Checking household power tools

Household electrical tools are checked using a more simplified technology. In this case, the responsibility for the timely implementation of this check and for the consequences of using a failed tool lies with its owner. In this case, there are no regulatory documents, the owner of the power tool must be guided by considerations of his own safety. Before each turning it on, it is advisable to check, at least according to a simplified scheme, including checking the reliability of fastening all the nozzles used for it. To reduce the likelihood of damage, the power tool must be thoroughly cleaned of dust and dirt after use, and stored in an appropriate place. It is recommended to check the power tools at least once a month by testing them in idle mode.

The frequency of checking the power tool must be documented. So in the event of a breakdown, the service center will quickly find and eliminate its cause.

But why is it so important to work with reliable tools?

Power tools should always be bought new; when buying tools "hand-held", you must carefully inspect them.

It is difficult to imagine a modern person without a power tool. Look around: almost every self-respecting man has in stock a certain number of electrical appliances and devices needed to carry out repair work. This whole set is difficult to replace with mechanical counterparts. But each instrument requires special attention.

In any production related to the use of a power tool, rules are introduced that govern the operation and maintenance of the entire tool.

The frequency of checking the power tool is determined according to the intensity of its use.

And here it is important to clearly understand the difference between the concepts of "verification" and "verification"

Frequency of testing of hand-held power tools

The frequency of testing a power tool depends on its type and purpose. The test is carried out in accordance with the instructions, which stipulate the terms and conditions of the tests. Today, there are several dozen tools that are used to work on electrical installations.

The health, and sometimes the life of people, depends on how reliable their protection will be. Therefore, the check of the power tool must be carried out on time in full accordance with the regulations. You can perform such a check and obtain information on the condition of the instrument in the laboratory of EnergoServiceGarant LLC

».

The laboratory of high-voltage electrical measurements checks power tools, which include:

- Screwdrivers.

- Side cutters.

- Pliers.

- Pliers.

- Voltage indicators.

- Other installation power tools.

How we are working?

The current "Instruction

on the use and testing of personal protective equipment used in electrical installations "(СО

153-34.03.603-2003) approved by the order of the Ministry of Energy of the Russian Federation. This is a description of various techniques, norms and procedures for completing individual electrical installations and production teams. The employees of our laboratory use exactly this instruction. The laboratory tests the power tool that is used when working on and above.

If the inspection and testing of the power tool is carried out in a production environment, the results are recorded in a special journal. If the check is carried out in our laboratory, you receive a protocol signed by the responsible persons and a complete guarantee of the safety of the instrument. Periodic inspection and testing of the power tool is carried out every 3 months (for

tool that is used when working with).

The rest of the instrument is checked every 6-12 months. Using the services of EnergoServiceGarant LLC

», You will be able to conduct high-quality tests of personal protective equipment and tools, save time and money by redirecting them to more important areas. Our company will carry out tests of any complexity in the shortest possible time and provide all the necessary documents for the further operation of the power tool.

Registration and accounting of verification

Power tools used in enterprises for professional purposes must be numbered and entered in the register. The management of the enterprise and the structural unit needs to organize a clear record of the storage, operation and inspection of manual electrical equipment. All the necessary information is recorded in a special prepared journal, and a corresponding protocol is issued based on the results of verification and verification. And also a mandatory measure ensuring the safety of this equipment is a qualified briefing of personnel with a knowledge test, in which the verification methods, as well as the rules for using it, are voiced under the signature. An important criterion for inspection and safe operation is the use of ancillary equipment such as carriers and extension cords. They also need to be checked once a year and to ensure this is the direct responsibility of the person responsible for the electrical system.

As practice and statistics show, whoever conducts at least a regular high-quality examination is less likely to come under deadly voltage. Especially you need to be careful when working in wet rooms (basements, bathrooms, etc.) and in the absence of a modern RCD (residual current device) in the power system, which quickly responds to breakdowns in the circuit.

Finally, we recommend watching a useful video that shows how to check the quality of an electric tool before buying it:

This technology is used to check and test the power tool. Now you know who conducts the verification work and at what frequency!

It will be helpful to read:

- Safety rules for working with electric tools

- How to use a megohmmeter

- Top Power Tool Manufacturers

- Checking the functionality of the circuit breaker

Posted:

10.10.2017

Updated: 11.10.2017

Types of PPE for electricians and their application

To ensure the safety of work with electric current, every electrician or technical engineer in the enterprise must receive personal protective equipment and receive instructions for their use.

An obligatory piece of equipment in many factories is a dielectric helmet. It will protect the head from mechanical damage or electric shock. The helmet is equipped with special insulation to protect against high voltage.

Helmet

In the side parts, special ventilation holes are installed, which, if necessary, can be closed with shields. The helmet is fixed on the head with adjusting straps and a forehead strap.

Protective glasses

Glasses are an essential element of an electrician's PPE. They are made entirely of plastic, since metal parts are unacceptable according to the norms. Clips are installed on the shower enclosures to prevent the glasses from falling. This is especially true if the electrician is working at high altitudes.

Note! Lenses are made of high-strength transparent plexiglass.The glasses fit snugly to the head, and therefore the eyes will be completely protected from various small objects

Work suit

PPE for an electrician is made of dense material. Before being released into production, experts conduct tests to ensure that the work suit can protect a person from an electric arc.

Electrician suit

Electricians should be equipped with winter and summer work clothing. Jackets must have several pockets where you can put small tools: screwdrivers, pliers, etc.

Respirator

Serves to protect the respiratory system from dust or gases. Respirators set a different degree of filtration, depending on the specific model.

According to the norms, respirators must completely adhere to the face, and therefore you need to look for a model that is most suitable for a specific head size.

Mask

Another must-have piece of equipment that every electrician in an industrial enterprise should be provided with.

A gas mask will be needed if an emergency situation occurs in production with the release of a substance harmful to the body. Thanks to special filtering elements, the human respiratory system will be protected.

Important! The gas mask must be checked regularly and do not forget to change the filters after the expiration date

Mittens and dielectric gloves

Gloves should be used if rough or heavy hand work is to be done to protect the skin from cuts. If work is to be done in the winter, then the electricians should be given gloves, insulation from the inside with fur.

Dielectric Gloves

Dielectric gloves protect a person from electric shock. Products are made of rubber, they can have various shapes:

- two-toed;

- five-fingered.

According to the manufacturing method, they are divided into seamless and sutured. Dielectric gloves are equipped with markings (the decoding can be found in the instructions), where there is information about what voltage they can work with.

Dielectric galoshes

In addition to footwear, the employee must be provided with shoes once a year. It should not contain metal fittings. The boots are made of genuine leather as it is non-flammable.

For your information! Galoshes are put on to protect themselves from step stress.

How to check and verify?

When checking electrical tools, a thorough external examination of the tested equipment is carried out for mechanical damage, violation of the integrity of the case, inspection of the insulation of the supply cable, analysis of the integrity of conductive conductors. In addition, the mechanical integrity of the plug and the quality of the contacts are checked.

Verification is a more thorough procedure that must be carried out at regular intervals. It includes a set of the following operations:

- Measurement of the insulation of the conductors of the cable supplying the instrument. Produced with a megohmmeter;

- Determination of the integrity of the veins using;

- Analysis of tool operation in idle mode for 5-10 minutes. In this case, it is carried out a second time (the instrument is considered verified if this value is not less than 0.5 MΩ.

According to the regulations, household power tools must be checked at least once every six months. If an industrial tool is constantly exposed to unfavorable factors (high temperatures, increased dustiness, chemical attack), the maximum period between inspections should not exceed 10-12 days.

The routine inspection procedure for professional power tools is different from that for household appliances.

Rules for testing protective equipment in electrical installations

There is a verification methodology approved by state and industry documents. Order of conduct:

- Mechanical tests must be performed before electrical tests.

- All test work is carried out by employees who have undergone preliminary training and certification. Failure to comply with this requirement is considered a gross violation and entails administrative liability.

- Protective equipment should be carefully inspected prior to inspection to identify the manufacturer's mark. The completeness must be complete. Insulating surfaces are checked for any mechanical damage.

- Electrical tests must be performed with alternating current. The temperature regime must be observed (from plus 25 to minus 15 ° C).

- Insulation currents and voltage indicators up to 1000 V are standardized.

- After an electrical check and measurement of parameters, protective equipment made of solid materials is checked by touching to detect the presence or absence of local heating.

- In case of breakdown or detection of discharges on the surface, exceeding the norms of current values through the tested medium, heating, the product is rejected.

Important! Do not use the product with any damage or defects found during testing. Product used for electrical safety must be stamped

The stamp marking must include the name of the product, manufacturer, date of manufacture, period of periodic testing.

The product used for electrical safety must be stamped. The stamp marking should include the name of the product, manufacturer, date of manufacture, period of periodic testing.

In the absence of a stamp or after the expiration of the validity period, the protective agent cannot be applied. The use of such products will be considered a violation of safety regulations with a risk to health.

Dielectric Gloves Life

Subject to the storage rules, dielectric gloves usually last 1 year or more (if there is a periodic check of the product - once every six months). The warranty period must be indicated on the packaging.

If safety precautions are not followed, a person wearing gloves can get an electric shock, which can cause muscle spasm, difficulty breathing, or even death.

Some people's skin is not conducts current, so they do not feel discomfort at first when they are electrocuted. However, there are signs by which it can be understood that an electric shock has occurred and medical attention is needed. It:

- A sharp fall of an employee if he was standing next to electrical appliances or electrical equipment;

- Deterioration of vision (the eye does not respond to light), understanding of speech;

- Stop breathing;

- The onset of seizures, loss of consciousness.

Electric shock can cause skin burns. However, if it is not there, this does not mean that everything is fine: the current may not affect the outer skin, but cause problems with breathing or heart.

It is important to immediately remove the person from the focus of the electric shock, since he himself will not be able to remove his hand from the wire. You cannot use your hands for this, you need to act with an object that does not conduct electricity

Then it is necessary to check whether the person has a pulse, breathing. If not, you need to immediately call an ambulance and start resuscitation (artificial respiration). It is also important to find the place where the current entered, cool it with water for 10-15 minutes, wrap the damaged areas of the skin with clean bandages.

Instrument Inspection Technique

It is allowed to use tested household and industrial power tools. For this, a clear algorithm has been developed that must be followed by everyone who wants to work with it. At the same time, you need to clearly understand the difference between verification and verification.

Verification is tests that are carried out in special laboratories located at every large enterprise. The tests include:

- Determination of the presence and health of the grounding circuit by using a special ohmmeter - one end of the device is connected to the terminal on the plug, and the other to the ground located on the instrument itself. Measurements should show no more than 0.5 Ohm, which satisfies the safety conditions for using the instrument.

- Measurement for the integrity and quality of insulation is checked with a megohmmeter at a voltage of no more than 500 V for a power tool designed for an operating voltage of 220 V. You can not turn it quickly, this will be enough to see the insulation resistance of the tool. In this case, be sure to remember to press the button that turns on the electric tool. The device should show an insulation resistance of more than 500 kOhm, if this value is less, work with it is prohibited.

- Then a trial test is carried out during idling for 5–7 minutes.

An overvoltage test can also be carried out on the power tool. In this case, a tool with a voltage of up to 50 Volts is checked with a test voltage of 550 V. If the tool is designed for a voltage higher than 50 V, but with a power of up to 1 kW, the test voltage should be 900 V, above 1 kW - 1350 V. The tests are carried out for 1 minutes.

Verification - carried out by visual control and inspection. You need to check not only the case, but also the cord connecting it to the power source

Pay attention to:

The integrity of the case, it can be cracks and breaks.

The power cable, there should be no visible drying out, damage, chafing, as well as traces of burning and heating

Particular attention should be paid to and check the points of entry of the electric cord into the case and to the plug.

The plug and its contact part, which will be connected to the network, are inspected and checked for integrity .. The check must be performed before starting work, and before switching on after moving to another workplace.

Naturally, professional laboratory verification is carried out only at large enterprises and firms; in domestic conditions, an employee, at least before work, should carefully examine the power tool taken in his hands.

The check should be carried out before starting work, and before switching on after moving to another workplace. Naturally, professional laboratory verification is carried out only at large enterprises and firms; in domestic conditions, an employee, at least before work, should carefully examine the power tool he has taken in his hands.

If we talk about the timing of the verification of the power tool, then according to the existing regulatory rules, the periodic verification of the tool should be at least every year, and it is necessary to check the power tool, as mentioned earlier, before each use. If manual electrical equipment is used in extreme climatic and industrial conditions, it is recommended to check it with a megohmmeter at least once every 10 days.

An important point! When checking the tool in the enterprise, first of all, you need to look at the date of the test. If the date is overdue or there is no tag on the test of the power tool at all, then it is prohibited to operate it - it must be removed and handed over for testing.

Consequences for non-compliance with the rules for checking PPE

The use of PPE that has not passed the periodic tests within the established timeframe in accordance with GOST 12.4.307-2016 is unacceptable.

First of all, this is a direct threat to human health and life. And if an employee receives an occupational injury when using PPE that did not pass the test, the employer becomes administratively liable under Article 5.27.1 of the Administrative Code of the Russian Federation. his death, due to the use of PPE that does not comply with GOST 12.4.307-2016, the employer is subject to criminal liability, in accordance with Article 143 of the Criminal Code of the Russian Federation.

One of the divisions of the company "METTATRON Group" is its own electrical laboratory. Where tests are carried out on stationary stands, in strict accordance with the instructions of the Ministry of Energy of the Russian Federation.Each test of protective equipment is drawn up in a separate protocol of the approved form and certified by the signatures of the responsible persons, as well as the seal of the electrical measuring laboratory.

Types of electrician gloves

Work with the equipment only with insulated tools after checking according to the rules (the laboratory checks the dimensions, the marking is applied, they are tested in the same place). Unplug all wires from sockets.

When performing repairs, do not touch metal surfaces with the body, if possible, stand on a dielectric mat. Do not perform electrical work while intoxicated, since at this time the resistance of the skin to a minimum decreases and there is a high risk of electric shock. The most important attribute of an electrician is special equipment that allows you to reduce the risk of electric shock to an absolute minimum. This type of clothing includes dielectric gloves, boots, galoshes, etc. Gloves are the most important in the work of an electrician - this is the main means of insulating an electrician to protect hands from contact with an electric current. They are intended for use at significantly low temperatures: from +50 o C to -40 o C, with a relative humidity of 85 to 95%.

By type, gloves are divided into:

- Two-toed;

- Five-fingered;

- Seamless;

- With a seam.

They are also divided into 2 subcategories - for electrical installations up to 1000 V (these models are not allowed to be used in work with voltages above 1000 V) and more than 1000 V, where they are used as an additional protective device. Often at low temperatures in rooms where electrical work is carried out, ordinary knitted gloves are worn under rubber gloves.

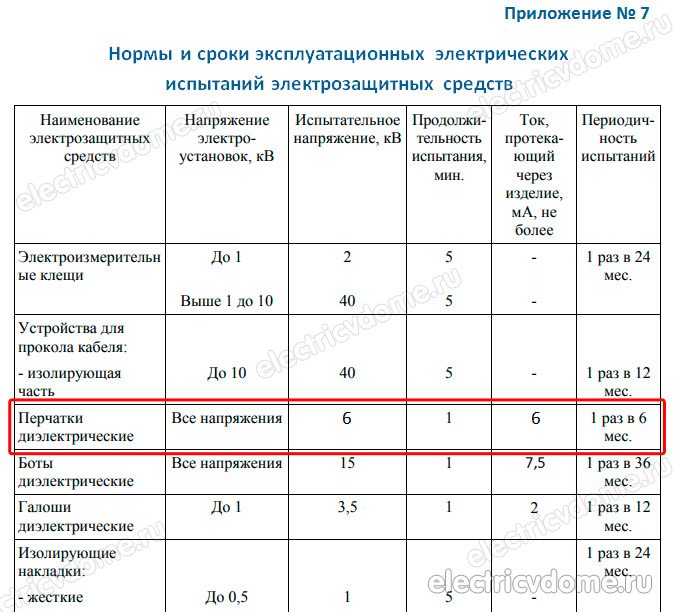

Dielectric Glove Test Frequency

Dielectric gloves must be tested at least once every six months.

It doesn't matter if they were kept in the warehouse all this time, or they were actively used in work. Such terms of testing dielectric gloves allow timely identification of damage to dielectric gloves, and also allow to determine their further suitability for use.

Do I need to test new dielectric gloves? Why test dielectric gloves when you can just throw out the old ones and buy new ones? Nevertheless, the rules are rules, you can't go anywhere, especially in large organizations, every purchase costs a pretty penny, but you have to work. Therefore, even new protective equipment must be tested before being put into service.

All personal protective equipment and the entire power tool must be checked periodically to ensure that it is in compliance with the regulations for use.

Especially for this there is a normative document “Instructions for the use and testing of protective equipment used in electrical installations”.

In addition to these rules, state standards must be followed.

Tests are tests, but before them a thorough external examination must be carried out. It's simple: if an external examination showed the presence of damage, then the tests can be omitted, because the test of dielectric gloves is necessary in order to detect / exclude damage and inconsistencies that are invisible during a surface examination.

If, after an external examination, you come to the conclusion that the gloves are suitable, then it is necessary to continue testing to fully ensure their safety.

There are all kinds of tests, but dielectric gloves are only electrically tested. The main measured parameter is the determination of the amount of electric current passing through the gloves. This parameter should not exceed a value of 6 milliamps. In addition, the absence of breakdowns is determined.