The device, principle of operation and application of the circular saw

At first glance, the device of a circular saw is as simple as possible - a powerful motor, on the shaft of which a cutting metal disc is put on. In the case of stationary tools, the engine can be located separately and transmit force to the working shaft by a belt through a system of pulleys, but hand tools, which are the vast majority of household tools, are made in one housing.

The complexity of the device is added by the need to use high-quality materials, strict observance of the centering of parts, plus withstanding serious security measures. The saw blade rotates at high speeds, so neglecting any of the above points will at best lead to tool breakage.

As a result, an impressive number of mechanical-electronic protective and blocking devices are added to the engine and the cut-off wheel, the purpose of which is to instantly stop and de-energize the tool if something goes wrong.

The principle of operation of a circular saw is clear from its design - a rotating disc with teeth cuts the board along which the tool itself is pulled. In the case of a stationary saw, everything happens the other way around - the board is pulled through a circle fixed on the bed and divided into two parts.

There is one important note to the use of a circular saw - it is not suitable for curly cutting and is intended to saw boards and other materials only in a straight line. There are models with an additional graduation of the leading sole, which allows the disc to be set not strictly perpendicular to the surface being cut, but at a certain angle, but the saw is also carried out strictly in a straight line

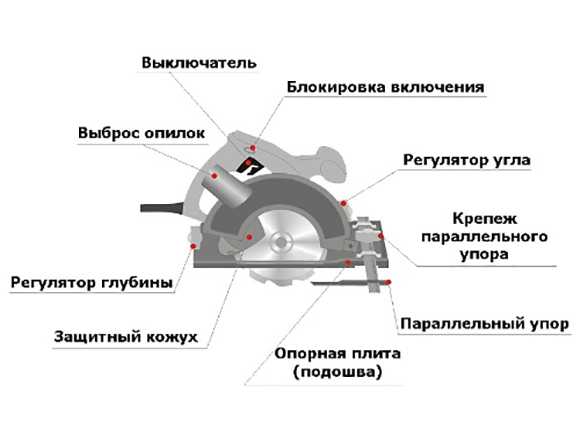

1. Upper main protective cover. 2. Power button 3. Switch-on lock button 4. Laser switch on button.

5. Support handle. 6. Body with motor. 7. Laser pointer 8. Cutting angle adjustment.

9. Saw blade. 10. Lower loaded casing 11. Support outsole.

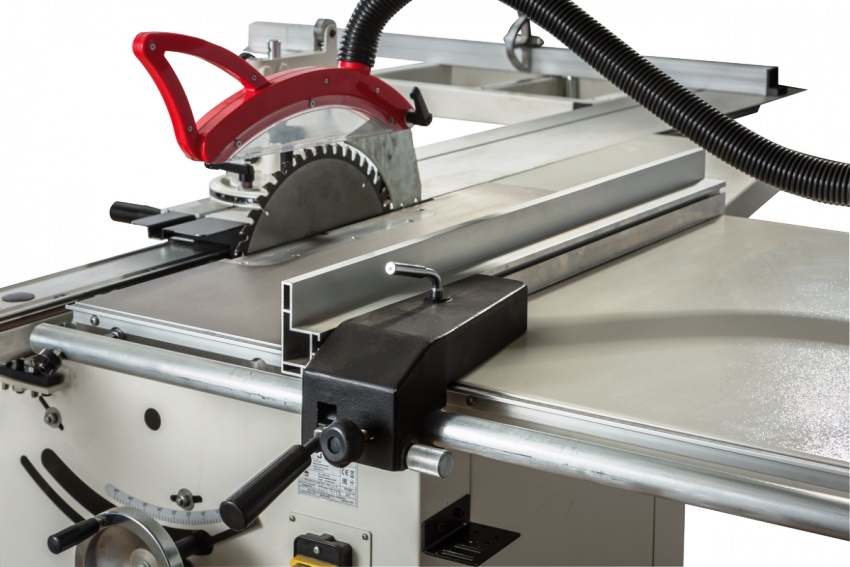

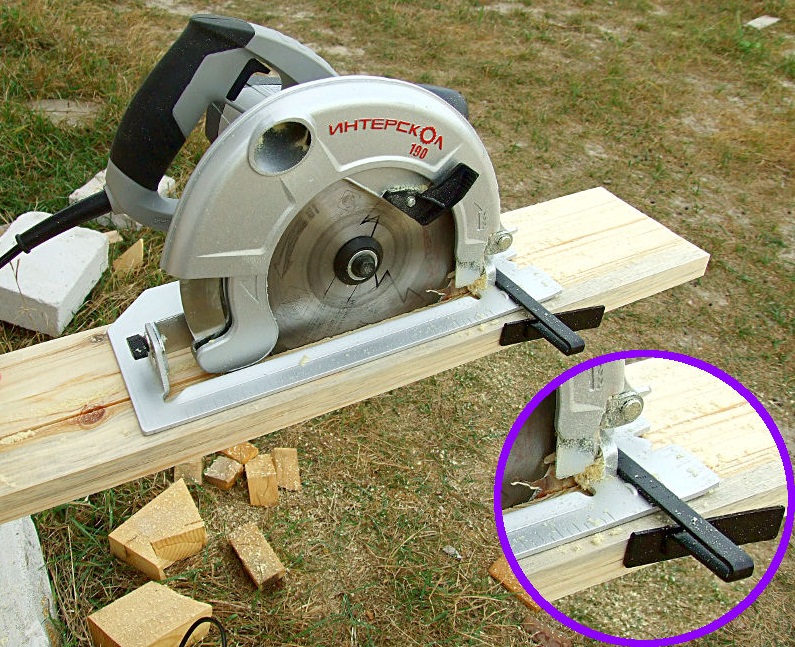

Homemade emphasis for circulars. Make A Table Saw Fence.

Step 3: Assembling the Stop - Part 1

What is needed, the circular and the parallel stop now have a guide channel. We unite our client remains together, with the help of a small piece of MDF in the shape of an inverted letter "T", it will be screwed on the back of the stop and inserted into the guide channel. The width of the channel directly depends on the thickness of the T-shaped MDF blank, which will ensure a tight placement of the T-shape in the channel.

Step 4: Assembling the Stop - Part 5

Align the stop position using an iron ruler, this will ensure that the stop is parallel to the saw blade. Connect, firmly, together the stop and the T-shaped mounting piece. Working with emphasis, I realized that hardwood is better than MDF, changing the T-shape from MDF took almost one minute. Any discrepancy in the ready-made settings will lead to changes in the general options, be prepared for this.

Read:

Step 5: Stop locking mechanism.

In fixing the stop, slots for an unusual stop are used. The locking mechanism is simple: a threaded bolt and a nut, a hole in either the upper strip of the parallel stop, a wooden washer. By tightening the bolt, the block pulls the stop down towards the tabletop and clamps very tightly.

Step 6: Conclusion.

The prize for the most beautiful project does not pull the emphasis, alas, it was made from waste wood and laminate, the entrance went and even bolts and nuts that were not used from industrial devices.Now the change in the size of the cuts is fast and much easier compared to the original stop system. I use the resulting niches in the “pockets” to store pencils, tape measure, ruler and other suitable tools, as the proverb says, they are “always at hand”.

Parts and accessories

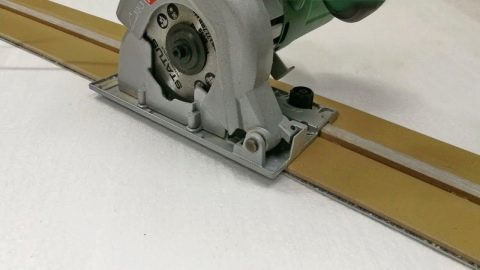

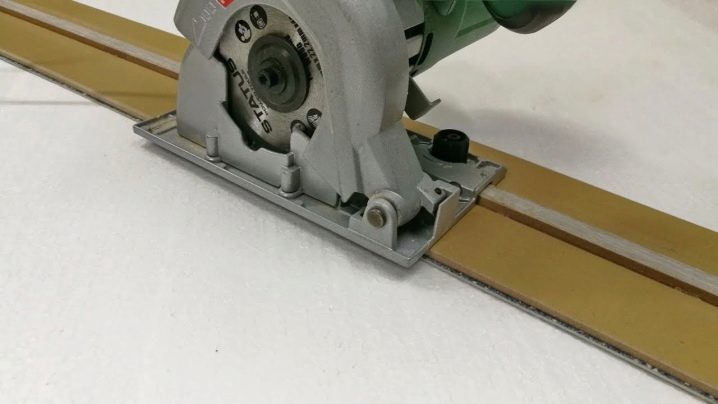

There are not so many accessories for circular saws, but their usefulness cannot be overestimated - this is a guide rail, rubber pads, an eccentric for adjusting the exact length of the cut. It makes no sense to talk about the last two in detail, but we will tell you more about the bus.

Every experienced carpenter knows: no matter how hard you try, it is almost impossible to get a perfectly straight cut, the saw constantly strives to deviate from the marked trajectory due to vibrations. And then a banal device called a guide rail comes to the rescue. It allows the hand-held circular saw to follow the intended path without deviations. For stationary circular saws, tires are made by attaching a pair of clamps, but in the case of a manual model, this is impossible.

When using a special rail, you only need to attach it with the help of special fasteners to the saw blade frame, and you can start working. The distance from the disc blade to the tire edge is no more than 20 mm. Unlike the rule, you do not need to monitor the possible movement or force of pressing the rule against the material, because fragile materials can be squeezed or broken - with a tire, you only need to smoothly guide the saw along the cut line. Branded tires are designed exactly according to the typical dimensions of a circular saw, so the edge of the tire practically touches the cutting disc, on special tires there are glued strips of soft material for better gliding on the material.

There is a huge number of accessories for circular saws on the market - bearings, stators, rotors, motor armature. These elements of the circular saw are most susceptible to breakage and wear, you can try to replace the broken part yourself, but do not forget that the warranty for the tool in this case will be nullified.

What are they?

When choosing a saw for carpentry work, inexperienced users are faced with a wide selection of a wide variety of options, because saws are circular, submersible, hand-held, battery-powered, wood-working, table-top, electric, as well as stationary, miter, mini-, hypoid. You can also find on sale such an option as a saw machine or a model with a brushless motor.

Circular saws are classified according to various criteria.

Depending on the size of the cut, saws are divided into the following categories:

- small - have a penetration depth of 40-46 mm;

- medium - depth is 50-55 mm;

- large - here the cut varies from 65 to 70 mm;

- professional - with depth parameters of 64-140 mm.

By design, some saw options are also distinguished, which will be discussed below.

Stationary saws

As a rule, these are oversized models that require special space, and sometimes premises for their installation and storage. They are designed to work in an intensive mode and perform a large volume of tasks. For example, they are relevant in large furniture production, where fairly large batches of wood have to be sawed every day.

Desktop options

These are small tools that do not require much storage space and can be easily transported. However, small dimensions are combined with reduced power characteristics, so their performance is several times lower than that of stationary models.

Manual

These are circular saws that are used when it is necessary to cut a number of parts from soft materials, such as plastic or certain types of wood.The device is optimal for occasional carpentry work - only in this case, reduced power and low productivity will not be considered a minus of the tool.

Depending on the scope of use, a number of modifications are also distinguished.

Professional saws

Such a tool is used in production workshops: where every day a huge number of wooden blanks of the most varied density and size are processed. Such devices can function continuously for a whole shift without requiring a break.

Household

As the name suggests, these models are optimal for use in everyday life when carrying out small repairs.

One of the most basic classifications is based on the types of operations performed.

Metal circular saw

It is a versatile tool as it can be used with any type of material: wood, plywood, plastics, as well as sheet metal, pipes and profiles. Unlike all other modifications, such a tool does not have an abrasive sawing surface, but a manufactured made of tool steel high strength.

Plunge-cut circular saw

This tool is indispensable when you need to make a groove in the surface of any part, for example, cut a small hole in a wooden surface for mounting a sink. The main advantage of a circular plunge-cut saw is the ability to make a cut absolutely in any part of the part, and not just along the edges.

Depending on the power source used, a number of modifications are also distinguished.

Cordless Saw (18 Volt)

As the name implies, it does not operate on AC power, but on an autonomous battery. Thanks to this feature, the saws are popular when working in hard-to-reach places, for example, at considerable heights or in areas where there is no tension. On average, such a cordless saw can work from 35 to 55 minutes without recharging. And in order to fully charge the battery, it will take much longer - at least 3.5 hours.

Network

These models operate on mains power. Their advantage is the ability to work for a long time without interruption. The disadvantage of this type of tool is associated with the fact that all work can only be carried out near the power source.

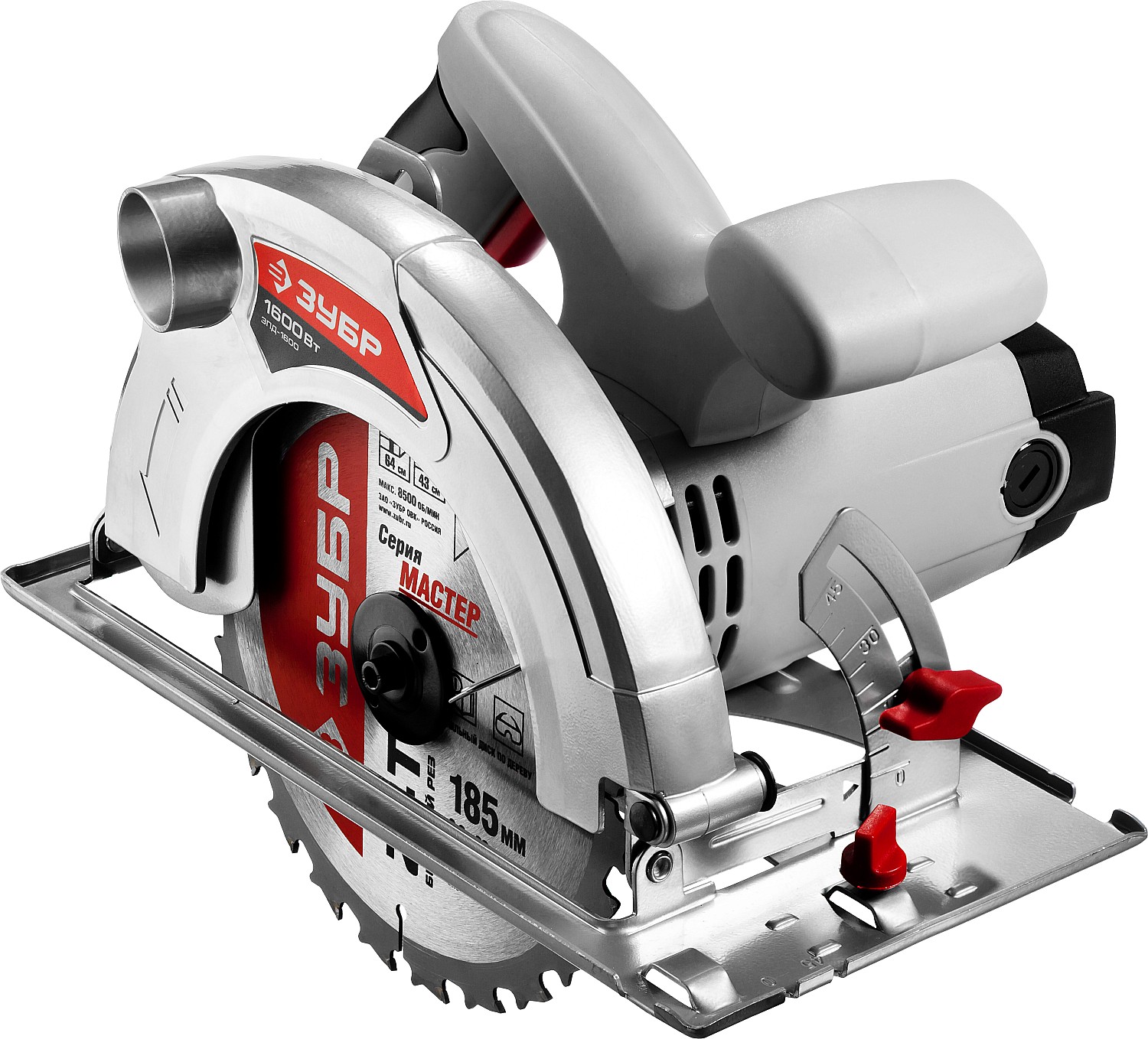

Saw brand DP-190/1600 M

This model of power tool is used for sawing a variety of materials, including planks, laminate and plywood.

The maximum possible cutting depth with this circular saw is 63 mm. The model is equipped with a 1600 W motor and is designed to work with a 190 mm disc. Safe and comfortable work with the saw is provided by a locking mechanism against accidental activation, a spindle lock and an adjustment of the cutting angle.

Specifications

During operation, the circular maintains 4800 rpm. Those who are interested in the Interskol DP-1600 model should take into account that it does not have an option for adjusting the speed. The unit weighs 5.5 kg. The device is not designed to operate at constant speed under load

Particular attention should be paid to the dimensions of the device, which are 348 × 263 × 240 mm. In operating mode, the unit provides a cut to a depth of no more than 45 mm, provided that the cutting angle is 45 degrees

In conclusion, we can say the following: the range of saws that can be bought in stores today is very diverse. Presented in them are products that are in high demand among buyers. Among the sawing devices, saws from the manufacturer Interskol are very popular among our compatriots.

In conclusion, we can say the following: the range of saws that can be bought in stores today is very diverse. Presented in them are products that are in high demand among buyers. Among the sawing devices, saws from the manufacturer Interskol are very popular among our compatriots.

The company has long established itself as a manufacturer of high-quality and reliable devices for various purposes. One of the reasons for the popularity of Interskol saws is their versatility. Many models allow you to cut not only wood, but also other, fairly dense materials.But so that the cutting of such materials does not end with unpleasant consequences up to the failure of the power tool, it is necessary to follow certain rules for working with circulars.

However, the most important thing is to choose the right unit, for which it is necessary to determine the range of tasks for the solution of which you will use this power tool from the Interskol company. It is also necessary to monitor the condition of key working units and not to overload the tool during operation. Then the Interskol circular saw will serve you for a long time and save a lot of money.

Interskol circular saws - model range

Interskol range of circular chain saws:

- hand-held disc network saw Interskol dp 140 800, power 800 W, main purpose household, can be used for non-professional household work, infrequent wood processing;

- hand-held circular saw Interskol dp 165 1200, a popular model of a circular saw of medium power, ideal for an average load, can even be used in industries, power 1200 W;

- circular circular network saw Interskol dp 190 1600m, professional saw, powerful, for intensive loads, circular power - 1600 watts;

- network circular saw Interskol dp 210 1900m, hand-held, but very powerful saw, professional, for difficult work in intensive mode, tool power 1900 W;

- hand circular saw Interskol dp 210 1900 em, has a slightly lower weight than the 1900m model, equipped with electronics;

- circular saw Interskol dp 235 2000m, one of the most powerful circular saws in the Interskol model range, mainly installed in machines for continuous work, has the largest weight of all circular saws in this category;

- submerged chain saw Interskol pp 165 1300 em, works on the electronics system, adapted for the installation of the Bosch bus;

- circular hand-held network saw Interskol dp 235 2050 m, professional saw, adapted for permanent work. Has a power of 2000 W;

- table circular chain saw, hand-held, Interskol dpn 250 1500, power 1500 W, is an autonomous structure for working with workpieces, supplied with a support table on legs, also equipped with two types of stops, a pusher and table extensions. Circular dpn 1500 is the best choice for small workshops, as well as for installation in a limited space for work (on the balcony, in the kitchen, garage, etc.).

The complete catalog of Interskol circular saws can be seen on the manufacturer's website, and also received upon request by writing to the company's manager via the e-mail indicated on the website.

Saw blade design

Circular saw layout diagram.

The circular saw is designed for cutting almost any soft material (soft metal, plastic, wood). High productivity, fast and accurate cutting makes this tool irreplaceable when working with wood.

Working with the circular saw is easy enough that even a beginner can operate it

However, it is very important to follow all safety rules, since their violation can harm your health.

The main elements of circular saws are:

- Electrical engine;

- frame;

- lever;

- saw blade;

- protective cover;

- platform with a guiding device.

Circular saw device diagram.

In the manufacture of the case, in most cases, heat-resistant and wear-resistant plastic is used. Sometimes in the construction market you can also find a metal case. Given the fact that a circular saw very often has to work in dusty conditions, most manufacturers equip the tool not only with a ventilation and cooling system, but also with a system for removing waste from the working area.If the design of the saws does not provide for an integrated dust removal system, then it is possible to connect a forced dust removal system using special adapters or industrial vacuum cleaners.

All circular saws are equipped with a collector electric motor with a power of 0.5 to 2.5 kW. This indicator will depend on such parameters of the instrument as maximum number of revolutions and the depth of the cut. Recently, battery-powered circular saws have appeared on the building materials market. For example, the BOSH company has released a whole series of such instruments, which are equipped with batteries of different capacities.

When choosing a saw, special attention should be paid to the quality of the platform. To reduce the cost of the product, most manufacturers use a stamped platform

The circular saw platform often has a ruler built into it.

Many companies equip the platform with a special ruler that allows you to control the material handling process.

An important element of the saw is the cutting disc. Currently on the market you can buy discs that allow you to process almost any material. If you need to quickly dissolve the boards, a wood disc is perfect for you. If you need to work with laminate, then you should buy the appropriate disc, which gives a smooth and high-quality cut. All this is achieved by using special carbide taps, increasing the frequency of the teeth and changing their shape.

How to choose the right circular saw

We have sorted out what a circular saw is and what types this tool is subdivided into. Next, you need to choose a saw taking into account the technical parameters.

The main ones are:

- Power... The more powerful the drive, the more dense the material the "circular" will be able to work with. But with an increase in the value of this parameter, the dimensions and price increase. On the other hand, a small power reserve significantly extends the tool life. It is necessary to find a compromise value.

- Rotation frequency... Affects sawing speed and the ability to work with different materials. The faster the blade rotates, the better the cut quality, the less likely the saw will jam. Frequency is not directly related to power, so it makes sense to choose more revving models. For professional saws, this parameter can be adjusted - smoothly or stepwise. Decreasing the speed can be useful when the saw is moving slowly - in this case, the surface of the wood can be charred and the plastic can melt. Also, the speed control device can be coupled with the useful function of stabilizing the speed under load.

- Cutting depth... Directly depends on the permissible outer diameter of the cutting disc. Both factors determine how thick the workpiece can be cut. In everyday life, 45 mm is enough for most purposes. For summer cottage work, you can choose a larger one - 55 mm.

- Possibility of working at an angle... Many models allow adjustment of the cutting angle. For most, this value is limited to 45 degrees and one way. Some saws are adjustable up to 69 degrees, sometimes tilting to both sides is allowed.

- Additional service functions are also important for work.

- Collecting sawdust that pollutes the work area and obscures the cutting line. It is produced by means of a vacuum cleaner connected through a branch pipe provided for this purpose.

- Laser pointer. Forms a mark in the direction of the cut. It is very convenient in poor lighting conditions or when the marking is clogged with sawdust.

- The accidental start blocking is an important safety feature. In most cases, it is performed in the form of an additional button that must be held down to turn on the motor.

- LED illumination of the work area can also be a useful feature.

- Soft starter - when turned on, the speed gradually increases to the rated speed.Reduces the dynamic jerk at the initial moment, reduces the starting current. Only powerful professional saws are equipped with this option. Do not forget that a soft start can interfere with the network, cause noise in radio receivers, flashing lights, etc.

- The handles must be rubberized - the work of the "circular" is associated with vibration.

- For many jobs, a guide bar will come in handy. For example, when sawing off workpieces of the same width or forming a quarter in a board.

- The electrodynamic brake will instantly, without inertial run-out, stop the rotation of the disc and reduce the likelihood of injury.

Many consumers prefer to choose power tools by brands. Such selection has a right to exist. Top 3 of our review were identified by the best manufacturers:

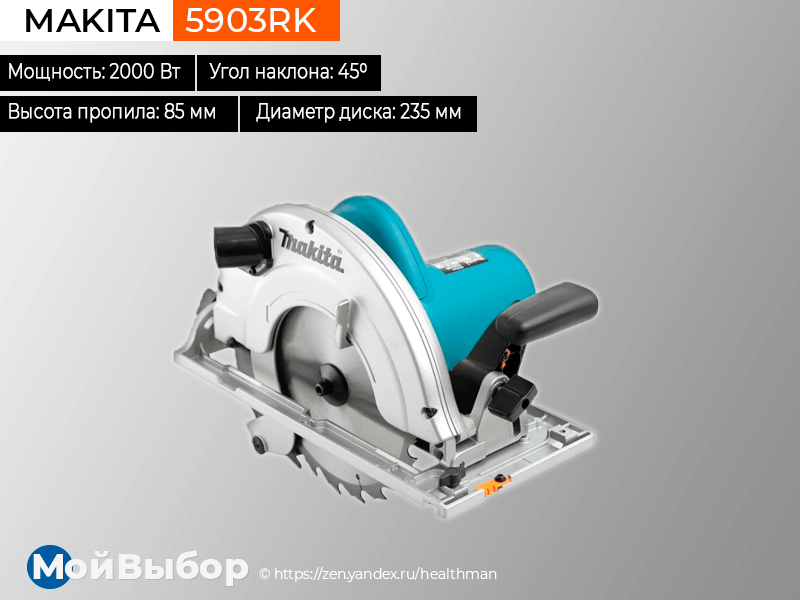

- Makita - a Japanese brand with production in China, one of the world leaders in the sale of power tools;

- BOSCH - a German company, synonymous with quality products;

- DeWALT Is an American brand owned by Stanley Black & Decker.

Buyers choose products from other companies supplying high quality circular saws to the market:

- RYOBI - Japanese brand, founded in 1943, the production of power tools has been going on since 1973;

- AEG (Germany) - has been producing electrical engineering since the end of the 19th century;

- Einhell - another West German company, the year of its beginning of activity - 1964;

- DIOLD - Russian brand, production facilities are located in China;

- Stanley - the tool of this manufacturer from Connecticut (USA) was used at construction sites as far back as the nineteenth century;

- Metabo - from German the full name of the company is translated as "drill for metal";

- Mafell - a small but well-known factory from Germany.

Interskol brand

Russian brand of electric and battery tools and related products, accessories, spare parts and consumables - Interskol. The company was established at the production facilities of the Bykovskiy plant of electrical equipment. The brand is over 15 years old, but it appeared even earlier. In the past two decades, Interskol has become a recognizable brand that has earned the love and popularity of power tool craftsmen.

Now the production facilities of the company are located not only at the Bykovsky plant, but also in Alabuga (the Republic of Tatarstan), where large production facilities and one of the largest and most modern plants of the company are located. It opened in 2014 and employs a minimum amount of human resources in tool assembly and production management. The main work process here is automated and carried out by special machines.

Interskol products are manufactured. besides Russia, in such countries of the world as China, Germany, Italy, Bulgaria, South Korea. To date, according to the manufacturer's information, more than 40 ml of Interskol units have been purchased throughout the Russian Federation.

The modern assortment of the company:

- tools for construction, general category (drills, screwdrivers, measuring equipment, construction vacuum cleaners, grinders, grinders of various types);

- tools for processing and finishing concrete (perforators, construction mixers, jackhammers, wall chasers);

- tools for working with wood (circular saws, miter saws, jigsaws, milling cutters, planers, machine tools);

- garden equipment (scythes, chainsaws, washers, petrol and electric mowers);

- SMM - means of small-scale mechanization, namely: knitting machines, oil and oil-free compressors, welding masks, generators);

- snow removal equipment (heat guns, snow blowers);

- various accessories for the tools and machines described above;

- equipment for spraying polyurethane (waterproofing installations).

How is it different from a circular one?

The main difference between a plunge-cut saw and a traditional saw lies in the position of the blade. It immediately catches your eye and does not allow you to confuse the models.If in a conventional saw it, although it is closed from above with a protective cover, is still clearly visible from below, in submersible models it is located above the level of the sole and is completely covered by a cover. The horizontal position of the disc relative to the sole also differs: in plunge saws it is maximally displaced to the edge, while in ordinary saws it is located almost in the middle.

The next difference is the principle of work execution. So, if when using traditional models, filing starts from the edge of the workpiece, then with submersible models it can be started from anywhere. To do this, you just need to set the required cutting depth parameters, unlock the "head" equipped with a spring mechanism, and place the device exactly in the place where you want to go deep into the wood. After the disc is immersed in the material, it is necessary to smoothly guide the device along the outlined line.

Another distinguishing feature of plunge-cut saws is the bar. This allows for even trimming of long boards, which cannot be achieved with a conventional circular, despite the fact that it has a parallel stop.