the main work on plowing or hilling the land, it is necessary to conduct a trial run in a small area.

It is important to work in good weather, after checking the sharpening of the working elements. In addition, before starting work, it is necessary to assess the condition of the soil.

Along with this, it is necessary to determine the optimal speed of work, since a correctly selected indicator will contribute to greater efficiency and quality of work. For example, if the speed is high, the hiller will simply spread the ground in two directions instead of creating a slide and furrow. When the equipment in the process of work goes too deep into the soil, it is necessary to tilt the rack forward, for which the toe is raised.

When it is necessary to plant potatoes using a hiller and a walk-behind tractor, marks must first be made with a distance of about 65 cm. After that, furrows are created and the planting material is laid out in them. After that, the wheels need to be replaced with rubberized ones, setting the wings to the widest possible position. Having put the unit in the aisle, they pass the entire row with a walk-behind tractor, covering the planted potatoes with earth.

This will determine the depth of tillage (furrow depth). If a moving type hiller is installed on the walk-behind tractor, it is necessary to adjust the width and height of the ridge.

In the disc model, the working width can be adjusted. To do this, the lower points of the disks are set aside by about 40–70 cm (the specific value will depend on the distance between the rows). When adjusting, make sure that the discs are located symmetrically in relation to each other.

With such devices, the soil is treated three times per season:

- when the seedlings grow up to 15 cm;

- when they grow up to 23–25 cm;

- at the time of flowering.

After self-assembly of the equipment, it is necessary to carry out trial work with it on the site. Its high-quality work depends on many factors: soil condition, weather conditions, correct setting and sharpening of working elements and many other indicators.

All settings of a self-made device are carried out empirically. To do this, it is advisable to first walk along a regular soil area and adjust the optimal value of the angles and depth of entry into the soil of the working surfaces of the hiller.

It is also equally important to determine the optimal speed of the unit. A correctly chosen pace of work has a positive effect on the quality of hilling, because at high speed the device will basically scatter the soil in different directions, while worsening the process of furrow formation.

In our country, potatoes are considered "the second bread", therefore, with the beginning of the new spring season, many summer residents strive to plant this useful product in their area. However, the process of obtaining a good harvest depends largely not only on planting, but also on further care (weeding, hilling) for this root crop.

Serving potatoes by hand is considered time consuming and time consuming. Therefore, the use of a walk-behind tractor with special mounted-type equipment is gaining more and more popularity among gardeners.

You can make attachments that are in no way inferior to industrial counterparts on your own, with the help of insignificant material investments.

Instructions for hilling potatoes

Three hilling operations are required throughout the season. This process consists in adding soil to the potato stalks. This is done to provide additional oxygen to root crops, and at the same time to eliminate weeds. In addition, hilling prevents tubers from freezing when the air temperature drops significantly and accelerates their growth.

The first hilling is carried out when the plants reach a height of 15 centimeters (in the middle lane this is about mid-May).The height of the poured soil layer should not exceed 10 centimeters, otherwise the development of tubers will be difficult.

Re-hilling is carried out when the plants reach a height of 20-25 cm, that is, approximately one and a half to two weeks after the first hilling.

The third time, these works are carried out in another one and a half to two weeks, but the height of the poured soil should be as large as possible. Note that some owners of personal plots do not perform the third hilling, nevertheless, it must be done. In order to learn more about hilling potatoes with a walk-behind tractor, watch the video.

Types of devices

Depending on what type of soil cultivation is needed, the appropriate hiller is selected. Let's consider the main types of this auxiliary equipment:

- Milling component for special equipment (a fairly common version of equipment for soil cultivation).

- Active component (more advanced design that allows a larger area to be treated).

- Disc hiller (here soil cultivation is carried out by rotating the disc mechanism).

- The hiller is two-row (here both sides are cultivated at once due to the equipment used).

Depending on the goals set, as well as the crops grown, the appropriate technical equipment for special equipment of the salute brand is selected.

In this video you will learn how to plant potatoes with a walk-behind tractor:

Milling

Here we are talking about a device that is made in the form of a milling cutter. The cultivation of arable land is carried out due to the uniform rotation of the blades due to mechanical action. These types of attachments are distinguished by their relatively low cost, as well as ease of operation. However, despite their simplicity, these models cannot handle a large area at a time, which is why they are not used for domesticating some crops.

Active

This type of cultivator for the Salyut 100 walk-behind tractor is not used so often. The whole reason is its high cost, as well as the need for additional customization. Here we are talking about a device that works in an automatic manner. In other words, no mechanical action is required since the work is done by transmitting torque through the drive. This type of mounted technical product is characterized by a large area of simultaneous processing, but for some crops it is not always sufficient.

Disk

The disk hiller is the simplest device, but at the same time it is quite popular. Here hilling is carried out by installing a special disc on the special equipment, which gradually processes the soil under mechanical rotation. This equipment has a relatively low cost, but it also does not allow to cultivate a large area at a time. This device is excellent for hilling a variety of crops.

Double row

Here we are talking about more advanced technical equipment, which allows you to simultaneously cultivate two rows at once. Here, the work is done by discs, cutters or other devices that are located on both sides. This component is easy to adjust, but it has a higher cost compared to other models. Hilling with the use of various spare parts for the device makes it easy to handle any crops.

This is interesting: disc hiller for the Favorit walk-behind tractor.

There are several types of hiller

There are several types of hiller

Manufacturing recommendations

Since the most popular among owners of personal plots are lister and rotary units, it is necessary to consider in detail the process of their manufacture. In turn, the devices of the first type have the simplest design: it is worth starting with them.

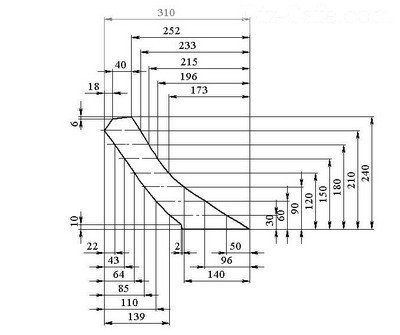

Lister hiller

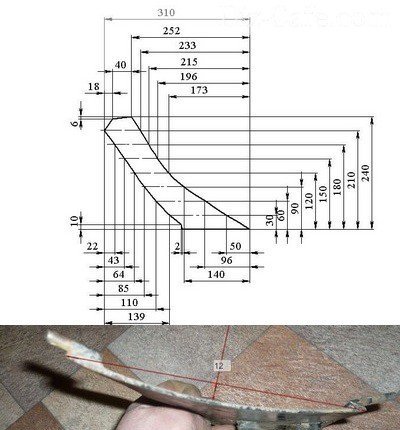

The drawing shows that the base is the main element. For its manufacture, you can use a steel sheet with a thickness of 3 mm. The bracket is a more critical part, and after manufacturing it is advisable to harden it. The material can be a 4 mm thick strip of steel.

For a field board, a 5 mm steel sheet is perfect. Some summer residents use springs as a material, but in such a situation, the metal must be subjected to preliminary tempering and only after that it must be hardened again. Given the thickness of the hiller parts, heat treatment may well be carried out using a gas burner.

For a field board, a 5 mm steel sheet is perfect. Some summer residents use springs as a material, but in such a situation, the metal must be subjected to preliminary tempering and only after that it must be hardened again. Given the thickness of the hiller parts, heat treatment may well be carried out using a gas burner.

During operation, the entire load falls on the rack and for this part it is necessary to use a metal strip of 8 mm or more. The weld bead is applied in two passes on each side of the joint. The last element of the lister hiller is the wings. They can be made from a thinner material such as a 2 mm sheet.

Disc aggregate

If the plot of land is small, and there is no opportunity to purchase a walk-behind tractor, then it is worth making a manual disc hiller with your own hands. However, now we will focus on the hinged device. Most often, difficulties in its manufacture arise when forming discs. However, it is absolutely not necessary to do these details completely yourself. If possible, use cutters from a broken seeder. Otherwise, it is necessary to make a template and cut out blanks from a 3 mm steel sheet. After that, they must be shaped so that the outer side of the part is parallel to the radius line.

Since this element is movable, it is advisable to install discs on bearings with oil seals. In this case, it is not advisable to use slip bushings, since there is a greater risk that they will jam.

Of course, it is possible not to complicate the design with this element, but it will be less comfortable to work in such a situation. If desired, a home craftsman can make various home-made devices for a walk-behind tractor, for example, a bed former.

The time spent on their creation will more than pay off during field work. Moreover, such devices are practically in no way inferior to branded ones.

Originally posted 2018-04-18 12:24:29.