Preparing to remove stripped edge or thread bolts

The main criterion for the correct handling of the equipment is the careful dismantling of the fastening materials. It is better to prevent damage than to remedy the consequences. When significant force was applied to unscrew the bolt, and the fasteners remained stationary, it is not recommended to continue dismantling. Excessive efforts will result in damage to the hardware. If the bolt is broken, the repair will take much longer.

Preparatory activities include several points:

- Remove rust and dirt. If the threads protrude above the part, clean the pitch with a wire brush.

- Tap the bolt head with a hammer. You need to hit the fasteners hard. The blows are aimed at breaking down the oxides that form over time. The maximum effect from blows will be only at the stage when the head of the bolt is still pressed to the base position. After tearing off the fasteners from the place, you do not need to knock so as not to damage the thread. The main thing is not to allow the bolt to bend.

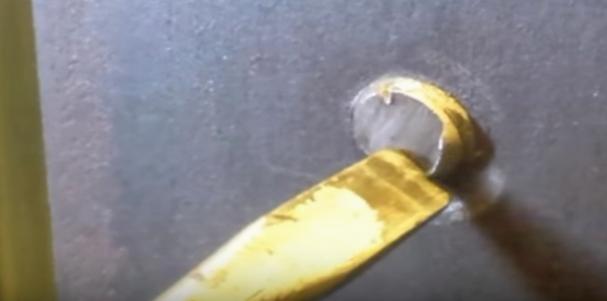

- An effective way to unscrew the bolt is heating the fixation point. The challenge is to heat the fastener and let it cool down. At this stage, rust begins to disintegrate, some substances burn out. The bolt is then much easier to unscrew. It is advisable to strongly heat the fasteners. This requires a blowtorch, acetylene torch, or gas torch. In each of the cases, it is necessary to adhere to safety precautions, since we are talking about an open fire.

- Lubricate the bolt with a light-flowing type of fluid. The most common product is WD aerosol. The advantage of such a tool is that it quickly enters all the cracks and spreads along the thread. A fairly effective composition is considered to be brake fluid and kerosene. To achieve the desired effect, after applying the agent to the attachment site, it must be left alone for a while. One hour will be enough, however, sometimes you have to leave parts for 12 hours.

Basic debris removal methods

With normal bolt loosening, different situations occur. The head may break off below surface level, or above. The location of the break affects how you can effortlessly remove the broken bolt.

The list of standard manipulations looks like this:

- The debris is coated with grease or rust remover if the part is old.

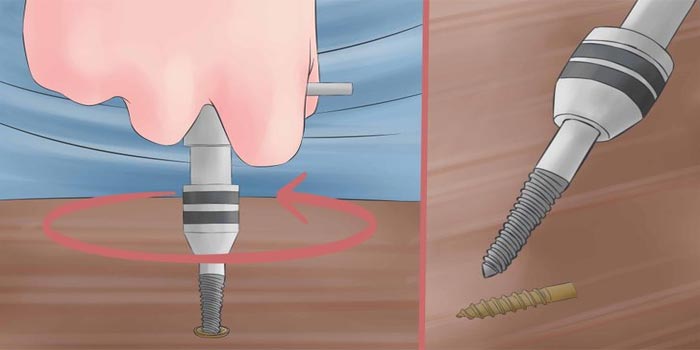

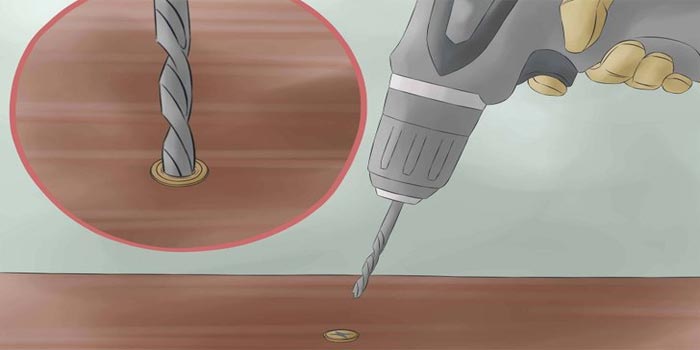

- The diameter of the extractor is selected, and, based on its size, a hole is drilled in the center of the screw body (to accurately determine the center point, use the guide sleeve provided in the kit).

- The tool is screwed in or driven in, it is firmly jammed.

- The fixed extractor is unscrewed together with the stuck hardware using a key or a knob.

After removing the part, place it on a hard surface and hit it several times with a hammer. This will help loosen the bolt and free the tool. When using a screw tool, the chip is simply unscrewed.

Next, we will consider the principle of operation if the scrap was formed in an atypical place.

Below the surface

A guide sleeve of a suitable diameter is placed in the recess. The hole is deepened with a drill. For a large screw, a smaller drill is initially selected. Then the twist is driven in, the crank is installed and the hairpin is unscrewed.

Above the surface

The unscrewing technique is similar to the previous one.You will also need a guide bushing, drilling a hole and an extractor, with which the damaged part is removed.

Flush break

In this case, there is nowhere to insert the guide sleeve. You will need a center punch to find the center point that is required to drill the hole. Then the procedure is repeated: the rod is inserted and the broken bolt is removed.

Extraction methods

Such tools turn out the remnants of fasteners of almost any diameter. The most commonly used fixtures are marked M1 - M16. The method of work depends on the place of the break:

- The break is below the surface. In order to remove the remnants of the bolt from the body of the part or from the depth of the coating, it is necessary to select the jig bush in the size with the stuck fragment and insert it into the recess. With the help of the core, the center of the part is marked. The mark should clearly point to the middle and be deep to avoid sliding off the drill of the corresponding diameter, which is used to drill the hole of the maximum depth. In the case of a large size of the stuck element, step drilling is performed: from small size gradually to the required one. Then the required rod is screwed in or hammered in with a hammer, and the splinter is removed with the help of a snap.

- If scrapping occurs above the surface, first you need to align the protruding part and repeat the previous steps.

For such manipulations, a tool is needed:

- Drill with drills.

- Extractor set.

- Hammer and core.

Tips for the correct selection and operation of the extractor - it is useful for any master to know!

Finally, I would like to make some useful recommendations to our readers, since practical knowledge is much more helpful than theory.

On the same AliExpress or AliBaba, you can find very advantageous offers.

To make the unscrewing procedure even easier, you can add machine oil, WD-40 or another lubricant, as these will maximize sliding.

When adding lubricants, remember to avoid combining them with excessive heat.

Do not forget that hardware is screwed not only into metal. If a bolt is destroyed in the thickness of wood or concrete, you can also use an extractor - the operating rules remain the same.

Avoid high speed when working with wood - this can lead to fire and unexpected damage to the material

Unfortunately, sometimes even the most sophisticated methods cannot help remove a stud or screw stuck inside. But even from such a situation there is a way out, similar to the solution of the riddle of the Gordian knot by Alexander the Great - just drill out the damaged element with a drill or perforator. Rough? Yes, but effective!

Extractor device and types

To remove the rest of the stuck part, it needs to be built up in some way. Savvy craftsmen use several methods. You can weld on to another mounting head bolt, or by drilling a hole, then hammering the handle of a triangular file into it, try to extract the debris in this way.

However, this is not so convenient. The work requires considerable effort, skills, and in some cases good luck, since it is not always possible to complete this operation. It is much wiser to use a device, which is of three types:

Wedge-shaped. Due to the sharp edges, the fixture is securely held in the pre-drilled hole. It remains only to unscrew the bolt with a regular wrench.

Rod. The principle of operation is the same as that of the wedge type. The only difference is in the wedge shape.

Screw spiral. Convenient fixture. Unlike the previous two types, the product is not driven in, but screwed into the hole. The tapered shape with notches resembling a thread enters the bolt when rotated and wedges. It is necessary to continue twisting in the same direction until the debris is completely removed.

Video: Types of the "unscrewer" of broken bolts

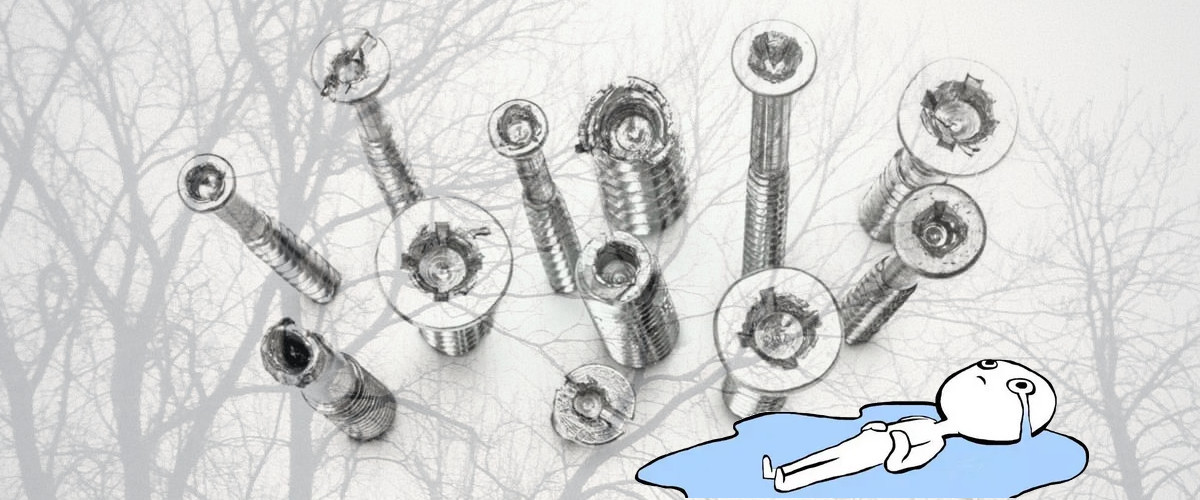

Extractor sizes allow you to select the optimal model for the stuck debris. They are sold both individually and in sets. The kit contains additional items to make your work easier. There may be a problem in removing the broken piece from the fixture. It can get stuck very firmly. Then you need to clamp it in a vice and carefully remove the device.

Precautionary measures

Like working with another tool, operations with an extractor require adherence to certain rules. For safe and productive work, you need to follow a few simple rules:

- Safety glasses must be worn to protect eyes from damage. Escaping shavings or metal debris pose a serious eye hazard.

- Using a larger extractor will destroy the walls of the debris and will be difficult to retrieve.

- The tool is made of hard but brittle metal. To avoid damage, distortions must be avoided.

- The body of the bolt remaining inside the surface must not have radial cracks. Otherwise, it will not work to drill a hole without violating the integrity of the walls.

- It is not allowed to use non-standard items for turning the extractor: pliers, pliers, etc., and to lengthen the handle of the crank with tubes. This can lead to failure of the rod.

- It is necessary to properly distribute the applied forces so as not to disrupt the threads of the spiral extractor.

It is clear that it is more efficient to carry out operations to unscrew broken fasteners with a special device. To do this, it must be of good quality and made of high-alloy tool steel or chrome vanadium alloy.

If the bolt breaks above the surface

In this situation, you can first try to unscrew the bolt with pliers or an adjustable wrench. If it did not work out in this way, then you can cut the bolt a little with a grinder so that you get a hole for a flat screwdriver and only then unscrew the bolt with a screwdriver, sometimes a hole for a screwdriver can be made with a chisel.

Read also: What is the name of the laser level

Also, if there is such an opportunity, you can weld another bolt or some curved metal rod from the protruding piece of the bolt and unscrew it for it. Some do not even weld, but stick with aggressive glue, but this option does not always work.

Device types

There are three different types of extractors for removing jammed fasteners, which differ slightly in the way they are operated.

- Spiral screw. They are considered the most effective and reliable for removing broken parts. They differ in a conical shape. Extractors of this type have a special thread, different on both sides. On the right side, the thread is for removing bolts and studs, which have the thread on the left side. And the left-hand thread on the extractor is necessary to extract parts with the thread on the right side. This tool works in a special way: it is not driven into a broken part, but simply screwed into a place previously drilled in the center of a screw or bolt stuck in the object. After the extractor is screwed in, it wedges, and then quietly unscrews along with the fastener. It will take a lot of effort to pull out a stuck bolt, therefore, in this case, a special tool is always used - a crank, which is necessary for high-quality clamping and rotation of some locksmith tools and, in particular, objects.

- As for the wedge-shaped extractors, they are made in the form of a cone with small edges. It is very simple to use: the tool must be carefully hammered into the pre-drilled hole of the broken fastener with a conventional hammer.After the device is driven in, it must be jammed, and then unscrewed with a wrench. This type of extractor is very easy to use, no special effort is required to unscrew the stuck bolt. However, in order to do the job efficiently, the extractor must always be driven in exactly in the center of the broken part, otherwise it will be extremely problematic to pull it out. Moreover, in the process of using the tool, it can sometimes be difficult to remove an already unscrewed bolt from the device itself.

- And the last type of extractor is a rod one. It has a rod-like shape with very sharp edges. This device is used in the same way as the other two types: first, a small hole is drilled in the center of the part, after which the device itself is wedged in it. The process of unscrewing the part is carried out using a suitable wrench. This type of device has one significant drawback: the fasteners already unscrewed from the object are extremely difficult to get from the tool itself.

As you can see, each type of device has its own specific features that must be taken into account when choosing a tool.

Alternative ways to unscrew a bolt with torn edges

Welding a nut as a way to unscrew a bolt without edges

This old tried and tested method brought many people out of the impasse during the renovation.

A specific case. The bolt of the front suspension arm on the old Suzuki Ignis has broken. Moreover, the distance between the lugs of the arm bracket did not allow either hammering or screwing the extractor into the debris. Welding in this case is the most effective way to unscrew the broken bolt.

The essence of the technique is as follows.

We select a nut of a suitable diameter, put it on the broken bolt and weld it on. If the bolt breaks flush with the surface of the part, fix the nut as accurately as possible in the center of the bolt. Cook

Carefully, without jerking, unscrew the broken bolt by the nut

Important!

Disconnect the battery terminals! Protect wiring, hoses, plastic products from melting and fire!

Let's say that the extractor and welding are not available to you. Then, if the bolt breaks in the thread, apply

Drilling is a great opportunity to turn a bolt without edges

First of all, let's calculate the drill diameter. The formula for a standard thread is simple - subtract the thread pitch from the diameter of the bolt (threaded part).

The next important point is how to avoid slipping the drill to the side? To prevent such a nuisance, there are conductors. A jig (simplified) is a plate with holes. In the holes, guide bushings (sleeves) are perpendicularly fixed, corresponding to the diameter of the drill. The jig is fixed to the part, the sleeves are aligned with the holes with the broken bolts. You can drill! It is the sleeve that will prevent the drill from deflecting.

The jig is indispensable if you need to remove a broken bolt from an aluminum part. Especially if it is the head of the engine block.

Knocking out metal residues

You can also combine drilling with punching out the remains of a broken bolt.

This technique is used if the threaded holes are through. Starting with the smallest drill bit, drill a piece. When the "wall" of it weakens enough, remove it with a punch. Then we clean the thread with a tap.

In this way, you can, for example, get rid of the fragments of the studs securing the intake pipe to the exhaust manifold on the VAZ2114-15 without removing the latter from the engine.

Heating to unscrew the stripped-off bolt

Consider this situation - there are no extractors, welding, conductor and good drills. How to remove a bolt if it is broken?

The problem can be solved (and sometimes very successfully) by heating the parts red-hot.After cooling, they will become more pliable and may well be unscrewed with a chisel, center punch, etc. The described methods of unscrewing broken bolts are not an exhaustive, universal answer to problems of this kind. For clarity - watch the material on the video.

Thank you for the attention!

How the extractor works to remove broken bolts

If you have read the description of the types of this tool, then you already imagine the whole simple procedure for extracting bolts. But without systematization, this material will be incomplete, and let's take a closer look at everything.

The first step is to map out the center of the broken bolt. For this we need a center punch and a hammer.

Then we drill a pilot hole for the extractor. When drilling, be careful not to move the axis of the hole to the side. Experienced craftsmen recommend drilling to a depth of three drill diameters.

Insert the extractor into the drilled hole and hit it with a hammer to secure it in place. Then use the tap wrench to start screwing the extractor into the broken bolt. When it reaches the stop, it will begin to unscrew the bolt. When working with the extractor, rotate only around its axis, in no case displacing the axis, otherwise you can break the tool.

When you unscrew part of the bolt, you can use pliers or a lock to continue turning the broken piece out faster.