Sharpening types

Specifically, the process is divided into three types:

1. Sharpening the front surface of a straight tooth

Read the same

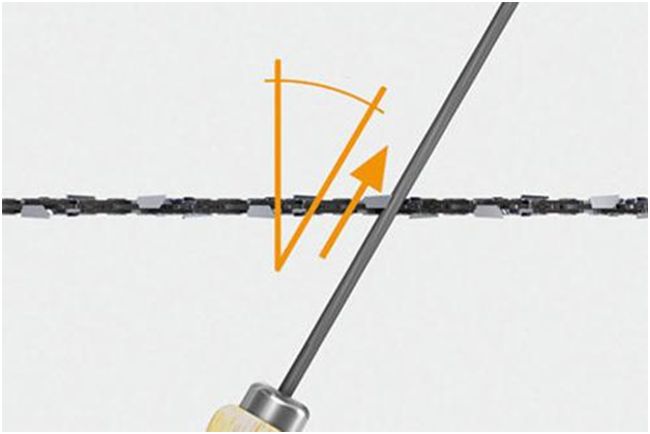

The tooth and abrasive wheel are installed perpendicular to each other, taking into account the fact that the saw itself must have a horizontal position. When, if the machine does not provide an angular tilt scale, use a pendulum goniometer

Next, you need to firmly fix the tools.

The process is contact abrasive wheel and the sharpened surface back and forth by means of a mechanism in the machine, while simultaneously pressing the tooth against the wheel in manual mode. This process is repeated with all saw teeth.

For convenience, a mark is made on the tooth from which sharpening began.

4.5. Sharpening a tooth beveled on the frontal surface

This type of sharpening predicts the performance of the same actions as with what, with the difference that the angle of inclination must be changed accordingly with the location of the teeth. You can measure the slope with a pendulum goniometer. First, the positive angles of the tooth are sharpened through the tooth.

Then the process takes place:

- Any next reason for soldering is sharpened;

- Then the angle changes to negative;

- The remaining teeth are machined.

- Rear face sharpening

This process foresees the possibility of configuring the position of the disc in such a way that the back plane of the soldering is in contact with the abrasive wheel.

Opposite there is no sharpening machine, you can make everything in artisanal conditions. How to sharpen a disc in artisanal conditions:

- Make a support for the saw that will hold the saw in place. This device must firmly hold the saw, otherwise the process will pose a danger to the performer;

- Adapt the stand, the disk itself will be placed on the busy (if desired, the angle of inclination can be changed to the supports);

Fundamentally! Abrasive saw and saw disc are made to be placed perpendicular to friends.

Fix the saw blade in its center so that it touches the circle in a suitable position (to maintain similar rear and front sharpening angles).

It should be kept in mind that after sharpening, no chips, cracks, gaps and other flaws should remain on the victorious teeth. If no glare is visible on the cutter, it means that the work is done correctly.

You also need to pay attention that the sharpened plane of the tooth and the material to be processed then are located on the basis of each other - if the material of the workpiece is hard, then the soldering should not be very sharp

Main characteristics

Like all tools and garden equipment associated with direct contact of the cutting element with the material, the chainsaw chain requires constant sharpening, lubrication and replacement.

When purchasing a new consumable, pay attention to compatibility. In order not to miscalculate and not to mislead the buyer, manufacturers of world brands use the universally established standards for marking the technical parameters of chainsaw chains.

The main parameters are:

- the angles of sharpening the tooth of the cutting element of the chain;

- shape (geometry) of cutting teeth;

- the height of the teeth relative to the cut stop (profile).

In addition to the parameters of the cutting teeth, the chains have different sizes, thicknesses and lengths. They differ in:

- distance between cutting elements (chain pitch);

- full chain length (number of links);

- the thickness of the guide pins relative to the chainsaw bar.

Next, we will consider in detail all the parameters on which the choice of the circuit depends.

Tool overview

Chainsaws are of two types: powered by electricity and petrol powered (ICE).According to builders, each type of chain saw is used for different purposes. If it is necessary to work for a long time, it is better to use an internal combustion engine saw. It is more productive and can work without stopping even the whole day. Its indisputable plus is autonomy, especially when you have to work in remote areas or in a forest where there is no electricity.

An electric saw is used when a small amount of material needs to be cut. Naturally, every time it needs to be turned on and off.

The hand chain saw is designed to cut material by hand. This tool can be used alone or in pairs. There is no difficulty in work. The main cutting element is located on the surface and is gripped on both sides. When the saw moves, the material is cut. Suitable for cutting thin branches.

How to extend the period from sharpening to sharpening a chainsaw

Maybe now we will utter common truths, but some neglect them too, apparently in the hope that everything will work out without it, according to the phrase of the hero, the famous cartoon "Vovka in the Thirtieth Kingdom" - "Oh, and so it will do ...". In no case should you cut with a saw if there are third-party objects in the tree or board, first of all, these are not extracted nails, metal tape. Once "driving" on a normal nail, of course you will even saw through it, but after that take a look at the cutting edges of the chainsaw chain, because sometimes it is already an irreparable marriage, with chips, plastic deformation of the teeth. In such cases, a hand-held chain sharpening tool may not always help. Before starting work, check the saw site for any foreign objects, the wood must be clean, preferably dry, although this is already how it will turn out. Do not cut on the ground without putting something under the cut. In this case, after the cut, you will have to go deeper into the ground, and this is, oh, how undesirable for your chain. Earth, sand, stones, all this can also quickly and irrevocably disable the chain of your chainsaw, forcing you, after one or two uses of the new chain, to start sharpening it. Make sure that the saw does not "bite" during the cut, so as not to overheat the metal and the saw blade. Watch chain lubrication, oil level in the reservoir. As a result, as you understood, the chainsaw, which seems to be such an "invincible" hand tool, itself needs protection if you want accurate, timely and effective work from it.

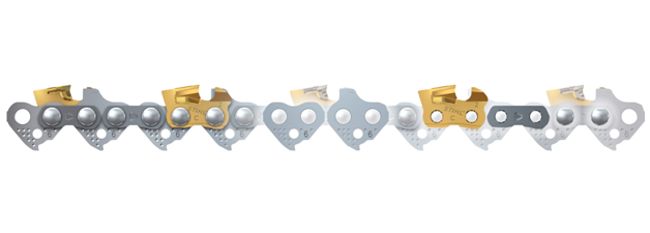

Features of the operation of the carbide chain

A common limitation of carbide is its shock sensitivity. The chain with carbide taps is no exception: in case of sharp and systematic contact with especially low-yielding or abrasive surfaces, fatigue stresses will gradually accumulate in the chain with victorious taps. Despite the rather high thermal conductivity of hard alloys, the heating of the tooth body during long-term operation of the chainsaw still occurs, which causes a decrease in hardness.

The second danger lies in the different values of the coefficient of thermal expansion for steel and carbide. Sharpening chainsaws equipped with carbide chains requires the use of a special sharpening tool. However, such chains are dull 6-8 times less than ordinary ones.

When using the winning chain, the following rules should be followed:

- When working with problem wood (burnt, flooded, with abrasive cement inclusions, etc.), the feed into the intended cut should be slower than usual.

- As the saw warms up, the feed rate can be increased.

- Sulfur-free formulations must be used to lubricate the chain before work, as it reacts with cobalt in any carbide.

Sometimes, in the case of sharply uneven hardness of wood, it is better to use old saw segments made of ordinary tool steel for cutting, the resource of which is almost exhausted.

Victory Chain Overview

Unlike saw blades, until now, victorious chains have not been widely used. Not in the home or in the logging industry. Even heavy duty harvester chains - forestry machines ranging from logging to delimbing loppers - often do not have winder inserts.

It is important not to confuse wood chains with chains for petrol saws for other purposes. For example, today there are diamond-coated chains on sale, structurally, in size and externally similar to wood chains.

They are designed for cutting brick, concrete and even metal. But they do not fit chainsaws in step, thickness and length, and they cannot cut wood. The wood simply smokes and burns from friction, as when drilling it with a victorious drill.

How to choose

The selection issue is relevant for inexperienced users. Professionals know almost everything about a headset and know how to choose what they need. For this reason, our advice will be aimed specifically at amateurs, not pros. So let's get started.

In order to choose the right one you need:

- Know the characteristics of the chainsaw, namely the pitch and length of the tire. You should not rely on the name and model of the chainsaw when choosing, because one chainsaw can be equipped with tires of various lengths and widths of the landing link.

- Decide in advance on the volume and type of work for which it is planned to use it. If you cut across, then choose chisel, along - chipper.

Important! You will have to sharpen the longitudinal cut (10) yourself or in a service center. A headset sharpened for longitudinal cutting is rarely found on sale

Separately, it is necessary to mention the choice of the Stihl headset. If you are planning to buy a chain from this manufacturer (they are considered to be of the highest quality today), then it is better to use a special search form that can be found on the company's website.

Having entered the data of the chainsaw into the search form, the program will automatically select and offer you suitable options. The service is convenient, but it has one big drawback, the selection is carried out only for Stihl chainsaws. In order to choose a chain for saws from other brands, you will have to arm yourself with a catalog.

How to choose a chain saw

When choosing a tool, you need to pay attention to the technical parameters of the chain saw. First, a few words about manufacturers

Popular brands undoubtedly keep their mark, but you can find other companies on the market offering quality products to customers. The cost of such a tool may be lower, and the technical characteristics may remain at the proper level. The Parma chain saw meets these requirements.

What you should pay attention to:

1. Engine power. This parameter should be taken into account if it is necessary to operate the tool for many hours in a row when cutting thick wood. For such work, a powerful saw is needed, and for cutting branches in the garden, a less powerful one.

It is worth paying attention to electric saws with a capacity of 2.5 to 4 kW. The maximum power, respectively, and the cost of the tool will be with a professional saw

For summer cottage work, a household electric saw with a capacity of up to 2 kW is quite suitable. Experts recommend choosing a tool with a power reserve, since voltage often drops in power grids.

2. Where is the engine located. In different models, the engine can be located longitudinally or transversely. In the first case, the tool will be convenient to use (cut at different angles), but it will also have a higher cost. With the transverse engine position, you can make a vertical cut or at a right angle.

3. The length of the bar - the longer it is, the thicker the log is powerfully cut.For seasonal work in the garden, it is enough to purchase a model with a shorter tire length - 30-40 centimeters.

4. Kickback protection - chain brake. For beginners, this function is especially important, since if the hands and movements are incorrect, there is a high risk of injury to the fingers. In addition, when working with hard species of wood, a kickback may occur and the saw will suddenly be thrown upwards - towards the person's head. The chain brake lever is located on the handle and upon kickback the user involuntarily presses this button.

5. Overheating protection. Not every chain saw has this feature. The thermal relay will cut off the power supply when the engine temperature rises. In some cases, it is this function that allows you to save the engine from combustion.

6. Blocking of inclusion - a guarantee of safety in work. If it is absent, then a person can accidentally press the engine start button and get serious injuries. Chainsaws from renowned manufacturers are equipped with this function. If there is no lock button, then you may be holding a fake.

7. Engine brake and smooth start-up. The gradual starting of the motor protects the motor. A useful feature not available on all tools is the overrun brake. It stops the chain instantly.

8. Tool weight. The powerful model weighs more than the less powerful one. The average weight of a chain saw of various capacities is from 1.5 to 5 kilograms.

9. Oil tank. It is included with every saw model and is designed to lubricate the chain during operation. Capacities can be different: for a household saw, the volume of the tank is 0.12-0.2 liters, which will provide two hours of continuous work.

The advantages of a gasoline saw

To understand the difference, let's take a closer look at the types of chainsaws:

- Household (lopper). Suitable for infrequent use: to cut firewood for a fireplace or sauna, cut off excess branches or cut down a medium tree. Chainsaws are less powerful. Among the advantages, it is worth noting an affordable price, compactness and convenience. The gasoline saw is designed for 25 hours of work per month, which means that it will work less than an hour a day.

- The semi-professional chainsaw is suitable for work on the construction site and for felling trees. The disadvantage of the tool is that the chain saw cannot withstand continuous 8-hour work. The tool is more suitable for home craftsmen and summer residents.

- A professional chain saw has a long service life (about 1000-1200 hours), it can work continuously for a working day. Such a model is not needed in the household, but it is useful for working in construction.

- Special chain saws. The range includes redesigned saws - with a single top handle for easy tree maintenance, rod saws for cutting large and tall branches, and cordless chain saws.

Cordless saws are the mobile version of the tool. The battery-powered chain saw can be carried from one place to another as it is powered by batteries. A cordless saw works as quietly as an electric one, but its power is not so great, so the saw can be used in a small summer cottage.

What are the advantages of a cordless chain saw:

- the tool turns on smoothly;

- no electrical cable;

- engine running noise - minimal;

- the saw does not emit exhaust gases;

- there is no need to clean the motor after use.

In addition, the saw is more maneuverable in work, since there is no electric cable and it can be used almost anywhere. Also, the tool is easy to handle and easy to transport.

- The pocket chain saw is a compact tool that fits in a box. It is a chain with teeth, along the edges of which there are handles. To make the cut, you need to throw it over the trunk. One person can work, but it will be inconvenient. Manufacturers recommend using the saw with two people, so the surface will be cut faster.In the process of working with the saw, it is necessary to move the handles at an angle to save energy. If the tool is used incorrectly, the middle sections of the teeth can quickly fail.

The mobile saw is often referred to as a touring chain saw, as the tool was originally designed for special teams and was part of a basic survival kit. The weight of the tool is only 100 grams. Such a saw will become a reliable assistant on a hike as a replacement for an ax.

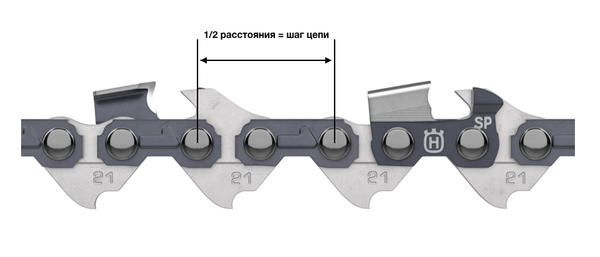

Chain pitch

This is the main classification criterion for all elements of the cutting system. It is defined as the distance between the three rivets of the chain divided by 2. Historically, chain saws were widely used in the North American continent, so the chain pitch was marked in inches. All manufacturers have 4 standard sizes for this marking: 1/4 ”, 0.325”, 3/8 ”, 0.404”. In millimeters familiar to us, this is respectively: 6.35 mm, 8.25 mm, 9.3 mm, 10.26 mm. This is how the chain pitch is calculated What does the pitch size technically mean? The larger it is, the more power of the chain saws and the diameter of the tree the chain is designed for. Let's make a reservation that here it is imperative to take into account other parameters of the cutting system, and the user experience of working with the tool. In order for the potential user to immediately understand the purpose of the accessory, Husqvarna designates the chain pitch for powerful professional saws as 3/8 "(for example, for the Husqvarna X-Cut C85 chain), and for amateur models as 3/8" mini (for example, for the chain Husqvarna X-Cut S93G).

This is how the chain pitch is calculated What does the pitch size technically mean? The larger it is, the more power of the chain saws and the diameter of the tree the chain is designed for. Let's make a reservation that here it is imperative to take into account other parameters of the cutting system, and the user experience of working with the tool. In order for the potential user to immediately understand the purpose of the accessory, Husqvarna designates the chain pitch for powerful professional saws as 3/8 "(for example, for the Husqvarna X-Cut C85 chain), and for amateur models as 3/8" mini (for example, for the chain Husqvarna X-Cut S93G).

Replacing the saw chain yourself

Companies that produce electric saws do not prohibit making a chain replacement with their own hands, on the contrary, they often complete new products with instructions for repairing and replacing individual parts. You should start by buying a new chain.

We check the chain for compliance, that is, we study its characteristics: length (depends on the tire), step size (relative to the sprockets), the thickness of the drive link

One of the common designs of budget saws is with side tension. To change the chain, we perform the following steps in turn:

- push back the protective shield while lowering the brake;

- turn the control tension screw with a screwdriver, unscrew the nut, thereby weakening the tension;

- remove the cover;

- we separate the tire with the chain from the sprocket;

- remove the old chain from the tire, install a new one in its place;

- we perform actions in the reverse order.

We tighten the chain smoothly, without jerking. We finally tighten it after closing the plastic cover with a screw and nut.

There are modern keyless chain tensioning systems, but many craftsmen prefer the traditional side tensioning, somewhat problematic, but proven and reliable.

Modern models of electric saws have so-called wing nuts for operating chain tension.

Thanks to this element, the replacement process is faster - and this is important for large volumes of work. After lowering the brake, unscrew the nut and remove the cover

Slightly pushing the tire back, remove the old chain, put on a new one - first on the sprocket, then along the entire length. Then we put the sprocket in place, tighten the nut. We turn the tension wheel in the direction indicated on the body and finally tighten the "lamb".

The last step is to check the chain tension. It should fit snugly against the tire when the brake is released, but rotate under manual influence. For a more effective check, it is recommended to run the saw at low speeds.

You can watch the video in more detail about chain tensioning:

Recent Entries

5 unusual zucchini dishes instead of pancakes and stews that have set the teeth on edge 8 folk remedies for fighting the Colorado potato beetle: for those who are against "chemistry" in the garden 5 ways to use garlic arrows that experienced gardeners know about

Measuring the degree of sharpening of a circular saw

As a rule, circular saws with victorious soldering are used occasionally, but for significant amounts of material for a long time. Therefore, it is completely normal that the incisors begin to grind over time. Sharpen this product if necessary. Finding the degree of sharpening is quite easy:

- When sawing the material, bulges, notches, chips begin to appear, and when cutting wooden objects - the corresponding smell and dark traces on the material;

- Working on the machine becomes more difficult, because you need to make more than just effort, and as a result, there is a powerful load on the engine.

Fundamentally! The lack of observation of the sharpness of the cutting edges of the disk leads to the fact that the product, in general, not just can no longer be sharpened or repaired. Therefore, it is worth laboriously taking care of the condition of the instrument.

It must be said that, you, these machines are provided with protective relays. If there are none, the device can malfunction more quickly if the sharpening is incorrect, in other words, not just right.

Varieties and main differences

A chain with a guide bar is a removable equipment, which means, for example, when deciding which chain for a chainsaw is better for a budget class calm, you can also consider carved elements of a different class. In other words, owners of budget gasoline chain saws can choose a durable saw set for their tools, which is more wear-resistant.

Trying to figure out which chains are best for a chainsaw, you can focus on the reviews of the owners of different power units. You can act differently by contacting specialists for professional advice. Really make the right choice, focusing on the rating and characteristics of the replacement equipment. To select the ideal components that do not reduce the performance of the tool and cause it to malfunction, take into account a number of criteria, according to which the carved element differs:

- the quality of the material from which the chain is made;

- chain length;

- chain pitch;

- the thickness of the replaceable headset;

- groove features;

- features of the links (there are two types in total).

For a number of characteristics, branded and budget chains differ significantly. Nevertheless, some operators of fairly powerful budget gasoline saws manage to combine the unit with a perfect saw set produced by Oregon, Husqvarna, and Stihl. If you believe unofficial data, recently, Hammer and Power Sharp models have taken the leading positions in the ratings of consumer demand for such products.

The higher the price range, the more likely it is that the proprietary chain compensates for the technical imperfections of the tool by improving work results even when performing complex sawing operations, due to an increased repair resource, due to the stability of a number of operational characteristics.

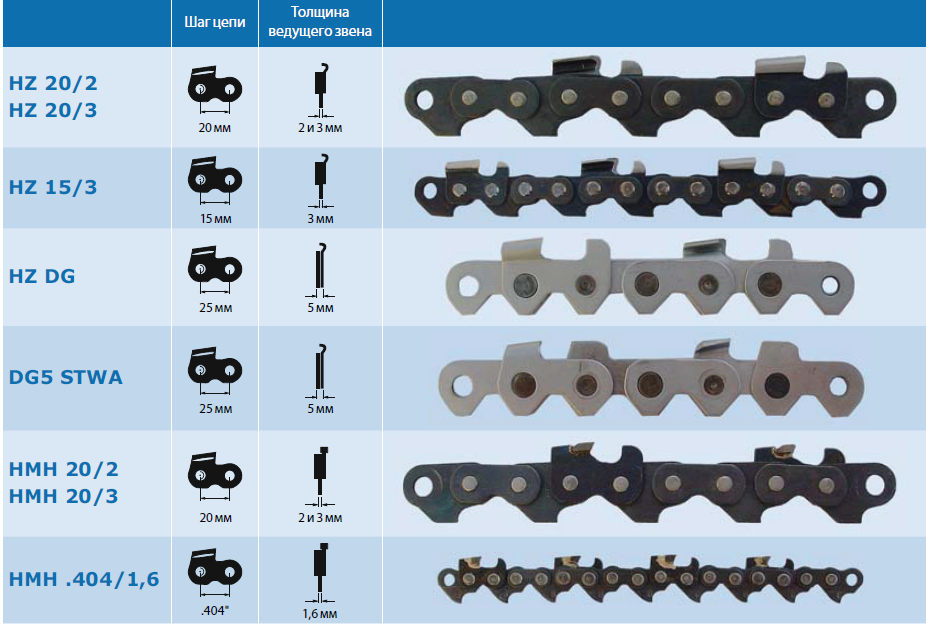

Determining the parameters of the chain shank

The thickness of the drive link, which is called the tail of the chain, is also an important selection criterion. In this case, the indicators are expressed in millimeters. There are five basic shank thickness sizes:

- 1.1 mm. This format is typical for small chainsaws with miniature chains for cutting the same branches.

- 1.3 mm. In general, such shanks can be attributed to the previous standard size, but if you need some safety margin when performing simple tasks, then they give preference to this format.

- 1.5 mm. An intermediate option that can be considered as a universal one. It is suitable for both domestic and professional use.

- 1.6 mm. Professional format, the main characteristics of which are robustness, reliability and high performance.

- 2 mm. A highly specialized chain with a large shank that withstands extreme loads in large diameter barrels.

The classification is clear enough and covers the entire range of applications.The question of which chain is better for a chainsaw with one or another power potential will have to be decided based on the size of the tire. Both the pitch and the thickness of the shank rather reflect the structural possibilities of compatibility, but they also intersect with the power load and the specifics of the operation of a particular unit. Therefore, the main emphasis in the choice is made on the instructions for the saw model and its intended purpose.

Selection of a quality chain

It is very difficult to find a quality chain in the modern world. The chain often loses its quality very quickly when purchased. To purchase a chain, you need to find a permanent trusted supplier who can advise on which chain to buy.

We recommend reading:

-

The best garden shredders: TOP-3 of the best models and brands of 2020 (95 photos and videos)

-

Which chainsaw is better? Tips for choosing the best and models of professional and household chainsaws (115 photos and videos)

- Garden inventory - the best tools, equipment and options for their use (110 photos)

If the chain serves well, then you should buy the same firm all the time. It is very rare to find high-quality material for your saw, since there are a lot of fakes.

One thing may be written on the packaging, but the quality does not coincide with what is written.

Maintenance and refurbishment of carbide chains

Sharpening is the most problematic aspect of using carbide-tipped chains. Regular sharpening is impossible, you have to use only diamond sharpening tools, which not everyone has. In addition, there are restrictions on the diameter of the sharpening machine spindle, which must be larger than the standard values (10-22.2 mm).

And the high price of a diamond grinding disc leads to the fact that it is advisable to purchase such equipment only for those craftsmen who constantly deal with cutting wood with high hardness or non-uniform density. Judging by user reviews posted on specialized forums, after high-quality sharpening, the resource of chains with victorious solders increases by 4-5 times.

However, in many cases, it is necessary to use a carbide chain until the cutting inserts are completely worn out or chipped, and then purchase a new one.

Soldering with copper or brass of a new carbide segment to the base of the tooth under normal conditions is also difficult to implement: you will first need to clean the surface from the remnants of the carbide, which requires an induction heating device for high frequency current (high frequency currents). In addition, induction brazing provides better adhesion of the carbide segment to the saw blade tooth, and its quality does not depend on the skill of the craftsman.

In principle, carbide links for Stihl saws are quite suitable for other brands (Husquarna, Makita).

How to find out which headset is on a chainsaw

There are several ways to determine the type of chain that is installed on a chainsaw. If the saw is new, just purchased, then the type and size of the chain are indicated in the documents (user manual, in the characteristics section). If the saw has already worked and it is not known whether the headset has changed during operation, then you can determine the type of chain by performing the following steps:

- Remove the headset and count the number of links.

- Use a vernier caliper to measure the shank width.

- Visually determine the type of cutting tooth. Sharp side edges - chisel, smooth edges - chipper.

- Use a ruler or caliper to measure the chain pitch.

Important! Incorrectly measured dimensions can lead to the fact that the new chain does not fit into the tire of the chainsaw or has a pitch different from the pitch of the sprockets, so you need to be more careful when taking measurements. Another option to determine dimensions that does not require the use of a measuring tool is to look at the marking

Shank width is indicated on the outside of the stop teeth. The widths on the prong are shown without one, i.e.if the number 3 is on the tooth, then the shank width is 1.3 mm, the other dimensions are the same

Another option to determine dimensions that does not require the use of a measuring tool is to look at the markings. Shank width is indicated on the outside of the stop teeth. The widths on the prong are shown without one, i.e. if the number 3 is on the tooth, then the shank width is 1.3 mm, the other dimensions are the same.

Some manufacturers, such as Oregon, have a model number stamped on the shank of their products. Knowing the number, you can easily determine the characteristics of the chain by finding information about the model in the catalog.

Shank top

Its design affects safety. Professionals are experienced, they adhere to all safety regulations and productivity is of the utmost importance in their work. Therefore, the construction of a "professional" chain usually does not have an upward extension of the shank, which allows for fast and aggressive sawing (eg Husqvarna X-Cut C85 chain). The average user doesn't have that experience. In order not to create the effect of instant rebound, especially when the rotating chain touches the wood with the nose of the tire, the upper part of the shank is made in the form of a "springboard". This will greatly minimize the rebound. This parameter is coded in the designation of new Husqvarna chains as the symbol "G" (in Husqvarna X-Cut saw chains SP21G, S93G, SP33G).