How to choose a quality tool and what to look for when buying

In order to correctly choose a good and high quality Hi-Jack jack, you need to know the list of existing models and the main characteristics.

Note!

It is important to take a jack with the expectation that it is suitable for a specific car

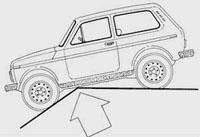

It is necessary to start the choice with the fact that the car for the hi-jack must have stubborn power points for which the car can be lifted with such a jack. If these points are absent, then hi-jack in this case will be completely useless.

If there are points and the car is suitable for use, then a model with a suitable working length must be selected. To do this, you can take a hi-jack from someone for a while and test it. The machine must be parked on a level surface and a jack must be installed at the back. Start lifting the car by the power step until the rear wheel is off the surface. In this case, a power reserve of about 25 centimeters should remain on the power bar of the device. The minimum allowable value is 15 millimeters. However, if the lifting mechanism reaches the top of the bar at the same time, then this size of the jack is not suitable for full-fledged work with this car.

It is also important to consider the size of the wheels. If, during the operation, standard wheels were installed, but soon, for example, in the summer, it will be necessary to install larger wheels, then this factor must be taken into account

Hi-jack is popular among off-road enthusiasts, and there they often have to change wheels depending on various factors.

Hi-jack with red cast iron power strip

Hi-jack with red cast iron power strip

It is recommended to choose a hi-jack with a red bar. It is the most durable because the bar is made of cast iron.

If the choice fell on a cheaper option with a black bar, then it is important to consider that its abilities will be slightly lower.

RUB 4,050 MATRIX High Jack 505195

Carrying capacity: 3 t

Lift height: 1 350 mm

Pick-up height: 155 mm

Weight: 16KG

A rack and pinion jack is a tool with an extremely wide range of possibilities. With proper use and compliance with safety rules, it is absolutely irreplaceable, opening the way to the most inaccessible places. In short, it is capable of lifting and moving an object. As a rule, the object is a car, but a hi-jack can also be useful in domestic use, even if this is not its key purpose.

For full use, you will need a platform for the base of the jack (to increase the support area and reduce pressure on the ground), as well as a special device that allows you to lift the car by the wheel (especially if you do not have power bumpers and thresholds installed). The list of accessories is not limited to these two devices, it is quite extensive and allows you to make transportation and use of the jack as comfortable and efficient as possible. It includes arm pads, various types of shackles (cable attachment devices), carrying cases and much more. Perhaps a hammer should be added to the list of mandatory tools - to ensure the mobility of the node sliding along the rail. The hi-jack is quite simple to maintain, but, like any functional thing in the arsenal of an off-road traveler, it requires attention. For example, you should always carry a can of WD-40 or similar lubricant with you and remember to clean the jack after mud baths. Like any heavy-duty tool, a rack and pinion jack is a safety precaution that should not be forgotten in the heat of off-road battles. The recommendations are elementary: always hold the jack handle firmly when lifting and it is always good to strengthen the soil under the base to avoid spontaneous loss of stability.And finally, the rack jack does not require certification, and its presence in the trunk greatly increases the number of accessible roads and directions.

Self-repair of a rack and pinion jack

A rack jack is a dream of many motorists, but not everyone can purchase it due to the high cost. With knowledge of mechanics and having drawings, you can make this type of device yourself. A homemade jack is much cheaper than purchasing a factory tool.

For independent production of the tool, two rack pipes are welded together. It is recommended that all parts be taken from durable steel. The welded parts should resemble a pyramid. Next, the base is made up and down from a steel sheet 5 mm thick. A hole must be made in the top sheet for the nut. A hole is made in the bottom sheet for a mechanical bar. It is necessary for the rotation to take place.

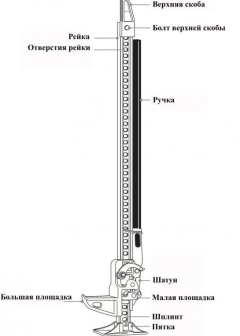

Instrument components

Instrument components

Only those who understand the technique and know how to use the schemes will be able to independently repair the rack jack. Rack types of the device represent a complex design, characterized by large dimensions and heavy weight. This can cause difficulties in carrying out repairs without craftsmen.

For long-term operation of the device, you must follow the rules of its use. In the process, the tool must be cleaned regularly. If the mechanism that works during lifting becomes dirty, it is washed and dried thoroughly. Work must not be performed if the mechanism is not lubricated. This can cause the jack to fail before the end of its service life. For processing, only Teflon grease is taken, it is also suitable from silicone, but not engine oil. It cannot be used as it accumulates dirt. This will cause the device to stop running smoothly.

In harsh driving conditions, off-road, the rack jack is an indispensable tool. Its service life and reliability of operation directly depends on compliance with the rules of use.

Review overview

The opinions of buyers about this modern equipment are very different, but most often users are satisfied with the purchased product, because it is quite specific - its scope implies certain conditions and human skills that not every motorist possesses. The possibility of repair and common spare parts allow you to use the product for a very long time.

Marked by buyers and impressive appearance. When such a "monster" is placed on the spare wheel or on the upper trunk, the car takes on the appearance of an all-terrain vehicle prepared for expeditions, even if there are very few other attachments. The operation of such devices can be dangerous if not handled correctly. This fact scares off some users who are little familiar with these jacks.

A more detailed and visual overview of the operation of High Jack rack jacks is presented in the following video.

Main characteristics

There are several types of Hi-Jacks. They can differ in size, height, rail travel and the ability to lift different weights.

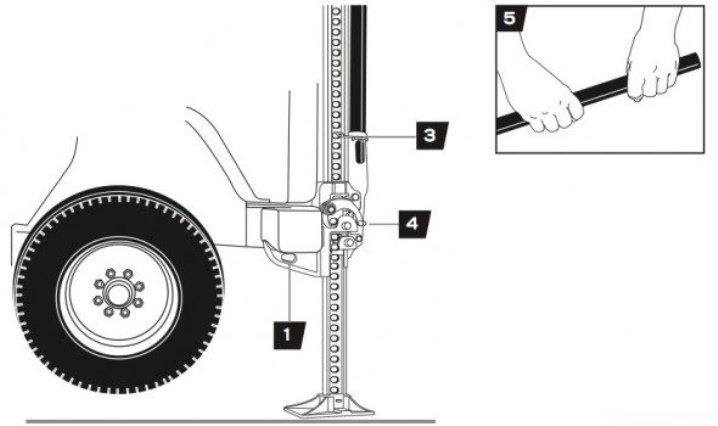

Jack construction:

- perforated ruler;

- lifting mechanism moving up and down;

- handle;

- a shoe protruding in the form of a support;

- rail, cast from durable steel.

Models are available in various colors. For example, black strips are marked with the number 4 and are made by stamping. Red models are marked with the number 5 and are cast in cast iron. The most durable and efficient is the cast-iron jack, that is, red.

On a note!

Among the special devices, the company produces plastic platforms, with which the jack can be used in sand, mud and other types of soil.

The most popular models are designed to lift around three tons of weight. They have the following characteristics:

- Carrying capacity - 3 tons.

- The rail travel is 700-1350 millimeters, depending on the selected model.

- Pickup height - 155 millimeters.

- The height of the bottom pickup is 155 millimeters.

- Weight - 13.3-16.9 kilograms, depending on the stroke length of the rail.

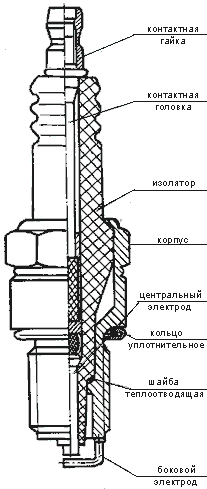

Design features of a rack and pinion jack

Among the large selection of car jacks, rack structures are the most popular. A characteristic feature of the design is the end of the rail, which is bent 90 degrees. Thanks to this, the motorist will be able to easily lift a car with a low seating position.

Rack jack concept

Rack jack concept

The advantage of rack and pinion jacks is that they can move the load both vertically and horizontally. In this case, the lifting and lowering of the load takes place without much effort.

Another distinctive feature of rack and pinion devices is the low pickup. Thanks to this, it is possible to lift the transport, which practically lies on the ground.

But the design also has its drawbacks. The unit, which can lift a load of up to 5 tons, will weigh about 40 kg. In addition, it is uncomfortable and large in size.

Depending on the weight of the cargo, the structures can be single-stage, two-stage and three-stage.

The principle of using the device

The principle of using the device

Possible breakdowns and their elimination

The original hi-jack is considered a very reliable device and rarely breaks. Most often, power failures from poor fastening or increased weight occur. In this case, it is necessary to replace the rail or other broken part.

We recommend using only original spare parts. You can buy cheaper Chinese counterparts, but they will last very little.

The Hi-Jack is a very popular tool among off-road enthusiasts. Due to its quality and reliability, it is a must-have accessory for everyone who regularly makes off-road trips.

How to use

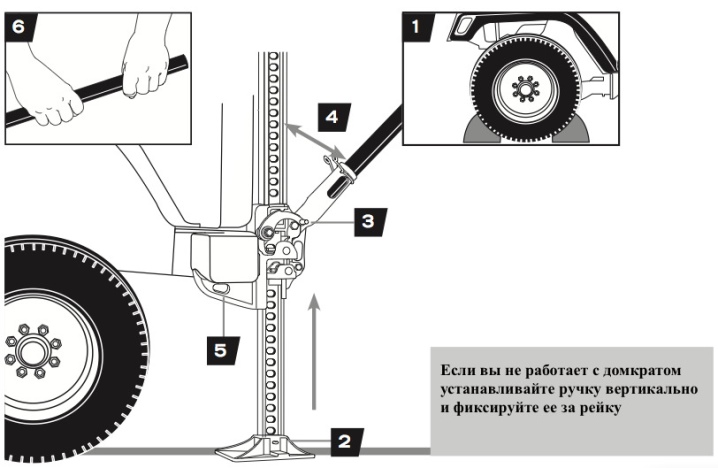

The described type of jack does not have many moving parts. Among them are a movable carriage, on which a lever is located, and a direction switching mechanism. There are only 2 of them: up and down. The mechanism itself is quite tight and switches not with a smooth pull, but with a sharp blow of the hand.

When the mechanism is in the down position and the handle is fixed, the carriage moves freely along the entire rail. If the mechanism is set to the up position, then the carriage works according to the principle of a reverse key and moves with a characteristic crackle only up the rail. This is necessary in order to quickly prepare the jack for work.

Before lifting, the jack must be at the correct angle in relation to the machine. It cannot be placed strictly perpendicular to the ground if a rise to a great height is required. As the machine is raised, the jack will tend to tilt towards the machine and may slip out and damage the vehicle. Therefore, the jack must be tilted slightly in the opposite direction from the machine. When you're done lifting, be sure to fold down the handle.

To lower the machine, the directional mechanism must be switched to the lowering position, while the handle must be locked parallel to the rail. At this moment, all the most interesting and dangerous happens. As you lift the machine, you will gradually increase the force applied to the handle. At the moment of lowering, everything happens exactly the opposite. When the lever is at a 90 degree angle to the rail and the mechanism flips 1 hole, the lever releases energy in reverse order (from higher to lower). That is, at this moment you need to be as careful as possible and ready for the possible jump of the handle out of your hand.

While working, remember that such a jack is a thing that you need to be able to work with in order to maintain your health. You cannot hold on to the rail with an "open grip" with your free hand, that is, so that your thumb is in the path of the bounced handle. The return force of the handle is directly proportional to the load on the heel of the jack.

If the right hand slides off the handle while pressing, it will hit the rail by inertia.If there is a thumb in its path, then there is a high probability of not just a fracture, but complete crushing of the bone. The same goes for the operator's head. It is inadmissible to find the head on the trajectory of the handle bounce.

Views

Now on the market there is more than a wide range of lifting mechanisms. Their list includes, for example, a gear jack. Moreover, all available devices can be divided into two main categories - manual and electric. In turn, each of them, taking into account the design features, has the following types:

- pneumatic;

- screw;

- hydraulic;

- rack and pinion.

In a situation with rack and pinion jacks, wall models deserve special attention. They are able not only to lift and lower the load, but also to move it horizontally. They are often used when manipulating heavy gates or covers of large equipment.

At the moment, one of the industry leaders is the American brand Hi-Lift. There are two types of rack and pinion jacks of this brand on the Russian market. These are devices made of steel and cast iron. They are equally successful in lifting and securing loads up to 1.5 tons.

Hi-jack jacks

The first rack lift of this type was invented at the beginning of the 20th century. Its creator is considered to be the inventor Philip John Harrah. He lived in the United States of America and had his own workshop. It was at that time that the era of automobiles began to flourish, so he worked precisely on special devices for this type of transport.

In 1905, he created the first rack-mounted jack and called it the Automatic Combination Tool. However, among the common people, the first High Jack received the name "Sheep Farmer's Jack". It was connected with the fact that sheep breeders at that time constantly carried wooden fences with them. They just needed to have a jack with them. At different times, the appearance of the device often changed, but the principle of operation with the help of the rail remained unchanged.

Device appearance

Device appearance

After a certain time, the name of the device was changed to Hi Lift, and then it got the current one - the Hijack jack.

Important!

Nowadays, such devices are produced by many different manufacturers.

The jack is especially popular among off-road enthusiasts. With its simplicity of design and ease of use in mud, the Hijack has replaced all other types of devices. In addition, it has great functionality, if necessary, it can replace a vice, various machines and types of hammers.

The official manufacturer is Hi-Lift Co, Ltd. It was founded back in 1895. This is the main company that holds all the rights and licenses for the original hijack. There are many other companies that create similar products, but most often they are fakes from Asian countries, mainly from China.

Original device from Hi-Lift

Original device from Hi-Lift

Official jacks from Hi-Lift Co, Ltd have maximum strength, minimum amount of plastic parts in the form of tips and handles. Designed for pushing, pulling with a hand winch, lifting and pressure generation.

Models from the manufacturer are lightweight and easy to use.

Load levels that the hi-jack jack can withstand:

- rated load is 4,660 lbs, or 2114 kg;

- the ultimate load is 7000 lbs, or 3175 kg.

The company produces a large number of accessories and mounts for the device, with which it is more convenient to move, transport and install.

Model rating

One of the key competitive advantages that sets Hi-Jeck apart from most other jacks is the lift height. However, other characteristics also matter when choosing a particular model of the lift.High-quality reviews and objective ratings, which include the best representatives of the model lines of leading manufacturers, help to understand the wide range of models on the market.

As already noted, the list of the most popular models includes the products of the American company Hi Lift. The rack jacks it produces are better known as the Hi Lift Jack. At the moment, they have found more than widespread use.

Hi Lift 485:

- length - 120 cm;

- weight - 13 kg;

- working lifting height - 99 cm;

- working load capacity - 2,268 kg;

- critical load - 3,175 kg.

Another fairly common model is the Hi Lift Jack 605. It has the following parameters:

- length - 150 cm;

- weight - 14 cm;

- working lifting height - 127 cm;

- working load capacity - 2,268 kg;

- critical load - 3,175 kg.

Another model of jacks on the US market and manufactured in China is the AE&T 48 T41003. The device is capable of lifting loads to a height of 10.5 m and weighs only 13 kg. In addition to these indicators, its main advantages include:

- maximum simplicity and ease of use;

- no slippage of the handle (lever);

- maximum stability provided by a wide support.

The Celestial Empire in this market segment is represented by MATRIX 505155. The model is made of high-quality material that provides adequate strength. The device is capable of lifting loads weighing up to 3 tons and holding them at the desired height. It should be noted that the lower pickup threshold of this jack is 153 mm, and the maximum lifting height is 0.7 m. It is widely used at service stations in the process of repairing cars and even minibuses.

Another representative of the family of Chinese lifting mechanisms that hold leading positions in the current ratings is the SkyWay S-01803005 model. Thanks to the introduction of advanced technologies and innovative solutions, the developers have been able to minimize the time spent on raising and lowering the vehicle and other loads using this rack and pinion jack. Smooth movement in both directions is ensured by a high-quality stepping mechanism. At the same time, the maximum carrying capacity is 3.5 tons.

Inforce 08-08-03 is a professional lifting equipment from a Russian manufacturer. This model has become part of the arsenal of many tire shops and service stations. One of the key competitive advantages in this case will be the maximum service life, even under the most severe operating conditions.