Varieties

Experts divide axes into three main groups:

- cleavers;

- carpentry, for felling in the forest;

- universal, for construction.

Each category includes several varieties that differ in the purpose and characteristic features of the elements. For example, carpentry tools used in the forest are distinguished by weight. The lighter versions (0.9 kg) are only suitable for limited jobs involving small workpieces.

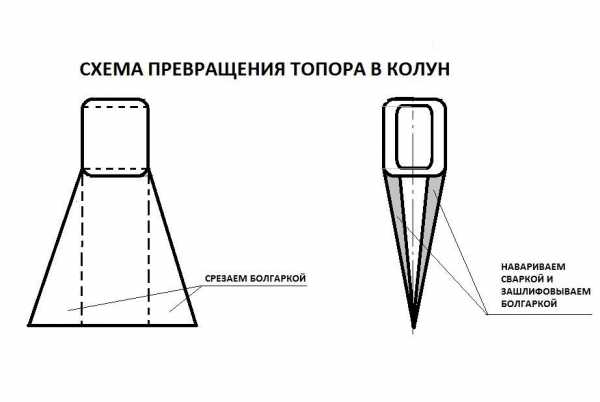

All cleavers have a single purpose - to split logs or cut branches. The operation is performed when chopping firewood. The tool has an interesting blade, the appearance of which resembles a drop. It has an extension of the metal part that is inserted into the handle. The tool is heavy, due to which thick wood is broken. The force of the blow is also enhanced by the long ax.

If you need to cut firewood of medium thickness, you will need a tool weighing from 1 kg to 1.7 kg. For splitting large firewood, heavy splitters weighing more than 2 kg are used. They are also complemented by an elongated hatchet.

The category of universal axes includes construction tools. In this case, the shape of the blade is characterized by an even edge. It is more convenient to trim boards or bars with such a tool. Even small parts can be processed with a sharp end, while the accuracy of the work will be quite high. The tool weighs up to 0.8 kg, so most of the work can be done even with one hand. For convenience, the carpentry handle is oval.

The steel of the blade of a carpenter's ax has the same value as that of other tools. The best options are forged. Modern tools are supplied with cast blades. Therefore, old axes are considered more valuable today.

Another version of the universal type is tourist. It is small in size. An important characteristic of this tool is high-quality sharpening. The product is reduced in size, and therefore must be sharp so that it is convenient for them to work.

Examples of tourist hatchets include many varieties, differing in execution. For example, there are options with a wooden handle, metal, lightweight, plastic. Metal versions of handles with rubberized parts have very good characteristics. A tool with a plastic handle is considered to be very fragile. A useful addition to any travel hatchet is the carrying case.

Of the rare varieties, the "adze" ax is noted. It is suitable in cases where grooves are needed in a log or bar. The ax is distinguished by a special type of metal part with an extension at the end, with a semicircular sharpening. It is easy to gouge grooves with such a pickaxe, while there is no replacement for this tool.

Forging axes

Forging a welded ax

Forging a welded ax

An ax can be forged using one of the well-known technologies: forging, solid-forged, riveting, drilling into a solid metal blank.

Each of these techniques has many nuances and complexities. But the most popular of them are:

- forge welding;

- one-piece forged manufacturing.

Forge welding uses two different metals with different strengths. For the body of the ax, ordinary steel is used, and for the blade, tool steel. Accordingly, the parts are welded together with their own alloys.

For the manufacture of a one-piece forged ax, high-quality carbon and alloy steels are used. The product is made in shape, after which it undergoes processing and grinding.

How to choose?

Carpentry is closely related to both tree felling and construction. Choose carpentry axes with medium-width blades. This will allow you to efficiently chop off branches, process logs. Modern products on sale are called tourist or garden products.

In carpentry work, sometimes it is necessary not only to cut, but also to cut. The rounded edge of the blade is very convenient for this.

It is important that it is not too sharp, otherwise the instrument will be very fragile.

The quality of the blade steel is selected by sound. Craftsmen advise to knock on the ax when buying it. A sonorous sound indicates the strength and durability of the selected specimen.

The classic carpentry tool handle is made of wood. The handle will be resilient if it is made of dense rock. The fibers of the wood should run along. Good wood for an ax is free of knots and cracks. Such a product will not break from strong impacts.

Wooden handles darken and dry out over time. Therefore, experts advise treating purchased axes with paint.

Metal handles are not affected by a harmful environment. All-metal structures are highly reliable. For convenience, they are usually supplemented with rubber pads. This addition prevents hands from slipping off the product during work.

Modern versions of the hatchet are made of fiberglass (fiberglass). The material is based on polyester resins. When they harden, they acquire the strength of a metal. Unlike wood, they do not rot, do not change their original properties, regardless of any impact.

Thanks to modern material, the performance of conventional axes is significantly improved. Experts believe that the impact of vibration that occurs upon impact is reduced. The grips are equipped with grooved inserts to reduce slipping.

The convenience of the handle is due to its shape. Most of the tools are made with a bend, this ensures a secure grip. The end of the ax is usually widened. This prevents accidental slipping.

For the carpenter, the weight of the tool is also of great importance. Carpentry models are often made light. This is necessary so that the hands get tired less, since such works are lengthy.

An important addition to the ax is the presence of a rubberized pad on the blade. It will cover the sharp edge and ensure safety when carrying the tool

A canvas cover is also required.

For more on carpentry axes, see the video below.

What is different from the usual?

For example, carpentry axes differ from taiga axes in the shape of the blade and the length of the handle. The tasks that the tools must perform are the opposite. With a carpenter's ax, you need to cut it as accurately as possible. The workers here are not in a hurry, since the main thing in the course of such work is not to make mistakes.

Fishing products or cleavers perform a different function - they cut wood quickly and deeply. The shape of the ax is made in such a way that it is faster to knock down a tree than with a carpenter's tool with equal effort.

Carpentry options do not have a powerful groove - a protrusion under the ax handle, which prevents the handle from breaking when vibrated. This projection absorbs about 50% of the load. However, this groove will not save the handle if it breaks against the chock. The carpenter's ax is not equipped with a wide front part. The blade of the fishing option is made at an angle. This allows the worker to use the tool like a cleaver. You just need to concentrate energy on the right blow.

The handles of carpentry and fishing tools differ in the angle of inclination. The first option has a smooth downward angle. The protruding edge of the ax is visible visually. The fishing tool simply does not have it. This very corner creates strong vibrations.

In addition to the blade, the carpentry version also differs in the hatchet. It has an ovoid cross-section here. The first half of the carpentry tool should not be very heavy and thin, otherwise it will quickly break. Aspen handles are considered to be of high quality. A good piece should be strong and lightweight. Homemade options are recommended to be processed not with varnish, but with drying oil. The lacquered ones will slip and turn out to be cold.

Specifications

The modern carpenter's ax is quite heavy. Typically, this is about 1.5 kilograms. This indicator is considered optimal, especially if wood processing takes a long time.

A characteristic feature of modern carpentry tools is a kind of blade sharpening. Its edge is rounded. Axes with straight blades, which are commonly sold in stores, require additional work. Otherwise, you will have to spend more effort. Detachable chips will not break on impact.

The ideal is the same blade angle of a modern ax as that of an ancient weapon - 35 degrees. The blade with a lower angle will be gripped by the wood grain. Large parameters will lead to unnecessary expenditure of energy.

If earlier the length of the ax was determined by the height of the worker, now this parameter is regulated by GOST. Standard sizes (40-50 cm) are considered to correspond to the average size of a person.

The modern ax is more often perceived as a versatile variety that will come in handy at a summer cottage, a picnic or in a household. The design of such tools is simple, but the methods and quality of their manufacture may vary.

Model rating

Carpenter's axes are made by forging from U7 and 60G steel. A properly processed and hardened blade material will have good hardness. Such a product will be durable and will sharpen well. Low carbon stamped steel will dull quickly and is too tough to sharpen well. Often the element crumbles when working with wood, therefore such a blade is considered defective.

The Izhevsk plant produces many instruments that are characterized by low cost. Low-cost products delight customers with high quality.

The following advantages are noted:

- reliable handle made of wood;

- optimal weight - 1.2 kg;

- a handle made of high quality steel;

- good sharpening.

There are also disadvantages:

- the opportunity to acquire a marriage;

- no hanging hole.

Japanese examples of carpentry axes differ from Izhevsk ones in increased ergonomics. Hanging hole on the handle is. The tool is made very comfortable, it sits in the hand of the carpenter like a glove. However, frequent use of such a tool does not entail any changes. The only drawback of the products is the high cost.

There are several more comfortable models with high sales ratings. For example, Fiskars 121440 * 10 is in demand. Its blade is hardened twice, has a special coating, and has an interesting shape. The handle is polyamide, but comfortable and reliable. The handle, made in the form of a hook, does not allow the tool to slip out of the hands. The company provides each product with a 10-year warranty.

The Matrix ax 21649 also has good sales ratings. The product is equipped with a handle made of modern fiberglass material. The blade is of high quality, forged, made of 60G steel. This carpentry ax belongs to the budget price category.