Popular models

Below are the most popular models of gasoline motor pumps.

- SKAT MPB-1300 is designed for working with clean, medium and strong liquids with particles up to 25 mm. Throughput 78,000 l / h.

- Caliber BMP-1900/25 - is used to work with clean and lightly contaminated liquids containing debris up to 4 mm in size. Throughput capacity 25000 l / h.

- SDMO ST 3.60 H - designed for work with clean liquids containing debris up to 8 mm in size, silt and stones. Throughput 58200 l / h.

- Hyundai HYH 50 - used for clean and lightly contaminated liquids with particles up to 9 mm. The throughput is 30,000 l / h.

- Hitachi A160E - designed for clean liquids containing debris up to 4 mm in size. Capacity 31200 l / h.

- SKAT MPB-1000 - used for working with liquids, clean and medium contamination with liquids with a particle content of up to 20 mm. Capacity 60,000 l / h.

- DDE PTR80 - designed for clean, medium and heavily soiled liquids with particles up to 25 mm. Throughput 79800 l / h.

- Caiman CP-205ST - used for medium contamination liquids containing debris up to 15 mm in size. Throughput 36,000 l / h.

- Elitech MB 800 D 80 G - designed to work with highly contaminated liquids with particles up to 25 mm. Throughput is 48,000 l / h.

- Hyundai HY 81 - used for clean liquids containing debris up to 9 mm in size. Capacity 60,000 l / h.

- DDE PH50 - designed for clean liquids with a particle content of up to 6 mm. Throughput 45,000 l / h.

- The Pramac MP 66-3 is used for clean, medium and heavily soiled liquids containing debris up to 27 mm in size. Throughput 80400 l / h.

- Patriot MP 3065 SF - Designed for use in clean, medium to severely contaminated fluids containing debris up to 27mm in size. Throughput 65,000 l / h.

- Huter MPD-80 - is designed to handle heavily contaminated liquids with debris up to 30 mm in size. Throughput 54,000 l / h.

- Hitachi A160EA - used for clean, light to medium soiled fluids containing debris up to 20 mm in size. Capacity 60,000 l / h.

LIMITATIONS AND RECOMMENDATIONS

Do not turn on the motor pump "dry" - before starting the engine, it is necessary to fill the working volume with liquid. The pump mechanism, due to the design features, is practically unable to pump air, and a "dry" start will lead to the wheel spinning to no avail (in fairness, let's say that if the unit is at the same level as the source, water can "go" but that's how lucky). In addition, it should be borne in mind that the circulating fluid cools the engine, and idling will most likely lead to overheating. By the way, it is for this reason that pumps are not able to "transport" hot media. However, any of our models will withstand 30 degrees, and cases when you need to pump warmer water are very rare.

Another subtlety: you need to ensure that no air enters the intake hose. As a rule, this happens if the end of the "trunk" is very close to the surface of the water. The appearance of an air bubble threatens "water hammer": the flow of fluid following the bubble can harm the impellers of the wheel.

If the average operating time exceeds an hour, or if the unit has to be shut down frequently, check for the presence of a non-return valve at the end of the suction hose. It will not allow water to drain back from the chamber, which will greatly simplify restarting.

When storing the unit in an unheated room, it is necessary to drain all the water from it so that it does not freeze inside the pump and spoil it.

Motor pumps vary in application.All of them are capable of pumping clean water, but not all are designed to work with aggressive media, such as salt water, alkalis, etc.

And if the latter is not so important in private use, then the former requires explanation. The source, as a rule, does not have to be selected, therefore, the degree of its turbidity has a very significant effect on the performance of the units.

In particular, it is undesirable for large particles to get into the impeller - they can damage it. Therefore, experts recommend installing filters on the suction hose of the motor pump (a filter is included in the kit for all motor pumps of the CC model range).

ADVANTAGES AND DISADVANTAGES

Motor pumps differ from electric centrifugal pumps mainly in the engine - the design of the working system is the same for them. It is clear that the main advantage of any such unit in comparison with electrical counterparts is complete autonomy and independence from the presence of a supply voltage. The place for the pump must be chosen so that it is not high above the surface of the water. For self-priming devices, "nature has set" a maximum of 8.5 meters; most modern motor pumps "stop" at 7 meters and are not able to raise water from a greater depth. If such a need is ripe, and there is no possibility to use an electric submersible pump, you will have to resort to a "trick" - to install an ejector. This is a special device that is lowered into the water together with a hose. During operation, part of the lifted liquid flows back through an additional "trunk", thereby increasing the inlet pressure. That is, the water is simply "pushed" from below.

The hose also contributes to the weakening of the flow. The wider it is, the less its hydraulic resistance. When buying a corrugated hose, keep in mind that only the outer side should be "wavy" (this increases strength). Inside, it is smooth. However, there are samples without an inner layer, corrugated on both sides. They worsen the pressure, and their declared durability may not be justified, so it is not worth connecting them to pumps.

GENERAL MOTOR PUMP TIPS

- For a small garden plot of 6 acres, a low-power motor pump (up to 30 m3 / hour) will be sufficient.

- For an autonomous water supply of a country cottage, a motor pump of average power (30-60 m3 / hour) is suitable.

- To drain medium-sized reservoirs, you will need high-power motor pumps (from 60 m3 / h).

WHERE MOTOR PUMPS ARE USED

Pumps with gas, petrol and diesel engines are called motor pumps. The area of their application is wide: utilities with their help fight the water that floods the basements, with the burst sewer. Signalers are pumping out flooded telephone wells. Vodokanals eliminate the consequences of accidents on water supply routes. Motor pumps are indispensable in flood control when the electrical networks are damaged and the electric pump cannot be used. Motor pumps are used for water supply, pumping drainage and fecal wells, for irrigation. There are specially designed motor pumps with a strong jet of water for soil erosion, if necessary, washing with a strong jet, for fire extinguishing and many other purposes.

How to choose a motor pump correctly

When choosing a motor pump, it is worth first determining the suction depth, that is, how high the pump should be above the liquid intake point. For a motor pump, the maximum indicator is 9 meters. If the pump is located higher than the suction depth, the capacity will be lower. This is due to the fact that the unit, in addition to pumping water, will overcome the resistance of the water. To avoid such a situation, it is better to purchase a hose with a smooth inner surface and reinforced from the outside. During the operation of the unit, the hose must be completely immersed in water, in this case the water has a cooling effect on the motor pump.

The choice of a particular category of motor pumps depends on the degree of water pollution. Each motor pump is equipped with a filter that does not let in particles that can damage the internal elements of the unit. In this regard, motor pumps are divided into three categories. The first category includes units that are designed for garden and suburban areas. These models are equipped with fine mesh filters. They allow you to pump water from rivers, lakes, basins and reservoirs. The second group of motor pumps is equipped with filters that allow pumping water from polluted reservoirs and flooded basements and other rooms where there are impurities, but not significant ones. The third group of motor pumps is designed for pumping water with large impurities. They are mainly used in the construction industry and to eliminate accidents. In addition to these three types of motor pumps, there are other types that are designed to work in a specific environment.

Performance is also an important indicator when choosing a unit. This indicator is directly related to the type of work performed. For work on a personal plot, it is enough to have a unit with a capacity of up to 240 liters per minute. To pump out water from flooded premises or to work with pools and reservoirs, the unit is required with a capacity of 600 to 1000 liters per minute. To work in the construction sector or to eliminate emergencies, a motor pump with a capacity of up to 1640 liters per minute is needed.

When choosing, it is also worth considering the temperature of the water with which the work will be carried out. The best option for motor pumps is considered to be water with a temperature of 20C. If necessary, you can pump out water at a higher temperature (up to 90C), the main types of units are designed for this. But it is worth remembering that the higher the water temperature, the lower the suction depth is required for normal performance.

What are motor pumps for?

The motor pump is used to supply the suburban area with water, which is extracted from wells and other water basins. In addition, a motor pump can be used to clean up liquids, for example, from a flooded basement or to clean a sewer pit. A motor pump is a necessary technique for a summer cottage that is poorly equipped with water and for a private house during a water breakthrough.

Motor pumps have a number of significant advantages over other types of units for supplying or pumping water. Firstly, the technique performs a wide range of works. Secondly, it is light in weight and size. Thirdly, motor pumps are reliable and durable. Fourthly, the unit is easy to operate and does not require any special knowledge. In addition, the motor pumps are mobile, which is not particularly difficult in the implementation of their transportation.

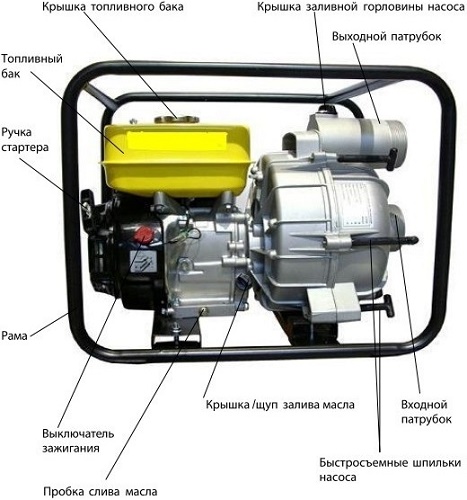

Design and principle of operation

The main component of any motor pump is a pump that pumps water at high speed. Two types of pumps are often used - centrifugal and diaphragm.

Their principle of operation is similar to pistons. By alternately squeezing the working fluid into the pipe, the membranes maintain a continuous high pressure flow.

The design with a centrifugal pump has a fairly widespread use. The motor turns the pump impeller, either by belt drive or direct connection. When twisted, the centrifugal pump, due to its design, generates a low pressure area on the inlet hose, due to which the liquid is drawn in.

Due to centrifugal forces, the impeller at the outlet forms an area of increased pressure. As a result, a flow of water is obtained, while there must be a working pressure on the outlet hose.

Most pumps are equipped with non-return valves. Gasoline motor pumps are supplied with meshes with cells of various sizes (the size of the cells varies depending on the possible degree of contamination of the pumped water) that act as filters. The pump and motor housing is mainly made of steel in order to protect the pump working units from damage.

To improve maintainability, most pumps have a collapsible casing (clean the mesh from dirt and other debris). Gasoline-powered motor pumps are installed on a reinforced frame to ensure stability during operation and safety during transportation.

The performance of a motor pump depends on the following factors:

- the amount of liquid transported (l / min);

- fluid head pressure on the outlet hose;

- working depth of liquid tightening;

- diameter of hoses;

- dimensions and weight of the device;

- pump type;

- engine's type;

- the degree of contamination (particle size) of the liquid.

There are also separate parameters, such as:

- engine characteristics;

- noise level;

- way to start the engine;

- price.

Brief instructions for working with a motor pump.

- Try not to allow the device to operate without liquid, as running "dry" the pump may overheat and fail. To minimize overheating, fill the pump with water before operation.

- Check the oil level and the condition of the oil filter.

- To safely store the pump for a long time, drain the fuel.

- To start and stop the device - follow the step-by-step instructions.

- Make sure that the hoses are not kinked, otherwise they may break.

- Before choosing a pump, specify the place from where the liquid will be pumped out. In the case of using a well or a well, you will not need a filtration system.

Views

Motor pumps are classified according to the operating conditions. There are those that are used to pump water without impurities and slightly contaminated, water with a high content of impurities.

To draw clean water, use a motor pump with a 2-stroke engine. For 1 hour, you can pump 8 cubic meters of water. The units are lightweight and small in size. They are popular with summer residents and villagers.

High pressure motor pumps are often referred to as "firefighters". This technique extinguishes fires and can also supply water over long distances. The motor pumps already have a 4-stroke gasoline or diesel engine. The water consumption is 600 liters per minute, and the water jet can rise up to 60 meters. Suitable for lots of land, far from water. The motor pumps are compact and easy to use.

If a pump is needed for processing dirt, then motor pumps are used, which ensure rapid suction of large particles. Such devices can pump 2 thousand liters of mud in 1 minute. The height of the water jet is 35 meters. The pipes in diameter reach an average of 50-100 millimeters.

For a summer cottage, units are often purchased that pump 130 liters of water in 1 minute. The rise of the liquid can be up to 7 meters. For a country house, these indicators are equal to 500-800 liters of water with a liquid rise height of 20-35 meters.

To drain the area and pump out the septic tank, a motor pump is used, which pumps 1 thousand liters of liquid per minute and raises it to a height of 25 meters.

In modern conditions, it is important to quickly and promptly extinguish the fire and prevent it from spreading to the site. This can be done with a motor pump.

Water, directed under pressure, extinguishes the fire, covers the surface of the hearth with a film that slows down smoldering.

High-pressure motor pumps are able to extinguish a fire in remote areas, in houses, high-rise buildings.

The fire engine pump is equipped with a non-self-propelled chassis, a high-power centrifugal pump, and a gasoline engine.

The motor pump starts immediately after refueling. The pump operates under high pressure, consumes 1400 liters in 1 minute, and delivers a stream of water up to 80 meters. Thus, a motor pump can extinguish fires and fires at a high combustion temperature, while taking into account the significant height of the water flow.

Such units can be transported on a trailer, cars, ATVs. Some models can be carried by hand.These features make it possible to extinguish a fire even in hard-to-reach and impassable places. The unit draws water from a natural reservoir of various capacities and a well. Modern technologies allow motor pumps to draw liquid from a depth of up to 8 meters.

So, modern motor pumps are multifunctional in terms of characteristics, compact, practical and durable in use. The main thing is to understand the principles of operation of this device.

An overview of the Sadko WP-5065p high-pressure gasoline motor pump is in the video below.

Let’s block ads! (Why?)

Types of motor pumps

Depending on the type of fuel used, autonomous motor pumps are divided into three groups:

- Gasoline;

- Diesel;

- Gas.

It should be noted that gasoline and gas installations have a similar engine design. Moreover, a gasoline unit can be adapted for gas by installing a special gear module on it.

Depending on the operating conditions, the following gradation of motor pumps is adopted:

- for pumping clean water;

- for work with slightly polluted and clean water (high-pressure or fire);

- for pumping heavily contaminated water and thick liquids (mud).

Motor pumps for clean water

As a rule, they are powered by a two-stroke engine. The productivity of such plants is relatively low (6-8 m3 per hour). The maximum size of solid particles that can pass through without damaging the pump does not exceed 5 mm. Due to their mobility, light weight and dimensions, they are very popular with owners of small non-electrified summer cottages and plots.

High-pressure (fire) pumps

Having met the word "fire" in the name of the installation, do not rush to classify it as a special equipment. This is how manufacturers designate household pumps that develop high pressure in the pressure line.

They are designed not only for extinguishing fires, but also for delivering liquid over long distances. Fire pumps are equipped with 4-stroke gasoline or diesel engines. The performance of such installations is noticeably higher than that of low-pressure motor pumps. It can reach 400-600 liters per minute with a lifting height of up to 60 meters.

It makes sense to buy such a unit for a large land plot or for a summer cottage located far from a water source. Despite its solid technical characteristics, the fire engine pump is not much heavier and larger than standard stand-alone pumps.

Motor pumps for pumping dirty water

Their main differences from the listed units are higher productivity and throughput. Solids up to 2.5 cm in diameter can pass through the mud pump.

Another useful option for such devices is quick access to the pump for removing solid objects that exceed its capacity. The performance of household pumps for pumping dirty water can reach 2,000 liters per minute with lifting heights up to 35 meters. The diameters of the inlet and outlet branch pipes are in the range from 50 to 100 mm.

Choice in the market

The range of fire pumps on the market is quite wide. There are models of domestic production, European, Chinese. Japanese motor pumps are in great demand. Since fire extinguishing is a responsible event, the choice must be made based on performance, reliability and availability for repair.

A striking example of a fire-fighting motor pump on a trailer is the Geyser 1600 model. Geyser is a Russian trade mark widely known for its products.

Motor pumps from this manufacturer are purchased by public utilities not only for fire extinguishing, but also for pumping water from basements, pits, sewerage systems.

Geyser 1600 is a high-pressure fire engine pump with a gasoline engine and an electric starter. It gives a jet of water up to 190 m high, with a maximum flow rate of 1200 l / min. The engine uses a 4-stroke domestic VAZ 2108, which makes it easy to carry out repairs in the event of a breakdown.On one full tank, the capacity of which is 20 liters, a fire engine pump can work a little over two hours.

Due to its power, versatility and reliability, the MP-1600 motor pump of the Melitopol plant "Hydromash" is in demand. It is currently marketed under the brand name MM 27/100. The motor pump is installed on a two-wheeled frame. It uses a ZAZ-4121 engine and wheels from GAZ-24. The water consumption is at least 1600 l / min, the maximum jet height is 100 m.The pump can suck in water from a depth of 7 m.

In addition to working with water, a fire engine pump can pump a foam mixture to extinguish fires. Control over the operation of pumps, motor, foam generator is carried out using the control panel.

Among other brands, fire-fighting motor pumps of increased power Aquarius are popular. There is always a demand for Tohatsu, LZPM, Robin Subaru pumps. There are positive reviews about portable fire-fighting motor pumps Koshin, Champion.

What is a fire pump

A fire engine pump is understood as a motor-pumping mobile complexes for pumping (feeding) through OTV (fire extinguishing agent) hoses to the hearth or fire-fighting equipment.

Water intake is carried out from open sources, reservoirs, hydrants, water pipelines. The operation of the MP is provided by a drive power plant (internal combustion engine, electric motor) or a mechanical structure.

Motor pump designation on the fire diagram:

-

portable:

-

mobile:

Fire pumps use:

- with limited technical capabilities of extinguishing, lack of water pipelines, fire extinguishing installations (remote areas);

- for the rapid organization of fire extinguishing with large capacities (in production);

- for swap;

- as an auxiliary device:

- before the entrance of the equipment;

- during extinguishing;

- on fire-fighting railway trains;

- for other purposes:

- filling containers, tank trucks, aircraft;

- pumping out of tanks, basements, reservoirs, trenches, holds in case of accidents;

- household (watering), archaeological, irrigation, prospecting work.

The pump quickly draws water and supplies it with the possible use of foaming agents to extinguish fires. For organizations, partnerships, MP will be cheaper than vehicles.

At enterprises, according to the classifier of fixed assets (OKOF), MP is referred to the section: Fire motor pumps.

Code 14 2944190, OK 013-94

What is the difference between a fire pump and a conventional one

In fact, in terms of performance characteristics, MPs are the same household pumps, but with increased capabilities and a mandatory framework for the airbag. There are also samples purely for the purpose of fire extinguishing. Differences:

|

Options |

water pump |

|

|

Fire department |

Household (regular) |

|

|

Pressure |

From 1 - 2 MPa and above |

up to 1 mPa |

|

Flow rate |

200 - 2400 l / min., Standard approx. 500 l / min. (Honda WH-20) |

130 - 200 l / min. |

|

Throw length |

30 - 80 m |

8 - 15 m |

|

Peculiarities |

|

There are no fire hoses included. |

|

Suction depth |

1.5 - 12 m |

1.5 - 5 m |

Requirements for motor pumps

Mandatory parameters of MP (GOST R 53332-2009):

- continuous work - from 2 hours;

- functionality at -40 to + 40 ° C;

- launch - up to 2 minutes;

- noise level - 90 dBA;

- trouble-free operating time - from 200 hours;

- switching cycles of vacuum units - from 300 hours;

- before the first overhaul - from 1500 hours;

- the term to write-off is 10 years.

MP elements:

- pump:

- centrifugal;

- membrane (less often);

- drive motor with starting, cooling systems:

- ICE on petrol, gas, diesel;

- on electricity;

- lines: suction, pressure;

- hose equipment (sleeve, barrel, heads);

- body (frame);

- additionally: foam extinguishing units.

What a fire engine pump should have:

- casing;

- control devices:

- pressure gauge, manovacuum meter (mandatory in the pressure line);

- tachometer;

- working hours counter;

- indicators of cooling, pressure in the lubrication system, accumulator, ignition;

- the ability to assemble / disassemble;

- drain;

- filter;

- valves of shut-off type and regulating at the suction, excluding reverse current;

- vacuum or other filling unit;

- manual (MPBV-80) or auto-control with 3-fold filling of the supercharger;

- stable paint and varnish special coating.

How to choose?

The choice of a motor pump is influenced by the following parameters:

- landscape relief of the working area;

- suction section height;

- the level of the required pressure;

- the volume of the pumped-over liquid;

- speed of work execution;

- permissible loads on the apparatus;

- dimensions of inlet and outlet nozzles;

- flammable liquid consumption;

- engine power level.

For the high-quality implementation of the planned work, it is necessary not only to choose the right motoblock, but also all the component accessories

An important part of this device are hoses, which are of two types:

- fences;

- pressure head.

Poor quality hoses made of unsuitable material cannot withstand high pressures and can be deformed by the sharp corners of gravel or slag. Factors influencing hose selection:

- engine power;

- pump motor life;

- the level of water pollution;

- the presence of aggressive chemical compounds;

- the size of the nozzles;

- the level of the required pressure;

- availability of transitional equipment.

Composition of the delivery hose:

- the inside is smooth;

- layer - tissue;

- the outer layer is corrugated and reinforced with an iron frame.

What gasoline is used to operate a motor pump

It depends on which engine the pump is equipped with:

-

Four-stroke engines with motor pumps are similar to those installed on a passenger car and work even on low-quality gasoline. But quality fuel will extend the life of the engine.

In the instructions of most manufacturers, the use of AI 92 gasoline is recommended. The use of fuels with lower octane numbers is impractical, the cost of repairing equipment will override the resulting savings. The fuel consumption rate is indicated in the pump passport and ranges from 1 to 3 l / h.

-

Two-stroke gasoline engines are similar to those found in light motorcycles and mopeds. Refueling them with pure gasoline is unacceptable, as it will lead to the crankshaft jam.

Refueling of such engines is carried out with a prepared fuel mixture of AI 92 gasoline and special engine oil. What kind of oil to pour into the motor pump is indicated by the manufacturer in its passport. The use of oils intended for motorcycles or outboard motors is not permissible.

In two-stroke devices, there are two working chambers - lower and upper, located below and above the pistons, respectively. This design prevents the connecting rod bearings from being lubricated with oil from the crankcase. Connecting rod bearings are lubricated with oil added to gasoline.

How to dilute gasoline for motor pumps and in what ratios the oils are added are indicated in the manufacturer's instructions. This directly depends on the engine model and oil marking. Recommended ratios - one part of oil is added to 50 or 40 parts of gasoline, which is 20 or 25 ml. per liter.

Lack of oil leads to engine seizure, and excess oil leads to the formation of intense carbon deposits on the piston and spark plug, the result is a loss of power. The gasoline consumption rate is reflected in the pump passport.