Peculiarities

A jack is a special stationary, portable or mobile lifting equipment with which you can lift absolutely any object to a certain height.

All jacks are characterized by:

- carrying capacity;

- lifting height;

- working stroke;

- own weight;

- pickup height.

The activity of the domestic company "Zubr" began in 2005. It was the jack that became the first mechanism that she began to develop and produce. Today, after 15 years, the Zubr jack is the choice of the majority of consumers. The popularity and demand for the product is due to a number of advantages and features that are inherent in the product, namely:

- quality;

- reliability;

- long service life;

- the use of high quality materials for the production of jacks;

- wide selection and assortment;

- manufacturer's warranty;

- availability of quality certificates.

Before entering the consumer market, Zubr jacks must undergo a series of tests, after which technical documentation and a passport are drawn up for each mechanism, and a warranty period is established.

Views

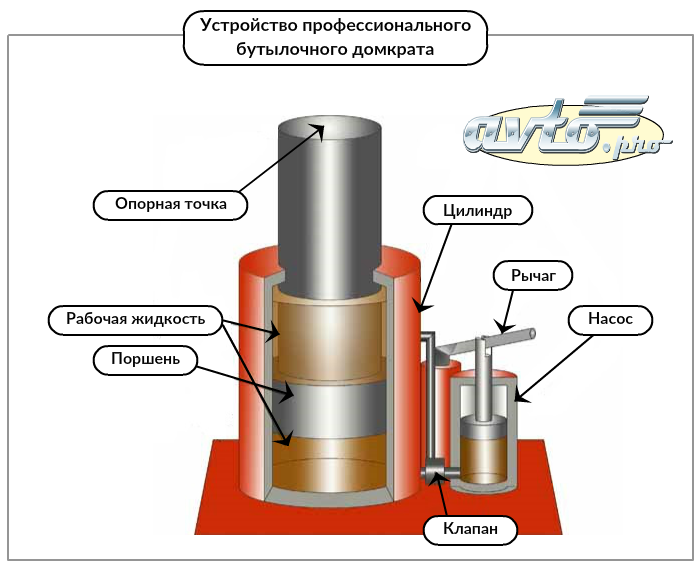

The most popular is the hydraulic bottle jack. In it, the stem is placed vertically. The device includes a mandatory complex for oil injection.

The telescopic design means replacing a conventional piston rod with a retractable piston. In this case, the lifting height of the load increases.

Diamond systems are attractive because they have 4 key lift points. This is very convenient when you need to raise the entire vehicle above the ground, and not just work with one of the wheels.

But for ordinary work in a private garage, a rolling jack will be more attractive. Its working height is low. But there is a trolley that makes it easier to move. Such a device is also useful for repairing other equipment.

The double-rod jack has one more piston (in addition to the main one). Its carrying capacity is quite high. Such devices are in demand in professional workshops. With their help, it is even easier to repair a heavy car, and it will not be difficult to bend any metal structure. But there are many other subtleties that a potential lift owner must take into account.

Model overview

The bottle jack MATRIX 50756 has good prospects. It is capable of lifting 5 tons of cargo to a height of 41.3 cm. At the same time, the lower pick-up level is 21.6 cm. This model has one pick-up level. The weight together with the case is 4.8 kg, the proprietary warranty is given for 12 months.

An alternative may be the modification "Stella NM 50". The device picks up the load at a height of 2.5 cm, and raises it up to 36.8 cm. The mechanics provides two main working levels. The mass of the device is 25 kg.

The Stella NM 50 model is useful for:

-

installation of various structures;

-

work on railway tracks;

-

construction of highways and various bridges;

-

lifting, lowering, clamping or spreading objects (but this jack is not suitable as a support).

Another attractive bottle model is Sorokin 3.205. Its lifting height is 17.5 cm. The load can be lifted up to 39 cm. There is only one working level. The total weight of the product is 5.5 kg, its two-stem design is very convenient.

Rock Force RF-tC50001 is perfect for tire fitting. The height of work with a load is 7 cm. The lifting height is 73.5 cm. The total weight is 44 kg. The scissor device is pretty rigid.

Alternative - "TOR DG-5". The stroke of the rod reaches 12 cm, and the height of the load grip is 19 cm.The size of the screw neck is 6 cm.The dimensions of the device are 10x10x19 cm.Support area 9.6x10 cm.

Fans of sliding models should take a closer look at the Nordberg N3205 variant. A pedal is provided that is responsible for fast lifting. The operating handle is completely ergonomic. Its tilt is adjustable with a latch. The designers have provided for the automatic centering of the loaded device.

For hydraulic jacks with a lifting capacity of 5 tons, see the video below.

How to use?

One of the key points in the proper operation of the described lifting mechanisms is the ability to correctly install them.

It is always important to keep in mind safety precautions, as we are dealing with heavy loads and an increased risk of injury. The jack must be located on a firm and as level surface as possible.

If one cannot be found, then it is necessary to take care of the maximum blocking of the lifted machine (the side opposite to the lifted one deserves special attention). For this, "shoes" and other recoil devices are used.

You will need to insert the handle that acts as a lever for the hydraulic pump. After the most smooth movements "up and down", pressure is built up in the working cylinder, due to which the support platform begins to rise with the car.

At the final stage of the lifting, it is strongly recommended to install special props.

It is important to remember that bricks and stones cannot perform their functions due to the risk of destruction under the weight of the load. After completion of repair or maintenance work, the vehicle will need to be returned to its original, horizontal position.

Using the appropriate valve, the pressure of the working fluid in the system is released, and the platform is lowered. In this case, you should also take care of the smoothness of the cylinder rod stroke.

One of the most important points in the operation of rolling jacks comes down to the fact that all manufacturers focus on the purpose of this lifting mechanism. The point is that such structures are an effective tool only for lifting loads to a certain height and lowering them, and not for holding

That is why you should always have at hand strong, reliable and maximum stable supports in the form of racks, tripods or "shoes" that ensure safety.

How to choose a rolling jack, see below.

Types and models

Today the following jacks are manufactured under the Zubr trademark logo:

- mechanical screw;

- hydraulic;

- hydraulic bottle;

- rack;

- movable.

Currently, in the process of developing new models, the company uses 3D modeling, which has helped to increase the reliability factor and the ergonomics of the mechanisms.

Let's take a closer look at each of the Zubr jack types.

Trolley

This model is one of the most demanded. This mechanism is characterized by reliability and high carrying capacity.

"Zubr MASTER 43052-2.1" is a compact, easy-to-use model with a lifting capacity of 2 tons and a lifting height of 385 mm.

Also worth noting is the model 43052 3 z01, which is characterized by:

- lifting capacity - 3t;

- pick-up height - 130 mm;

- lifting height - 410 mm.

Rack

Off-road enthusiasts and those who drive large and heavy SUVs call these jacks "Hi-Jack". They are strong, reliable, durable, do not require additional maintenance. The maximum lifting capacity of the rack jacks is 6 tons.

The most popular models are "Hi-jack" rack and pinion, mechanical, 3t, 125-1330mm and "Zubr 43045-3-070".

Hydraulic

This unit is very often called a bottle unit. It is reliable, convenient in operation, and is characterized by a sufficiently large lifting height. You can choose a model for both a car and a truck. One of the most popular models of the hydraulic mechanism is the Zubr-43060-2 bottle jack.

This model is characterized by:

- lifting capacity - 2 tons;

- lifting height - 347 mm;

- pick-up height - 181 mm.

Also in demand are models 43060-3 and 43060-5 with a carrying capacity of 3 and 5 tons.

Mechanical screw

This type of jack is also quite popular among motorists. It can only be used in work with passenger cars, since the lifting capacity of a mechanical screw jack does not exceed 2 tons. One of the most frequently purchased models is the Zubr Expert 43040-1. The maximum weight that this unit can lift is 1 ton, and the lifting height is 383 mm.

It is here that you can see the entire range, get expert advice.

Troubleshooting

Screw jacks, although more reliable than some models, also tend to break. Of the most frequent breakdowns, one can single out a breakdown of a thread or a burst nut. If the thread breaks, then you need to buy a new tool. In the second case, it is easier: you can order the manufacture of a similar nut in the workshop and then simply replace the cracked one. But still, for the sake of your own safety, it is worth buying a new, high-quality tool.

Choosing between many offers is always difficult. Each manufacturer tries to put their instrument in the first place, and sometimes it is not clear which model to buy. For a more detailed acquaintance with this or that jack, you can read customer reviews or watch a video suitable for this topic.

Criterias of choice

How well all the factors and characteristics of the equipment are taken into account will determine how well the mechanism will cope with the task and how long it will be able to serve.

So, when choosing a jack, you need to be guided by the following criteria.

- Carrying capacity. Each jack is designed to lift a specific weight. If you buy a unit with a carrying capacity of no more than 2 tons, and a truck starts to lift it, most likely the jack will break without lifting the transport.

- Pickup height. This is the minimum height from which the jack can operate.

- The height of the rise. This parameter denotes the maximum height limit to which the equipment can lift a load.

You also need to consider the cost. It is influenced by the technical parameters of the device, especially the carrying capacity

It is also important to understand for what purpose the jack is being bought.

But if, for example, this lifting mechanism will participate in the construction process or for a service station, it is best to buy a more powerful model. There are jacks that can lift loads weighing tens of tons and are designed for constant, uninterrupted work. The cost of such devices is quite high.

How to choose a quality tool

Due to the fact that today the market for tools for repairing vehicles is replete with various models of jacks, when buying, you should pay attention to the carrying capacity, design, type and many other characteristics. It is worth noting that the market is more and more filled with imported models, which are not always of high quality.

Such a wide variety requires a careful approach to the selection of jacks for vehicle repairs.

First of all, when buying a lift, you need to take into account the following parameters:

- lifting height and type of drive;

- carrying capacity;

- maximum pickup height.

Each model has certain restrictions on the carrying capacity, and in order to determine which design is best for the car, the technical documentation must be carefully studied.

Important!

If the parameters of the lifting capacity are incorrectly selected, the hydraulic bottle jack 5t will often break and lose stability. Also, during its operation, the car may fall on the driver and injure him.

Criterias of choice

The most important parameter for any type of hydraulic jack will be its lifting capacity. When selecting it, you cannot focus only on the dry weight of the car. Sometimes it has to be lifted in a tucked state, and even with a loaded trunk and / or interior. It is recommended to add another 10-15% to the estimated full load. Then any unpleasant event will be completely excluded.

Of course, we are talking only about quality jacks. And such copies can be bought either directly from manufacturers and their dealers, or in large chain stores where they sell a variety of goods. But a specialized outlet will still be better than any supermarket.

In practice, the height of the load is of great importance. Moreover, we must not forget about such a value as the pickup height - if you ignore it, in many cases the jack will be useless. The dimensions and weight of the lift are important primarily for those who are going to carry it with them by car. However, the need to constantly drag an unnecessarily bulky device in the garage or car service will not inspire anyone. Experts advise not to be limited to these criteria.

Thus, the chemical composition of the hydraulic fluid can be of great importance. The efficiency of work in hot or cold weather depends on this. It is also useful to know the amount of effort that will have to be applied. In order for the pressure relief rate to be maximum, it is necessary to buy a model with a two-way valve. You can find out such characteristics in technical data sheets, in official catalogs, as well as in consultation with official suppliers.