Types, properties and characteristics of a hydraulic jack

The modern market of components and spare parts for cars is distinguished by a variety of hydraulic lifts. Popular device types include the following:

- bottled and movable;

- hook;

- diamond-shaped;

- hybrid.

The bottle lifter has a simple design that allows it to be used in many applications.

With their help, a load is lifted, the mass of which ranges from 2 to 100 tons, and most of the bottle models work in a vertical plane. To activate the mechanism, it is necessary to prepare a support platform with a large plane, and with the help of a two-rod structure, the lifting height is adjusted.

Bottle jack in action

Bottle jack in action

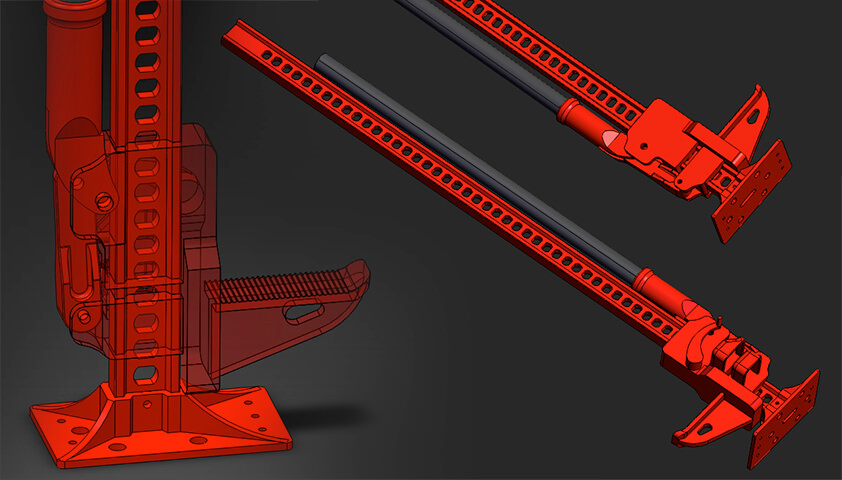

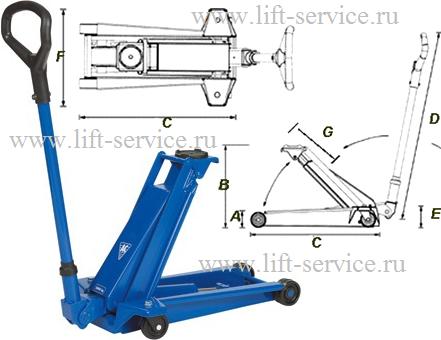

Sliding rack and pinion lifts operating in a horizontal plane have a wheeled cart that should be placed under the object to be lifted. With the help of the translational movements of the lever, it is necessary to pump up the pressure for the stem to exit, as a result of which the arranged toggle switch comes into action. In order to lower the load, you should unscrew the lever back, but it is strictly forbidden to rush, because the car may fall sharply.

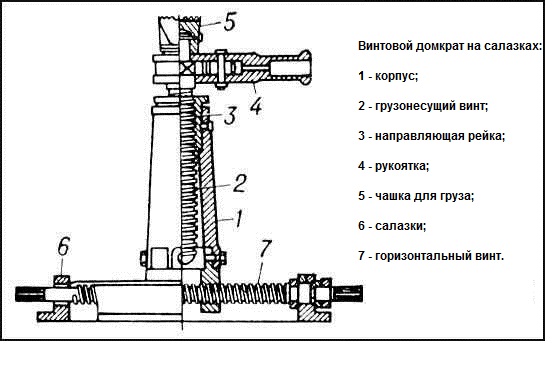

If it is not possible to use a stationary model, you can use a hook jack, which allows you to hook and raise the machine to the required height. But the distance under the load must be at least 15 mm, some hook structures are equipped with step adjustment.

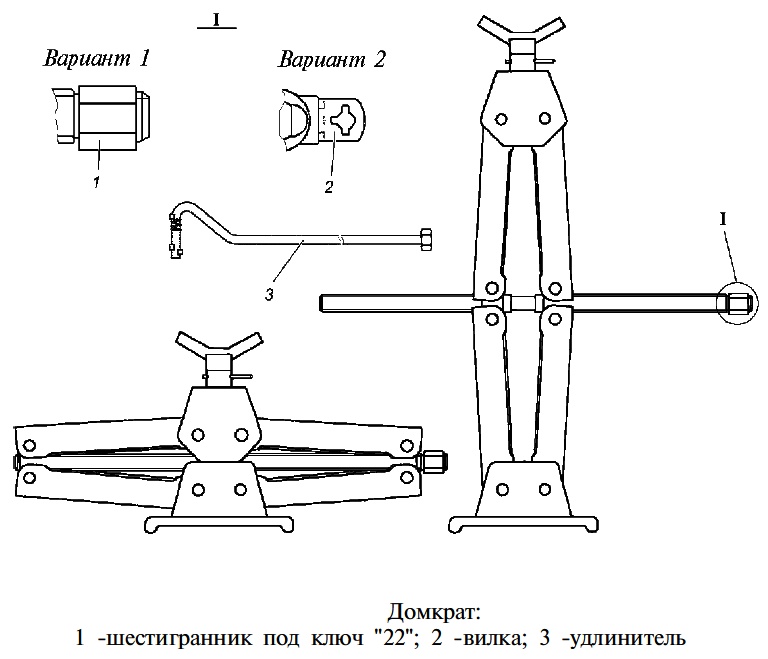

As for the diamond-shaped lifts, they consist of four frame elements, which are interconnected by means of hinges. The process of lifting the vehicle is carried out due to the fact that the angles between the frame elements change.

Hybrid jacks are so named because their design combines a bottle-type and roll-up type of jack. Lifts with two lifting platforms are used in car services where vehicles of various brands, classes and modifications are serviced.

Note!

One of the hybrid lifting platforms must be raised to a height of no more than 375 mm above the floor level, and the other - by 700 mm. The drive is represented by a foot pedal or a lever, and to facilitate the operation of hybrid models, an electromechanical drive is recommended.

Recommendations for use

After the end of use, the jack must be unloaded. Store the device in a warm and dry place. Due to the ingress of excess moisture, the mechanism can rust, and the cold will negatively affect the quality of the oil. It is recommended not to operate the jack in severe frost.

The loads on the device must not exceed those for which it is designed.

With constant use, bleeding (oil change) should be carried out every 2-3 months. With rare use - once every six months.

Thus, in the event of a hydraulic jack breakdown, there are 3 things to check:

- The quality and quantity of the liquid.

- Air bubbles in the system.

- Dirt, loose valves.

In most situations, cleaning and changing the oil is enough to solve all problems with the device.

For lifting weights, man has invented many devices. If you briefly describe the principle of their work - the transformation of the distance traveled into effort.

Let's consider examples of such transformations:

- Lever arm. On the long side, the distance traveled is greater and the effort is less. On the short side, vice versa;

- Block system.The cable, passing through a certain number of blocks, loses distance with each loop, proportionally acquiring additional tractive effort;

- Gears with different gear ratios. The small gear turns quickly and with less effort. Big is the opposite;

- Chain (belt) pair. The smaller pulley rotates effortlessly and faster. A larger diameter pulley develops a high torque on the shaft at a lower rotational speed;

- Communicating vessels. Two piston pairs, connected to each other, work on the principle of a lever. A piston of a smaller diameter moves with a large swing at low effort. While its larger "brother" moves a short distance with a proportionally increased effort.

A hydraulic jack works on the principle of communicating vessels.

The relatively compact size (in comparison with the force that the tool can develop) makes it indispensable when working with large weights. Portable bottle jacks (this is their second name) develop forces from 1 to 20 tons. Larger specimens can weigh up to 200 tons.

In this case, it is hydraulics that is one of the safest devices for lifting heavy weights.

How does it work?

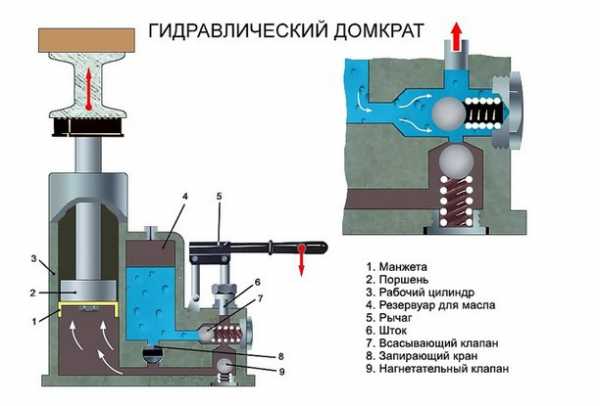

The principle of operation of most lifts can be explained by the example of hydraulic models. Their functioning is based on Pascal's law and the principle of communicating vessels. At the same time, all existing samples of mechanisms have a common property - this is the obligatory use of a lever (handle) in one form or another. The main distinguishing feature of most modern jacks is mobility.

It is also important to consider the absence of assistive devices. Today jacks are most commonly used in the following areas

- Construction. Lifting of blocks and structural elements, as well as their fixation. Special attention should be paid to lifting systems for the installation of drywall and other sheet materials. There are also tensor jacks designed for screwing with a certain force of connections under load.

- When repairing vehicles of varying complexity - from changing a wheel on the way to performing more complex work in the conditions of car services and tire shops.

- As a lifting device when it is required to move and mount various dimensional parts or equipment on supports.

Description

Each type of hydraulic jacks, including bottle jacks, assumes certain features of the device. However, they all, regardless of type and model, have the same rod lifting mechanism.

The list of the main elements of such devices includes the following elements.

- Lever that plays a key role when pumping working fluid (oil) between reservoirs inside the lift.

- A plunger that moves parallel to the arm. In this case, in the process of moving upwards, the liquid is collected from one container, and when descending, it is pushed into another. In this way, the necessary pressure is created under the jack rod.

- The piston, which is the base of the rod, which is as close as possible to the inner surface of the hydraulic cylinder and is driven by the increasing pressure of the working fluid.

- The rod, which is the final structural element, abuts directly against the load and moves with the piston.

- Reverse-acting valves (2 pcs.), Due to which the oil moves from one cylinder to another and does not flow back. So, one of these devices opens when a vacuum is formed, and closes as soon as pressure is created. In parallel, the second valve functions in reverse.

- The bypass valve is an important element of the mechanism, which is responsible for normalizing the working pressure. Its function is to open a flap located between two oil tanks. Due to the actuation of this valve, the stem is lowered under load.

Taking into account all the technical characteristics, performance indicators and design nuances, bottle jacks can be called the simplest. This is primarily due to the lack of additional devices and mechanisms.

Model overview

Speaking about the best small jack constructions, it is worth paying attention to the DN30P14 model. Low load mechanism is made according to one-sided scheme

The stem return is provided by a special spring. Its stroke reaches 1.4 cm. The maximum carrying capacity of a device made in Russia is 30,000 kg.

Other technical parameters:

- pickup at a height of 58 mm;

- oil tank capacity - 0.58 l;

- own weight - 3.94 kg.

The device is suitable for use in confined spaces. It can be used when leveling bridge spans. The highest hydraulic pressure is 70 MPa. Permissible temperatures are not lower than -15 and not higher than +50 degrees. The jack is coated with durable powder paint.

It is useful to take a closer look at the high, long lifts. For example, to the Ulyanovsk URD-01_1t model. It is a decent quality reliable device for field work with a car. Wherever problems arise, repairs are greatly simplified. The highest lifting capacity is 1 ton, and the highest lifting height is 0.41 m.

When choosing vertical jacks according to their characteristics, it is worth taking a closer look at the KRAFTOOL KRAF-43463-4 modification. The two-rod mechanism has a bottle design. It lifts up to 4000 kg of cargo. The smallest grip height is 0.17 m. The load will be lifted to 0.42 m.

Models on wheels deservedly fall into the rating of the best jacks. For example, the 3T Gigant HTJ-3. It is equipped with a support serrated bowl, therefore the load is securely fixed, breakdown is completely excluded

Important: the manufacturer recommends using its design in conjunction with a safety stand to reduce the risk of injury. Special coating reduces the risk of corrosion

Other features:

- pickup at a height of 0.135 m;

- lifting to a height of 0.4 m;

- total weight - 16.7 kg;

- total lifting capacity - 3000 kg;

- the handle for turning and the case are missing.

It is worth thinking about buying branded Chinese jacks model "Sorokin FrogLine Jack 3.432". The total load reaches 3500 kg. The model can be used in tire centers and various service stations. Net weight - 38 kg. The pickup takes place at a height of 0.135 m, and the rise goes up to a height of 0.495 m.

You can also consider JET 8.0 t JBJ-8 JE655558. This bottle jack is used both horizontally and even upside down. It will lift up to 8000 kg of cargo. The stroke of the rod reaches 0.125 m. The mass of the jack is 6 kg.

Also good hydraulic devices include:

- Ombra OHT150;

- Stels 51133 Quick Lift;

- Matrix Master 51035;

- Kraft KT 800115.

What kind of work does the bottle jack device allow?

Jack characteristics table.

The sphere of application of bottle jacks is the car service associated with the maintenance and repair of cars. The bottle-type jack is widely used in the railway industry, since it allows the repair of railway trains.

The hydraulic jack is used as a power unit for presses, pipe benders or pipe cutters. If, after inspecting the mechanism, it can be concluded that the device is working properly, then work should be started. In combination with a large carrying capacity, the compact size of the tool allows it to be used in garages and workshops. The device can be transported in the trunk of a car, which allows for the replacement of punctured wheels if necessary.

The bottle jack mechanism is reliable. Hydraulic jacks are used in the car repair process, which must be lifted and fixed at the desired height. For example, the mechanism allows you to remove a car wheel for its subsequent balancing using special equipment.

It is convenient to transport it, which is carried out exclusively in a vertical position, since oil in the horizontal position of the tool is capable of flowing out. In general, its service life is determined by the number of gaskets and oil seals in its device.

Bottle type hydraulic jack design and features

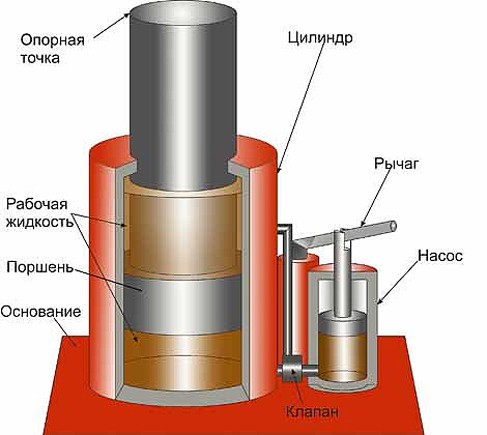

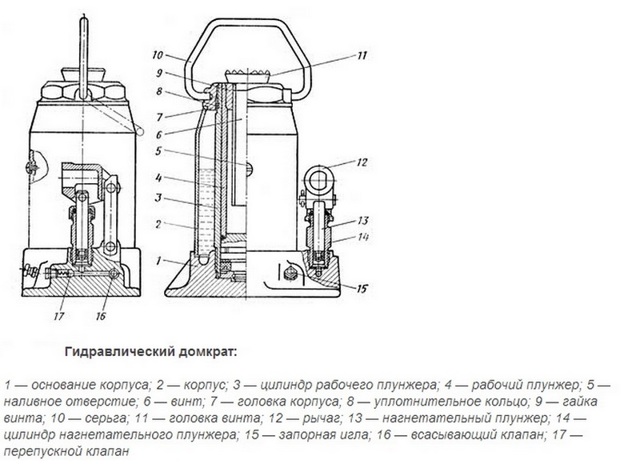

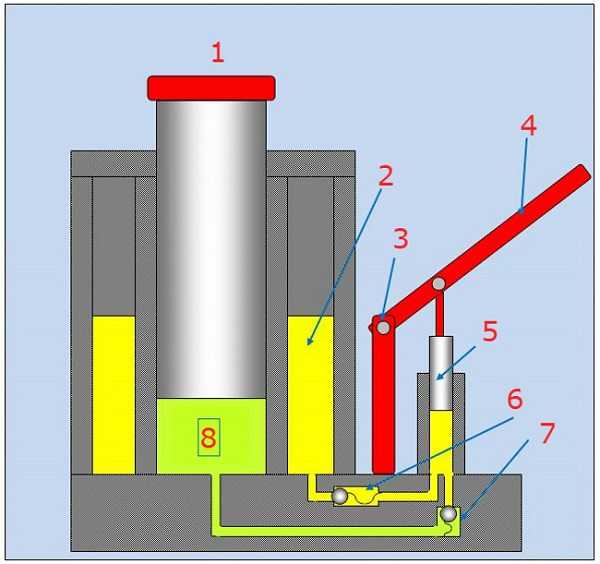

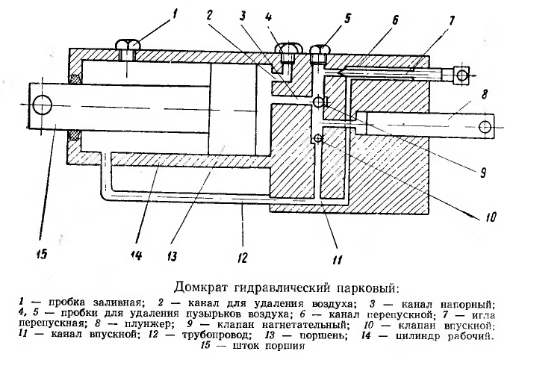

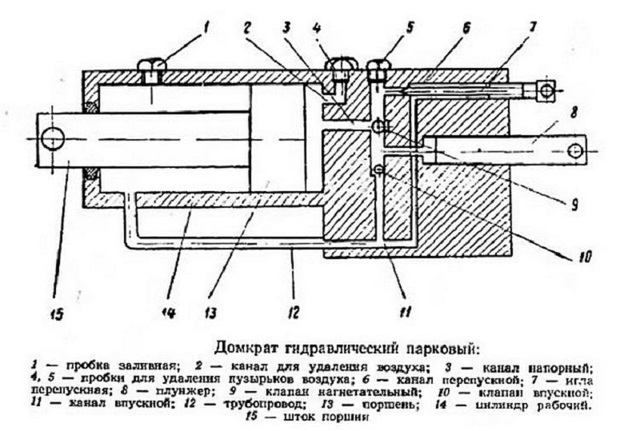

Bottle jack device.

The bottle jack device is shown in the figure. Each element that makes up the structure corresponds to a certain number, implying the presence in the mechanism:

The suction valve is located on the tank nozzle. This should prevent fluid from returning to the reservoir if the pump plunger is lowered. The position of the discharge valve refers to the cylinder nozzle, which prevents the hydraulic fluid from leaving the cylinder when the pump plunger is lifted.

The valve is opened with a special screw that allows pressure relief in the device. Then the load is lowered to the ground. In general, this design is time-tested.

The connection of the bottle jack to the pump or pumping station is carried out due to the presence of a coupling half, which is a quick disconnect. It eliminates fluid loss due to disconnection of the tool from the pressure source. The main structural elements are:

The bottle jack quick-release coupling eliminates fluid loss as a result of the tool being disconnected from the pressure source.

- Frame.

- Extendable plunger (piston).

- Working fluid (hydraulic oil).

The body serves as a guide cylinder for the plunger and at the same time a special reservoir for the working fluid. If the jack has a lifting capacity of up to 20 tons, then the location of its lifting foot is marked in the part of the screw that is screwed into the plunger. Therefore, the initial height of the mechanism can be increased by loosening the screw.

The plunger must pump oil from one common reservoir to another under the piston. When oil appears under the piston, it should move. The oil is no longer returned to the general reservoir due to the actuation of the valve. As the plunger operates, more and more oil flows into the reservoir under the piston from the common reservoir.

An integral part of a bottle jack is a liquid, which has the characteristic of an incompressible working material. This allows you to smoothly lower and raise the load, as well as fix it at a certain height, ensuring accuracy when braking.

Spindle oil allows you to smoothly lower and raise the load, as well as fix it at a certain height.

The speed of the lowering of the load can be controlled by the hole required for the outflow of a special liquid coming from the cylinder, which can have a different composition. It is possible to use antifreeze mixtures, which include the following components:

- Alcohol.

- Water.

- Technical glycerin.

- Spindle oil.

Spindle oil solidifies at temperatures below 35 ° C. When choosing a bottle jack, lift and pickup heights are taken into account, not just lifting capacity. The lifting capacity may be sufficient to lift the vehicle and the stroke will be low. This requires control over the level of hydraulic fluid, oil seals and their tightness.

Possible breakdowns, and how to repair them yourself

Any equipment begins to fail over time and require special maintenance. The first thing that is needed for a hydraulic type jack is periodic inspections of the mechanism's operation and oil topping. Also, after a certain interval, it will be necessary to flush it and completely change the oil.

The most common reason for the breakdown of such a device is the failure of oil seals and gaskets. This leads to oil leakage from the working tank. Also, stem sticking may occur on return. It can be prevented by correcting the problem the first time an oil leak is detected. This requires draining the oil, disassembling the mechanism and replacing the seals with oil seals and refilling with fresh oil.When everything is ready, the fluid is pumped through the assembled device.

Sometimes just accumulated dirt or corrosion can wedge the stem, which helps to disassemble and flush the device, as well as special anti-corrosion treatment.

Repair kit for jack

Other breakdowns occur if the device was operated incorrectly, then the following may occur:

- Extend the piston jerkily or slowly. This indicates that air has entered the working compartment and it is necessary to add oil and carry out pumping.

- Decrease in pressure on the piston. Most often, the problem lies in the intake valve, which may require repair or replacement.

- Lift piston stop. This phenomenon with a rolling jack is associated with a clogged filter or the fact that the oil has run out.

- The piston stops rising altogether. Often the problem is that there is no liquid in the reserve tank.

Most jack breakdowns can be repaired after disassembly. However, if the problem appeared due to mechanical damage to the piston or something happened to the outer casing, then it is recommended to replace the device.

Important!

If the jack is broken, you need to read the instructions, which must be attached to each device. It contains a diagram, the necessary information on operation and maintenance periods .. It is necessary to ensure that the device is not constantly in overload mode, that is, when selecting a jack for working with a machine, it is necessary to select such that its carrying capacity has several tons in stock

If the jack is subjected to emergency loads and is not inspected from time to time for a lack of oil, then a whole tape of breakdowns will not be long in coming

It is necessary to ensure that the device is not constantly in overload mode, that is, when selecting a jack for working with a machine, it is necessary to select such that its carrying capacity has several tons in stock. If the jack is subjected to emergency loads and is not inspected from time to time for a lack of oil, then a whole tape of breakdowns will not be long in coming.

Advantages of rolling jacks for cars:

- Compared to other types of jacks, there are models with very high lifting capacities.

- As a rule, such devices are equipped with a reliable fixation and there is no need to be afraid of a breakdown.

- The construction is very stable and comfortable.

- Man spends little effort.

However, it should be noted that such a device has 2 drawbacks: the need for a flat surface, which is not always the case in case of a breakdown on the road, and oil freezing when operating in low temperatures.

In all other respects, rolling jacks are very practical. They save the efforts of drivers and foremen. In addition, a wide variety of models allows you to choose exactly the device that is most suitable for working with a particular vehicle or for service in a service station.

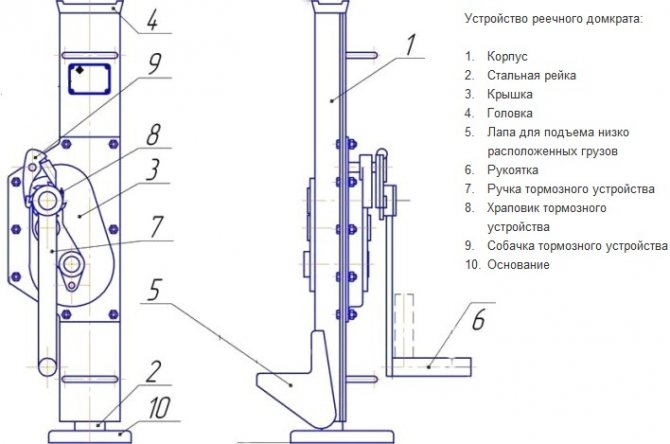

Jack device

The principle of operation is the same for all hydraulic jacks.

- Turntable, abutting against the bottom.

- Hydraulic cylinder rod. Due to the reciprocating movement and through the system of power levers, it controls the lifting of the thrust platform.

- The main cylinder of the hydraulic system. The main power unit.

- Lever or handle. Has the ability to rotate 360 °. Serves as a pump lever for moving the working fluid into the reservoir of the hydraulic cylinder. In addition, it can perform a control function - turn on / off the pressure valve or drain valve. Usually, for ease of use and storage, the handle is removable.

- Plunger. Serves as a pump.

- Drain valve control screw. Allows the vehicle to be lowered by relieving pressure in the system.

- A spring that creates a force to return the jack piston to its original position when the pressure in the system decreases.

- Removable transport handle.On some jacks, it may be absent or stationary.

- Hydraulic repair kit. Required set of seals for service.

- Cover that protects the main cylinder rod from dust and dirt.

- Metal wheels.

- Leverage.

- Frame. It can be made of steel and aluminum. Professional sliding jacks are distinguished by more massive and sturdy bodies, which is associated with more intensive use.

Car hydraulic trolley jack works on liquid. The principle of operation is based on the movement of the piston. The pressure required to lift the load is created by pumping the working fluid into the working cylinder by means of a plunger. The plunger is driven by a long lever. The cylinder is located horizontally and is connected through a system of levers with a thrust platform. The presence of valves and the use of communicating chambers greatly increases the force that is applied to the lever. The appearance of oil in the piston cavity causes it to move, extending the rod. To prevent the oil from going back, a shut-off valve is used that closes the outflow.

Lowering the platform is carried out by turning the screw, which opens a special valve. As a result of the pressure release, liquid is released from the working cavity, the load is lowered to the required height.

The trolley mechanisms are small in height, but have very high stability. They acquired this quality thanks to the large platform, which serves as a support, and also gives strength to the structure itself.

There is also a shut-off valve in the jack device, the purpose of which is to fix the load during lifting.

For greater reliability and safety, you can use a trolley jack with a lock. The locking pawl allows you to keep the weight at the required height without unnecessary effort.