Mini tractor from the Neva walk-behind tractor

Converting a walk-behind tractor into a small tractor may be slightly different. It all depends on the design features of the walk-behind tractor and its capabilities. Consider the principle of manufacturing a mini-tractor from Neva motoblocks.

As in the first case, before making a minitractor, you need to study the diagrams. They detail the dimensions of the elements and the order of their installation during assembly. The procedure for rework will be as follows:

The procedure for rework will be as follows:

- The frame is made in the same way as in the first case. To create it, use pipes of different sections. Fastening of the frame elements is carried out by means of bolts and welding;

- Next, proceed to the manufacture and installation of the chassis. To mount the rear wheels, use an additional axle, which can be made from steel pipe. Press the bearings and bushings into both ends of the latter, which will be equipped with the rear wheels;

- Further, the tractor from the Neva walk-behind tractor must be equipped with a motor. Moreover, the engine can be installed both in the front and in the rear of the frame. In the second case, the front and rear wheelbase of the minitractor will need to be expanded;

Mini tractor from the Zubr walk-behind tractor

Such a tractor from a walk-behind tractor has a good power plant that runs on diesel fuel.

To get a high-quality design, you should pay attention to the following elements:

- Installation of a hydraulic system that will allow the use of attachments.

- The front beam is equipped with special or native wheels that will ensure correct balancing.

- The engine is mounted on the frame at the front, which maintains the correct balance of the tractor.

To make the homemade product as strong as possible, all its parts are connected with special fasteners and processed by welding.

Required tools and materials

The first stage of the work consists in drawing up the drawing and preparing the equipment. A diagram of nodes and mechanisms, if you have the appropriate skills, can be developed independently or you can use those presented below.

As for the accessories, ready-made factory conversion kits are suitable - in any case, they are cheaper than the mini-tractor itself. But this option is suitable only for those who do not want to save on absolutely everything.

Making a homemade tractor will become impossible without:

- Grinders and disks.

- Fasteners and hardware (bolts and nuts).

- Channels and pipes with a metal base.

- Drill coming with drill sets.

- Welding equipment.

- A set with tools.

You cannot do without two suitable wheels, together with a hinge and a driver's seat, a steering mechanism, pedals, and the walk-behind tractor itself. It must have a sufficient power level.

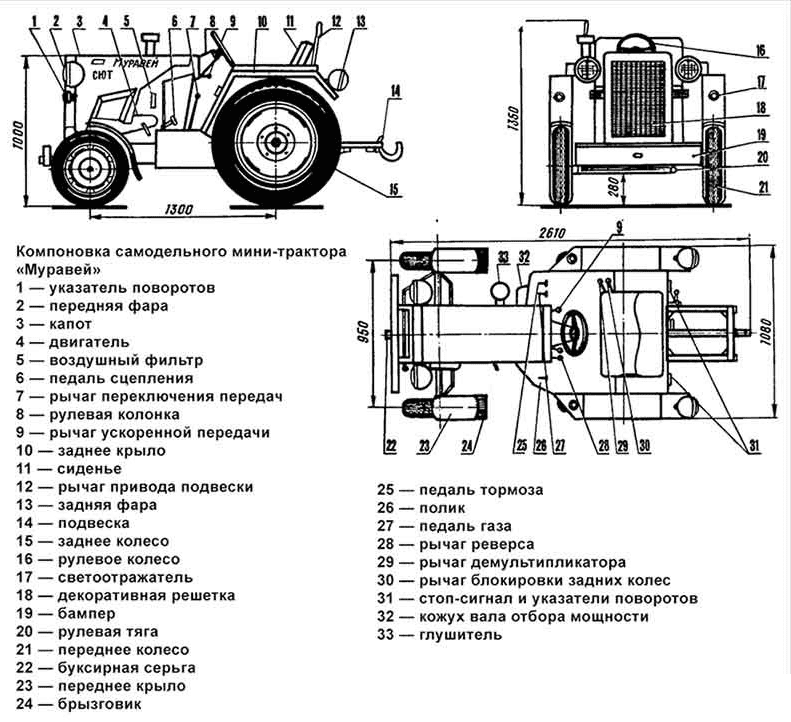

Examples of drawings of mini tractors

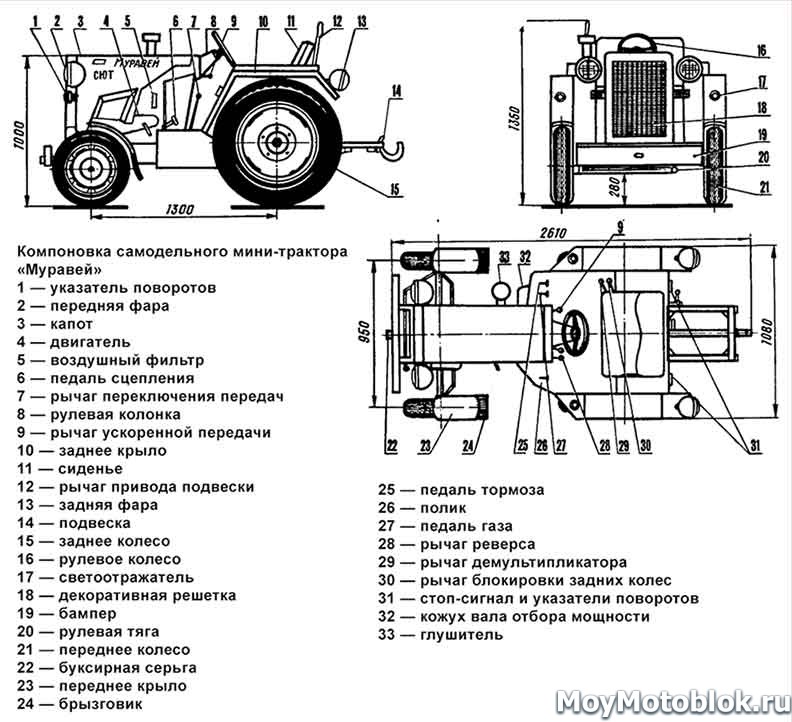

Overall dimensions of the mini-tractor

Layout drawing of the mini-tractor "Ant"

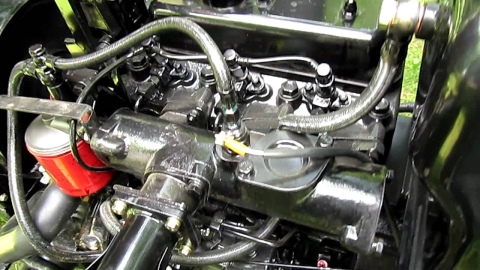

Kinematic diagram of a mini tractor

It is interesting: Which KUHN to install at MTZ

How to make a mini tractor from an MTZ walk-behind tractor?

To remake walk-behind tractors of this brand, you should also take into account their design and capabilities. MTZ units have a sufficiently high power, which makes it possible to make a full-fledged tracked mini-tractor out of them. It will be distinguished by high cross-country ability and excellent traction with the soil, due to which the quality of plowing the soil of such a machine will be several times higher than that of wheeled mini-tractors.

Before starting work, be sure to study the drawings, in which you will find all the information required for the alteration. The procedure for assembling a mini tractor is as follows:

The procedure for assembling a mini tractor is as follows:

- First, put the walk-behind tractor into operation mode with a mower;

- Then completely dismantle the front platform of the unit;

- Install a caterpillar drive in the front of the mini-tractor being manufactured;

- Install an adjusting rod in the niche for mounting the steering rod. This element will increase the rigidity of the entire structure;

- Weld the driver's seat to the top of the frame;

- Next to the motor, arrange a platform for mounting the battery and hydraulic valve.

Making a three-point hitch

The hitch is used to connect additional equipment to the tractor, for example, a plow.

The hinge must be movable both in the horizontal plane and in the vertical one. In the first case, mobility helps to reduce the stick out when steering. Vertical suspension movement is required to lower the equipment into working condition or raise it to the transport position.

A hitch for a mini tractor is made from various parts taken from old agricultural machinery. It is rather difficult to describe how to make a three-point hitch at home. Therefore, it would be more correct to use the following video, which indicates the dimensions of all parts of the device.

Attaching a mini tractor with a belt clutch

The V-belt transmission for a minitractor is similar in structure to the classifications discussed above. It also consists of main and driven components, which in this case are represented by pulleys.

To equip it, we need:

- 2 belts, the length of which should not exceed 140 mm. Each of them will take over the function of forward and reverse gears;

- spring rollers that will help tension the belt belts;

- guide plate made of durable metal;

- 2 guide bars, commensurate with the size of the pulleys.

The work progress consists of the following actions:

- a three-groove pulley is installed on the engine crankshaft, which will eventually become the leading link in our homemade design;

- the input shaft of the gearbox gearbox is also equipped with a second pulley - this is the basis of the clutch driven mechanism;

- we observe the rule according to which the pulleys that are closest to the motor must form two strictly parallel planes;

- we equip the spring-loaded bracket with rollers, which will create the effect of tensioning the belts or loosening if necessary;

- we will equip the reversing belt with a special guide - a metal plate. In this case, the belt itself must be connected to the pulley and roller with its opposite side;

- we install guide strips on the rear pulley and rollers, which should bend around the resulting structure from different sides.

The described clutch design for a mini tractor is quite simple to assemble, resistant to motor vibrations. Promotes stable operation of the mini tractor and is considered the most budgetary option: there is no need to buy expensive spare parts and shell out for their expensive maintenance.

How to make an all-wheel drive mini-tractor from a walk-behind tractor. Instructions for assembling a mini tractor from a walk-behind tractor

For those who are interested in how to make a mini-tractor from a Neva, Forte walk-behind tractor or from Zubr equipment, you need to know that the manufacturer does not really matter, this does not affect the efficiency of the tractor. The main thing is to correctly develop a drawing and a construction scheme. Also, the owner of the equipment can use ready-made developments.

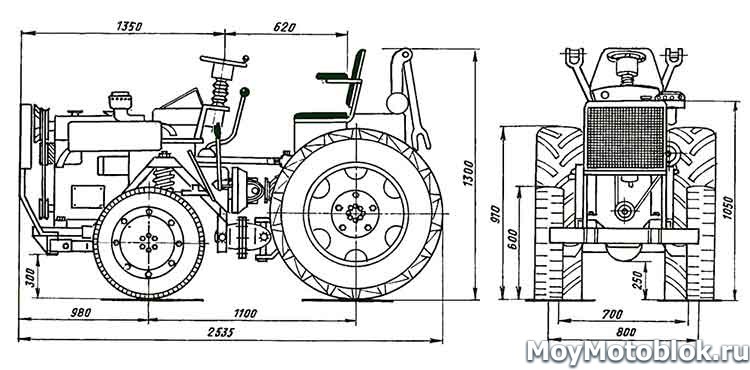

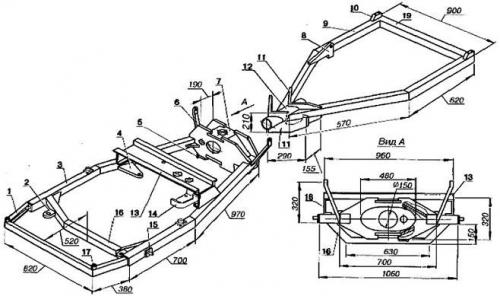

Homemade tractor drawing

Kinematic diagram of a mini tractor

Frame and body

To build the frame, it is allowed to use metal pipes and corners. Bolts should be used as fasteners, but welding will be required to create a strong connection.

Drawing 1 - structure frame

A mini tractor with your own hands can be equipped with a body. This will give the equipment not only a presentable look, but also protect the components from dust, mechanical and climatic influences. In this case, stainless steel sheets are used.

Operator's seat and steering gear

After completing the manufacture of the frame with a body for homemade equipment, the operator's seat should be attached to the structure. Here you can use the driver's seat from any vehicle. It must be installed in such a way that the driver can easily adjust himself to the position of the seat - the height and angle of inclination. The steering wheel is created according to the principle of building the installation in karting. But here you need to strengthen and shorten the thrust.

Chassis

A wheel kit for converting special equipment into a mini tractor should consist of four wheels with a diameter of 12-14 inches.

Drawing 2 - undercarriage

Drawing 3

If you install wheels with smaller dimensions, then the mini tractor will bury itself in the ground while driving, and in the opposite case, the control will become more complicated.

Equipment running-in

After completing work on the creation of a mini tractor, you need to treat the body with an anti-corrosion agent and paint it. Next, the equipment needs to be run in, so the operator can make sure that all mechanical components are working.

Once the technique has been tested, it can be supplemented with a head light, awning, hydraulics and other devices.

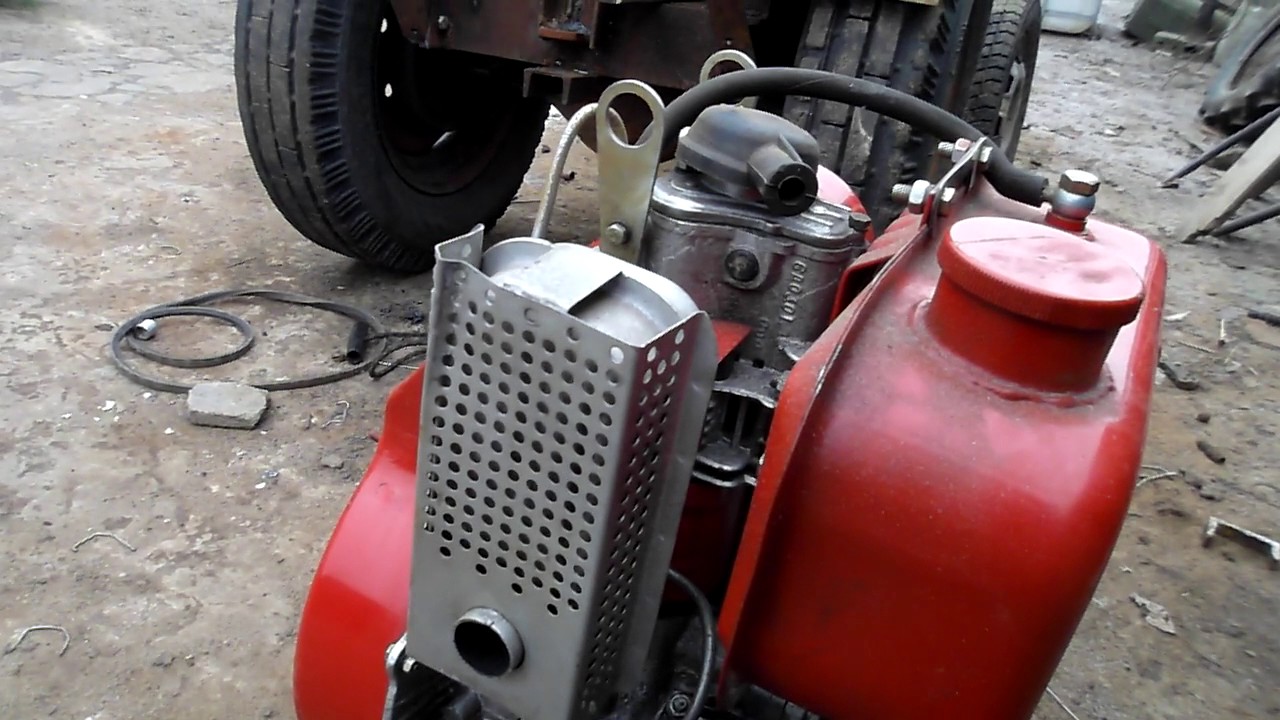

DIY mini tractor. Choosing an engine for a homemade tractor

If you decide to assemble a mini tractor with your own hands, then first of all you need to choose a power unit for it. The ZID engine is often used as the latter. This is a four-stroke unit with a volume of 0.52 liters. and a capacity of 4.5 l / s, which is quite suitable for processing 2-3 hectares of land. The engine is easy to maintain, so it is often installed on various home-made equipment, moreover, it is easy to buy it on the Internet.

Another option for homemade products is the UD-25 engine. This is a two-cylinder unit with a capacity of about 12 l / s and a volume of 0.42 liters. Although this type of motors has long been discontinued, there are a large number of offers on the Internet for the sale of this unit. You can buy it for about 5,000 - 8,000 rubles.

Often, when making homemade tractors, craftsmen use motors from cars. For example, you can find mini tractors with an Oka engine.

This engine has a power of 29.3 l / s and a volume of 0.649 liters. In fact, this is a VAZ engine (VAZ 21083), only in a lightweight version, since it has 2 times less weight. A distinctive feature of the Oka engine is low gas mileage and high efficiency.

A more expensive option is a Zhiguli engine. The motors of the VAZ car line have an engine power of 59 l / s (VAZ 2101) and above. A tractor with a VAZ engine is a fairly powerful unit that is able to cope with almost any agricultural work.

It is easiest for owners of walk-behind tractors to make a mini-tractor for a household, since this unit already has all the necessary control units. All that remains is to make a suitable frame and the tractor is ready.

How to make a mini tractor with your own hands. Choosing an engine for a homemade tractor

If you decide to assemble a mini-tractor with your own hands, then first of all you need to choose a power unit for it. The ZID engine is often used as the latter. This is a four-stroke unit with a volume of 0.52 liters. and a capacity of 4.5 l / s, which is quite suitable for processing 2-3 hectares of land. The engine is easy to maintain, so it is often installed on various home-made equipment, moreover, it is easy to buy it on the Internet.

Another option for homemade products is the UD-25 engine. This is a two-cylinder unit with a capacity of about 12 l / s and a volume of 0.42 liters. Although this type of motors has long been discontinued, there are a large number of offers on the Internet for the sale of this unit. You can buy it for about 5,000 - 8,000 rubles.

Often, when making homemade tractors, craftsmen use motors from cars. For example, you can find mini tractors with an Oka engine.

This engine has a power of 29.3 l / s and a volume of 0.649 liters. In fact, this is a VAZ engine (VAZ 21083), only in a lightweight version, since it has 2 times less weight. A distinctive feature of the Oka engine is low gas mileage and high efficiency.

A more expensive option is a Zhiguli engine. The motors of the VAZ car line have an engine power of 59 l / s (VAZ 2101) and above. A tractor with a VAZ engine is a fairly powerful unit that is able to cope with almost any agricultural work.

It is easiest for owners of walk-behind tractors to make a mini-tractor for a household, since this unit already has all the necessary control units. All that remains is to make a suitable frame and the tractor is ready.

Types of replaceable cultivator nozzles

The cultivator for a motor-tractor can be equipped with various attachments.

They are divided into several types:

paws - necessary for plowing the soil while removing weeds. There are several types of these attachments. Chisel attachments are designed to loosen the soil to a depth of 15 cm. Pointed universal shares are used for continuous or inter-row plowing of the soil to a depth of 14 cm. Attachments of this type do a good job with crushing the earth and cutting weeds. One-sided flat-cut tines are designed exclusively for cutting large weeds;

- harrows - nozzles of this type are used for soil cultivation between rows and in protective zones;

- feeding knives - used for loosening the soil in the aisles and simultaneously embedding fertilizers in the soil. The maximum working depth is 16 cm;

- needle discs - designed to break up the earth crust and kill weeds. The working depth is 4 cm, and the ground shift is 1–2 cm;

- hillers - these attachments are used to cut ridges and destroy weeds in the aisles. Maximum processing depth - 16 cm:

- irrigation irrigation ditches - used to prepare furrows for further irrigation. The furrow depth does not exceed 20 cm.

All replaceable attachments are fixed to the cultivator racks by means of a bolt connection. To prolong the life of the equipment, you should regularly clean it of weeds and avoid contact with too wet soil.

Do-it-yourself fracture mini-tractor from a walk-behind tractor. What is required

Before starting work, you should make sure that you have all the necessary parts, materials, and tools.

So, what is required for work:

- Motoblock. It must be chosen taking into account the above recommendations. It is he who will serve as the basis for a homemade mini tractor.

Motoblock Neva - the best option for rework

- Additional wheelset with axle. It is imperative to purchase bearings for the wheels, as well as a steering unit.

- Metal sheets, pipes and corners. The material is needed to create the body and frame of the structure.

- Elements for fixing parts and mechanical assemblies. In this case, washers, bolts, nuts, welding are used.

To carry out the assembly, in addition to the details, you also need to prepare a number of tools:

- welder;

- drill screwdriver;

- a set of wrenches of different sizes;

- pliers;

- Bulgarian.

A homemade unit has a number of advantages. First of all, this is the cost.Even if the DIY needs to buy a cultivator, they will spend less money anyway. In addition, you can create special equipment of the desired size, degree of adhesion to the ground, as well as performance.

As for the disadvantages, they are that hand-made equipment is much inferior to factory models in the level of reliability. Also, this technique often requires repair work.

Mini tractor from the Neva walk-behind tractor

Such a home-made tractor is one of the best, as it has compact dimensions and high productivity. For alteration, a walk-behind tractor is used as a basis, two additional wheels and an axle.

To correctly carry out the alteration, you should adhere to the following rules:

- Additional wheels should be 14 to 18 inches in diameter. Too small ones can throw the tractor, and large ones will not allow it to move normally.

- The engine of the walk-behind tractor can be located at the back. In this case, it is necessary to widen the track width for better balancing.

- The tires of the equipment are equipped with lugs for higher grip on the ground.

This model is very simple and suitable for conversion. It will be a good option for working in any area.

It is interesting: Color wiring diagram of the old-style MTZ-82 tractor: disassemble point by point

Transmission units

Very rarely, craftsmen complete engines with standard gearboxes. This is due to the fact that often the native box is not able to provide the required effort on the driving wheels, so you have to look for ways out of such difficulties. One of the options is the connection of a relatively low-power engine, for example, the M-72 and the box from the GAZ-51 (53).

For such combinations, a new clutch cover or adapter with stud holes has to be made, which ensures the alignment of the engine crankshaft and the gearbox input shaft. The adapter can be made of steel or aluminum based alloys.

When making a homemade tractor with their own hands, craftsmen often supply it with a power take-off, a thing that is extremely necessary if it is necessary to work with hydraulic hinges. Power take-offs are also used from serial automotive or agricultural equipment, or they can be homemade (there is nothing fundamentally complicated there).

Bridges, like wheels, can be used in a variety of ways, from an elementary device from a scooter "Ant" to serious bridges from a truck. Bridge alterations, as a rule, boil down to shortening the stockings and semi-axles (to give the required track dimensions), as well as the design of new seats for the bearings of the semi-axles in stockings.

What is it for?

First you need to find out the main nuances of the work ahead. A clutch of any type is designed to solve a very urgent problem - the transmission of torque to the transmission. That is, if such a part is not supplied, normal operation is simply impossible. Moreover, without a clutch, it is impossible to quickly and smoothly disconnect the engine crankshaft from the transmission. Therefore, it will not be possible to guarantee the normal start of the mini-tractor.

Friction clutches are unambiguously preferred by designers at factories. In them, the rubbing parts provide the transfer of torque. But a self-made clutch can be performed according to a different scheme. The main thing is to understand everything thoroughly before finally deciding something. According to a number of experts, it is much better to use a belt connection on a miniature machine. In this case, its objective shortcomings practically will not manifest themselves. But the benefits will be fully disclosed. In addition, the simplicity of the manufacture of such a part is also important for farmers. The sequence of work is as follows:

- take a pair of wedge-shaped belts (best of all 1.4 m in length, along profile B);

- a pulley is added to the input shaft of the gearbox (which will become the driven link);

- spring-loaded bracket of 8 links connected to the pedal, complemented by a double roller;

- install stops that reduce wear when the engine is idling.

If you put just such a clutch, then the work will become much more efficient. The reliability of the entire system is increased. And in terms of labor costs, a belt clutch is definitely the best choice. Recommendation: You can use an already used gearbox. There is another option for doing the job. A flywheel is placed on the motor. They take the clutch from the car and use a special adapter when installing it. There is no need to pay for this adapter - great products are made from crankshafts. Next, the clutch housing is installed. It must be placed with the pallet facing up.

Important! We'll have to check if the flange mountings of the input shafts and the crankcase are compatible. If necessary, the gaps are widened using a file.

It is also advisable to remove the checkpoint in this scheme from the old car. It is best if the distribution box is included in the kit.

How to make a mini tractor from an MTZ walk-behind tractor?

To develop a high-quality and fairly productive tractor, use MTZ 05, MTZ 09, MTZ 12 walk-behind tractors or other models. They are equipped with a two-cylinder engine that shifts the center of gravity forward.

To develop a high-quality and fairly productive tractor, use MTZ 05, MTZ 09, MTZ 12 walk-behind tractors or other models. They are equipped with a two-cylinder engine that shifts the center of gravity forward.

When reworking, the main task is to eliminate the problem of displacement of the center of gravity:

- Set the machine for mower operation.

- Remove the front pad and replace the front wheel from the motorcycle, as well as the steering wheel.

- Attach an adjustment rod to the upper part of the frame, which will make the structure more rigid.

- Weld on the driver's seat.

Install the engine and do not forget to install another platform that will house the hydraulic valve and battery. An additional steel frame for hydraulics needs to be installed at the rear, and a handbrake is mounted at the front.

The end result is a compact three-wheeled tractor with high productivity. You can see how he looks in the photo.

Variety of designs of clutches for tractor mini-equipment

There are several classifications of clutches for mini tractors. Let's consider the most common ones.

Depending on the mechanism for transmitting torque to the gearbox of the minitractor, they are:

- frictional;

- electromagnetic;

- hydraulic.

The first, which are most often found in modern factory models of mini tractors, include 3 components:

- leading part;

- slave;

- control system.

Revolutions are transmitted by friction between driving and driven parts. Friction clutches are also called mechanical. Their performance is regulated by the frictional properties of the parts from which they are made, and to increase them, you can use various friction pads that change the friction force in one direction or the other.

In electromagnetic, the connection between the engine and transmission takes place through a magnetic field or through the use of a special powder with magnetic properties. It activates the electromotive force and closes the magnetic field between its components.

The operation of hydraulic couplings is based on the force of the flow of the working fluid, which acts on the driven parts of the mini tractor. If the flow force is constant throughout the work, they speak of hydrostatic couplings. If it is variable (dynamic), then it is a hydrodynamic coupling.

Hydrodynamic clutches are widespread in most modern high-power tractors, since they wear less gearbox and cause smoother operation of the entire traction unit.

According to the number of discs, the clutch is classified into:

- monodisc;

- multi-disc.

The basic element of multi-plate clutches is a housing with a notched inner surface. It is into it that the discs with grooves along the outer circumference will be inserted. They rotate freely along an axial path and transfer torque sequentially between the gearbox and the engine flywheel.

Installing the undercarriage

After the installation is completed, the attachments for the hitch are mounted on the front and rear axles, and on them the wheels. Basically, those that came with the walk-behind tractor are installed on the back, and on the front - from a passenger car. In this case, the tread pattern must be deep. This is an important aspect, since the technique will receive high cross-country ability, and the grip of the wheels with the ground will be improved.

To equip a homemade tractor with a full-fledged chassis, you need to buy hubs with brakes. In this case, it is desirable that the kit also includes steering rods, wheels, a gearbox and a column. But they can also be altered - removed from a car.

Some gardeners supplement the front suspension with shock absorbers for comfortable operation.

Application area

The all-wheel drive mini-tractor, made by hand, has quite good cross-country characteristics, which makes it possible to perform virtually the same scope of work as shop counterparts, such as Uralets, Kubota, Bulat 120, Yanmar, Belarus 132n, Scout.

Of course, the power of a home-made unit may be somewhat weaker, but at the level of domestic use, this fact is almost imperceptible.

Application area

The main area of application of this do-it-yourself unit is agricultural work. This term covers a fairly wide range, including many related works. In other words, a homemade mini tractor is needed for the following purposes:

- plowing of land holdings for the purpose of their further use;

- cultivation of the soil, as well as getting rid of weeds;

- harrowing the soil;

- sowing operations on treated soil;

- planting and digging potatoes.

In principle, this is the main purpose of the mini tractor, for which it is made. But, its application can be significantly expanded if a special connection for additional equipment, mounted and trailed, is provided in its design.

If everything is done correctly, then your homemade product can additionally perform the following work:

- transportation of various goods (transportation of firewood, construction waste, etc.);

- snow removal in the winter season;

- mowing lawns and lawns, and making hay for livestock.

As we can see, the mini-tractor breaking the classic 4x4 with its own hands can significantly facilitate the life of any rural resident, because with the help of this technique it becomes possible to perform all types of work that are required with competent maintenance of subsidiary farming.

The indispensability of a home-made unit is also due to the fact that a minimum of investments and funds are used in its manufacture, which is very important for rural areas. For more information about the work of an all-wheel drive mini tractor, see the video:

For more information about the work of an all-wheel drive mini tractor, see the video:

Pros and cons of a homemade mini tractor

The popularity of homemade mini tractors for the household is explained by their advantages:

- Convenience. Thanks to this device, agricultural work is carried out faster and does not fatigue.

- Ease of operation. The homemade tractor is compact in size, so it does not require a separate storage room. Spare parts for replacement can be bought in the store - they are sold together with walk-behind tractors (Neva, Scout, Bison), from which the mini-tractor is assembled.

- Advanced functionality. Various equipment can be used with this device.The homemade tractor is suitable for plow, cultivator, harrow, potato planter, etc. Some varieties can be converted into cranes.

- Saving. The price of a mini tractor in the store is quite high, so sometimes it is better to purchase a walk-behind tractor and modify it yourself. In this case, many parts are free of charge, since the use of spare parts from old equipment is allowed.

- Knowledge of construction. When independently converting a walk-behind tractor into a mini-tractor, the owner will know all the design features. This will allow him to troubleshoot the work himself, without contacting special services.

The disadvantages of such products include their low reliability. At home, you cannot make equipment similar in quality to the store one. The use of second-hand parts during operation only diminishes reliability. Lack of skills can cause malfunctioning of the machine.

The main types of homemade tractors:

- Multifunctional machines.

- Mini tractors for garbage collection and grass mowing.

- Riders.

The first type is a machine for soil cultivation, garbage collection, grass cutting. A homemade all-wheel drive tractor, as a rule, is equipped with a medium-power motor. It can cope with an area of 6 hectares. It is possible to install attachments on it, allowing you to expand the range of goals to be performed - for example, a rotary auger snowplow or even an excavator bucket.

Rear-wheel drive micro tractors can be designed for a narrower list of tasks, including processing an area of up to 2 hectares or arranging lawns - it can be equipped with a rotary tiller for cultivating the land, a mower.

Riders apply fertilizers, treat the area with pesticides. They can be equipped with permits for other purposes, when it is necessary to process a small plot of land.

Making a mini tractor with your own hands. Areas of use

Homemade mini tractors have similar technical features as full-fledged units of Belarusian, Chinese and Russian production, presented in stores. That is why, the area of their application will be practically the same.

Naturally, the main work for a self-made unit will be plowing, cultivation, and also other processing of land. This task is paramount, because it is his harvest that feeds the farmer, i.e. what he planted with his own hands, and without proper soil preparation, this is almost impossible.

Application area

This, in many respects, explains the necessity and indispensability of such equipment for agriculture in general, as well as for specific farmers in particular.

In addition, with the help of a homemade mini tractor, you can carry out a whole list of typical works:

- cleaning snow masses in winter;

- transportation of small loads;

- cleaning of household waste, as well as various vegetation;

- hay making;

- planting and digging potatoes, beets, etc.

It is understood that the possibility of performing such work is realized only in combination with certain equipment, which serves as an auxiliary one. We are talking about trailers, rotary and segment mowers, snow plows, etc.