Basic ways

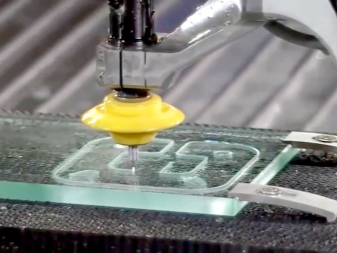

Glass cutting is the most important step in the processing process. As a result, the product acquires the specified dimensions and shapes, as well as the possibility of artistic finishing that improves its appearance. These actions, depending on the desired result, can be performed in various ways and methods on specialized machines.

Mechanical

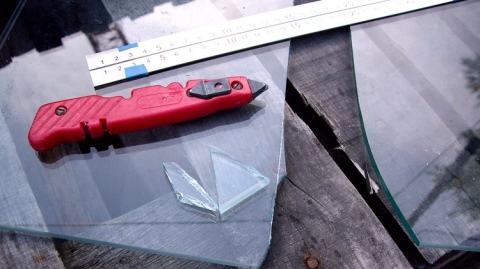

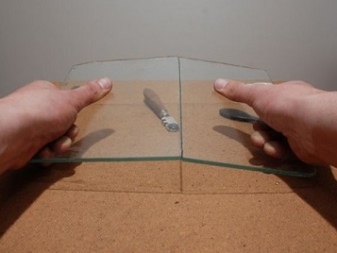

Manual cutting exists and is quite common, but it is usually only used for small repairs, otherwise it is impractical. The oldest and most widespread method of processing and cutting glass is the mechanical method. This is currently the most suitable processing method. This method involves the use of special wedge-shaped cutting rollers made mainly of tungsten.

Despite the outdated mechanical cutting technology, it still has significant advantages:

- the highest cutting speed - up to 120 m / min;

- low cost of equipment and ease of maintenance;

- the workpieces can be of various sizes and shapes.

The most common disadvantages of mechanical cutting are:

- chips and roughness of the cut due to mechanical defects in the material;

- the need for subsequent processing and finishing of the cut edge;

- when cutting it is necessary to use special fluids.

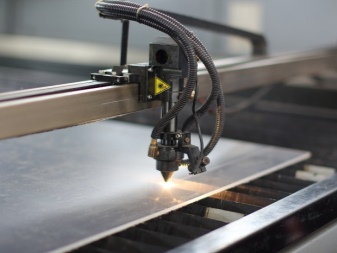

Laser

Laser cutting was initially tested on thin metal. More recently, the same method has been used to cut glass using special devices. There are two types of laser cutting. The first is an original technology called thermal evaporation laser cutting. This process is currently practically not used, since it is the slowest and consumes a large amount of energy. The method itself consists in evaporating the glass to the end. The main disadvantage of this option is the presence of residual stress in the material due to heating, which can lead to breakage of the product along the edges of the cut.

The second method, which is currently used, has been developed as a result of the improvement of thermal evaporation. It was found that it is not at all necessary to completely vaporize the glass with a laser; low thermal conductivity and thermal resistance allow the use of the thermal cleavage method. The principle of this method is discrete heating of glass along the entire cut line. This is followed by a sharp cooling, and in this area a tensile stress is formed, breaking the glass clearly along the drawn line.

Laser cutting has several advantages:

- high-quality cut with a flawless edge;

- curly cutting is simplified;

- it is possible to cut glass with a large thickness;

- no mechanical impact is exerted on the product;

- ease of regulation and control of the cutting process.

The glass laser cutting process is currently under development. Therefore, like all new technologies, this method has its drawbacks:

- Low-emission material (reflective infrared radiation) is not suitable for laser processing;

- expensive machines requiring careful use;

- low processing speed - from 5 to 10 m / min.

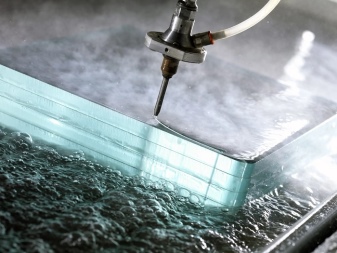

Waterjet

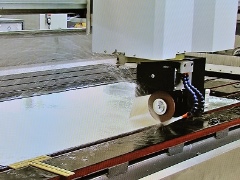

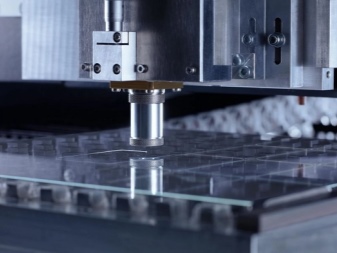

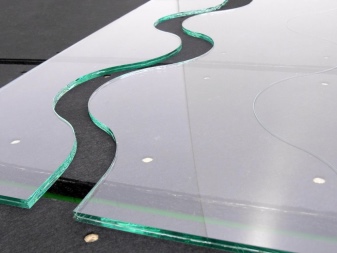

Waterjet cutting was made possible in the 1980s by the use of powerful hydraulic pumps that allowed the fine, sharpened granules of shredded materials to be mixed with water. The technology is designed for cutting a wider range of materials.Glass is very suitable for this method, which leaves a matte edge that is easy to polish.

The advantages of this cutting:

- excellent edge quality, which makes sanding unnecessary;

- no chemical and thermal effects on the material, slight mechanical stress, no cracks;

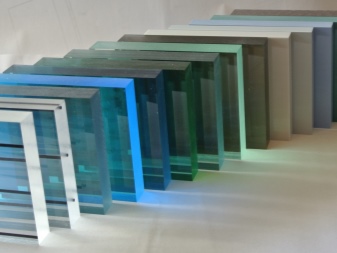

- the ability to cut very thick and laminated glass.

Despite the advantages, there are also disadvantages:

- very low cutting speed (0.5-1.5 m / min) depending on glass and equipment;

- high costs of equipment operation;

- the need to prepare a large amount of water.

Preparation and cutting process

In order to cut tempered glass, the first step is to lower its strength and change its structure. Annealing is used for these purposes. It removes the stresses that have been created by tempering this glass during its production.

Annealing is performed according to the following technology:

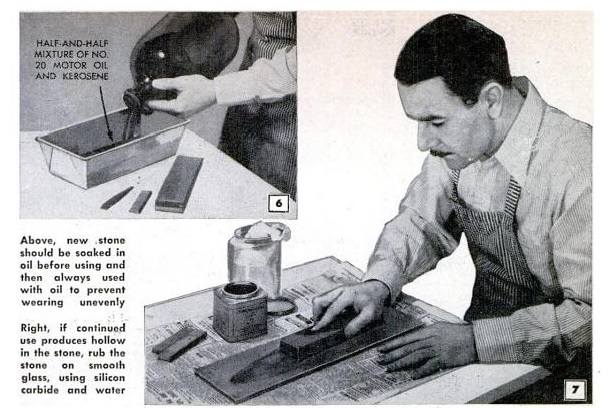

Before cutting the glass, it must be marked.

The first important step is to soak the glass. This should be done in water at a constant temperature. The temperature of the water is gradually increased until the viscosity of the glass is equal to the viscosity in the furnace. This will require careful time keeping. The viscosity inside the furnace is 1013 Poise. Different brands of glasses from different companies have different viscosity values, so there is no point in listing them. Also, the duration of the procedure directly depends on the size of the glass to be soaked. Large sheets (window) are soaked, on average, 12-16 hours.

The next step is to heat the glass in the oven. It is necessary to heat the glass to the temperature of its heating. Depending on the manufacturer and brand, it can be different - from 470 to 680 degrees Celsius. It cannot be higher than 680. The required number can be found on the marking or in the accompanying documents for the glass

It is important to remember that American manufacturers indicate temperatures in Fahrenheit, so these values should be converted to Celsius. The glass should not be kept in the oven for a long time, it is enough just to reach the required temperature.

When the glass has reached the required peak temperature, it is removed and cooled.

Cooling should take place to temperatures that are less than the deformation temperature (1014 Poise). In this case, it is necessary to ensure the slowest possible cooling. Next, the glass should be cooled to a temperature of 20-25 degrees Celsius. To do this, the glass is simply left in the room (or other room).

When the glass has become room temperature, it is necessary to mark the cutting lines on it using markers and rulers. Then cutting is done. It is made in the same way as ordinary glass - a "groove" is made with a glass cutter, along the cut line, and then the unnecessary pieces are beaten off with light blows. For a more accurate cut, wooden rods of small diameter are placed under the "groove". This is required if you want to make a very neat cut line.

When the glass is cut, it is worthwhile to attend to its tempering. At the first and second stages, the texture was “simplified” and tempered glass became the most common one. Therefore, it is necessary to re-temper it to give it its previous (initial) properties. For this, points 1 and 2 are completely repeated - the glass is prepared in terms of viscosity, then heated in an oven to the temperature specified by the manufacturer.

Cooling during quenching differs significantly from cooling when imparting normal properties to tempered glass. To do this, a ventilation unit (powerful) is pre-installed in an open area, and ideally, the temperature in the room is lowered to 10 degrees Celsius (which does not negate the need for a fan). The glass is laid out on a pre-prepared machine (it should allow air access from both sides of the sheet) and the fan is turned on for intensive blowing. Both sides of the sheet should be blown at the same time.After cooling the workpiece to room temperature, the glass becomes ready for installation.

After reading the glass cutting method described above, many people will choose to skip this procedure. And they will be 100% right. Since it is difficult, unreasonably expensive and dangerous for life and health. In addition, without experience, there is a high probability that the blanks will deteriorate and this "experiment" will be very expensive. It is much cheaper, easier and safer to contact a company that has a laser cutter or to order glasses of the required size from the manufacturer.

Safety engineering

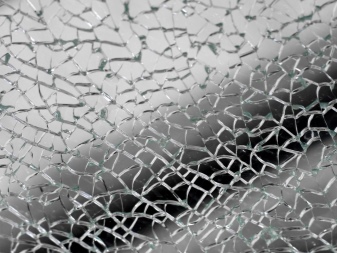

When glass is cracked, the fragments have several sharp edges.

Large fragments easily cut through the skin and muscle mass.

Small fragments are invisible to the eye due to their transparency, but they can get stuck in soft tissues and form suppuration. Here are the basic rules that must be followed when cutting glass with a glass cutter:

- You can work with glass only with protective goggles. During work, small particles can enter the cornea of the eye, cause pain and even lead to loss of vision. If you do get into a piece of glass in your eyes, do not try to remove it yourself.

- It is advisable to cut glass with gloves. Many masters neglect these requirements, but in vain. After all, the sharp edge of the glass easily cuts through soft materials. Better if she cuts through the glove than the skin. If you feel that the cloth gloves glide on the glass or reduce sensitivity, use rubber-coated products on your fingers.

After the workpiece is cut, carefully clean the work area. It is best to combine vacuum cleaning with wet cleaning. It is better to dispose of the rag or rags with which the floors and the table or workbench were washed.

Features of working with different types of glass

Before you cut the glass with a glass cutter, make sure that the glass in front of you is exactly the type you are working with. It does not matter whether it is old or new - there should be no traces of foreign substances and particles on its surface that interfere with cutting it accurately and evenly. Tempered glass cannot be cut at home. Tempered, it is no longer subject to processing: it is easy to break, since such a glass sheet has lost the properties inherent in ordinary window glass.

Its unsuitability for cutting is associated with a bending impact force that is 7 times higher than that of simple glass. Being resistant to breaking, it resists any mechanical stress, including cutting.

The slightest pinching will immediately lead to a crack, diverging in all directions. Cutting of tempered glass is carried out only on particularly precise machines that do not allow lateral and tangential overload, which easily transforms the hardened sheet into a small crumb, consisting of cubic blunt fragments. Tempered glass sheets and products are processed before annealing, which deprives the glass of the ability to cut into pieces without cracking in all directions.

Corrugated (corrugated, wavy, patterned) glass is cut from the smooth side. Trying to cut the leaf from the decorative, "curly" side, the master will not achieve the continuity of the furrow along which this leaf breaks. An intermittent groove, at best, will make the cracking line uneven, at worst, a section of the glass sheet will simply break. It is better to entrust its cutting to a roller glass cutter, which has a perfectly smooth blade rotating around its axis.

It is possible to scratch the furrow even with a regular steel nail. A red-hot, sharp knife also helps to quickly cut the blade without spending much effort.

Acrylic glass is easy to saw and cut, even standing on an edge and having a thickness of no more than 2 mm, in this case it is not necessary to heat the knife. Thicker transparent acrylic can be easily cut with a grinder or saw.A sharpener or file will allow you to quickly and efficiently align the edge along the required cutting line.

Large sheets, exceeding several square meters, are cut at the glassworks using devices that supply fluid under high pressure. Plexiglass is easy to cut with the help of a constantly heated thin wire pulled into a string - it quickly and evenly enters it, like a fishing line in butter at a temperature of 5-10 degrees Celsius.