Advantages and Disadvantages of Clamping Fasteners

Floating fastener

In such a nut, the lower segment with the upper one is not dependent on each other, they rotate by themselves. It is used in angle grinders instead of a standard nut. The advantages of such a fastener are as follows:

- to unscrew it, it does not need a specialized wrench (a regular open-end or a simple cap will do);

- the circle is not pressed tightly, therefore, the clamping fastener can be unscrewed freely.

There is probably only one drawback - its cost is slightly higher than the typical one.

Regular nut

It is practiced in various instrument modifications. It is included in the package of cheap angle grinders. Fastener advantages:

- firmly presses the circle;

- low cost.

Disadvantages:

- a dedicated wrench is required for unscrewing;

- often spontaneously sticks to the circle, and special skill or equipment is needed to turn it off.

Fastener superflange

Specialized moving inner nut made by Makita. Advantages:

- makes it possible to freely remove the circle, no matter how tightly it is tightened in the process of work;

- increases user efficiency.

Minus - the cost is significantly higher than that of other fasteners for angle grinders.

Self-locking nut

Replaces the conventional clamp fastener. Advantages:

- no special wrench required for unscrewing;

- freely dismantled;

- high wear resistance;

- durable.

Disadvantages:

- quite expensive;

- can sometimes stick to the circle and in this case it should be turned off as usual.

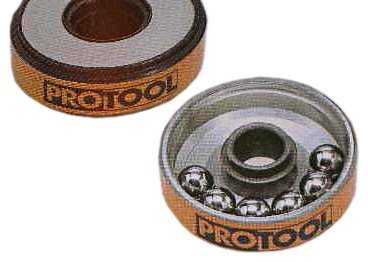

Fastener with auto-balancer

The structure contains bearings inside the nut. During operation, the bearings are dispersed inside to balance the vibration processes. Advantages:

- the grinding disc works 50% longer;

- there is no vibration;

- multiplies the tool life.

The disadvantage is the high cost.

Types of clamping nuts

Unlike other tool assemblies, the nut for angle grinders is the part that the operator encounters most often. This is due to the fact that cutting and grinding wheels are consumables and their service life is short. The period of useful use is reduced when the grinder is skewed during operation: this leads to the destruction of the circle.

The design of the clamping mechanism includes two parts:

- Pressing area.

- Rotating area.

Due to the constant rotation, constant pressure is created on the wheel, excluding the possibility of unwinding.

Modern industry offers users the following types of pressing accessories for grinders:

- Classic. The standard nut design is used in the production of budget segment grinders. The advantages include low cost and ease of execution, which ensures reliable fixation of the circle. The disadvantages are the need to use a special wrench, as well as periodic interruptions in operation, as a result of which the nut sticks to the disk, which makes it difficult to dismantle it.

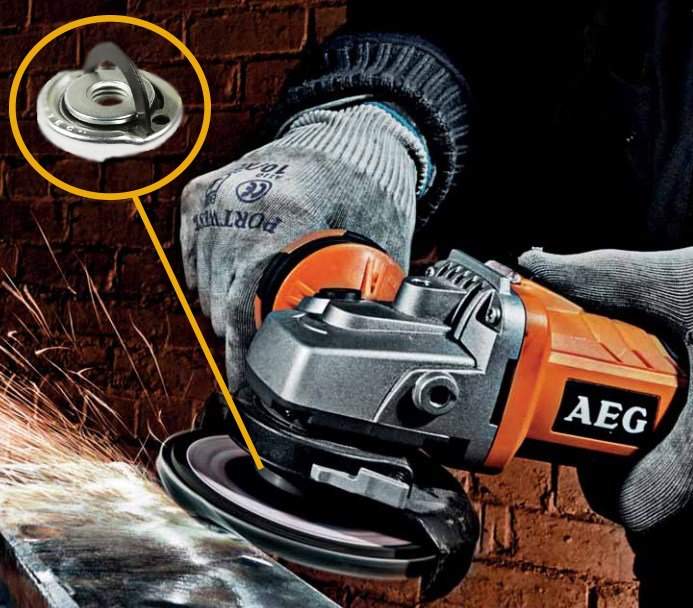

- Floating. The peculiarities of the structure are the presence of two unconnected parts, combined into a single mechanism. They are used to complete the middle class grinders of both domestic and foreign production. The main advantage is the presence of a hexagonal element, which is tightened with a classic open-end or box wrench.In comparison with the above-described design, the possibility of sticking to the working wheel is excluded. The only drawback is the cost, which is slightly higher than that of the classic model.

- Superflange. Designed by the popular Makita brand for high quality tools. A feature of the execution is the movable inner part. This increases the productivity of the tool and makes it easier to remove the nut - even if the wheel breaks, you do not have to put additional effort. Minus one - the price, which is much higher than that of competitors.

Despite the fact that the superflange was developed as a product for the Makita tool, nothing prohibits its use on grinders of other brands.

- Quick-clamping. New generation of fixing devices. A robust attachment made of high quality steel will allow you to remove the circle with only light hand effort. They appeared on the market not so long ago, so the design has one drawback - with prolonged use, they can stick to the surface of the circle, like standard models. The cost of self-locking mechanisms is less than that of a superflange, but higher than that of a floating fixture.

- Fasteners with an autobalancer. The main difference from similar mechanisms is the presence of metal balls inside the structure. During operation, they are evenly distributed throughout the interior space, reducing tool vibration. This increases the service life of consumables and the grinder itself. The only limitation for widespread use is the very high cost.

What is a compression nut?

LBM is a convenient, transportable and reliable tool designed for cutting and grinding stone, ceramic, metal and sometimes wood surfaces. Working with an angle grinder only looks relatively straightforward and straightforward from the outside; in practice, it requires certain abilities and knowledge. Using a grinder, a specialist must be as careful and focused as possible. If you do not adhere to the established safety rules and work technologies, then various injuries are provided to you

Failure to follow the required precautions can result in the worker being crippled for life.

Of course, developing any of the modifications of the grinders, the manufacturing companies strive to insure the user as much as possible when operating the tool, but one should also use the mechanism carefully and have an idea of its certain properties. A very significant aspect when choosing angle grinder - the type of pressing fastener supplied to it

A specialized clamping nut is produced with each angle grinder. By means of it, a grinding or cutting wheel is fixed. The design characteristics of the nut are quite interesting. As the clamping fastener is pushed onto the shaft, one part of the fastener is pressed against the disc, and the other part rotates, forcing the bottom of the nut to grip the disc more and more. Actually, this nut is able to create an abundance of difficulties for the owner of an angle grinder.

The fact is that cutting and grinding discs, although they have different thicknesses from 0.8 millimeters to 3 millimeters, are fragile and thin under any conditions. Even slight body swaying contributes to the skewing of the cut-off wheel in the slot. As a result, it starts to wedge and may crack. A change is needed.

It turns out that in the course of long-term work with the tools, the clamping nut tightens spontaneously, after such tightening with your fingers, it can no longer be unscrewed. You will definitely need a special key with two horns, which is included in the set.If your unit has an ordinary clamping fastener, then you need to find a key, which, when needed, disappears somewhere (it is advisable to tie it with insulating tape to the cord), and then, after suffering, unscrew the fastener. There is also the worst option - to grind off the nut on emery. However, there is a way out of this situation, and not even one.

Nut selection (most popular brands)

Bosch SDS-clic

Bosch is familiar to almost everyone, it produces a really good-quality tool and has repeatedly confirmed its own reliability in the course of improving the power tool. For example, their innovation is the SDS-clic quick-locking nut. She shocked everyone with her own perspective. The creators, in an effort to help reduce the time for changing grinding wheels, did not create new wheels at all, but made it possible to shorten the change time. Everything is done in one moment with your hands, without a key, both tightening the circle and unscrewing it.

FixTec

Multifunctional quick-clamping fasteners for the angle grinder, which guarantee a reliable clamping of the wheel and no danger when using tools. They are used on the spindle, the most running thread M14. The use of equipment with a diameter of up to 150 millimeters is recommended, and ultimately users effectively use FixTec even on angle grinders with a circle diameter of 230 millimeters.

The pros are as follows.

- Rapid change of equipment, less than 12 sec.

- Circle jam protection.

- Tightening and removal without a special key.

- Turnkey holes for unexpected moments.

- Multifunctionality of use on grinders of the overwhelming mass of manufacturers. It is used on the most popular types of circles with a diameter of up to 150 millimeters, a thickness of 0.6 - 6.0 millimeters.

MAKITA 192567-3

Multifunctional quick-clamping nut for angle grinders. By means of it, the employee is able to fix the circle smartly and without the use of auxiliary devices. This nut is compatible with discs of any size - from 115 to 230 millimeters. Typical thread (M14) makes it possible to install a self-clamping fastener on an angle grinder from different companies.

For a BOSCH quick-clamping nut for a grinder, see the following video.