Views

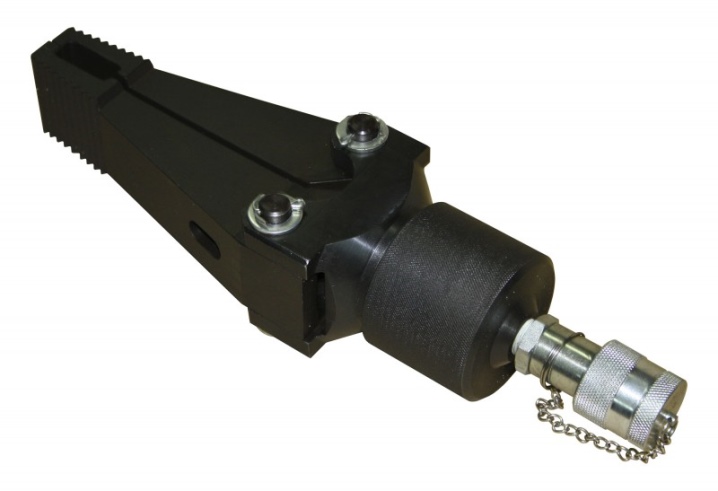

A bottle jack is often used to move a car, as well as to raise it. The full name is bottle plunger hydraulic jack. Its main part is a cylinder. Opening the cylinder reveals a piston inside. Depending on the design, the main working fluid (hydraulic oil) can be located both in the cylinder itself and in the reservoir below it.

Direct actuation of the device takes place using a plunger pump. It is quite small in size. However, this modest detail is enough for the oil to be forced through the bypass valve into the cavity under the piston. The diameters of the plunger and cylinder of the jack are selected in such a way as to reduce the required force to a minimum. When fluid is pumped under the piston, it will mechanically push it out.

Following this, the weight above the piston also rises automatically. To lower the jack, slowly bleed off the hydraulic oil under the piston. It will flow from there to the top of the cylinder or to a special reservoir. The performance of the system as a whole and other nuances largely depend on the capacity of this reservoir. When they talk about a "vertical" jack, they almost always mean the bottle scheme.

The telescopic jack is arranged somewhat differently. Its main working element is the same piston. But already 2 pistons are installed by default. Thanks to this addition, the lifting height can be increased quite significantly.

Importantly, dual-piston systems perform as well as traditional models with only one piston. But the complication of the design makes the equipment more expensive and heavier, therefore, it is mainly used by repair organizations, and not by individuals.

But the wedge jack is no longer needed by motorists. Often such a device is used in industrial forestry. It is also used in the construction of wooden houses. The bottom line is simple: a special wedge moves horizontally. Such a solution is versatile and reliable, it can lift a load for many years in a row without any problems.

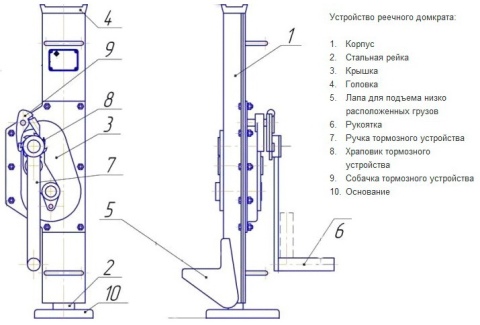

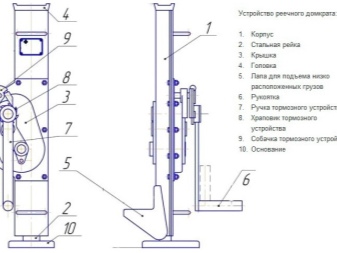

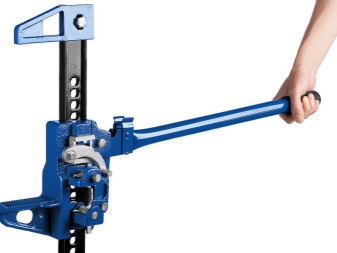

A rack and pinion jack is a mechanism with a manual type of drive. These models are used to lift loads during:

- construction;

- repair;

- restorative;

- dismantling;

- reconstruction;

- assembly rooms;

- some other works on objects of various kinds.

The main working element is a one-sided gear rack. The bottom end is folded back so that loads can be lifted at right angles. The support cup is positioned as low as possible. The retention of weights that have been lifted on the rail is carried out using special locking knots. The lifting capacity can be 2500-20000kg.

But in car services, a rolling jack is often found. It will be useful to purchase it for advanced car owners. Such a device has a horizontal design. They are screwed onto the body when assembling the wheel. They also allow you to roll up the lift without lifting it from the surface (except perhaps to overcome thresholds and other obstacles). The reliability of the support is precisely ensured due to the fact that simultaneously with the raising of the car, the device goes deeper under it.

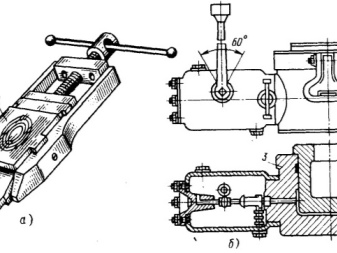

The gear mechanism is typical for gear jacks. The mechanism is driven into motion by unscrewing the handle. Lifting capacity may vary from 3000 to 20,000 kg... But for private use, you can also buy a screw jack.

Selection Tips

In order for the jack of the considered carrying capacity to reliably serve for a long time, when buying it, you need to pay attention not only to the design features, but also to its intended purpose. One of the main criteria when choosing equipment is considered to be the carrying capacity, since each model has its own minimum and maximum indicators.

The lift height also deserves special attention, usually most of the models are designed for 40-50 cm. This is enough to replace a wheel or provide easy access to the handbrake cable. In addition, it is worth checking with the sellers and the lifting speed, which directly depends on the working stroke. The larger it is, the better the lifting device is considered. It is also worth studying the reviews about a particular model, since it is absolutely not necessary to overpay only for a well-known brand.

In the next video you can familiarize yourself with the characteristics of a hydraulic jack with a lifting capacity of 5 tons.

Views

Today, manufacturers offer three main types of jacks for 5 tons: hydraulic, pneumatic and mechanical. Hydraulic devices work by pumping brake or working fluid; both single-valve and two-valve models are on sale.

In turn, hydraulic jacks are subdivided into bottle jacks and rolling jacks. The bottle-type device is considered the most popular because it has a high lifting capacity. Its only drawback is its small size, which makes it unstable. A rolling jack is used mainly for vertical lifting of a load, it drives under the car, unlike the previous version, it is convenient to use, works in any conditions and has good stability.

Pneumatic jacks are equipped with a lifting mechanism, which is activated by pumping air into its cavity. As for the mechanical form, it is the simplest lifting equipment, they are often equipped with cars. The price for such devices is low.

Jacks for 5 tons differ among themselves and in design features, depending on which they are divided into five types.