Advantages and disadvantages

For a detailed examination of the range of Bosch circular saws, it is necessary to highlight the positive and negative characteristics of the tool. The advantages of the product include such features as:

- a distinctive advantage of the entire model range of the proposed devices is the equipment of the units with high-performance engines, which additionally have a stabilization system that excludes equipment failure in unforeseen cases;

- the devices have a number of auxiliary tools, thanks to which you can adjust the angle of inclination and the depth of cut on the work item;

- circular saws work in conjunction with the Constant Electronic system, which allows you to operate the device at a constant speed of rotation of the saw blade; in addition, the tools have the ability to fix the spindle, so that you can quickly replace consumables;

- Bosch saws are characterized by high cutting accuracy; during work, the operator can observe the line of the cut being created;

- the tools of the entire line of the brand have an ergonomic body that facilitates the operation of a professional and household type;

- the mechanism of circular saws also has a built-in blocking against erroneous starts;

- the tools are distinguished by smooth start-up and protection against motor overloads;

- circular saws are convenient to operate for left-handers and right-handers, and the saws make very little noise during operation;

- many models have built-in illumination and laser-type markers.

But, like any other equipment, saws have the following disadvantages:

- powerful units stand out with impressive weight;

- the technique has a high cost when compared with the Chinese counterparts on sale.

Operation and maintenance

The manufacturer of circular saws recommends that you familiarize yourself with the instructions for working with the tool before using it in order to avoid personal injury.

- First of all, before connecting the tool, you should check the serviceability of the unit and the available accessories, including the cable and plug. Even with minimal defects, it is prohibited to operate the device, since there is a risk of electric shock or short circuit. During the warranty period, it is necessary to carry out repairs only within the framework of the service center.

- When working with a saw, the operator must provide himself with personal protective equipment. This applies to masks, goggles, noise protection headphones. And also the master must perform the cut in shoes with rubber soles.

- The tool needs regular inspection and maintenance after each use. Parts should be lubricated regularly, do not use defective disc blades, clean the tool from shavings.

For an overview of the Bosch GKS 600 Professional circular saw, see the video below.

Let’s block ads! (Why?)

Things to remember when choosing a saw blade

- For ripping, use saw blades with large cutting teeth. Thus, you will achieve a better and more accurate cut, as well as preserve the engine's performance;

- Small toothed discs are used for cross cuts. In this case, the cut comes out very clean, the part practically does not require additional processing;

- For cutting hard and valuable woods, we recommend using thin, alternating tooth discs. When using such saws, the maximum cleanliness of the cut is achieved.

- The presence of slots and grooves on the blade leads to a decrease in noise during operation, in addition, it prevents premature wear of the saw.

Application area

Today, the scope of operation of this tool is not limited only to professional use in the framework of woodworking industries and sawmills, so the inventory is sold in many building supermarkets.

The circular saw is a high-performance tool with which you can cut large volumes of timber, wood-containing materials, as well as soft types of metal, plasterboard products and other modern raw materials used for construction, renovation and domestic needs. As for the Bosch circular saws, the line of tools, due to their characteristics, is in demand during the construction of large facilities, as well as for the arrangement of personal plots and the construction of outbuildings, the collection of cabinet furniture.

But in the light of its productivity, such a tool is still limited in scope, since the device is designed to solve problems related to precise and straight cuts. However, the work done with a circular saw will always be distinguished by a high level of accuracy and accuracy of cuts, where a jigsaw or a chain cutting tool cannot handle. The products manufactured by the Bosch brand can be used for processing high density materials. In addition, it is implemented with a certain set of additional functions that allow solving problems of any complexity. It is also worth noting that the most popular material with which work with circular saw - wood. It can be cut both along and across the fibers, this nuance does not affect the quality of the cut.

How to understand the assortment?

Before deciding to buy, they find out what it will be used for, then they begin to study the models presented by the store by:

- parameters;

- functionality;

- technical specifications.

Disk electrical appliance

The disk electrical appliance in the design is produced:

- Manual - with low power and low productivity for use in home workshops.

- Stationary - for use in production with a large volume of work; Tabletop - for household cutting of materials, where the average power will not become an obstacle to the activity.

For household materials cutting

The choice of a tool is influenced by the frequency of its use. Suppose, with intensive activity, they go to the store shelf, where only professional saws are located, and if the employee begins to gain skill, you can learn from a simple household device. In this case, the best power tools for the home will be inexpensive, compact, and easy to use.

Bosch circular saws overview

Recently, the Bosch hand-held circular saw, along with other power tools, has become a reliable assistant in most domestic households. The tool is used when performing repair and construction work, making furniture and joinery, for other household needs. With the help of a hand circular saw, you can rip and cross-cut wood at different angles. The main advantages of a circular hand saw are its mobility, reliability, productivity and simplicity.

Bosch is the oldest manufacturer of hand and power tools, electrical products and household appliances. The company was founded by German mechanic Robert Bosch in 1886 and was originally engaged in the production of magnets, starters, headlights, windscreen washers and other components for the automotive industry. In the early 30s of the twentieth century, the concern established the production of household appliances, soon woodworking machines and hand-held power tools appeared in the company's catalog.

Today, the factories of the concern are located in many countries of the world, and the annual gross turnover exceeds 70 billion euros. Bosch circular saws are assembled in factories in Germany, China and Taiwan. To understand where this or that saw was made, we recommend reading the accompanying documents and looking at the markings of individual units and parts. However, according to many owners of Bosch hand-held circular saws, the country of origin does not really matter. All equipment of the concern is assembled on modern equipment and meets international quality and safety standards.

The company's management pursues a balanced pricing policy and does not overstate the prices of its products. In the Bosch range of miter saws, you are sure to find a tool that suits your budget.

- Bosch equipment is assembled at the factory using modern equipment;

- Circular saws are equipped with reliable, efficient electric motors;

- The company offers an extended warranty (up to 36 months) for most tools;

- The concern took care of high-quality warranty and post-warranty maintenance of equipment.

Which circular saw is better to buy

The length of the cable here should be at least 3 m, this will allow you to work with the tool without carrying. It is also desirable that the device be equipped with a soft start, which prevents overheating and reduces the load on the power grid. Also, in order to avoid this, it is necessary that this or that model has overload protection.

If you plan to cut large volumes of wood and thick beams, you cannot do without professional models, the disc of which can penetrate to a depth of 65-140 mm. In other cases, products with lower rates are sufficient. The most optimal speed of its rotation is from 4000 to 6000 rpm per minute.

Summing up the results of this rating of the best circular electric saws, it is worth saying that of the inexpensive, the most acceptable options here will be circular models from domestic manufacturers. It is they who have the most favorable ratio of quality and price. The rest of the units are also very good, but you need to understand that their high cost is often associated only with the popularity of the brand, a particularly vivid example of this is BOSCH.

Classification by technical characteristics

Depending on the type of production, the material to be cut, you have to focus on the most suitable file. When cutting plywood or chipboard you will need a plunge-cut hand saw.

Natural wood is cut with a circular for metal, they work with it on hard materials. The saw can be powered from the mains or battery. These devices differ in their power ranging from 800 watts. up to 1200 W

You need to pay attention to the rotational speed of the disk. If the saw is designed for a small number of revolutions, its masters compare it with a simple hacksaw, the level of productivity depends on this indicator.

With intensive rotation, the disc will less jam in the workpieces, provided that it is selected of the correct diameter. For high power, the same cutting element is needed, which is responsible for the cutting depth (40-140 mm), corresponding to the force of the engine, which is transmitted to the shaft.

Specifications

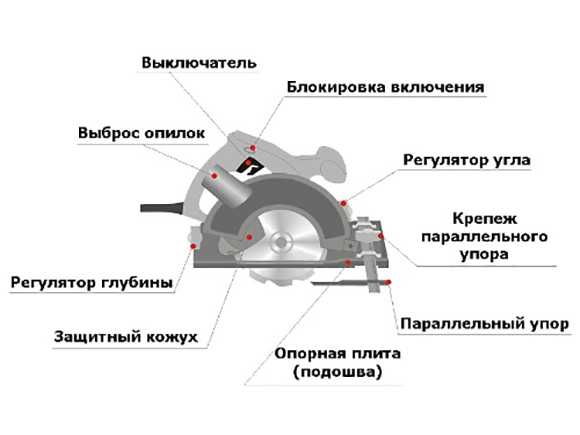

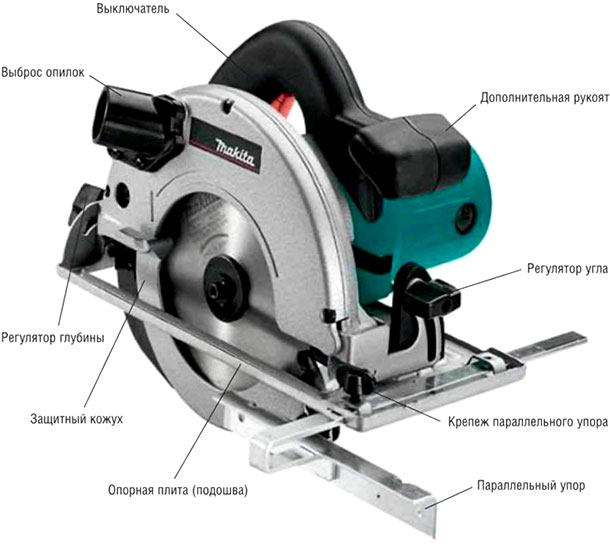

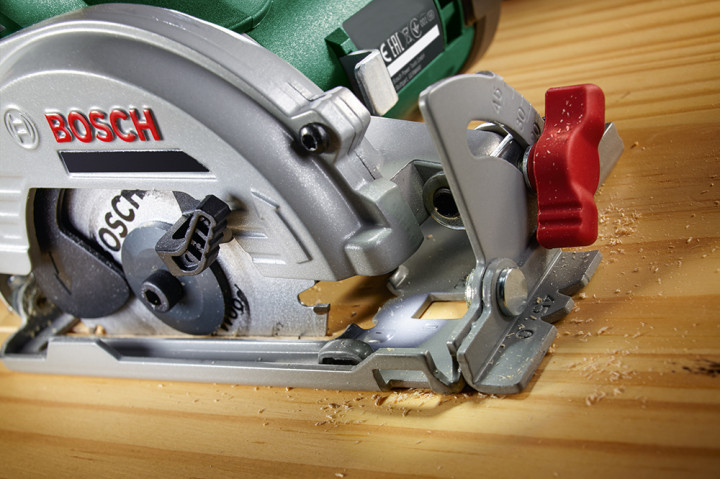

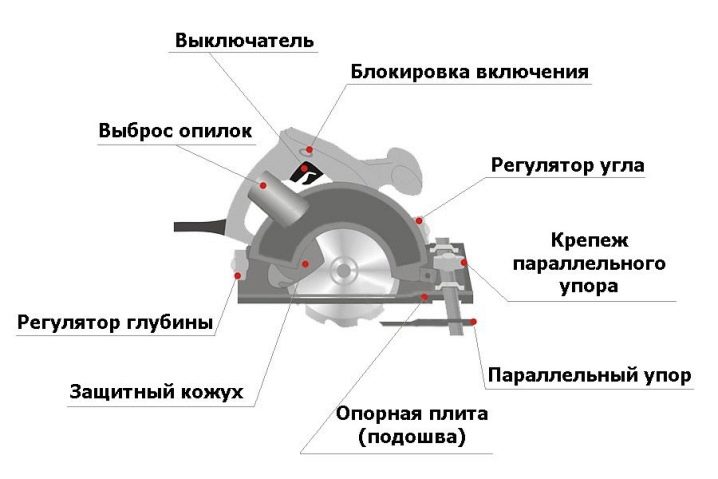

According to its design features, the tool is a body with a motor with a shaft, a saw blade, and a protective cover placed in it. In addition, some modifications may have additional elements. Electric brands of Bosch saws differ in the level of motor power, on which the performance of the device depends, in the size range, in the shape of the cutting disc and in the presence or absence of additional functionality. Of the auxiliary devices, circular saws can be equipped with articulated mechanisms, a ruler or a nozzle for chip evacuation.

Depending on the power, Bosch saws come with several technical characteristics.

- The performance of the electric motor is from 0.8 to 1.2 kW.A similar tool is recommended for sawing canvases 4–5 centimeters thick. The device can work with cutting elements with a diameter of 130–160 mm. Such models are used for small-scale work.

- Units up to 1.8 kW. These saws can cut up to 6 centimeters deep. Discs with a diameter of 200 mm are used for the tool.

- Saws with a capacity of more than 2 kW. This product is suitable for sawing wood and soft type metal sheets. The devices are equipped with saw blades with a diameter of 350 mm.

The Bosch brand offers customers several types of circular saws.

Manual. This type of equipment stands out for its minimal weight and compact size, but this does not reduce the performance of the devices, in light of which the hand tool belongs to the universal line of products.

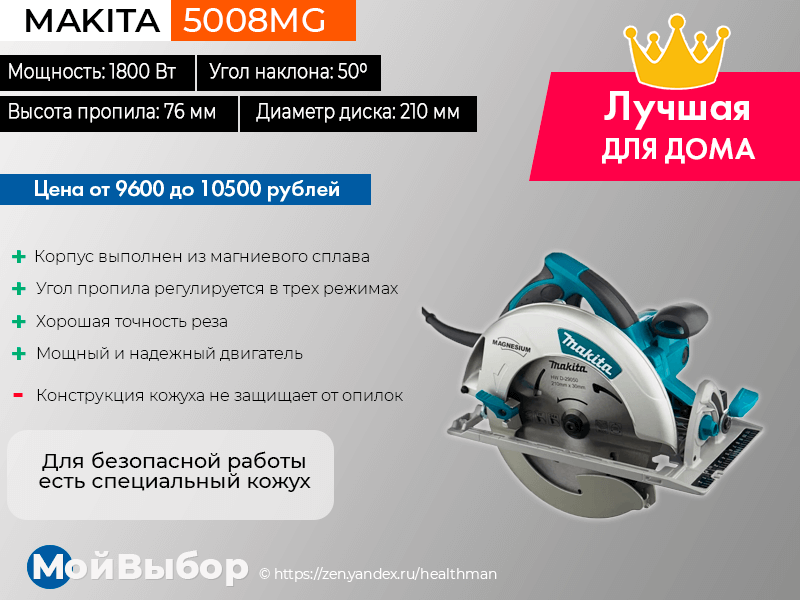

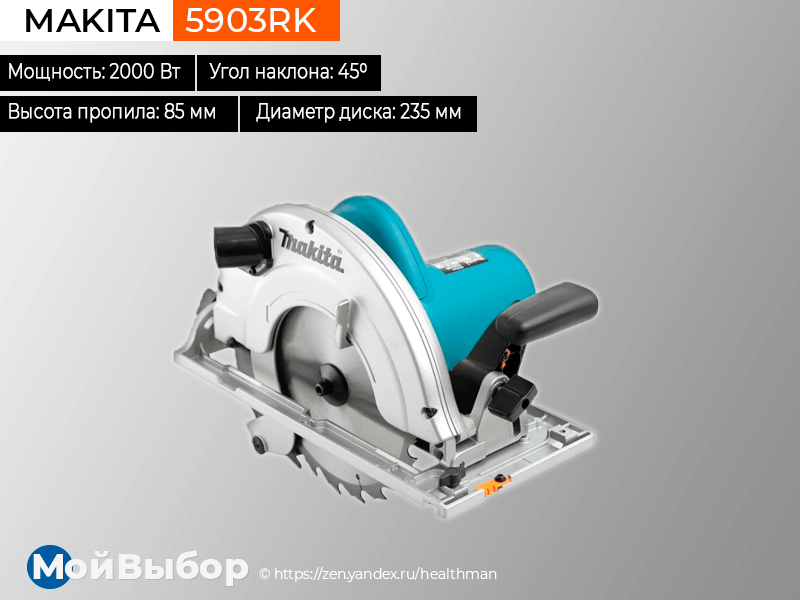

Makita products

Makita HS7601

Without the Makita HS7601 brand, the rating of circular saws, which occupy the first places in terms of assembly quality, long operation without breakdowns, will not be complete.

If you combine all the advantages with a tool with an average price of 7,000 rubles. the parameters will be commensurate. The Makita circular saw motor rotates the saw blade up to 5000 rpm. This is a reliable device, distinguished by its stability in performing working operations with precise cuts in the presence of:

- good power;

- speed;

- solid cutting depth;

- dust collection;

- reliability;

- high ergonomics.

During operation, the chips are blown away by a special device, which provides an unobstructed view. An electrical appliance can handle raw materials of any hardness, both wood and metal. Cutting is controlled by control buttons, the quality of cuts depends on the installed discs for each material separately. The sawing elements are easy to change, they are located on the housing cover. Interestingly, the Japanese sold their development to the British, who are now a manufacturer of goods under the Makita brand.