How to choose?

Choose according to the volume of your plot or forest in which you will pick berries. If you have plans to collect fruits only for eating or for jam, then you should not spend money and purchase a whole combine or vacuum collection. A simple hand tool will suffice.

It can also be customized for the types of berries you need. In fact, even with a manual unit, you can pick different types of berries. For example, if you have cranberries growing, then it is better to purchase an instrument in which the partitions are made of solid metal. Due to this feature, there will be no tangling of plants.

The vacuum collector will help you pick berries such as gooseberries, wild raspberries, strawberries, wild strawberries, currants, lingonberries, cranberries, sea buckthorn and many others. You can even pick hazelnuts.

Pay attention to the price too. A vacuum berry picker costs about 29 thousand

rubles and is intended for those who make harvesting their own business. Of course, it is worth remembering the price of a mechanical harvester, namely 1-9 million rubles. This is a high price for a medium-sized plot.

Classification of berry harvesters

Based on the level of mechanization, it is customary to divide all berry harvesters into:

- Manual without mechanization of processes. Their creation was inspired by ancient prototypes that have been used on our lands since time immemorial, resembling frequent rakes on a short handle with a bag or box tied to them. These are now very ergonomic handled containers equipped with a wire or sheet fence to grab stems or branches;

- Manual with mechanization of processes. On the modern market, they are represented by hand-held products that use a motor for frequent translational movements of the removing unit in order to peel the berries from a branch, or their vacuum suction; 3. Automatic under the control of the operator. Outwardly, they resemble ordinary forage or grain harvesters, with the difference that they do not have bevel blocks and digging elements. And the separation processes, taking into account the fragility of the product, have their own characteristics.

According to the available assembly volumes, industrial berry units and devices for home use and small farms are distinguished.

How to make a do-it-yourself harvester for collecting lingonberries and other berries?

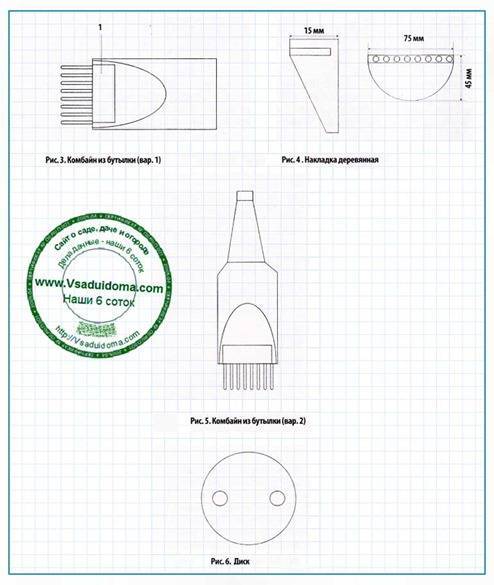

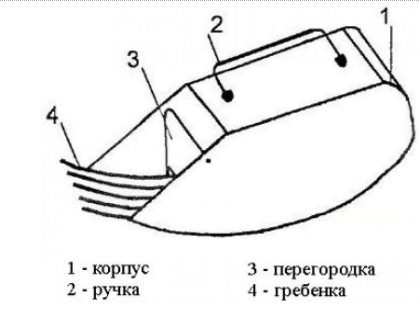

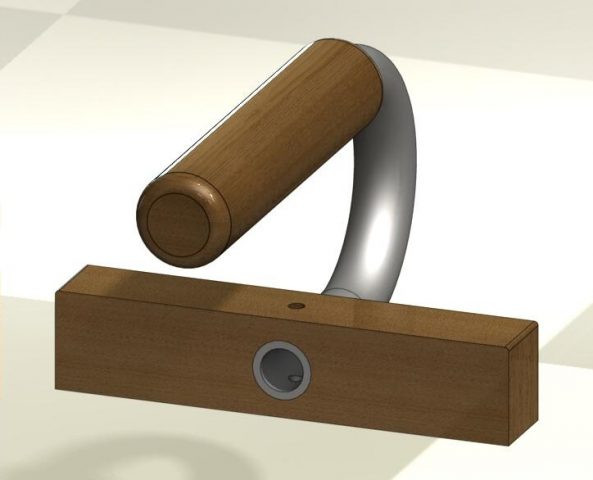

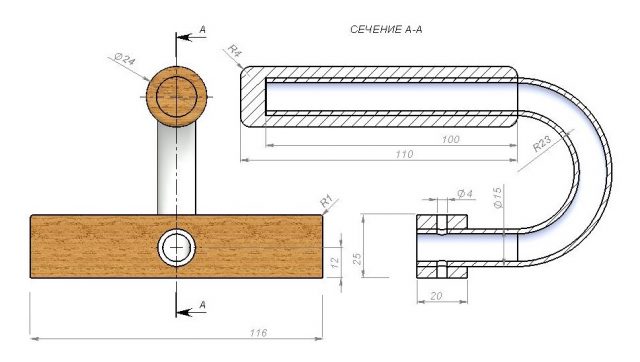

A manual harvester for collecting is easy to make yourself using the following drawings:

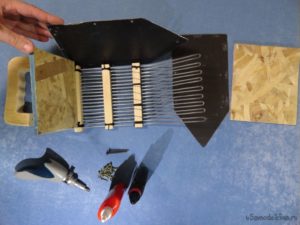

Of the materials you will need:

Of the materials you will need:

- metal wire;

- wooden slats;

- Sheet steel;

- pieces of plywood or plastic;

- fasteners.

The production process itself is as follows:

The production process itself is as follows:

- Patterns are made from paper of all parts, except for wire;

- With metal scissors, the bottom of the device and its body are cut out of a sheet of steel;

- On a separate narrow sheet of galvanized steel with a width equal to the dimensions of the berry collector, one edge is bent - the future cutter;

- In the second part of this piece, holes are drilled every 0.4-0.5 cm, the diameter of which is equal to the diameter of the wire;

- The wire is cut into segments of 10 cm in length (the size of the wire should not exceed 0.3 cm), and inserted into the prepared holes, after which it is fixed by welding, bending the plate with hammer forging, wooden lath or in any other convenient way;

- The ends of the resulting rake are bent with a side to protect the berries from rolling;

- The body is assembled using the selected fasteners, and the part with the rake is screwed to it. You can additionally sheathe it, for example, with wood or plastic for the safety of hands and plants;

- The handle can be made by bending a galvanized steel tube or double narrow plate. You can use any analogue that is idle on the farm (door, from a construction trowel, etc.). It is fastened by welding to the metal top of the structure or on bolts, for which holes must first be drilled.

To give the handle anti-slip properties, you can wrap it with duct tape.

Thus, it is not at all difficult to make a berry harvester yourself, and cheap and affordable materials, as well as tools, will be used for this.

The only remark: the size of the container depends on the planned collection volumes, but here it is important to look for a competent balance between them and the convenience of holding the entire structure by hand, as well as the characteristics of the growth of crops

Drawings and dimensions

For blueberries, gooseberries, cranberries and lingonberries, the simplest dipper with a depression is suitable. A comb with teeth 10-15 mm long, which are 4-5 mm apart from each other, is attached to it in front of it. The bucket is equipped with a handle at the back for more convenient operation. The berries are easily plucked from the bush and rolled into a container, and then they can be poured into a bucket or other container.

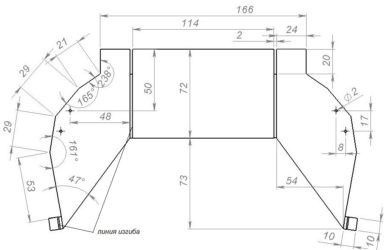

The parameters of such a berry collector will be as follows:

-

base in the form of a rectangle with sides of 72 and 114 cm;

-

sidewalls that are U-shaped according to the drawing below;

-

comb teeth 2 mm thick and 10 mm long;

-

the distance between the teeth is 5 mm.

Figure 1. Drawing of a metal berry collector

This is due to the fact that they have too large leaves that do not pass well between the teeth of the comb. It is recommended to collect strawberries on a large scale with commercial berry collectors-vacuum cleaners, which cause minimal damage to the delicate trunks and mustache of the plant.

How and when to pick blueberries without damaging the berry: personal observations

I live in a middle climatic zone, and I judge the beginning of the ripening of blueberries by watching the fruits of black currants in the country. As soon as they begin to turn from brown to black, you can immediately go to the forest.

This usually happens at the end of the first week of July. At this time, the blueberry is not yet fully ripe, there are many small and green berries. Collecting them with mechanized devices is not worth it: there is a lot of waste.

The leaves (like the fruits) on the shrub hold very firmly and, falling between the teeth, crush and deform the berries, and, breaking away from the branches, greatly complicate the collection. Garbage is soaked in juice, it is poorly separated.

During this period of time, I recommend abandoning any mechanisms and picking the berries only with your hands. I have a low speed: it turns out on average a little more than 1 liter per hour, but for home preparations and consumption it is quite enough, and I am not engaged in selling.

Accelerate collection at this time:

- a container for berries, made on the principle of a non-spill inkwell, the ribbon of which I hang around the neck;

cups on the fingers of each hand, saving the movement of the berry's hands to the container.

I consider the end of July and August to be the optimal time for harvesting with mechanized devices: blueberries are gaining strength, and the fruits, reaching their maximum size and the largest amount of vitamins, have a pleasant taste.

For this period, I make my mechanized devices. Now it is not a problem to buy a factory-made blueberry harvester. But making it with your own hands, taking into account their individual abilities, is prestigious for a home craftsman.

At the same time, it is necessary to take into account a number of technical features that take into account the physical properties of a ripe berry. I refer to them:

- fruit size;

- effort of separation from the stalk;

- the state of the juice and the crushing strength of the casing;

- the presence of debris.

How the size of the fruit affects the design of the puller

Ripe blueberry berries usually exceed 6 mm in diameter.

I take this indicator into account with the gap between the teeth of the combine, choosing it at least 5 mm. It allows you to:

- cut off some of the underdeveloped fruits, leaves, needles, other debris;

- pick only ripe varietal berries;

- do not damage the shrub.

Which tooth shape is safer to pull blueberries from the stem?

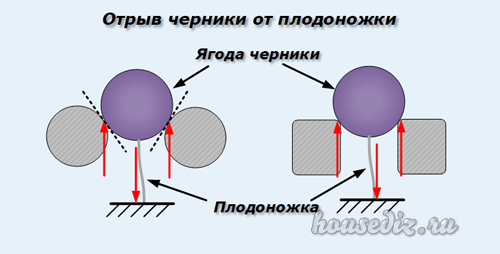

Among the harvesters produced in an industrial way, designs with teeth made of round wire prevail.

It is more convenient to make them in this way, but this does not work very well when the berry is detached from the stalk. Shown this process in the figure. I share my observations.

In a round tooth, the fetus is pulled into the depression shown by the dashed lines and is slightly crumpled. A flat surface immediately tears the berry off the stalk, deforming it less.

At the same time, it is important to avoid sharp edges at the ends, which can push through the thin shell. I do this by forming a very small chamfer on the edges.

The width of the prong also affects the performance of the fixture. A narrow profile fits better between twigs and leaves, creates less clusters of them. This reduces the formation of debris in the gaps, does not injure ripe fruits and the blueberry itself so much.

Advantages and disadvantages

The big plus is the simplification of the collection and the increase in the speed of work. Even self-made units will allow you to work several times faster, and in 7-8 hours a novice collector will be able to collect 12-15 kg. Very impressive numbers when compared to the bare-handed collection method.

Another plus is the low price. On average, berry pickers cost about 900 rubles. You can recoup this price on the first day or after several hours of work. You can make such a unit yourself, but for this you need to try.

The disadvantage of using the harvester is damage to berries and bushes. The thing is that when you pluck the leaves and young branches along with the berries, then you make the bush less fertile. Such a harsh method of plucking badly affects how the crop will be next year. In addition, you litter the leaves and debris that falls to the ground from the branches.

Hand picking berries

Unfortunately, the remoteness of the berry stands significantly complicates their collection. Swampy terrain, forest jungle, mosquitoes and midges do not add to the fun either. But the main difficulty lies in the size of these berries, it rarely reaches 10 mm, and even less in the northern regions. Historically, picking wild berries is done by hand, so the fruits are less damaged, and fewer leaves and twigs get into the baskets. However, this method has very low efficiency, even an experienced berry grower in a good year may need more than one hour to collect the coveted bucket. A less agile collector is unlikely to fill a bucket in a day.

Finnish manual harvester for picking blueberries and other berries

A very convenient hand-held device was invented in Finland, the design of which is certified in many European countries as environmentally friendly. It represents:

- a plastic container (similar to a closed, very large scoop);

- rubberized comfortable handle;

- metal berry cutter;

- protected knitting needles.

The latter can be bent with a pin, or have plastic balls-restrictors at the ends. In practice, these knitting needles pry on a branch with berries until they meet the cutter, then they are torn off from the base and shaken off into the container.

This design does not damage the bushes of berry plants, and the garbage accompanying the collection is easily removed by sieving through the size cells of a special sieve.

What is such a combine harvester?

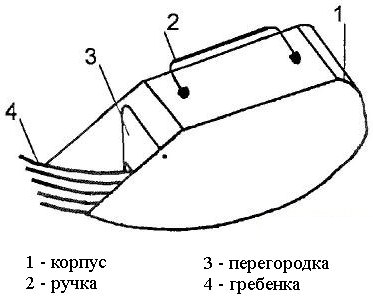

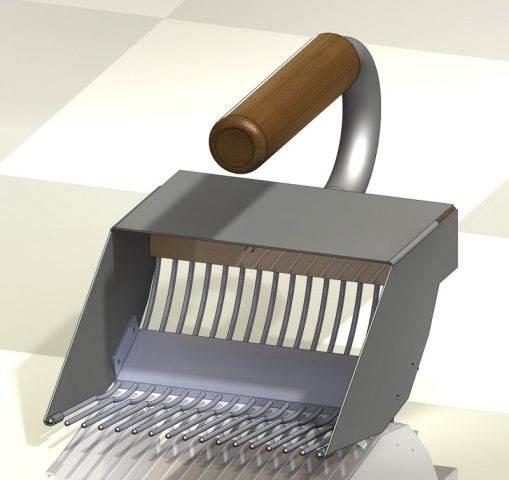

Structurally, the lingonberry harvester is a deep bucket, to which a special comb with long teeth is attached at the front from the bottom, and the handle for holding the entire device is at the top.

The disadvantage of this model is a thin metal handle, which is inconvenient to hold in your hands and which quickly rubs calluses.

The main working body of such a device is precisely the ridge.The length of its teeth is 10-20 cm, so that in one movement it was possible to grab and "comb" a whole lingonberry bush. The distance between the teeth is approximately 4-5 mm. It is in such gaps that the leaves and stems of the bush easily pass, but the berries no longer fit.

Practice shows that the lingonberry harvester is also suitable for harvesting cranberries, bearberries, as well as large blueberries and blueberries. Small blueberries pass between the teeth and gag easily. Other berries - strawberries, cloudberries, currants - cannot be removed with such combs, since the leaves of their bushes are very large and do not pass between the teeth.

The reception area of the device is deaf, and berries picked by a comb accumulate in it.

When working, the collector holds the scoop in his hand, brings the comb to the base of the bush and simply lifts it up. At the same time, stems, branches and leaves pass between the teeth, and the berries are plucked and rolled into the depth of the receiving chamber. At varying intervals, the picker pours the berries from the combine into a bucket or basket.

Thus, it turns out to remove the berries from one bush in a few seconds. With manual collection, the same operation takes at least a minute.

In a well-designed combine harvester, the comb does not have sharp cutting edges and therefore does not scratch the stems of the plant and does not break off the leaves. Even the edges of the teeth in them are rounded and do not scratch the stems. That is, in a good case, the tool is harmless to lingonberry bushes. In many cases, when such devices are made by hand, they contain areas that are dangerous for plants, due to which the bushes are damaged.

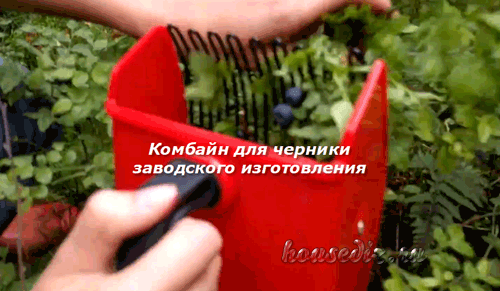

Such devices are manufactured by many manufacturers and, therefore, have different appearance and design features.

For example, in Karelia and the Leningrad region the Finnish MARJUKKA harvesters are very famous. They are made of durable plastic and therefore light enough, but durable. The photo shows a classic version of such a device:

And here is a model for children in the form of a chanterelle:

Its price is the same - 750 rubles.

Simpler devices can be made of steel:

and sometimes they don't even have teeth, but just a rounded grill in the front part:

It is these models that are considered the safest. Already such options:

... pluck a large number of leaves that do not pass between the teeth. It is these harvesters and their analogues that are considered poaching and it is with them that the Ministry of Natural Resources is fighting. And they are the ones that are cheaper (within 300-400 rubles), for which they are most popular among the population.

And on the plantations of cranberries or blueberries, real mobile harvesters are already used:

Actually, such manual deep buckets with handles are also called manual combines. Nevertheless, other devices for collecting berries work on a similar principle, often not at all like buckets.

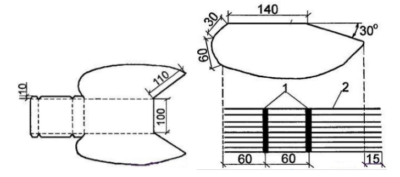

Standing cranberry picker

Such a device can be made by a master who is fluent in instruments. It is quite complex, but it can, without bending over, pick cranberries. All the details of the box are cut out of a piece of thick plywood, the comb strip is also cut.

The comb is made simply:

- a number of holes are drilled in the bar;

- cut the wire into pieces of the desired length;

- the teeth are fixed in the holes with glue.

Note! To prevent the cranberries from spilling out during collection, install a movable plate.

The back wall of the bucket is made integral, the lower part is movable. It is attached to the upper part on furniture hinges, and fixed to the side walls with pieces of rubber. This design allows you to stand up to pour the cranberries into the bucket.

To do this, one end of the rope is attached to the lid, the other is tied to a movable handle, which is bolted to a high handle made of 2 plastic tubes. Their length is determined empirically so that the collector is comfortable.

Wooden chopiks are hammered into the holes of the tubes, and plywood plates are screwed onto the outside with self-tapping screws.The tubes are attached to the box using furniture corners and bolts. The connection turns out to be mobile, which is very convenient when picking blueberries while standing. A narrow strip of plywood is screwed to the top of the tubes - a handle. It is wrapped with a soft cloth and tape.

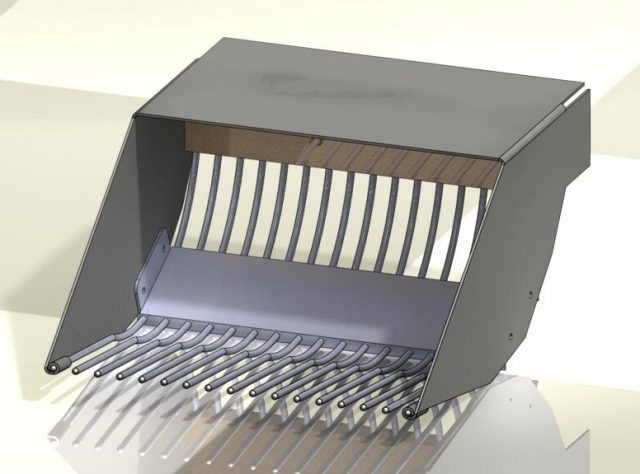

What is a blueberry harvester?

Before you make an apparatus for harvesting a blueberry crop, you need to figure out what it is. The berry collector is a device that greatly facilitates the harvesting of ripe berries. With the help of such a combine, the harvesting procedure does not last a few hours, but a matter of minutes.

> The main element of this tool is the elongated teeth, which are shaped like ridges. The distance between the teeth is 5-8 millimeters, and the length of each of them reaches 25 centimeters. This size allows the comb to safely pass the leaves and stems of the blueberry bushes.

The next important detail of the product is a bucket equipped with a small handle. When harvesting ripe berries, the comb is positioned so that the prongs point up. Then the structure is carefully pulled along each row. All berries will be automatically plucked by tines and placed in the bucket.

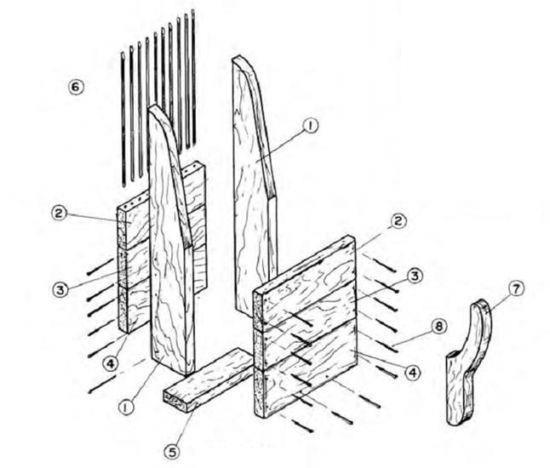

Details

The harvester will consist of two side pieces, a toothed bottom, a rear and a top. It is also worth installing a partition that will prevent the berries from falling out.

The bottom will be rectangular. On one edge, cuts are made with a circular saw. They should be about six centimeters long, with a five millimeter spacing between the prongs. If you have a sander, you can make an impromptu bend of the teeth.

The sides must have one slanting cut. The bottom will be longer than the top. Next, a cover and a rear wall are made according to the dimensions of the combine.

In order for the collected berries to remain inside the device, it is necessary to install a retainer on the front wall. It can be made from soft iron, plastic, or rubber. On the bolts, this part is planted in such a way as to be able to open. The back should also open so that the berries can be unloaded into the container.

Similar designs: rakes, shovels, shovels, combs and others

The principle of "combing" berries from herbaceous bushes is implemented in some devices, either simpler in design, or designed to further simplify the work of the picker.

For example, the simplest options are regular wooden scoops with long teeth on the leading edge:

Some of their options are simplified as much as possible:

And in some homemade models, a great balance is struck between simplicity, cheapness and functionality. For example, here's a harvester:

is made of wire, thread and bag, while being very compact and not inferior to industrial versions in terms of ease of use.

In these cases, the typical combine design is simplified for the fastest possible production. However, these options have their drawbacks. For example, a scoop has low sides and, if the slope is accidental, the berries fall out of it easily. And wooden buckets get dirty quickly.

In other cases, inventors are working to ensure that the harvester can pick berries without bending over or crawling through the forest on their knees. The simplest option in this case is a special rake:

They can, without bending over, comb the bushes, from time to time pouring the gathered berries into a bucket.

A more difficult option is to combine a rake and a combine. Simply put, a combine with a long handle, which allows you to change the angle of inclination of the bucket itself. The video shows an example of such a device:

And, by the way, pay attention: even such complex structures can be made by hand. And with proper manufacturing, the resulting harvester will be no worse than an industrial one.

Therefore, it is worth saying a few words about how to correctly implement the basic principle in such a product.

How to make a blueberry harvester

A device is assembled from plastic, wood, metal. A bucket in the form of a box or a cloth bag acts as a berry collector. The main working mechanism of the combine is the comb. The optimum length of the teeth is 6 cm. The width of the gaps is 5 mm. The comb can be adapted from a store comb or made by yourself. Usually, the material for the teeth is steel wire or wooden skewers.

In the video, more about the homemade harvester:

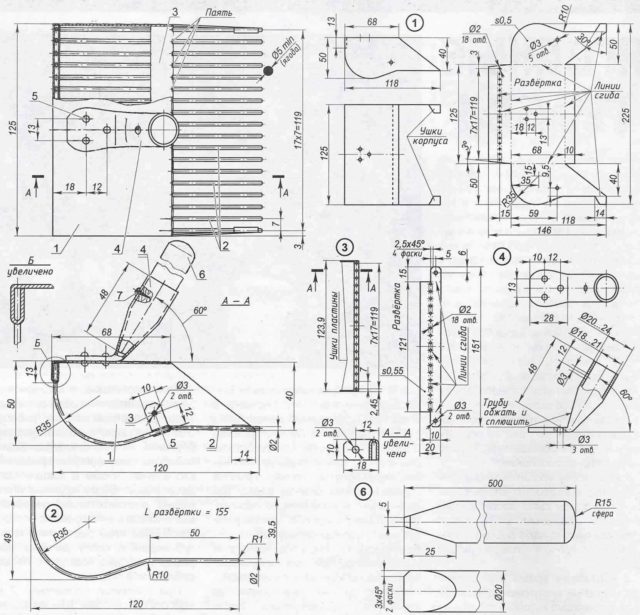

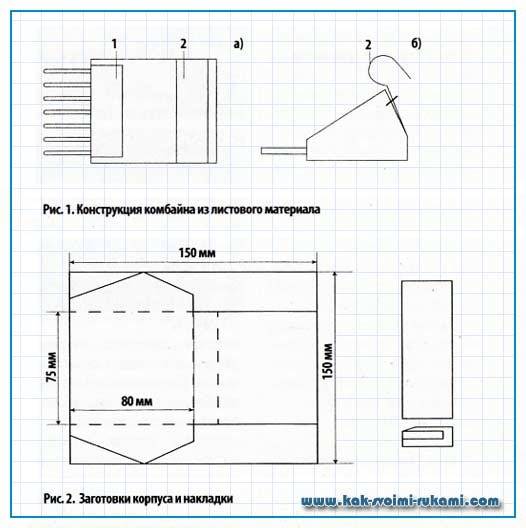

Blueberry picker from sheet metal

A durable harvester is made from thin sheet stainless steel. In extreme cases, galvanized is suitable. Consists of a scoop for picking blueberries from the bucket and the handle. To manufacture the first element, perform the following steps:

- A rectangular blank is cut from sheet steel. The stiffener is bent according to the drawing. On the long curved shelves, holes are drilled in 5 mm increments, where the wire teeth will be inserted.

- Adhering to the drawing, a body element is cut out of the metal. The side shelves are bent, forming a U-shaped workpiece.

- The comb teeth of the combine are made of stainless, bend-proof wire 2 mm thick. The elements must have the same curvature. It is more convenient to bend the teeth on a wooden template.

- The last element of the combine bucket is the lashing block. A 10 mm thick wooden lath is drilled every 5 mm. The teeth will be inserted into the mounting block.

When assembled, you should get a bucket, but so far without a handle.

For the handle of the combine, you will need a piece of aluminum or metal-plastic pipe. The workpiece is bent with the letter "U". A wooden round handle is put on one end. The other end of the pipe is inserted into a hole drilled in the center of the bar. Its size is equal to the parameters of the fastening bar for the teeth.

When all the units of the combine are prepared, they start assembling. First, the bucket is assembled. The body is connected to a stiffener and a fixing bar. Self-tapping screws, rivets are used for fixing. The wire teeth are placed in the holes with glue so that they do not fall out. The handle is attached with a bar to a fastening bar fixed to the bucket. Two wooden elements are pulled together with self-tapping screws.

A ready-made ladle for collecting blueberries is tried in practice. If the teeth severely injure the blueberry branches, check the gaps. It is possible that some of the elements are bent and tightly clamp the shoots.

Wooden blueberry picker

A simple do-it-yourself blueberry harvester is made from plywood. In fact, the device resembles an excavator bucket. 5 blanks are cut from plywood: side elements of the same shape and size, top cover, back plug and bottom comb. It is easy to cut four fragments with a jigsaw. The difficulty lies in the manufacture of the fifth part - a comb. On a rectangular piece of plywood, the teeth are accurately traced with the same gap. Each cut is carefully carried out so as not to break the comb element.

The workpieces are connected together with self-tapping screws. A U-shaped handle is attached to the top cover of the combine bucket. It is made from a thin tube or steel plate.

Blueberry harvester from a plastic bottle

A primitive harvester can quickly be built from a PET container. The bottle acts as a fruit picker for blueberries and a comb. If, while walking in the forest, you come across a fruitful bush, but you don't have a combine with you, you should look into your backpack. Ketchup, kefir or other product in a bottle taken for a picnic will have to be used quickly. If there is a choice, it is advisable to take a rigid container with a wide neck of small volume. Additionally, you will need a stick from the materials, which is not a shortage in the forest, a piece of rope or scotch tape. From tools you need a knife or scissors and a marker.

Laying the bottle on one side, draw a window in the form of a flag with a marker on the side wall. The working side, directed by the teeth to the bottom of the container, is shaped into the English letter "W". A fragment is cut out according to the marking with a knife or scissors. The edges of the comb are sharp enough to cut blueberries.The stiffer the bottle wall, the stronger the comb will be.

The cut fragment is discarded. It is not needed for a combine. The bottle is tied tightly to the stick with the bottom up. It is advisable to use scotch tape. The bottle will slide off the rope. Harvesting is carried out by pulling the device along the branches. A sharp blueberry picking comb cuts the berries with three prongs and rolls them down the neck of the bottle. When the fruit collector is full, unscrew the cap. Through a wide neck, the berries are poured into a wallet.

Features of picking blueberries and strawberries

Collecting blueberries and strawberries is a laborious and painstaking process. The berry is small, the bushes are low and grow densely. Harvesting by hand is incredibly difficult - you literally have to pick one berry out of solid greenery. In this case, it is necessary to stand leaning towards the ground.

Picking blueberries

Most often, blueberries are found in pine and small-leaved forests. Finding a berry plant is quite simple: a clear sign of the presence of shrubs is a wild plant - wild rosemary. It has a pronounced smell, which will become your reference point.

There are also cultivated varieties of blueberries that gardeners grow in their summer cottages. The bushes of such plants are higher, but less often, and the berry is larger, and therefore it is much more convenient to collect it than forest one.

Hand picking blueberries in the forest

Hand picking blueberries in the forest

Bushes can be up to 40 years old. The oldest ones occupy a large area and have a spreading shape. There are many berries on them, but they are smaller than on young plants.

The most delicious and healthy fruits grow on young growth, the age of which does not exceed 10 years. They have thin green twigs, and thick side branches are practically absent.

It is recommended to collect blueberries in small plastic buckets or baskets. It is not worth pouring the harvested crop from one container into another, since the berries, although strong, are easily damaged. It is not worth picking blueberries after rain, it is better to choose dry morning weather.

Collection of forest and garden strawberries

The collection of strawberries has its own characteristics. Both wild forest and garden berry - she loves well-lit, open areas. Ripe and ready-to-eat fruits are bright red in color and easily detach from the stalk.

Hand harvesting strawberries

Hand harvesting strawberries

The fruit cups can be removed immediately, or the berries can be sorted out later. The best time to pick strawberries is in the morning, when the dew dries up. The fruits must be collected in small containers of 2-3 kg. Pouring is not recommended, the berry is soft and easily damaged.