Switching to working position

Correct installation and ensuring suitable working conditions are the main tasks that need to be solved in order to get excellent results at the stage of wall and floor marking.

Other nuances:

- It is recommended to work with the level at a certain distance from the desired surface; in addition, the permissible minimum approximation of the device should be taken into account, as this can significantly impair the quality of measurements

- Installation of the laser level is performed on the selected area only if there are no objects between the level and the surface of the walls, otherwise the beam will be refracted, and the level will not allow checking the degree of curvature of the surface

- Work should be carried out under the condition of complete immobility of the apparatus, it is placed on a horizontal surface, it is best to use special devices for this purpose (tripod, stand)

- The level in most versions has the function of self-leveling along the horizon, and additionally a bubble level is provided in the design.

Among other things, installation and further work should be carried out on the site, provided that people have been warned about this and there are no animals in the vicinity, since there is a possibility that the beam will hit the mucous membranes of the visual organs.

Scope and device device

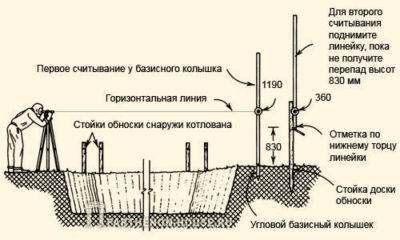

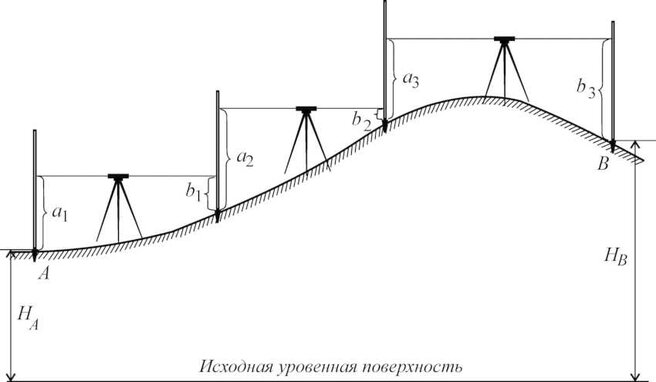

Using the latter, you can determine the elevations of points on the plane relative to some base level. During construction, the need for such operations arises constantly. After marking the axes of the future object, the site must be planned, that is, to make it even. Levelers will tell you where to remove the soil and where to fill it up. Determining the depth of the trench for the foundation - again, a level is needed. You cannot do without this tool when installing screeds or concrete floors, especially if they have a large area. Measurements made with a level will help make the base perfectly flat and avoid overspending of concrete or cement mortar.

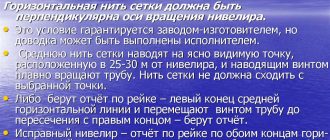

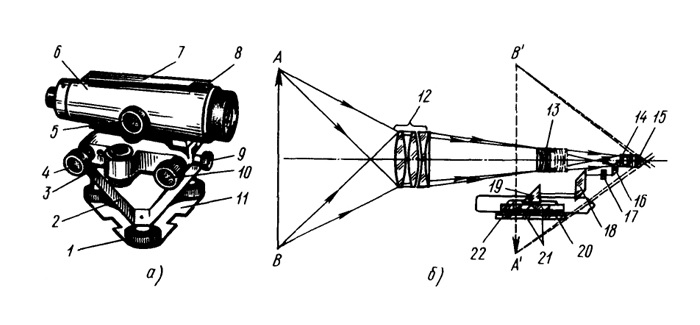

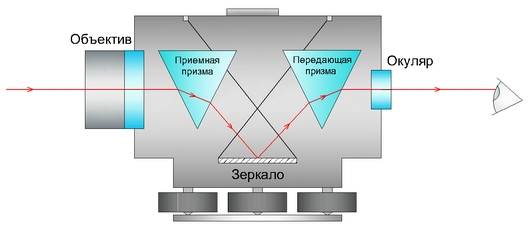

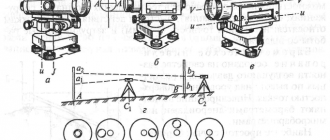

Diagram of optical level elements ..

An optical level is a telescope mounted on a support - tribrach. The latter is equipped with three lifting screws that allow you to change the inclination of the pipe in two mutually perpendicular planes, achieving a strictly horizontal position. In this case, the leveling device is guided by the readings of the bubble level, which is also built into the stand. You will need a tripod to set up the level. It is best to use aluminum, which is both strong and lightweight.

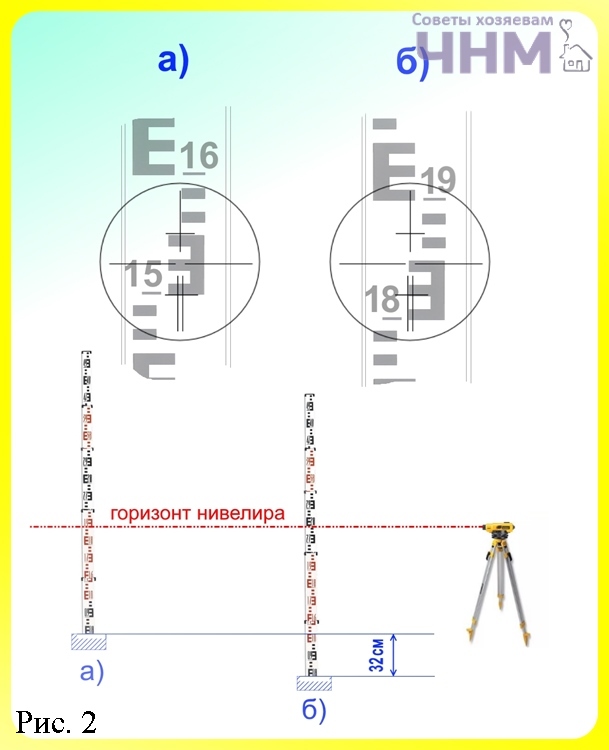

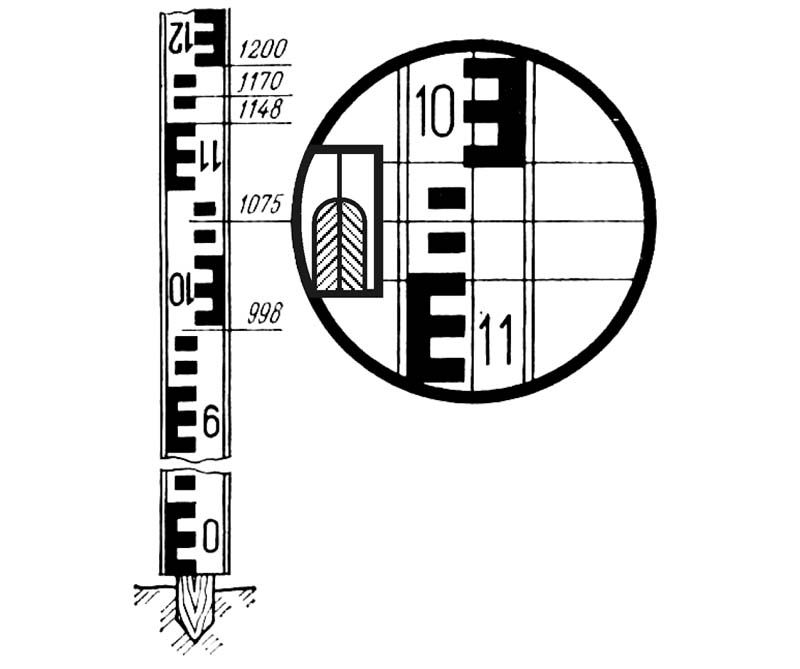

The permanent companion of the optical level is the measuring rod. Before carrying out work, you need to get an assistant who will hold it while you take measurements. The scale is applied to the rail from two sides: on one side - in centimeters, on the other - in millimeters.

Setting up the laser level

If the device has already been installed according to the instructions, then you should not start working immediately - you need to wait a little. Before starting work, check the level for accuracy. For the first stage of verification (accuracy of laser tilt of the plane), you need to place the device at a distance of 5 m from the wall.

If the distance between them is less than 6 mm, then the device is configured correctly.

The second step is to check the accuracy of the vertical angle. It is necessary to fix a plumb line with a cord 2.5 m long on the same surface.After that, you need to direct the level beam at it.If the deflection of the laser beam is less than 3 mm, then the device can be considered correctly set up.

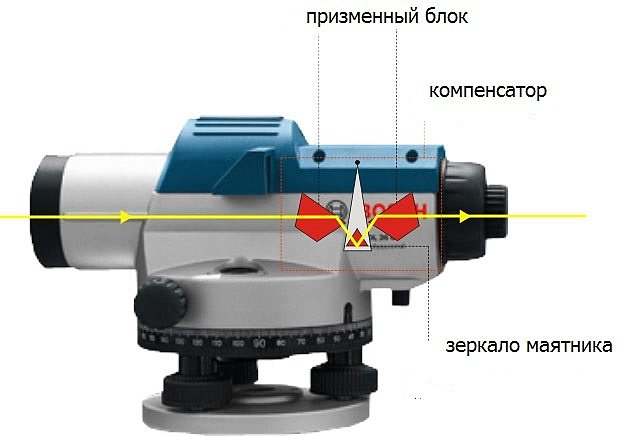

Each such device usually has its own list of functions. The main of the latter is the installation of two streams: horizontal and vertical. Sometimes they can be turned on at the same time.

Circular level check and adjustment

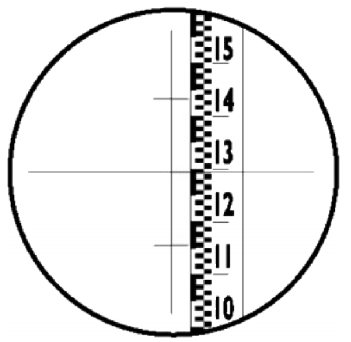

Leveling rod device: a - crutch, b - shoe, c - readings on the rod.

To set up an optical level yourself, you need to start by checking the circular level. It is the normal at the so-called zero-point to the grinding surface. The main condition for this is that its axis should be parallel to the axis of rotation of the device.

To check, you need to install the telescope parallel to any 2 lifting screws, with their help you should try to move the bubble of the circular level to the zero-point, and then turn the upper part of the level 180 degrees around the vertical axis.

If after this action the bubble remains in the center of the capsule, this check point can be considered completed. If this did not happen, then it is necessary to make an adjustment - perform a series of settings to obtain the desired relative position of the device parts and their normal interaction. To do this, using the screws for adjusting the circular level, it is necessary to displace the bubble by ½ deviation to the center of the capsule. Residual inaccuracies are eliminated using so-called lifting screws. These actions are carried out several times until the desired result is obtained.

Additional accessories to make it easier to work with the level

Laser receiver - increasing the range of the laser beam

A laser receiver can be of great help if you work outdoors. With it, you will see a clear projection of the beam even in blinding sunlight. Moreover, the distance that the laser "reaches" will double. Just buy both the laser level and the receiver from the same manufacturer, otherwise there are cases of incompatibility of devices of different brands.

If your level is not designed to work with a receiver, then in this case, you can find a way out. There is a very simple device - a baffle plate. By fixing it on the object, you can get some increase in the beam range.

Target - we hit right on target

The target is a simple accessory that is included in the kit for almost all laser levels. The plastic plate with concentric circles painted on it looks exactly like the paper targets for shooting at the shooting range. After all, both of these targets have the same goal - to hit the bull's-eye. Well, you can shoot not only with bullets, but with a laser beam.

Such a thing is very useful when the distance between the level and the object is large enough. For example, you need to make a hole in the wall a few centimeters higher than in the opposite one, while the distance between the walls is 40-50 meters. Try to see the marks of a pencil or marker at this distance! If you fix the target instead, then aiming at it with the beam will not be difficult. Even if the shooter is not very accurate.

Some levels have one more device in the kit that improves the accuracy of the laser "shot". This is a kind of optical sight located on the body of the device. It is called an optical sight, and with its help you can easily "reach" the target, even at a distance of 100 meters.

Reika - draw perfectly straight lines

The rail is useful when you need to draw several parallel lines on the surface of the object, the distance between which is the same. And with the help of the rail, the height of the level fixed on the tripod is changed. Then it can be returned to its original position.

Level adjustment

by echomeadmin

If the verification reveals any deviations in the settings or significant errors in the measurements of the level, it should be adjusted, i.e. exact reduction to the declared manufacturers technological and operational characteristics. A successful alignment procedure will result in a fully functional instrument that guarantees the required measurement accuracy.

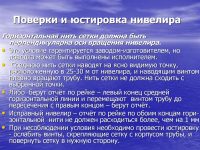

One of the main points of level verification is to determine the position of level bubbles and a grid of threads. Inconsistency of these settings requires mandatory adjustment.

Since the adjustment of the device can be violated at any time of operation, in order to avoid the appearance of systematic errors in the measurement results, in some cases it is necessary to check and adjust the levels quite often, maybe even daily. In general, leveling measuring instruments must undergo metrological certification annually, and in case of repair work, shocks, falls and other mechanical influences that entail misalignment of the level, according to the situation, outside of the next check.

Before the meter goes on sale, the manufacturer compulsorily performs verification and adjustment of the instrument. Depending on the type of level - laser or optical - the adjustment is carried out in different ways.

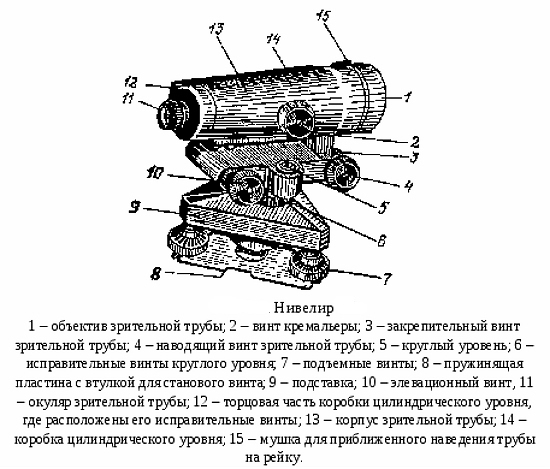

Level with compensator

Correct operation of the level with the compensator is characterized by the horizontal line of the telescope sighting beam of the ground level surface (angle i) within the compensator's coverage area.

If verification has revealed a deviation of the mesh, then adjusting the level with the compensator consists in loosening the screw fasteners of the mesh and bringing the plate with the mesh to the correct position: the horizontal thread of the mesh should be perpendicular to the axis of rotation of the level, and the vertical line should coincide with the plumb line. It is recommended to check the correctness of the compensator every time before starting work.

Laser level

The correct position of the vertical and horizontal planes is checked by verification and, if necessary, the laser level is adjusted. The position of the planes is adjusted by shifting the center of mass of the pendulum by screwing or unscrewing special screws responsible for the location of each plane and setting the correct parameters.

Self-alignment

You can perform the simplest procedure for checking and adjusting the laser level yourself using the 180 degree method. In a certain way, marking is carried out along the path of the beam at different positions of the level: normal and rotated by 180 °. If the edges of the beam and the markings made coincide, then there is nothing to worry about - the device is completely serviceable. Otherwise, its adjustment is required.

All that can be done in terms of independent settings is:

- by turning the screw, shift the center of gravity of the level;

- adjust the frontal and lateral roll of the planes with the platform screws;

- using a plumb line by adjusting the screw, achieve the ideal position of the pendulum.

The rest, more precise settings can only be performed by qualified specialists from specialized companies.

By whom and how is the adjustment carried out?

If careful reading of the instructions and attempts to independently adjust the device to the desired results have not led to the desired results, you should contact specialized metrological service centers that have certificates and licenses to perform such metrological procedures as verification and adjustment.

State licenses and certificates of admission to a certain type of work in geodetic activity confirm the quality of the work performed and the services provided, as well as compliance with the requirements and state standards of the material base used and the qualifications of specialists necessary for carrying out the work.

Adjustment result

The result of adjusting the characteristics of the device may not always be positive. If the device at any stage of the settings does not give the desired results or it is impossible to bring them to them for various reasons, the level is recognized as unusable and taken out of service with a corresponding mark in the technical passport.

How to level correctly on the ground?

Levels are a group of devices that can be used to check the flatness of a surface or determine the exact position of certain objects in height. Items can also be random marks or areas of the earth's foundation, it is not necessary to use specific landmarks.

Hydrostatic leveling scheme.

The quality of construction work will depend on the magnitude of such an excess and its correct measurement. From the estimated zero level of the lower floor of the building, it is possible to determine the depth of the foundation, groundwater flow, etc.

Leveling options on the ground:

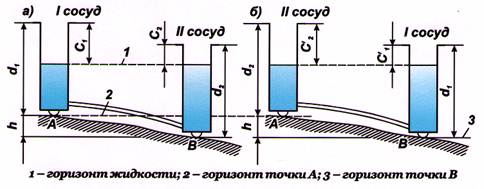

- Hydrostatic measurements. They are based on the property of the same placement of liquid in combined vessels. They have 100% accuracy and allow measurements outside the visibility range between the selected marks. This method of measurements involves laying and filling extended tubes with a special liquid, which is far from always convenient to perform. Therefore, this method is rarely used.

- Trigonometric method, which uses a rotary theodolite. The advantage of this method is that you can take measurements yourself. Such measurements can be taken at the corners, however, it is much more difficult to deal with this device than with an ordinary or laser level. It should also be taken into account that it is very expensive.

- Barometric measurements are used in the process of drawing up a plan and marking out large-scale architectural complexes. In this case, to take measurements, you will need to purchase barometers and install the program on your computer. Measurements in this way in private housing construction are practically not performed, since the elements necessary to perform the work are not cheap.

- The geometric method allows you to measure elevation angles using the simplest levels. Measurements should be made correctly in a single plane. In this case, specialists set marks, move them from one place to another, and make entries in the measurement log.

The simplicity of measurements using the simplest level, its compatibility with the needs of building houses made this device the most popular in the design of various types of work - from pouring the base to determining the accuracy of a gable roof.

To work with an ordinary level, you definitely need a partner who will hold the ruler. An exception is the use of the trigonometric method.

How to check the laser level for accuracy

To be able to rely unconditionally on the readings of the laser level, it must be checked. The technical characteristics of the model indicate the maximum permissible error for this device. It is indicated in mm / m (millimeters per meter)

Naturally, the smaller it is, the better, and this is one of the key parameters that you should pay attention to. But even comparing different devices of the same model, you can see a significant difference in the readings.

For a normal repair result, the deviation should be minimal, and you can determine it by checking. In theory, this check should be done before buying, but few stores will give you this opportunity. Then you can check the laser level at home, and if it has not passed the test, return or change (do not lose the receipt). The verification procedure itself is in the video. There are a lot of manipulations, but they are not difficult.

Where else will you need a level

What else is a laser level needed for:

- Pasting walls with wallpaper.To do this, set the level under the ceiling at the required distance and focus on the line. In this case, you do not need to do the so-called skips.

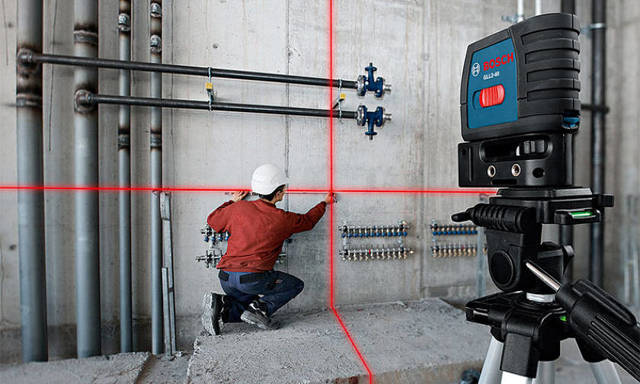

- Installation of tiles will help to carry out a device that can cut the beam into 2 or 4 perpendicular beams. On the wall from such a projection of intersecting lines is visible, the thickness of which is the seam between the tiles, and the edges coincide with the edges of the fastening elements.

- Painting and finishing of flights of stairs and other inclined structures. In this case, the horizon is leveled at the desired angle (the apparatus itself is tilted and fixed on a tripod).

- Installation of household appliances, especially those requiring suspension and leveling.

- Assembly and installation of furniture.

Buy or Rent?

As you can see, a laser level or level is a versatile tool that can be used not only for construction, but also for numerous repairs, furniture and equipment installation. Note that non-professional devices are quite inexpensive - you can buy a laser level at an affordable price - from 3 thousand rubles. A professional level will cost a round sum, but its functionality is not intended for domestic use.

It is advisable to rent only professional levels, but only accompanied by a qualified surveyor - it is quite difficult to understand how to work with such a complex device without special knowledge.

Foundation

Features of rotary models

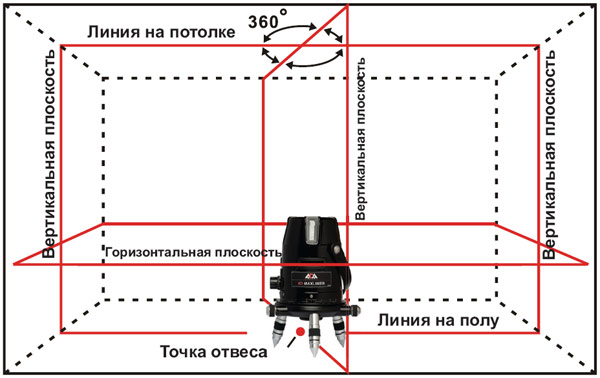

These are the most technologically advanced devices designed for marking on a construction site. A key feature of such models is the presence of a rotating detector, which contains two lasers. They can move at a speed of about 600 rpm, projecting a beam in a range of 360 °. How to work with a rotating level? The technique of handling such devices generally corresponds to typical laser devices, and the difference lies only in the organization of the final marking. That is, if the beam in conventional models gives information about one characteristic, after which it needs to be moved, then the rotary technique from one position allows complex calculations. This approach is especially effective when installing windows, performing surface finishes and other operations where you need to obtain information about the position of different objects within the same room or construction site. However, in open areas, there may be limitations related to the distance to the target object.

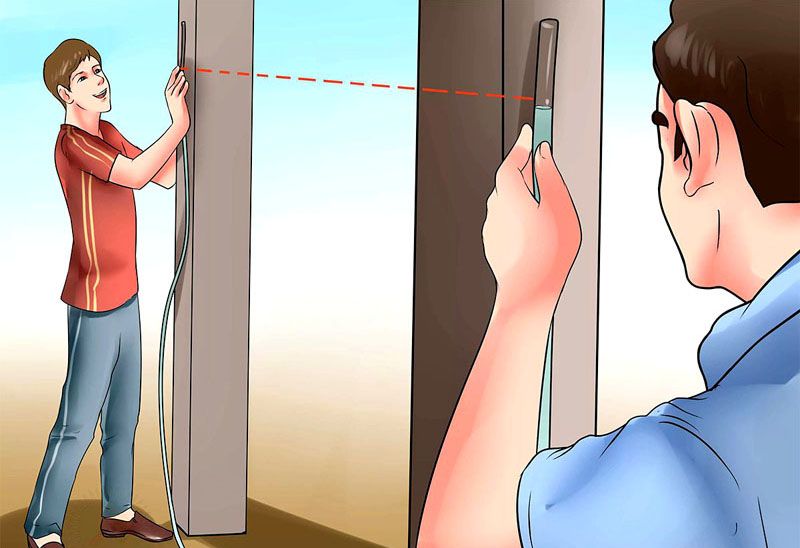

How to bring the laser level into working position

This is important - the quality of the marking directly depends on how correctly the laser level is located. Therefore, you need to find a place suitable for it and install it properly.

There are a number of requirements necessary for the full operation of the device:

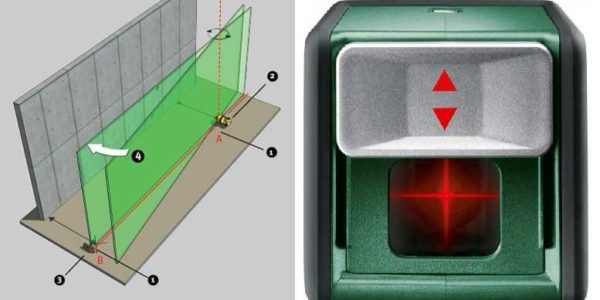

Step 1. There should be no obstacles in the path of the laser beams. Otherwise, the refraction effect will interrupt the projected line.

Step 2. Position the laser level at the optimum distance to the object. The maximum allowed is indicated in the instructions and should not be exceeded. Decreasing the distance reduces the likelihood of error, so if possible, try to put the device closer. The maximum allowed can be increased by using a special beam receiver. This option is used when the object is at a great distance.

Step 3. During operation, the level should be on a flat surface (the table surface is suitable), on a tripod or a special holder. It should be securely fixed, since the complete immobility of the device is a guarantee of obtaining accurate data. No shaking or movement is allowed.

Step 4. Before starting measurements, align the level to the horizon. For this we use the bubble level built into the device. Some models have a self-leveling function.It works like this: until the device stands level, a signal is given. If there is no signal, then everything is fine and the device is installed level.

Step 5. First, you need to warn the people nearby about the upcoming work. Animals should also be taken away or carried away. After all, accidental hit of the laser in the eyes can injure them.

Step 6. Here, in fact, are all the recommendations. When they are met, you can turn on the level and perform the necessary work.

Possible mistakes

The most common mistake when using a level is incorrect installation. Neglect of even small deviations from the level can lead to significant errors in the further production of work. The greater the measurement distance, the greater the deviation from the exact value.

Another mistake is the wrong choice of numbers on the staff scale. Only whole numbers are selected, no fractions. This error complicates the subsequent comparison of the selected number with subsequent readings. Fractional values are more difficult to compare with each other.

The lack of constant additional adjustment can lead to a gradual increase in the error, which will be invisible at the initial stages. In the future, this will negatively affect the quality of the work carried out, which, as a result, may threaten the safety during the operation of the facility.

See the video below for tips on how to properly operate the level.

Leveling and leveling - what is it

A level is a technical device with the help of which surveyors and builders take measurements of elevation points on a plane. Its main task is to build a stable horizontal line, relative to which any deviations will become noticeable.

Before the invention of the level, level measurements were carried out in such a simple way. It is not known for certain what exactly served as containers. One can only guess

Before the invention of the level, level measurements were carried out in such a simple way. It is not known for certain what exactly served as containers. One can only guess

If you look through the eyepiece of a modern device, you can see that, in addition to bringing the object closer, the level superimposes a system of thin lines on its image, called a reticle or reticle. This grid creates a pattern on top of the object from vertical and horizontal stripes, which the person is guided by.

It is at such a picture that the surveyor looks so enthusiastically and with concentration during the measuring work.

It is at such a picture that the surveyor looks so enthusiastically and with concentration during the measuring work.

Leveling is the process of surveying using a level. In other words, this is a determination of the difference in heights of two or many points on the earth's surface relative to a conditional level (for example, ocean level, river, etc.) or elevation.

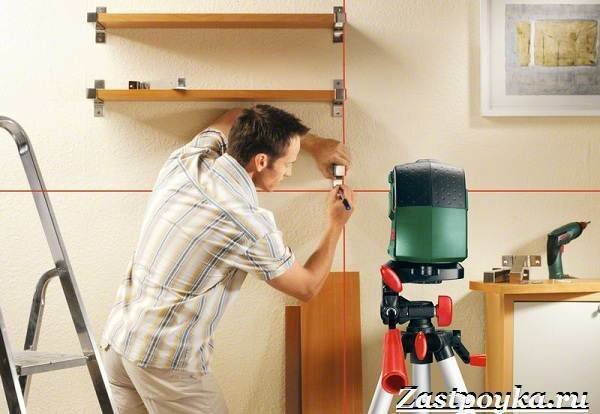

An example of using a laser level to mark the place where handrails are attached to a staircase

An example of using a laser level to mark the place where handrails are attached to a staircase

Laser level models can draw such lines directly on the object. In laser devices, lines are drawn 360 ° in several planes at once.