Drill marking

To drill a stainless steel, you need to use a special tool. Any drills, including those for stainless steel, have a specific marking. It indicates the specifications, material and size of the tooling.

Basic designations:

- The letter "M" - indicates the presence of molybdenum in the composition of the product. Its percentage is indicated by the number following this letter.

- Letter "R" - tooling is made of high-speed steel. The percentage of tungsten is indicated by a number.

- The letter "K" - indicates the presence of cobalt in the alloy composition. Its quantity is indicated by a number.

Foreign manufacturers make HSS marking, which contains information about alloying components, their quantity:

- HSS-TiN - During production, a titanium coating is applied to the surface of the tooling. Due to this, the indicator of strength and wear resistance increases. Specifications do not change when heated to 600 degrees Celsius.

- HSS-E - contains cobalt.

- HSS-E VAP - special drill bits designed for drilling in stainless steel of various thicknesses.

- HSS-R - Gimbals with increased strength. It is used for drilling bronze, cast iron, brass, cupronickel.

- HSS-4241 is a tool for working with aluminum blanks.

Selection principles

When choosing, you need to consider:

- product color;

- the purpose of the equipment;

- sharpening quality;

- symmetry of the incisors;

- tooling material, type of protective coating.

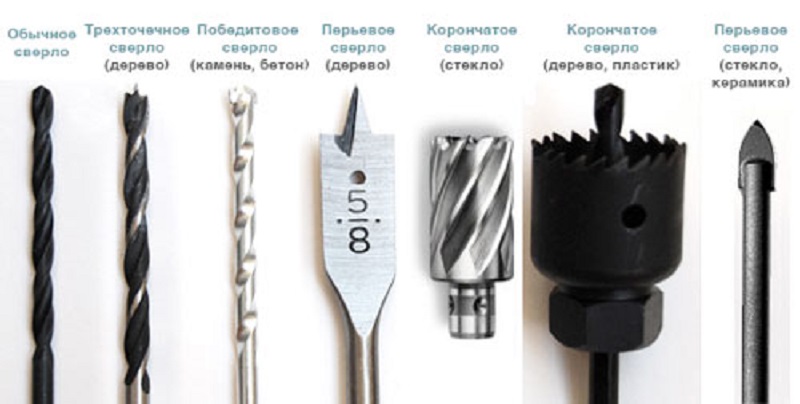

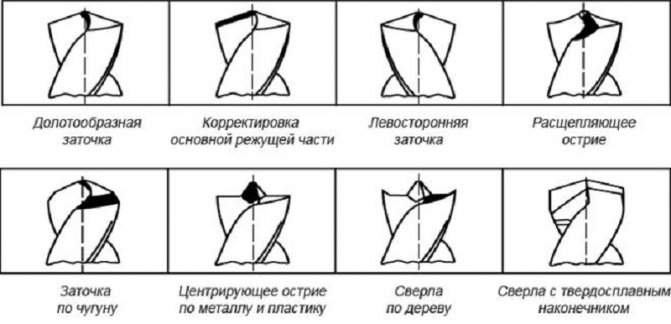

Drills of various types (Photo: Instagram / koleso_ast)

Advantages and disadvantages

Advantages:

- the ability to perform various technological operations;

- strength, reliability, durability;

- low price.

Manufacturers and prices

Manufacturers:

- Bosch;

- Haisser;

- Ruko.

Drill bits with the designation of the USSR are considered the most reliable and durable. The price of a classic drill with HSS marking is 500 rubles.

Drill brand Bosch (Photo: Instagram / sergei.wood_man)

Drill classification

To date, there is more than one classification of this cutting almost any surface of the tool.

Depending on the design of its working part, it is possible to distinguish: spiral types of drills for wood, centering, as well as flat and even drills of exclusively one-sided cutting, and used only for deep drilling.

If you look at the photo of drills on wood, paying attention precisely to the design of their tail, then the following types can be distinguished:

- conical;

- cylindrical;

- 3,4,6-sided;

- SDS drills.

Also, all tools can be conditionally divided into several groups, based on the type of material that they can handle. So, these are long drills for wood, as well as drills for hard concrete, glass, high quality metal, stone with ceramics, as well as universal tools.

Species overview

Long drills can vary considerably in shank design. There are devices with cylindrical and tapered shanks... The first are thin cylindrical metal rods. Four grooves are placed on their surface (2 screw and 2 spiral) - they are needed for cutting material and removing chips.

Cylinder drills are used for drilling steel, wood and non-ferrous metals. They can be left-handed or right-handed, but the first option is more common. According to GOST, these devices are manufactured with a centering recess, but some of them can be manufactured without it.

Cylindrical drills are sometimes made with a small neck to facilitate grinding.The total length of these drills can be up to 320 mm.

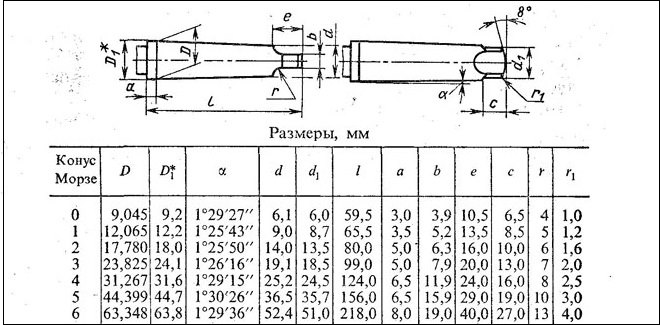

Tapered shank models are considered to be the preferred choice among professionals. They fit securely into the drill chuck while providing the most accurate centering during operation.

The tapered shank type avoids burrs and irregularities in the material when drilling. The upper part is completely smooth at the end, the walls of the drilled holes will also be smooth.

The conical type devices have the most convenient design, which allows, if necessary, to replace them with a new model. Such tools are used for drilling metal. But they can work with wood or plastic.

Using these drills, you can make holes of different diameters in alloy or carbon steel, cast iron, sintered alloys, non-ferrous metals. The fastening of the drill itself with a tapered shank is carried out thanks to the adapter sleeve. Fixtures of this shape are manufactured with a spiral working part.

There are several types of long drills for metal, which differ in strength, the fixing part to the equipment, the cutting part and the working surface for chip removal.

Next, we will consider the most common models of extended nozzles in more detail.

-

A ground version for metal with a tapered shank. This type is suitable for working with products made of building and structural metal or cast iron. The drills are made of high speed steel HSS and have a sharpening angle of 118º.

-

Cutters made of a quick cut have an admixture of cobalt, and are covered with a titanium-nitrite layer on top. They are used in work with steel parts with the highest strength (900 N / mm²).

-

Extra-long and long metal elements. They are equipped with cylindrical shanks and have a reinforced stem. For efficient chip removal, a parabola-shaped spiral groove is made in this version. This type of drill is characterized by increased rigidity.

-

Long or extra long pointed spiral nozzle. Has a taper shank. This option is used for drilling holes with both large and small diameters.

-

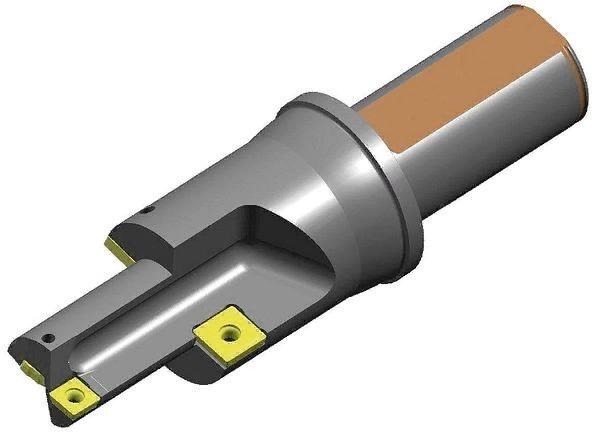

Drills for drilling hollow parts. They have a small cutting part.

-

A device for drilling holes in hard alloys. They have an angle of sharpening of the cutting part of 135 ° and a shank in the form of a cone.

Extra long drills can be divided into several separate groups depending on the structure of the working parts.

-

Pen drills for metal stand out. Such models are used for drilling deep holes of large diameter. They are equipped with centering sharpened tips. They also look like a small flat shoulder blade.

-

Core drills are of particular importance. These models can also be suitable for creating large diameter holes (it can be up to 150 mm). They are used to work on milling and drilling machines. The devices first cut out the contour of the future hole, and then they make the recess itself on the surface.

-

There are models with a cone-shaped working part. These attachments are used for drilling non-ferrous metals or steel. But they process metal sheets of small thickness, which should be less than 10 mm. They can be made as standard, or they can have a stepped design. The latter facilitate further processing of the metal.

Models with a tapered tip allow you to make indentations of different diameters. This will not require regular change of the drill in the chuck. These tools are perfectly centered.

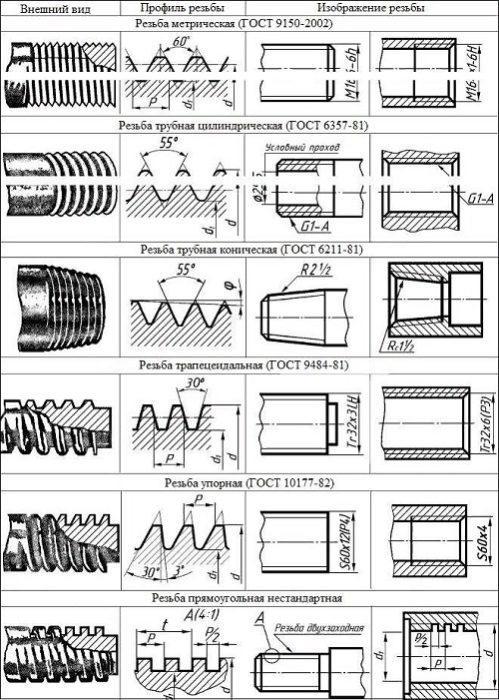

How to understand the labeling

Marking helps to choose the right tool for drilling products made of metal. It is not difficult to understand it.The marking of drills, depending on their working diameter, contains the following information about the presented tool.

- On miniature products, the diameter of which does not exceed 2 mm, no marking is applied at all.

- The marking of drills, the diameter of which is in the range of 2-3 mm, contains information about the grade of steel from which they are made, as well as about the size of their cross-section.

- The marking of drills for metal with a diameter of 3 mm or more contains the following data: working diameter, steel grade, imprint of the manufacturer's logo.

So, the letter "P" in the marking of drills for metal means that they are made of high-speed steel. The composition of steel alloys used in the manufacture of drills for metal work may contain additional substances that improve their performance. Such substances, in particular, can be molybdenum, which is indicated by the letter "M", and cobalt, indicated in the marking by the letter "K".

Drill markings are applied to the shank of the product

Foreign manufacturers include more detailed information about the presented instrument in the labeling. Having decided to purchase such drills, you will receive the following data from their marking:

- name of the country of origin;

- manufacturer's trademark;

- steel alloy grade;

- working diameter of the tool;

- accuracy class;

- short recommendations on materials that such a tool can handle.

Popular brands of tools from foreign manufacturers

In order to know, when choosing drills of foreign production, which ones are better suited for solving certain technological problems, it is enough to have an idea of the material to be processed with their help. So, foreign manufacturers give the following recommendations for choosing a tool with a specific marking.

HSS-R and HSS-G

It is recommended to drill with tools with such markings:

- steel parts made by simple casting and injection molding; products made of carbon and, the strength of which does not exceed 900 N / mm2;

- products from metal alloys containing aluminum, graphite, copper, nickel, zinc (bronze, brass, cupronickel, etc.);

- billets from gray and ductile iron.

Drill geometry HSS-R and HSS-G

HSS-G Co 5

Drills with this marking can be used for processing metals, the strength of which reaches 1100 N / mm2. Such metals, in particular, can be the following steels:

- carbonaceous;

- stainless;

- thermally improved;

- acid-, heat- and heat-resistant;

- alloyed.

Self-centering ground drill HSS-G 5% for drilling in hard metals

HSS-G TiAN / TiN

If there is such a designation on drills for metal, it means that titanium-aluminum-nitride spraying is applied to their working part. Such a coating significantly increases the resistance of drills not only to corrosion, but also to wear, which contributes to an increase in their service life. Tools with such markings can also be used for processing metals and alloys with strengths up to 1100 N / mm2. Manufacturers recommend using the following types of drills for processing:

- malleable and gray cast iron, in the structure of which graphite inclusions have a spherical shape;

- copper-based alloys (brass, bronze, cupronickel);

- steel billets obtained by casting (including injection molding).

Classification

You can find different types of drills on sale. They are classified depending on color, material, type of shank, type of coating, accuracy class.

By color

A faded yellow tint appears after a vacation in production. Additional processing increases the durability and strength of the tooling.

The bright yellow equipment is distinguished by its durability and wear resistance. It has a low friction rate. The tooling has a titanium coating, which provides it with increased strength.

Black color indicates additional steam treatment. It is a robust rig with a long service life. The cost is not very high.

The lowest quality drills, which have not been subjected to additional processing, are gray. Such equipment has a low price, but it will not be possible to save money, since the drills quickly break.

By material

Drills are made from different types of steel:

- carbon tooling;

- alloyed instrumental;

- high-speed.

Additionally, carbide plates are fixed on the cutting parts.

Steel drills (Photo: Instagram / linkorspb)

By form

Views:

- Stepped, tapered. They are also called gimbals. The working part has a conical shape. Designed for drilling holes of different diameters in metal sheets up to 2 mm thick.

- Centering. Multifunctional drill bits that are needed to create special holes in metal workpieces. Parts are fixed in drilling equipment.

- Elongated. Used to create blind, through holes.

- First. Tool with replaceable inserts. It can be used to make large diameter holes with smooth walls.

- Crowned. Hollow crowns that have many sharp teeth at the edges. Suitable for drilling holes in thin metal sheets up to 30 mm in diameter.

- Threaded. They are used for cutting threads in pre-prepared holes.

- High precision. With their help, you can perform precise technological operations.

- Left-handed. Equipment for highly specialized purposes, which is needed to drill out damaged equipment from holes.

The most common type of drills for metal is spiral. Designed for drilling holes of different depths and diameters.

Conical drills (Photo: Instagram / dismart_kh)

By type of shanks

Shank types:

- Conical. The accessories are designed for high power, professional drills or industrial drilling machines.

- Cylindrical. Suitable for power tools.

- Hexagonal. Used for clamping in jaw chucks, clamps.

By type of coverage

Drills can be applied:

- titanium aluminum nitride;

- titanium carbonitride;

- diamond chips;

- titanium nitride ceramic coating;

- oxide film.

The latter type of coverage is the most affordable and reliable.

Cobalt drills (Photo: Instagram / vmiha80)

Accuracy class

Accuracy class:

- Normal accuracy with marking B. Designed for drilling holes in terms of accuracy up to grade 15.

- Normal accuracy with marking B Designed for drilling holes up to accuracy class 14.

- Equipment of increased accuracy with A1 marking. Suitable for making holes in accuracy from 10 to 13 accuracy classes.

Differences in the work of an extra-long drill from a conventional one

Extra-long metal cutters are subject to more heat than ordinary cutters. This is due to the large area of contact of the tool with the channel walls and poor heat transfer due to the closed space. Therefore, it is necessary to organize forced cooling during drilling.

An elongated drill has an increased bending strength, but if you drill continuously, passing the channel at a time, then the probability of breakage of the drill due to metal shavings formed in the channel is very high

It is important to remove these chips from time to time by returning the tool back.

Fast and continuous feed of the cutter can also destroy the tool, so you need to go forward with short feeds.

An extra-long drill for metal is difficult to work with a conventional electric drill: it is impossible to perfectly hold the tool perfectly straight. The hole may turn out to be of poor quality, parallelism will not be respected, the probability of breaking the rig is high

All this can be avoided by drilling with a special machine.

To drill hard alloys, it is necessary to work at low shaft speeds.This will prevent the cutting edge from overheating and becoming damaged.

Sharpening of cutters for metal must be performed on special equipment, strictly observing the angle. It's better to use a template for this.

What the color of the drill can tell you

In addition to the markings indicating the composition of the steel and impurities, you need to understand what the color of the drill indicates. This will tell you what additional processing the metal has gone through and how this will affect the characteristics of the tooling. Here are the common colors.

Steel gray

These are the simplest drills without additional coating. If left in a humid environment for a long time, they will rust. During drilling, do not apply excessive pressure on the tool, otherwise the rod may break.

Golden hue

This color indicates hardened. The processing makes the outer part very strong, but increases the inner fragility. Drills keep sharpening for a long time, but tend to break. Periodic re-hardening is required to prolong their service life.

Golden bright color

These drills are immediately visible on the counter with their vibrant color. The effect is provided by surface treatment with titanium. The coating reduces frictional wear and promotes long service life. The drills are of the high-strength class and cost accordingly.

Black color

The steel is steam treated. An inexpensive way to increase external strength while avoiding internal fragility. Drills hold sharpening better and last longer than gray drills.

Characteristics

The technical parameters of the drills produced depend on the color:

Black - indicates increased wear resistance of the product;

A drill with a light golden hue means that the cutting tool does not have increased fragility; it is tempered during manufacture in order to relieve internal stress;

Bright golden - the ability to reduce friction during operation, the products are distinguished by good strength;

Gray - the tool is designed for a short service life, the cheapest, low quality.

Having memorized the color of the drill, we pay attention to the diameter of the working edge, which determines its marking. Small tools (up to two millimeters) are not marked

The letter "P" - the very first letter, means that high-speed steel was used in the manufacture of the drill.

All technical data about the drill can be read on its shank:

- What is the diameter;

- Learn about the hardness of steel;

- What are the alloying elements in the alloy;

- Understand the technology, the manufacturer.

As mentioned, there is no marking on small diameter drills!

The most expensive, durable tool is cobalt. Also, drills with the USSR marking are most appreciated.