The device and principle of operation of an electric compressor

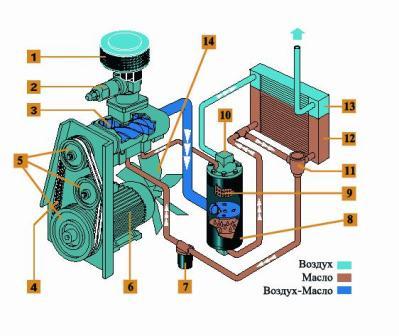

For domestic needs, piston-type compressors are often used. The main distinguishing quality of such a unit from the industrial (screw) type is its simplicity of design. The device consists of the following main components:

• cylinders;

• pistons;

• motor mechanisms;

• regulation systems;

• lubrication systems;

• cooling devices;

• mounting parts.

The principle of operation of the device lies in the motor functions of the pistons, which lead to the capture and delivery of air to the cylinder area. During the return process, the air is compressed, as a result of which the pressure force increases. After reaching the desired value, the suction valve closes, while the discharge element opens the movement of compressed air into the line. This cycle is repeated throughout the operation of the unit.

Best Reciprocating Air Compressors Oil-Free

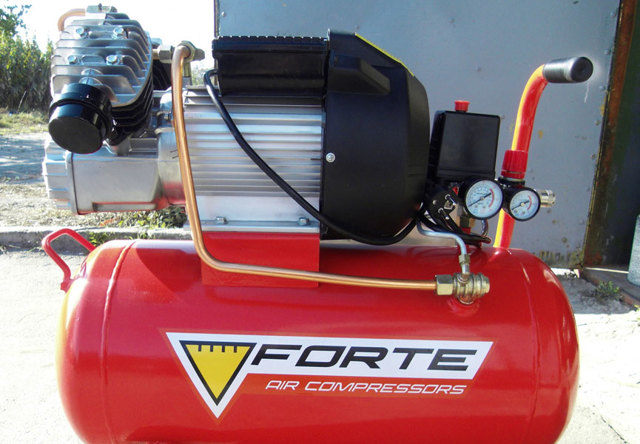

Reciprocating air compressors can be classified as household models. The electric motor drives a piston located in the cylinder, which causes air to be pumped. Oil-free technologies do not pollute the atmosphere, but they are noisier and more expensive than oil models, since they require more money to produce them.

Fubag Handy Master Kit

Compressor set Fubag Handy Master Kit is a complete system for a car and other household needs. It can be used to inflate tires, balls, boats, and any other similar things. The working pressure is 8 bar. Equipped with a flexible rubber hose 5 meters long. Unit weight 7 kg.

Dignity

- Technical indicators;

- A set of attachments for different uses;

- Convenient to carry;

- Low price.

disadvantages

- Noisy;

- The filter clogs up very quickly.

Buyers using this device are advised to additionally secure the hose with a hose clamp at its base. Otherwise, it may start to fly off during operation.

Metabo Basic 250-24 W OF

The reliable air compressor with 100 l of effective Metabo Basic capacity is suitable for semi-professional use. Low maintenance costs. The volume of the receiver is 24 liters. Rubberized wheels make the unit mobile, but stable at the same time. And thanks to a reducer with a pressure gauge, it is possible to adjust the working pressure depending on the tasks being performed.

Dignity

- High performance efficiency;

- The build quality of the device;

- Overload protection;

- Manufacturer's warranty for 10 years.

disadvantages

High price.

Caliber KB-1100M

System Caliber KB-1100M includes a pumping unit with a pressure gauge, a set of nozzles for inflating tires, boats, balls, inflatable rings and others. The principle of air compression is one-stage. The maximum pressure is 8 bar. The unit is made in the form of a small case, which is convenient for transportation. Small dimensions make the compressor mobile, not only the space for its storage and transportation is reduced, but the time of its readiness for operation increases. The simplicity of the unit does not require frequent maintenance and will allow you to fix problems yourself.

Dignity

- Good performance for a household appliance;

- Compact;

- A light weight;

- Lots of attachments.

disadvantages

- Time of continuous work just over half an hour;

- Short hose.

Caliber KB-1100M is not recommended to be used for purging.And it is better not to keep the device in working mode for more than 40 minutes. It is worth keeping it safe.

Craton AC-300-50-OFS

The model generates clean compressed air in which there is no oil dust. A good professional model with a fifty-liter reverse, with a capacity of 300 liters per minute. The compressor of the device is two-cylinder. Air compression is two-stage. Two wheels and a handle are provided for transportation.

Dignity

- High performance;

- Durability;

- Sufficiently compact size;

- Low price.

disadvantages

- Noisy;

- The assembly flips a little in the process.

Users are advised to carefully inspect the structure before first use. Perhaps, somewhere it will be necessary to tighten the bolts, knots. They can be twisted asymmetrically in strength.

Denzel RS 1 / 6-180

Ultra-compact, mobile electric 220V air compressor, perfect for garage, home. The maximum pressure is 8 bar. Output capacity - 180 liters. The volume of the receiver is 6 liters, which makes it possible to use the device for blowing.

Dignity

- Powerful;

- Suitable for many home appliances;

- Possibility of installing an additional receiver;

- Low price.

disadvantages

Very noisy.

For personal needs in the garage, at home - a great model. Buyers talk about the durability of using this model, even with active use.

The best welding inverters

Design and principles of work

Most often, compressor units are made of stainless steel. This approach ensures the durability and reliability of the devices, but at the same time negatively affects the mass and mobility of the device. The basic building blocks of any jackhammer compressor are:

- suction type air filter;

- compressor block;

- engine;

- Lubrication system;

- cooling system;

- current condition sensors (air pressure, filter system condition, oil temperature, etc.);

- devices for removing accumulated condensate and oil;

- valves of several types: safety, non-return, etc.

Moreover, the absence of any element from the above is unacceptable and should be the reason for refusal to purchase. In this regard, carefully study the appearance of the device, as well as its internal characteristics (this can be done on the basis of the instruction manual attached to each unit without fail). The compressor is used when it is necessary to compress air to a certain required volume. During this process, among other things, oxygen is purified from various additives (dispersion impurities or vapors). To do this, the unit draws in air inside.

Which air compressor is better to buy

You can choose an air compressor by answering the question for what purpose it is needed. The simplest models make everyday life easier, they are suitable for inflating tires or painting a fence. More powerful ones will be effective both in personal use and in industrial use, they will help to paint the car and come in handy for repairs. Professional units are suitable for performing large amounts of work.

The following models became the leaders among each type of compressor:

- Abac Spinn 3 10/200 is the most efficient, reliable industrial compressor system;

- Remeza CB4 / F-500.LB75 - an expensive but durable device;

- Fubag Handy Master Kit is a universal budget household model, you can inflate tires, boats, balls, etc.

Everyone decides which air compressor to choose based on the required functionality of the unit

It is important to follow the operating rules and in case of malfunctions, contact the service offices in time

How to Choose a Household Electric Compressor?

Among the main criteria for choosing a unit is its mobility.It depends on the indicators of weight and dimensions how quickly and easily the equipment will be transported to the place of work, and the connection will be made. An even more significant argument is the power of the compressor, since the duration of operation and the strength of the air flow pressure depend on it.

When familiarizing yourself with the technical characteristics of the model, it is worth paying attention to the performance. This indicator will determine the effectiveness of the processing of any material over a certain period of time.

You should also take into account important factors affecting the selection parameters:

• for what purposes it is planned to use the unit;

• duration of the system operation;

• whether the equipment will move from one facility to another;

• the number of mode switchings per shift;

• features of the operating conditions.

It is preferable that the structure is integral, because during operation, all elements vibrate, which can unbalance individual modules. The belt drive in the device will ensure reliable operation of the unit and reduce efficiency losses.

One of the most durable and successful motors is considered to be an asynchronous type, which is powered by a 220 V network. Many years of operating experience show that mechanism breakdowns are rare, and the design has a simple device that does not require special care.

The safety of using the compressor will be ensured by an automatic emergency power off. Protection is triggered instantly when the maximum permissible temperature of individual nodes is reached.

Those who plan to use a long-term operating mode are advised to pay attention to the volume of the receiver. The indicator will reflect the time during which the equipment can be used without interruption.

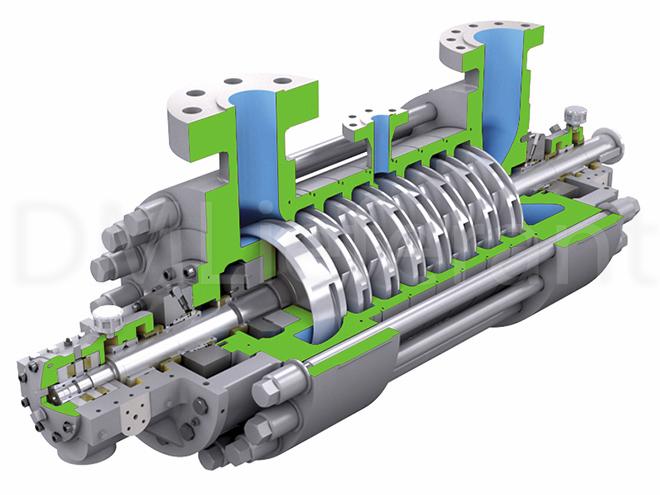

Best Screw Air Compressors

Units of this type pump air due to the compression resulting from the rotation of the screw pair. This technology is more efficient than piston technology, but more energy intensive. Care must be taken when cooling the screw air compressor as they heat up more than other types of appliances.

Fini Plus 16-10 (IE3)

The industrial device Fini Plus 16-10 (IE3) is suitable for medium-sized production. Output capacity - 2050 liters. The required supply voltage is 380 V. The power of the device is 15 kW, the pressure is 10 bar. The receiver is not provided. The unit can be controlled via the Easytronic Micro II controller, which maintains the compressor in operating mode, shows the operating characteristics, monitors the operating hours, and if a malfunction occurs, the controller will report an error and, if necessary, turn off the device.

Dignity

- Good performance;

- Easy to install;

- Manufacturer's warranty;

- Adequate price.

disadvantages

- Large weight;

- Large dimensions.

Like all Fini products, this device does not fail in operation. In case of problems, you can contact the service center specialists.

Abac Spinn 3 10/200

The stationary Italian compressor unit Abac Spinn 3 10/200 at the outlet gives a capacity of 320 liters. The volume of the receiver is 200 liters. A pressure gauge is built into the small structure. It is convenient, there is no need to purchase additional equipment. The device works quietly.

Dignity

- Performance;

- Low energy consumption;

- Multifunctionality of use;

- Good build quality.

disadvantages

High price.

Many entrepreneurs prefer the Abac brand. The products, although expensive, are worth it. And there are no problems with the work of warranty, service.

Comprag ARD-1508

The Comprag ARD-1508 unit is a modern industrial compressor unit. Productivity - 2300 liters per minute. The volume of the receiver is 270 liters. Pressure - 8 bar. Power - 15 kW. Built-in dehumidifier.The device is equipped with a noise-protective casing, which provides a quiet operation mode, which allows the Comprag ARD-1508 to be operated close to the workplace.

Dignity

- High efficiency;

- Large receiver volume;

- Low noise level;

- Durability.

disadvantages

Very high price.

Working with this unit requires a thorough preliminary study of the operating recommendations. Safety precautions should be strictly followed.

Advantages and disadvantages

Household compressors have undeniable advantages:

• have small dimensions and weight;

• provide good performance;

• simplicity of the device allows for the replacement of individual units;

• the ability to connect to various equipment;

• high pressure indicator in one compression stage;

• wide range of applications;

• the unit easily tolerates frequent switching on / off modes;

• functions even in dusty rooms.

• rapid wear of pistons and rings, which entails additional costs during the period of operation;

• possible pulsations of flows in the suction and discharge pipelines;

• in comparison with screw equipment, the efficiency of the piston system is lower.

Optimum electrical compressor performance

The performance of the unit is ensured by the following technical indicators:

• working pressure in the range of 8-12 atm .;

• power is about 2 kW;

• the volume of the receiver is not less than 50 liters;

• protective automatic shutdown;

• the presence of cooling elements that increase the service life of the asynchronous motor;

• belt drive.

Air compressor of which company is better to choose

Compressor units are screw, piston, oil, oil-free. Some are good for the garage, some are good for professional auto repair shops, some are environmentally friendly

Having decided on the type of device, it is important to choose a manufacturer. The best compressor companies are as follows:

- Fubag is a German brand that produces professional, semi-professional equipment for cars, construction, welding. The products of this company are famous for their excellent quality. Fubag factories are located in Germany, Switzerland, France, Italy.

- Metabo is a German manufacturer with almost a century of history. Metabo produce electric tools, accumulators, compressors. All development, production is carried out in Nürtingen.

- Caliber is a Russian company founded in 2001. Since then, it has been actively developing. The caliber is produced by power tools, garden tools, pumping and battery units.

- Kraton is a manufacturer that began its activity in 1999 with the production of saw blades, cutting wheels for metal. Now it offers modern power tools, car products, household air compressors, drilling tools, hand tools.

- Denzel is a German brand known for its advanced approach to the production of equipment for construction, repair, cars, garden tools. The entire range has international certificates of conformity.

- Fiac is the Italian leader in the production of compressor equipment. Romano Lucchi founded the company in 1977. Now Fiac products are represented in dozens of countries around the world.

- Aurora is a diversified company producing welding equipment, generators, compressor units, car high pressure washes. The greatest demand for Aurora products is in European countries, in Russia.

- Remeza is a manufacturer of compressor equipment, nitrogen generators. The devices are intended for domestic, industrial use.

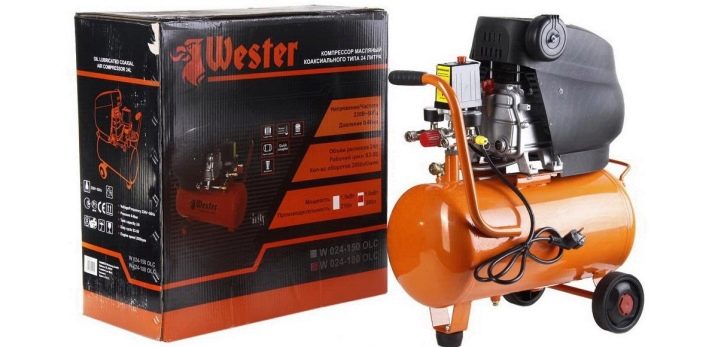

- Wester, a company that started producing burners in 1995, has significantly expanded its range. In 2009, as part of Wester, an automated full-cycle plant was put into operation, work on it is carried out around the clock.

- Fini is an Italian company founded in 1952. At the time, Fini were producing electric motors. Now the brand is engaged in the development, production of compressor units.

- Abac is a concern founded in Italy in 1948. Abac manufactures air compressors. Plants are located in Italy, other European countries, the United States of America, Southeast Asia.

- Comprag is a German company that has currently opened a plant in the Moscow region. Comprag manufactures compressor equipment of various designs.

Air Compressor Rating

Air compressors have a wide range of applications, as well as a wide variety of models that differ in design. Analyzing devices in all parameters is not an easy task, however, highlighting a number of main characteristics, a rating of units was compiled. So, the comparison took into account:

- Power;

- Performance;

- Maximum pressure;

- Compressor type;

- Manometer type;

- Receiver;

- Durability;

- Price.

In the course of the study, screw units, oil piston, oil-free piston units were considered. In each category, the leaders are highlighted in terms of a set of indicators.

Best Car Compressors

What kind of compressor do you need?

The device for working with a jackhammer must be selected depending on the nature of the construction activity, as well as on the number of jackhammers at the construction site. There is a classification of compressors for jackhammers... According to the division, devices are:

- diesel;

- air;

- gasoline;

- electrical;

- mobile;

- stationary.

Air compressors are used in the course of various types of work in various areas of construction activities. For example, such devices are often an integral unit in the chemical industry, in the metallurgical industry. In addition, firefighters use similar structures. If we talk about devices of an electric type, then they are necessarily used at a voltage of 380 V and in the presence of no more than two jackhammers. Electrical units are quite compact in size, easy to operate, do not require constant maintenance. Traditionally, the design of such a unit includes a reverse and wheels, but pneumatic automation, on the contrary, is absent.

However, in the event that there is no electricity at the construction site, and more than two jackhammers are used for work, then a diesel or gasoline compressor will be an excellent assistant. These devices also have their own subspecies - they are piston and screw. Professional builders assure consumers that the latter option is more efficient: it runs quieter and longer, uses less fuel, and is more reliable and easier to use. At the same time, the screw unit is superior to the piston unit in cost. Compressors, classified by mobility, are divided into stationary and mobile. The advantage of the latter is its smaller dimensions, while the former is of lower cost.