How to choose a hacksaw for wood

The choice of a saw, whether for garden work, or for repair and construction purposes, should be approached responsibly. Indeed, when buying the wrong tool, at best, there will be difficulties in work, it will be difficult to achieve the desired result, and at worst, there is a risk of injury.

A hand-held hacksaw is, without a doubt, a necessary tool in the household

There are different types of hacksaws for woodworking, which differ in many ways. For example, the convenience of sawing and the service life of a hacksaw depends on the blade.

In total, when buying a hacksaw for wood, you should pay attention to three components:

- Cloth (steel grade, length);

- Teeth (their size, shape, distance between them);

- Handle model.

Blade length and size

A hacksaw for wood should be chosen based on your needs: for cutting small, small building materials, a 300 mm hacksaw is enough. If the purpose of the purchase is repair, use in the country, or, even more so, construction, it is advisable to choose a saw with a base of 450 - 500 mm. Also, we must not forget about the "golden rule" of choosing a hacksaw: the length of the tool should be at least twice as long as the workpiece being cut.

The most common hacksaws - with blade lengths from 350 to 600 mm - are medium sizes. It is believed that up to thirty-five centimeters are mini-saws, and over 60 cm are large. The success of working with wood depends on the correct choice of blade length.

Classic hacksaw with a comfortable and ergonomic handle

Tooth size and shape

This property of the saw affects the main factor of the tool - its purpose. It is easy to find the right size using the TPI coefficient. This is a special scale that shows the number of teeth per inch of the blade's working length. Often this factor is indicated directly on the working surface of the tool.

Advice! Hacksaws with a large tooth are well suited for roughing, initial work on construction sites, sawing trunks. Working with small incisors will take more time and effort, but the quality will be higher.

Hacksaw for wood with double-acting blade

Differences in incisors in appearance

Triangular tooth configuration is considered standard. Variations allowed: acute-angled or isosceles triangle. The advantage of these teeth is that they are easy to sharpen. The cut is quite neat without rough chipping.

Using a triangular hacksaw is best for cross or rip cuts.

Correctly set, hardened blade-shaped cutters to handle any type of wood

The version with a hardened cutter is good for its energy consumption - you do not have to sharpen anything yourself, because the saw will be as sharp as possible. However, an unhardened cutter can always be sharpened "for itself" (or when it becomes dull), which cannot be done with hardened teeth.

With small cutters, the cut will be more accurate, but the work will take more time, with large ones - on the contrary, you can cut off faster, but a rough cut will come out.

Sharpening saw teeth is a difficult task, so if you do not have sufficient experience, it is better to entrust this matter to a professional.

Handle design

The handle design is an important characteristic affecting the quality and safety of work. Handles come in different shapes, depending on the purpose of the hacksaw. They can be made of different materials: wood, plastic, metal, or rubberized.

There are 2 types of handles:

- reversible (with the ability to easily change the canvas)

- classic.

Important! An uncomfortable hacksaw will slip in your hands, bend and walk poorly on the starting material, which can lead to injury.

The efficiency of work directly depends on how well and conveniently the handle of the hacksaw is made.

Material requirements

In order for the hacksaw to serve you for a long time, you should choose a model whose blade and handle are made of high quality materials.The cost of such a hand saw will certainly be more expensive, but you are unlikely to achieve a quick and high-quality cut with a cheap option.

A stainless steel hacksaw will last for decades

Varieties of hacksaws for wood

Hacksaws are presented in a wide range, they can be divided into three large groups, which have their own classification:

- with a butt;

- to create a curved cut;

- Japanese.

If you plan to perform delicate work, then it is worth using a tool with a backing, in which a brass or steel strip is additionally installed on the upper edge of the canvas, which prevents bending. These hacksaws are classified as follows:

- tenon;

- with a dovetail;

- with an offset handle;

- edging;

- model.

The first on the list are the largest, since their main purpose is to work with thick boards and firewood. Equipped with a closed handle, which is ideal for comfortable fixation of the instrument in the hand. A smaller version of this model - the dovetail - is used for working with hard wood species.

If you have to work with through thorns, then you should use a hacksaw with an offset handle. The user can adjust the element, while it is convenient to work with both right and left hand.

When you need to make a thin cut, there is no better tool than an edge saw, which has a compact size. But the smallest of all the presented options for this tool is a model file.

If it is necessary to cut out a curved part, a completely different tool is used. This category also has its own classification:

- onion;

- openwork;

- jigsaw;

- narrow.

A bow hacksaw is usually 20-30 centimeters long, with 9 to 17 teeth of the same size per inch on the cutting blade. It is possible to turn the canvas in the required direction so that the frame does not interfere with the view. There are folding tourist models on sale that take up little space.

In the case of an openwork file, the working surface reaches a length of 150 mm, and the frame is made in the form of an arc. The main areas of use are artificial material and solid wood.

As for the jigsaw, its frame is also made in the form of an arc, but deep, since the tool is necessary to create strong bends in a thin material, for example, veneer.

A narrow hacksaw is also known in the professional world as a circular hacksaw, since it is used in the middle of a wooden blank. The cutting element is very thin and tapers towards the end. It is thanks to this shape that it is possible to create curves with a large angle. The design provides a pistol-type handle, on which you can attach the desired blade.

Professionals know that the range of hacksaws is not limited to this, since there are also Japanese edged saws, which not every beginner could have heard of. Their classification includes:

- kataba;

- dosages;

- rioba;

- mawashibiki.

The main distinguishing feature of all these hacksaws is that their blades work for themselves. The teeth on the blade are very close to each other, so the cut is narrow, without serious breaks in the wood fibers.

In a kataba, the cutting elements are located on one side. The tool can be used for both longitudinal and cross cutting, therefore it is considered universal. In comparison with the described model, the rioba has a cutting blade for cross-cutting on one side, and for longitudinal cutting on the other. When working with such a tool, it is worth keeping it at a slight angle.

The step of the teeth of hacksaws can be from 14 up to 32 teeth per inch... With the development of technical progress, this instrument passed from the category of manual classics and began to be made electric. In the design of electric hacksaws, there is a powerful motor that provides the necessary power for cutting branches.

Stationary silent vertical machines have the greatest power, but some portable models are also not inferior. The power depends on the type of power supply. Rechargeable batteries are inferior to stationary electric ones, but they can be used even where there is no way to connect to the network.

Also, separately in the category of the described tool, there is an award - a product with a thin blade of no more than 0.7 mm. The cutting part fits very tightly into the last made of wood. Used with one or two hands for small cuts or cuts.

Classification

There are several varieties designed to perform specific tasks. They are divided into groups according to different characteristics.

By type of canvas:

- Narrow. It is used for sawing various shapes with a relatively large radius of curvature of cutting lines.

- Regular. This is the most common type of saw and has a standard blade width and is designed for a variety of applications.

- Obushkovaya. These instruments have a wide blade with a fine tooth. Capable of making clean cuts with high precision. They are used for precise critical work on a template or pre-applied markings. A peculiarity of the butt hacksaws is the need to process material that is obviously thinner than the canvas - the presence of a butt will not allow it to pass through the cut.

- Luchkovaya. A narrow blade with a small tooth is stretched between two support bars. This design combines several possibilities - a clean, accurate cut, cutting precision and high productivity.

By the type of tasks performed:

- Classic. It is used in most situations when you need to saw off a piece of board, saw through a beam or solve other issues of a common nature.

- Undercutting. Used to fit protruding elements. The handle of such a saw is placed so as not to interfere with the blade in contact with the material along its entire length. A special case of a scoring saw is a lining structure. This group also includes tenoning and edge saws.

- Circumferential. The narrow blade allows you to make a figured cut. You can cut a closed loop by starting from a pre-drilled hole. The free end of the blade is not fixed, which requires accuracy during work - it is easy to bend or deform the saw with a careless movement.

- Plywood saw. It has a wide blade that allows you to hold a straight cut without the danger of pulling it to the side. The teeth at the start of the blade allow you to start the cut from the middle of the plane.

- Reward. This saw is capable of performing specific tasks - cutting grooves and other structural elements. It has several handles, and the way of working is closer to the method of processing with a plane. Requires skills and experience from the master.

- Folding saw. Usually, the handle of such a tool is disconnected or rotated, making the total length of the hacksaw noticeably shorter. Convenient for a hike, trip or other field conditions.

The tradition of carpentry in this country presupposes a virtuoso mastery of the instrument, the quality of which is elevated to the rank of art. The technique of working with Japanese saws cannot be repeated with a conventional hacksaw, since the elasticity of the blade, the ability to maintain shape and flatness are used.

The names of the tools are little familiar not only to beginners, but also to experienced specialists:

1-Kataba 2-Ryoba 3-Dozuki

- Kataba. Saw with teeth on one side of the blade. Has a universal sharpening that allows you to perform both longitudinal and cross cut.

- Ryoba. The blade of these tools is equipped with teeth on both sides of the blade, with a notch on one edge for a longitudinal cut, and on the other for a cross cut.

- Dozuki. The flexible blade is designed for precise and accurate cuts. in the area of the handle, the teeth become smaller, which is convenient for performing critical work.

- Mawashibiki.Narrow blade with fine teeth, capable of fine and clean work.

A common feature of Japanese hacksaws is their relatively small size and specific application. Unlike European tools, which are effective when moving away from you, Japanese saws are all designed for moving towards you. This is unusual at first, but experienced people testify to the significant advantages of this technique.

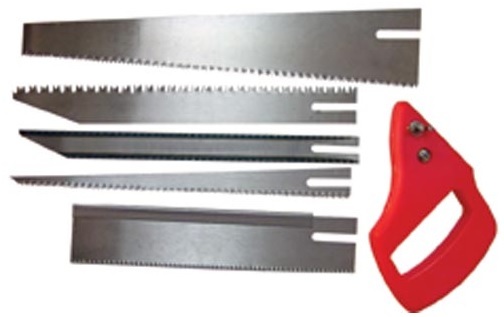

Photo of hacksaw blades for metal

We also recommend viewing:

- What are aluminum rivets

- Best screwdriver bits

- Which polyurethane foam is better

- Overview of drills and drills for rock drill

- Overview of diamond core bits for concrete

- The best concrete drills for drills and hammer drills

- How to choose a good diamond blade for concrete

- Which abrasive disc is better to choose

- Wood milling cutters for hand router

- How to find the right grinding wheel

- Which drill chuck is better

- Choosing good wood drills

- Types and sizes of staples for the stapler

- Why do you need a unipack

- Metal brush for grinder and drill

- What and how to choose a line for a trimmer

- Which drills for metal are better

- Which chainsaw oil to choose

- Cut-off wheels for grinders

- Metal pipe clamps

- How to choose a galvanized bucket

- How to choose a circular saw blade

- Types of jigsaw files

- Varieties of petal circles

- What is tow

- Nylon ties

- Types and application of electrical tape

- Choosing a light plastic bucket

- How to choose safety glasses

- Why do you need masking tape

Help the site, share on social networks

Model rating

Of the domestic manufacturers, I would like to highlight the Enkor model range, which is made of carbide steel. One of the best representatives is the Enkor 19183 model, which is distinguished by the size of the teeth of only 2.5 mm. The tool comes on sale with a comfortable handle and hardened teeth, which indicates a long service life of the product.

It is impossible not to highlight Japanese saws, for example, the Silky Sugowaza model, which is used for the most difficult work, since its teeth are 6.5 mm. Gardeners and summer residents prefer to purchase such a tool for shaping the crown of fruit trees when they want to work quickly without much effort. The special arc shape makes it easy to cut unnecessary branches.

Swedish hacksaws do not lag behind domestic ones in quality. Among them, the Bahco brand stands out, which has established itself for its high quality. In the universal tool category, the Ergo 2600-19-XT-HP model stands out for medium-thick workpieces.

Varieties

By combining the above factors, manufacturers have developed and are currently producing standard products with different blades, handle and tooth shapes. To understand how to choose a hacksaw for wood, you first need to familiarize yourself with the existing types of saws.

Type 1: Classic

The main type of saw that almost every man has, even those far from construction and carpentry. This hacksaw can have a blade of any length with a different number of teeth, often the tool is equipped with interchangeable blades that come with the purchase.

Type 2: Narrow

Its other name is circular hacksaw. It takes the name from the main application - lines of various shapes are cut out for it, moreover, it does it neatly and clearly. It is also used to cut through round, square holes. The saw blade is narrow, the teeth are frequent, can be located both on one working plane, and on both.

When working with a saw, you should be careful: if the movement is uncertain, the blade will turn in the other direction, therefore, the choice of a hacksaw for wood with a narrow blade should be stopped on a product made of high-quality hard steel that will not bend during the sawing process.

Type 3: Backed

A hacksaw with a backing is equipped with a stiffening rib (the same backing), which does not allow the blade to bend during operation. Thus, the tool is not able to make a cut lower than the width of the saw blade.

The hacksaw is always equipped with a comfortable handle at an angle of 450 to the blade for easy execution of work.

Type 4: Bow

For plumbing, an archery saw is indispensable: it serves to cut rough parts of the trunk, knots, to cut figures from plywood and other wood materials, to cut wood along and across the fibers. The use of a bow saw is so widespread that it alone can replace a small woodworking machine.

The wide range of work carried out slightly obscures the main disadvantages:

- Bulky. A bow saw is a complex structure, its bearing part is made in the form of a large curved arc, to which a blade with teeth narrow as a thread is attached.

- Fragility. It is necessary to work with the tool extremely carefully: the blade during operation can fly off the mounts and break, its frequent replacement is required.

Type 5: Reward

The award saw takes a lot of effort to master. It is a tool that resembles a plane. It is equipped with two handles. Its main application is cutting grooves and spikes, the depth of holes and depressions can be of different sizes, moreover, on rocks of any hardness.

Type 6: Folding tool

A mechanical hacksaw that you can take with you on a hike or on vacation. It is compact, lightweight, and completely safe when folded. The folding hacksaw has fine teeth and a short, pointed blade.

How to choose a saw?

A hacksaw for wood is available on the market in different versions. How products can differ:

- Tooth shape and size;

- Canvas size;

- The steel grade from which the working part (blade) is made;

- Handle shape.

A hacksaw saw with a change in one of the above parameters can radically change its characteristics. Also, sitting comfortably in the hand of one master is completely unsuitable for another. These factors need to be considered when choosing a tool for different purposes.

Tooth size

This parameter affects the quality and speed of work. For the convenience of determining the size and number of teeth, the designation TPI has been introduced, indicating the number of teeth in one inch. This parameter can be seen in the description of a hand saw for wood, often the value is applied to the blade.

- A hacksaw for wood with a large tooth gives a rough cut at high speeds. It is useful for cleaning the area from branches, sawing boards for firewood and other events where you can get by with the rough ends of products and trunks. For such instruments, choose TPI 3… 6 tooth size.

- For products that need to be cut accurately and evenly, a fine-toothed hacksaw with TPI 7 ... 9 is suitable. This is used for sawing fiberboard, chipboard, laminate, in repair work. The performance of such a tool is significantly lower than that of a coarse-toothed one.

A carpenter's hacksaw is selected, first of all, according to the size of the tooth. So, for ordinary wood, small and large are suitable, and for "delicate" materials such as fiberboard, a fine-toothed saw is needed. In stores, you can now find similar designations: "for wood", "for drywall", etc. Their main difference is the size of the teeth, which is optimal for cutting each of the materials indicated on the label.

The teeth are distinguished in shape, depending on this, the tool acquires a different purpose:

- The hacksaw for ripping is equipped with triangular teeth with oblique corners. Their appearance resembles hooks that are sharpened on both sides. Because of this, the saw slides along the grain of the wood and cuts the blade evenly, almost without chipping.

- The cross sawing tool is equipped with isosceles triangle teeth. A mechanical hacksaw of this type cuts when going back and forth, but it can only be used for processing dry wood.

- The hand saw for mixed sawing is equipped with both types of teeth alternately arranged one after the other. Long curved ones cut the material in the forward direction, the triangles in the opposite motion expand the channel for passage and catch the chips and sawdust.

In modern models, the teeth alternate with voids. This allows you to use the saw on dry and freshly sawn wood, coarse unnecessary fibers are removed through the holes.

Choice of steel

For the tool to last longer, you should choose high grades of steel for the production of the blade. It is better if it is stainless.

Teeth can be hardened or regular. Ordinary ones can be sharpened at home, saws with hardened teeth are disposable, after wear nothing can be done with them. They are easy to recognize by their dark color as in the photo.

Blade length

This parameter is determined by the size and pitch of the saw tooth.

- The mini-hacksaw is always equipped with small, frequent teeth, the length of its blade does not exceed 350 mm;

- The universal hacksaw has an average tooth size and a length of no more than 550 mm;

- A wide hacksaw is equipped with large teeth with an increased pitch, the length of its blade is over 600 mm.

In addition to the length, the canvas can vary in shape. A traditional saw has the shape of a rectangle narrowed on one side. This is a versatile type of tool that can cut anything.

The rounded blade is adapted for working with branches and other objects at a distance: it is lightweight, easily glides over the wood without much effort.

Handle shape

This part of the saw determines the convenience of work. The tool should ideally blend into the hand and be comfortable. For the manufacture of pens, various plastics are used that are pleasant to the body.

An important note - the material should not slip if the hand suddenly fogs up. For this, grooves and grooves are provided in the handle body, a rubberized pad

How to choose a saw?

A hacksaw for wood is available on the market in different versions. How products can differ:

- Tooth shape and size;

- Canvas size;

- The steel grade from which the working part (blade) is made;

- Handle shape.

A hacksaw saw with a change in one of the above parameters can radically change its characteristics. Also, sitting comfortably in the hand of one master is completely unsuitable for another. These factors need to be considered when choosing a tool for different purposes.

Tooth size

This parameter affects the quality and speed of work. For the convenience of determining the size and number of teeth, the designation TPI has been introduced, indicating the number of teeth in one inch. This parameter can be seen in the description of a hand saw for wood, often the value is applied to the blade.

- A hacksaw for wood with a large tooth gives a rough cut at high speeds. It is useful for cleaning the area from branches, sawing boards for firewood and other events where you can get by with the rough ends of products and trunks. For such instruments, choose TPI 3… 6 tooth size.

- For products that need to be cut accurately and evenly, a fine-toothed hacksaw with TPI 7 ... 9 is suitable. This is used for sawing fiberboard, chipboard, laminate, in repair work. The performance of such a tool is significantly lower than that of a coarse-toothed one.

A carpenter's hacksaw is selected, first of all, according to the size of the tooth. So, for ordinary wood, small and large are suitable, and for "delicate" materials such as fiberboard, a fine-toothed saw is needed. In stores, you can now find similar designations: "for wood", "for drywall", etc. Their main difference is the size of the teeth, which is optimal for cutting each of the materials indicated on the label.

The teeth are distinguished in shape, depending on this, the tool acquires a different purpose:

- The hacksaw for ripping is equipped with triangular teeth with oblique corners. Their appearance resembles hooks that are sharpened on both sides.Because of this, the saw slides along the grain of the wood and cuts the blade evenly, almost without chipping.

- The cross sawing tool is equipped with isosceles triangle teeth. A mechanical hacksaw of this type cuts when going back and forth, but it can only be used for processing dry wood.

- The hand saw for mixed sawing is equipped with both types of teeth alternately arranged one after the other. Long curved ones cut the material in the forward direction, the triangles in the opposite motion expand the channel for passage and catch the chips and sawdust. In modern models, the teeth alternate with voids. This allows you to use the saw on dry and freshly sawn wood, coarse unnecessary fibers are removed through the holes.

Choice of steel

For the tool to last longer, you should choose high grades of steel for the production of the blade. It is better if it is stainless.

Teeth can be hardened or regular. Ordinary ones can be sharpened at home, saws with hardened teeth are disposable, after wear nothing can be done with them. They are easy to recognize by their dark color as in the photo.

Blade length

This parameter is determined by the size and pitch of the saw tooth.

- The mini-hacksaw is always equipped with small, frequent teeth, the length of its blade does not exceed 350 mm;

- The universal hacksaw has an average tooth size and a length of no more than 550 mm;

- A wide hacksaw is equipped with large teeth with an increased pitch, the length of its blade is over 600 mm.

In addition to the length, the canvas can vary in shape. A traditional saw has the shape of a rectangle narrowed on one side. This is a versatile type of tool that can cut anything.

The rounded blade is adapted for working with branches and other objects at a distance: it is lightweight, easily glides over the wood without much effort.

Handle shape

This part of the saw determines the convenience of work. The tool should ideally blend into the hand and be comfortable. For the manufacture of pens, various plastics are used that are pleasant to the body.

An important note - the material should not slip if the hand suddenly fogs up. For this, grooves and grooves are provided in the handle body, a rubberized pad