Rack - a device for sharpening drills for metal: design features

Depending on the scale of the tasks, they can be of different sizes. Installation is fixed on a lathe or grinder with bolts. Their construction consists of:

- grounds;

- fastener for clamping the tool;

- thrust mechanism;

- a screw that regulates the flow;

- clamps.

There is a scale on the purchased sample, it adjusts the angle with high accuracy. If you are using an independent device, then it will be more convenient to use templates of different diameters, they can be made of wood.

A simple attachment from a nut for sharpening a drill at home

For manufacturing, you need a minimum of scrap materials. Let's look at the image:

Instructions for creating:

- Take two nuts of different sizes, with the smaller one cut 9 mm cuts from three edges on each side.

- The sharpening angle should correspond to the resulting edges - 120 degrees.

- Weld the second product to the first with the welding machines so that the holes are in the form of a triangle.

- Pick up and screw in a bolt that matches the size of the small nut. It will clamp the tool being machined.

A workpiece is pushed into such a holder. It is securely fixed with a clamp. Now you can bring the part to the abrasive wheel and not worry that you will cut off too much or with the wrong angle.

Do-it-yourself drill sharpener for drills

We told you that you can buy an attachment for an electric drill. They are usually made of plastic and have standard connectors. You can make an analogue at home, recommendations:

- make metal parts, not plastic;

- connect the emery wheel to the chuck using a ring;

- an emery cone can be made on a lathe;

- the outer case (a cover with holes of different diameters for the required tool dimensions) is best made of wood, but it can be made of steel.

To make it easier for you to do homemade products, let's see what the purchased model consists of. This is explained in the video and shown by the commentator after the analysis:

Grinder device

This power tool is also used for sharpening, it is easy to explain - installing an abrasive disc is a natural task of an angle grinder, and fastening at the right angle to a rotating abrasive is easy to make. Let's see how it looks:

A metal corner must be attached to the casing; it will serve as a guide. The adjustment is done manually. There are also disadvantages, these include the fact that the disc itself is subjected to uneven loading and can crumble with prolonged use.

Holder for sharpening drills from door hinges

Another interesting home option.

Many people think it is overly complex. But we will consider making:

- the lower part is fixed on the handcuff;

- the upper one moves the workpiece;

- the lower finger must be pulled out, leaving only the upper one;

- one of the loops should be cut into two parts - one of them adjusts the slope;

- you need to weld a metal corner, cut a thread for a bolt in the drilled holes;

- then you need to weld the lamb to rotate the thrust mechanism.

More detailed step-by-step instructions in the video:

Spiral type

This requires a sleeve whose diameter exactly matches the size of the drill. These can be copper, aluminum tubes. The guides should be carved out of wood. Holes are drilled in the bar at a given angle - a tool will need to be inserted into them.Separately, you need to create a handcuff, which is responsible for the emphasis and the correct position of the workpiece.

Operating tips

When processing wood with nozzles using a drill, the contractor must adhere to the following requirements.

The device used must be securely fastened in the chuck.

In the presence of any, even minimal backlash, work cannot be started.

One of the key conditions, taking into account which allows you to avoid injuries and other troubles, is the mandatory fixation of the workpiece being processed.

While working, it is advisable to hold the drill with both hands, which is especially important for powerful equipment.

If the performer wants to turn on the reverse, he needs to wait until the instrument in use has come to a complete stop.

When processing wood, special attention should be paid to pressure. It should be pretty strong, but not overwhelming.

In addition, the performer should not experience discomfort from small particles that fill the space of the room when working with wood. Inhaling them is strongly discouraged, which justifies the use of a respirator - an inexpensive and highly effective personal protective equipment. Also, do not neglect the glasses, which negate the likelihood of foreign objects getting into the eyes. This advice is especially relevant in situations where processing is done with wire brushes.

For one of the woodworking attachments, see the next video.

A drill is a tool whose main function is to impart rotational motion to a drill.

The drill is indispensable when carrying out repairs and construction of any complexity. And all this, thanks to various attachments, adapters, attachments, adapters and other devices that make the drill a truly universal hand tool.

Drill bits - the ancient pioneer of drilling

By the degree of mechanization, drills can be divided into two types - manual and electric. But, regardless of the type, any of them can be used to perform such work as: drilling holes, stirring solutions, grinding, cutting off and twisting / unscrewing screws. The drill can be used as a pump for pumping water and even for plucking chickens. An impact drill, according to its characteristics in everyday life, can replace a hammer drill.

It is unlikely that another tool can be found on the market that would perform as many functions. Of course, the quality of work performed using attachments for a drill is somewhat different from that which could be obtained using a special tool. But, in special cases, in the household and everyday life, this is quite enough.

What is a drill bit what types of adapters are there, what they are for and how to choose the one you need - that's what our article is about.

The attachment is an optional accessory that allows you to expand the functions of the drill.

Of the many types of them, we will select the most popular and consider them in detail.

Commercial Drill Sharpeners

You can buy an already created specialized machine, but its use always has a certain range of functions, that is, the tasks are always narrowly specialized. The use of a homemade device, in turn, has the following advantages:

- profitability - it can be made from scrap materials;

- gaining experience - you will better begin to understand the specifics of the operation of each apparatus, if you make it yourself;

- unique goals - if you are working with non-standard shapes, sizes, the easiest way is to make your own sharpener.

But if you want to buy a finished machine, let's see how they differ.

The main types of factory devices

They are divided into two types:

- with a standard set of modes for classic sizes;

- with the ability to adjust all parameters.

The latter is much more functional, but also more expensive.It is made in the form of a mechanism on a bed, static, made of steel, therefore it is not subject to transfer. The second is a drill bit, therefore it is fully adjustable with this construction tool (the number of revolutions is created manually).

Drill attachment for plucking birds

Plucking poultry is a laborious process, especially when several carcasses need to be processed. Therefore, many farmers were constantly in search of new solutions not only to facilitate work, but also to reduce the total time. For this purpose, the Feather Drill Bit has been specially developed, which removes feathers from the bird in a matter of minutes. It is similar to a dishwashing brush, except that silicone fingers protrude with bristles here, which, when the shaft rotates, pull feathers out of the carcass. At the same time, the bird is brought up on different sides.

A drill attachment for plucking a bird, which can be bought for an average of 1,500 rubles. processes poultry carcasses in just 2-3 minutes, without leaving a single feather. The result is smooth, intact skin. The device is effective not only for processing chickens, but also gives a good result when plucking geese. The drill attachment can be used not only for fresh, but also for frozen poultry.

The plucking attachment for a drill is a metal tube-drum centered on the machine

Helpful advice! It is not recommended to scald the carcass with boiling water before using the nozzle, which will reduce the efficiency of the processing process.

The main advantages of the feather drill bit, which you can buy in any specialized store, is the speed, simplicity and mobility of use, which does not require certain skills and additional processing of the carcass before plucking. A significant disadvantage of the device is that after this mechanical process, damage remains on the carcass, which worsens its appearance. Therefore, if the bird is intended for sale, it should be plucked manually.

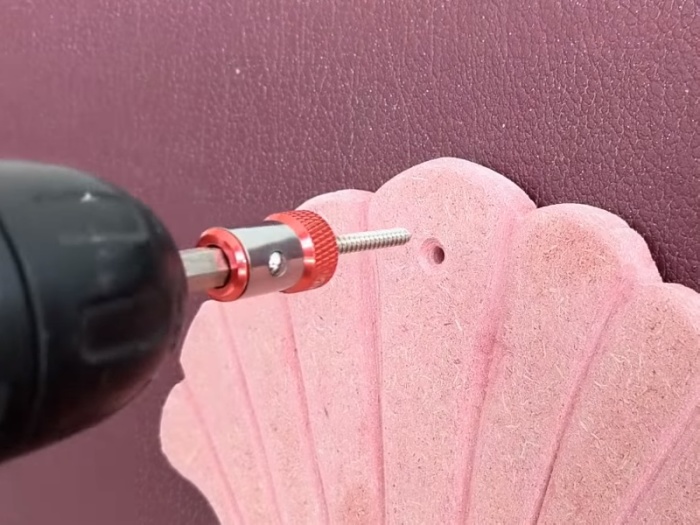

Drill attachment for sharpening drills

This device consists of a plastic case, inside which a special-shaped emery wheel rotates. It is he who allows you to form the required sharpening angle on the working part of the tool. The circle is mounted on a shaft, which is connected to the drill by a special coupling. It is activated when the tool is turned on.

Many modern models have an end cap on the body, in which holes of different diameters are located for sharpening drills of different sizes. These holes are made in such a way that the sharpening element is in contact with the emery wheel in a certain position.

The principle of operation of the nozzle for drill sharpening is simple - with turning on the drill, the chuck rotates the grindstone located inside

The drill sharpening process is performed as follows. The product is inserted by the cutting part into the hole of the nozzle of the corresponding diameter. After starting the drill, the emery wheel begins to rotate, sharpening half of the drill part. Then the product is turned over in the hole 180 degrees, and the procedure is repeated. This sequence of actions is performed several times until the required parameters of the cutting part of the drill are achieved.

The drill attachment for sharpening drills, which can be bought for an average of 350-500 rubles, has 15 holes with diameters from 3.5 to 10 mm. Products can be sharpened at an angle of 180 degrees thanks to the special shape of the stone. The simple design of the device allows you to perform work quickly and without special skills.

However, it should be remembered that the device is intended for sharpening sagging cutting edges. For a full-fledged sharpening of heavily worn products, an emery wheel will not last long.

Helpful advice! When buying an accessory of a certain model, you should take into account the diameter of the drill chuck.

There is also another type of additive.This is a drill attachment for sharpening knives and scissors, which is presented in the form of two emery wheels set on a shaft and located at a certain distance from each other. The price of such a device is about 250 rubles.

The attachment for sharpening knives and scissors for a drill is easy to operate, does not require special skills in its use

What are the attachments for?

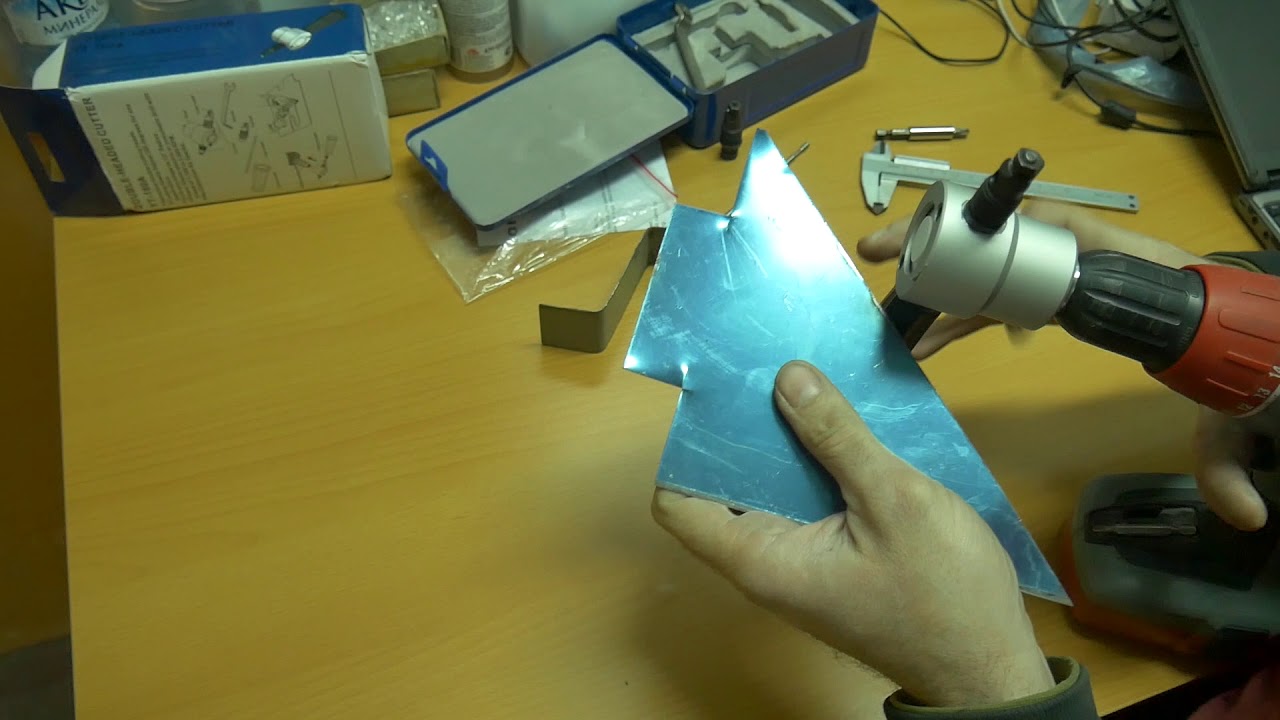

Various types of cutters, as a result of repeated repeated movements, cut metal with a matrix. As a result, durable metal lends itself to processing. Thus, we cut, punch holes or grind a metal surface. Point impacts allow you to work accurately without disturbing the structure of the elements. In addition, the natural protective layer of the product is preserved.

Using nozzles, you can act on the following metals:

- 2mm aluminum plates;

- copper, brass, iron, zinc and steel elements;

- galvanized parts with a thickness of 1.5 mm;

- stainless steel 0.8 mm thick.

At what point do you need to sharpen the tool

Turners working for a long time without prompts will understand the state of the working edge, but beginners can take advantage of these signs:

- an extraneous sound is emitted - creak, whistle;

- rapid heating occurs;

- the resulting hole is of low quality, there are notches on it;

- chips are not generated from all grooves.

If the procedure is not performed in time, the faulty tool may break (the tip breaks off, the workpiece deteriorates) or gets stuck in the steel. As a result, the device will be pulled out of the hands. Possibly broken equipment or injury.

Types of cutters

There are several types of cutting tools. These include: cylindrical, end, disc, end and slot.

By the type of destination:

- angular;

- shaped;

- keyed;

- to provide grooves of type T.

On the surface:

- plastic;

- tree;

- metal;

- glass;

- others.

Sharpening is difficult because the length of the cutting base is large. Therefore, specialized tools are used. In some cases, grinding is carried out manually, but the worker who performs this work must have experience. An unskilled employee can allow defects and defects appear on the teeth: cracks, burrs or pits, and therefore the tool will need to be ground again, and this will lead to a decrease in size.

Other types of attachments

When it is not possible to make a hole in the usual way, you need to use an angle drill bit. The working head of such a device can be rotated at different angles relative to the axis of rotation of the drill chuck. The main disadvantage of the tooling is the increased risk of drill failure. Therefore, the most popular is the 90-degree angle drill attachment, which is fixed on the drill neck. The price of the product is on average 800 rubles.

For craftsmen who are engaged in the manufacture of furniture, various types of cutters are in great demand. They can be undercut and pointed. With their help, you can make grooves of different shapes and depths, process holes and remove defects. The cost of the equipment is in the range of 350-450 rubles.

The design of the teeth of the nozzles-milling cutter provides a soft plunge into the workpiece, and can be repeatedly reground

To mix the solution of different consistency, a drill mixer is used, which is selected taking into account the density of the solution. So for kneading glue, liquid putties and other fluid mixtures, spiral devices are used, which exclude splashing of the solution. To mix the concrete, hexagonal nozzles are used. Mixing mixtures using this nozzle will be performed quickly and efficiently. However, in order not to reduce the efficiency of the device, the volume of the mixture for mixing should be maintained. The price of the nozzle is 500 rubles.

Helpful advice! When choosing a mixer attachment for a drill, it is necessary to take into account the power of the tool. Increasing the load can cause the winding to burn out.

Indispensable in concreting is a nozzle-vibrator for concrete on a drill, the price of which is about 900 rubles. It is used to compact the concrete mass during its laying, namely, it is designed to remove bubbles and air layers from fresh concrete. A drill with a power of at least 1500 W is required for the attachment.

To carry out turning work on wood, a home craftsman simply cannot do without a drill attachment for cutting wood, the average price of which is 2,000 rubles. To pump liquid, you can use a pump nozzle.

The material of manufacture of the impeller of the mixer nozzle affects what substances can be mixed with it.

A wide selection of different attachments, fixtures and fittings makes the drill a versatile tool that is indispensable when performing repair work and for other household needs in a domestic environment. This is a simple and optimal solution to avoid the purchase of expensive specialized power tools.

Peculiarities

In fact, any conventional drill is already considered a tool attachment, because it can be easily separated from its body and changed to another. Along with conventional universal drills, which differ in size, material and thread, there are also special nozzles that are used for certain materials. There are special attachments for working with metal, wood, glass, ceramics and others. However, all of them are united by one single purpose - drilling holes in the material.

Additional attachments allow you to transform your drill from a hole punching tool to a completely different device. When using them, you can cut, bend, grind and pump material. This variety of functions allows one drill to be used for many different operations, with the purchase of only inexpensive bits. There are whole sets that represent a small box or suitcase, which contains the most popular attachments. They contain those elements that are most often used to solve minor everyday problems.

Varieties of drill bits

Many craftsmen are accustomed to using a drill for its intended purpose, namely for drilling holes. But not everyone knows that this tool can be turned into a multifunctional device, supplementing it with special attachments, fixtures and stands, which will make the drill universal and indispensable in any work.

Angle drilling attachments and attachments allow you to make a hole where it is impossible to reach with a conventional drill

With the help of special drill bits, which can be bought at any specialty store at an affordable price, you can drill holes of all diameters, cut, grind, polish, twist, mix and mill. There is also a pump attachment for a drill designed for pumping liquid. The attachment for plucking chickens is simply irreplaceable in the household. With the correct and competent use of additional attachments, the result will not be of the worst quality, as with the use of a special single-purpose device, but the cost of such a universal tool will be several times lower.

By design, all existing attachments are divided into:

- accessories for drilling holes and crowns;

- scissor attachments for metal cutting;

- stops;

- corner fixtures;

- grinding and polishing attachments;

- equipment for milling wood and metal;

- sharpening devices;

- feathering nozzles.

Drill pump attachment is used for pumping and pumping liquids, for example, for draining water from rain barrels and children's pools

When working with any drill attachment, you must follow the safety rules:

the equipment must be securely fixed in the tool holder;

the drill must be held with two hands, which is especially important for powerful models;

constantly adjust the pressure of the tool;

work in personal protective equipment;

after completing work for several minutes, do not touch the drill to avoid burns.

Working with a milling attachment

The drill is designed for drilling large and small holes. This power tool should not be used for cutting sheet metal and milling. However, with the development of technology, various drill bits began to appear.

It is important to keep in mind some peculiarities when using this tool as a hand router:

- The design of the drill and its moving elements are not designed for constant heavy loads. Because of this, you cannot often work with a milling cutter on hard materials.

- If the power tool has a plastic gearbox, replace it with a metal gearbox if possible.

- The drill and milling chuck does not support lateral loads. This must be remembered during operation so that the nozzle does not fly out.

- The quality of the cut is much worse due to the low power of the drill motor.

When working with an electric drill as a hand mill, it is necessary to observe the functioning of the moving elements and turn off the tool when they are heated.

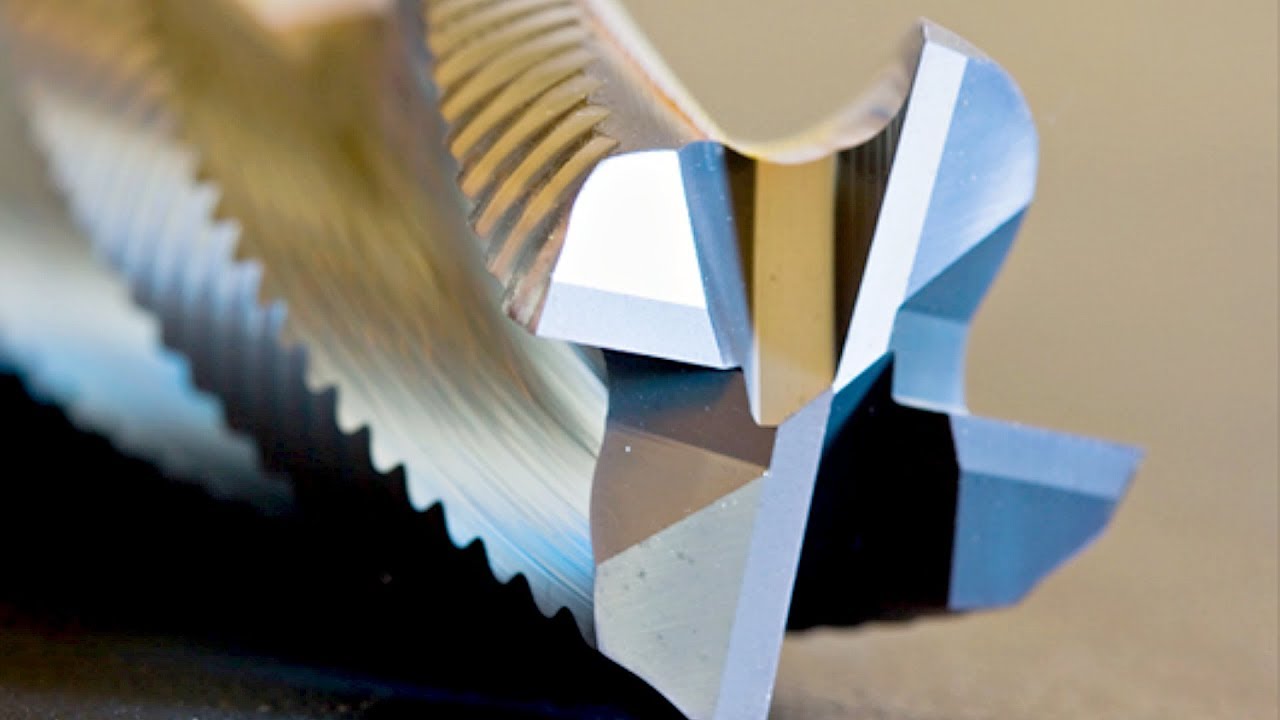

Cutter tooth geometry

Performance depends on correct sharpening of the teeth. Work surface configurations are used to solve even the most difficult tasks.

The spiral cutter is executed with a large and small inclination of the teeth at a given angle. The purpose of this type of tool: for roughing and finishing operations, including variable steps.

The tilt angle is the angle formed between the flat end and the edge of the flute of a standard cutter.

Angle value:

- small, no more than 35;

- large 35 and above.

An excellent option for starting and finishing machining is the angle of inclination of teeth - 38. Rectangular tools have the maximum value.

A tool with a variable pitch is in demand, along the length, the pitch of the spiral is measured.

Features of choice

Before purchasing a large and expensive set of drill bits, you need to think about the advisability of such a purchase. First, you need to know the purpose and operation of each nozzle. Secondly, you must have a minimum of experience with such a tool. And thirdly, you need to know the estimated frequency of use of each of the attachments.

If such a purchase is deemed appropriate, you should pay attention to the following features

- Price. Quality tools cannot be too cheap. However, the highest price on the counter is not a guarantee of a long service life. It is best to stay at the middle price segment.

- Manufacturer. It is better to choose products from trusted manufacturers than new and unverified brands. In this case, you should carefully study the documentation and beware of fakes.

- Place of purchase. The risk of running into a manufacturing defect and fake is much lower when buying construction tools in a specialized store, and not in a regular market or in a supermarket.

- Package. A quality tool is always well packed. The box contains all the necessary information both about the product itself and about the manufacturer. All accompanying documentation, including instructions, must be inside the box.

- Guarantee. The manufacturer, confident in its product, will always provide a guarantee for any attachment. If the store does not issue it at the time of the sale, the purchase should be carried out elsewhere.