Additional functions

Ease of operation, maintenance, as well as the level of safety in the process of preparing concrete mix, largely depends on the availability of additional functions in the concrete mixer. These include:

- Method of loading and unloading components and ready-mix. In cheaper models, the process is carried out manually, but for large volumes it is preferable to purchase a self-loading concrete mixer.

- Method for regulating the position of the pear. So that the mixture does not pour out during mixing, and in the finished form the solution can be conveniently unloaded into the desired container, it is desirable that multi-mode drum position latches be installed on the concrete mixer.

- Purpose and permissible conditions for work. These characteristics are significant when the mixer is expected to be used frequently and regularly, regardless of natural and seasonal conditions.

- Noise level. Additional noise suppression elements will not only make the process quieter, but also provide a pleasant atmosphere throughout the construction site.

- Waste volume. This takes into account the amount of dust released into the atmosphere during the mixing process. To make the concrete preparation process relatively safe, choose a machine with dust emission controls.

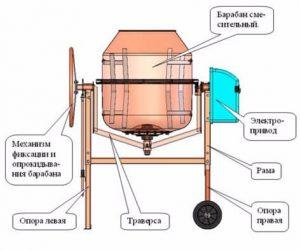

Concrete mixer device

Constructive features and device of a concrete mixer:

- Main drum. This is a special container in which ingredients are poured and water is poured to prepare concrete. The functionality of the device is influenced by the size, type.

- Stanina. According to its design features, it is equipped with different elements - a profile or pipes. All parts are firmly connected to each other. Wheels provide convenient movement.

- Internal blades. They are directly involved in the mixing process. The solution is homogeneous, without lumps.

- Engine. The motor is gasoline and electric. It is designed to drive the drum, blades and gears.

- A device for tipping the bowl and unloading it. It helps to extract the finished mixture.

Each concrete mixer is equipped with a central unit with a control board. There is a button for supplying electricity and stopping the device. Users will be able to adjust the mixing speed of the concrete.

Which concrete mixer to choose - criteria, requirements

Depending on how much the solution will be needed, how often it will have to be prepared and under what conditions, an ideally suitable model of equipment is selected.

In this case, the following criteria must be taken into account:

- The principle of operation of the concrete mixer.

- Mains voltage on site and unit capacity.

- Theoretical fuel consumption.

- The size of the mixing pear.

- Permissible cycle period for continuous operation.

- Time of work on mixing concrete.

- The number of people involved in the process.

- Manufacturer reliability.

- Additional functionality that affects the speed, quality and ease of mixing of components.

What are concrete mixers

Before buying, you need to study all types of concrete mixers. They differ in design features, technical characteristics.

By the duration of work

Concrete mixers are:

- Cyclic action. They are suitable for summer cottages or private construction, because they are equipped with a small drum. Stops are required during operation. Concrete mixers of this type quickly consume their resource if used improperly.

- Continuous action. They can work without stopping or shutting down, simplifying the task for builders who mix large portions of cement daily or regularly.

By the principle of work

Concrete mixers are classified by the way they mix dry ingredients and water

When choosing, you need to pay attention to the differences and types

Gravity type

The container spins in a circle, the blades move inside. The master can change the position and tilt, control the intensity of stirring. The structure can be easily disassembled into separate parts, cleaned of concrete residues. The device is allowed to be transported.

The principle of operation of gravity concrete mixers.

The principle of operation of gravity concrete mixers.

Varieties of concrete mixers by type of drive mechanism:

- Toothed rims are provided along the entire circumference of the drum. They are made from plastic, steel or cast iron. Internal mechanisms and board are not protected from debris penetration. Cast iron crowns are inexpensive but generate noise during operation. The plastic elements are quiet during operation. Steel crowns are durable and more reliable in operation. Crown concrete mixers often fail, but need to be repaired.

- Gearboxes. These are durable structures that will last a long time. They rarely fail, but repairs require contacting specialized companies.

The advantages include the presence of powerful electric motors, therefore, energy consumption is minimized. Manufacturers equip structures with wheels and a sturdy frame to move the structure around the construction site.

But there are also the following disadvantages:

- after each use, it is required to thoroughly wash the drum, pear and surface of the concrete mixer (a thick layer may gradually form, which worsens the quality of the solution);

- if the consistency is too liquid, the mixture often splashes out during the operation of the blades inside the thicket.

When choosing, you need to pay attention to the technical characteristics, because manufacturers make powerful models. For their operation, a connection to a 380 W network is required.

Forced action

In such a machine, a stationary container is provided. Only the blades are spinning inside. Such a concrete mixer is used to prepare a mixture with additional plasticizers. The bowl is large. These concrete mixer models are not suitable for private and small construction.

The advantages include obtaining a high-quality solution, the possibility of dosing its unloading. Disadvantages - there is a possibility of stones falling into the space between the wall and the blades. Crushed stone leads to jamming of the mechanism. Some models have a skip. This is a special elevator that simplifies the process of conveying the concrete mixture into the container.

By drive type to energy source

Types of drive to power source concrete mixers.

By drive type to energy source:

- Manual. These are unpopular and less demanded models, because they differ in a small bowl volume. It requires an operator to operate the concrete mixer, so labor costs increase. The advantages include the ability to work independently.

- Models with hydraulic and pneumatic drive. The mixing organs are supplied with liquid or air at a high level of pressure. Concrete mixers are widely used in industry, because additional equipment connection is required for efficient operation.

- Motor-driven. These models are equipped with gasoline or diesel engines. They work autonomously. Disadvantages - hum during operation, high cost of gasoline, exhaust gases that are harmful to human health.

- Electrical. They are equipped with drums of different sizes.

How to choose a good concrete mixer for home and garden

Before buying a concrete mixer, you first need to decide on the optimal bowl size. How to choose a concrete mixer? Sorting out this is not at all difficult - you just need to decide what exactly the technique will be used for.

- For the construction of small buildings, such as a garage or sauna, and small repairs, a unit weighing up to 22-24 kg and a maximum capacity of 100 liters is suitable.

- For the construction of larger structures, for example, summer cottages and one-story houses, it is best to choose equipment over 40 kg and a volume of 100-150 liters.

- For the construction of houses from several floors, a concrete mixer with a capacity of 150-300 liters with a weight of more than 50 kg is required.

- What is the best concrete mixer for large-scale construction? If you are planning to build a warehouse, a barn or a multi-storey building, you will have to fork out for a unit with a volume of more than 300 liters and a weight of 160 kg or more.

But expert advice doesn't end there.

Before buying, be sure to pay attention to the characteristics of the concrete mixer that you liked

- Whether it is amateur or professional. If you do not plan to use a concrete mixer all the time, you do not have to buy an expensive unit, which will then simply gather dust in the garage. If all you need is to just knead the concrete a few times, you can save money by armed with an amateur model.

- Material. On sale you can find cast iron, steel and even plastic models. Moreover, of course, the quality and prices vary significantly. Which concrete mixer is good? The most reliable are cast iron units.

- Motor power. Here the "the more the better" formula does not work. The power indicator must correspond to the dimensions of the unit and the time of its continuous use. For a compact household concrete mixer, 700 W is quite enough, for a 12-hour operation, about 800 W is suitable, and for constant use, 1000 W will not be enough.

- Season. Much even depends on the weather. For example, many concrete mixers are not suitable for winter use. The mixture in them will not cook well, and the machine itself will remain cold. That is why manufacturers always indicate on their units the minimum temperature at which use is permissible.

- Voltage. If you are looking for a concrete mixer for your home, the professional model that requires 380 volts is unlikely to suit you.

- Strength. If the drum seems to be too smooth and too tight, it is most likely made of thin steel sheets. There is no need to talk about reliability here. Bowls with large weld seams are often more durable and of better quality.

- Overload sensor. An extremely useful option that ensures the safe and correct use of the machine. Some models are equipped with automatic sensors that turn off the engine in case of overheating. Such a device will serve you much longer.

- Unloading and loading. These processes should be comfortable enough for you. When choosing a concrete mixer, be sure to check how correctly the loading and unloading is organized. Otherwise, you will have to do it manually.

- Colour. You might be surprised, but this is also an important parameter. According to the rules, orange and yellow aggregates are considered safe. The thing is that the bright case minimizes the risk of bumping into the switched on device at night.

Taking into account all these points, you can easily buy a good concrete mixer that will serve you faithfully for many years.

The principle of operation of the concrete mixer

Today there are 2 main and several types of special-purpose concrete mixers.

Main types

- Concrete mixer is compulsory. Distinctive features:

- the drum is motionless;

- mixing of the mixture takes place by means of internal movable blades.

- Gravity concrete mixer. Unlike the previous type:

- rotation is carried out precisely by the drum;

- the blades at this moment remain in one place.

Modern types of special purposes

As additional varieties in a number of classifications, the following options can be distinguished:

- The turbulent concrete mixer is characterized by an increased mixing speed of components without loss of quality indicators. Great for mixing aerated concrete and other mixes for quick completion of large-scale construction.

- Planetary concrete mixer is a kind of forced cyclic type, but instead of blades it has a more complex element (drive sprocket) in the device. It fully justifies its use in the conditions of large construction sites due to the receipt of a high quality mixture in a short time, but requires special preventive maintenance. A significant disadvantage is the high consumption of energy or fuel during operation.

Mechanism device

Another important factor in relation to the principle of operation of a concrete mixer is the design of the main working element. On this basis, concrete mixers are distinguished:

- Gearboxes are more reliable, but, accordingly, expensive.

- Coronal units will cost less, they can break during operation, but unlike gear units, they must be repaired.

Peculiarities

Tools for construction work must be of high quality and reliable, do their job well. Zitrek concrete mixers are produced by a small company located in the suburbs of Prague. The family business started out with silver mining tools. Today, products are manufactured at factories in China, Russia, Hungary, Italy and Croatia.

In the manufacture of construction equipment, modern technologies and high-quality materials are used. The company's employees are constantly developing and learning something new. This development approach allows customers to use reliable and efficient concrete mixers. In the Russian market, Zitrek is famous for its comprehensive engineering support of projects.

Concrete mixers have a number of features.

- Motors for 220-380 V are installed, which ensures high performance.

- The gears, crown and pulley are made of cast iron. The high strength of the material guarantees wear resistance even with active use.

- Stiffeners and bolted connections are provided. This guarantees extra durability.

- There is protection against overheating and power surges.

- Suitable for the preparation of even multi-component mortars.

- The gearbox is protected from mechanical damage, so it does not break down during use.

Concrete mixer power

The power potential of concrete mixers has quite wide parameters - in the range of 150 W-3 kW. This indicator affects the possibilities of continuous action and the available volume of preparation of the mixture for 1 cycle.

To determine the appropriate parameters, consider the following recommendations:

- up to 700 W - such concrete mixers are quite suitable for use in domestic conditions, that is, for private construction;

- from 1000 W - applicable in large-scale projects with large volumes of concrete mix, as they provide a sufficiently long cycle of continuous operation.

Concrete mixer designs

To choose a concrete mixer, you need to familiarize yourself with the basic structures. There are two types of mixers: forced mix and gravity mixers. Forced ones consist of a stationary container, inside which mixing blades rotate. Due to the design features, they work only with solutions - without large aggregate, they also require more powerful engines, and, accordingly, consume more electricity. All this leads to the fact that they are used mainly by professionals.

Forced type concrete mixer

For developers and for domestic use, gravity concrete mixers are more suitable. This is a barrel-shaped container, inside which strips-blades are welded. This container rotates around its axis and can change its position relative to the horizon. With an inclined tank, the most intensive mixing occurs. This design allows you to make both mortar (cement + sand) and concrete (cement + sand + gravel or other coarse aggregate).

Gravity concrete mixer (one of many options)

There are two types of drives - gear and crown.Gearboxes are more reliable, but their repair is a very difficult and expensive undertaking. If suddenly such a mixer breaks down, then it is easier to buy a new one. The crown structure breaks down more often, nevertheless, replacing the crown is a matter of a couple of hours and a relatively small amount of money (1000-2000 rubles, depending on the crown material). All this led to the popularity of wreath-type gravity concrete mixers.

A geared concrete mixer usually has a characteristic design - the engine is located under the bottom of the tank

Leading manufacturers of concrete mixers

A huge assortment of domestic and foreign concrete mixers is presented on the construction market. It is not so easy to choose a good model among them without overpaying for a loud brand and non-existent options. The highest quality units are considered to be from France, Germany and Italy. In addition, the buyers highly praise the concrete mixers made in Croatia and Poland. But when choosing such equipment, you should understand that equipment of foreign brands costs many times more than domestic counterparts. If you cannot afford an expensive imported unit, you can easily pick up an equally high-quality model from our manufacturer. The main thing is to know which brands you can trust. Especially for you, we have selected the top 12 best domestic and foreign brands of concrete mixers. It included:

- Limex;

- Zitrek;

- GuyNoel;

- Altrad;

- Denzel;

- Vortex;

- Lebedyan;

- Caliber;

- Profmash;

- RedVerg;

- Caiman;

All these brands have long won the trust of users, so the demand for their products is steadily growing from year to year. If you are choosing a concrete mixer, take a closer look at the equipment of these manufacturers. Having bought such a unit, you will definitely not regret your choice.

Which crown of a concrete mixer is more reliable

If you make a rating of concrete mixers in terms of reliability, then, firstly, you need to pay attention to the material from which the crown is made. It is he who is responsible for the life of the concrete mixer.

Cast iron

A cast iron crown is used on most mixers of the middle price category. The cast iron crown is easy to manufacture: the cast iron melt is poured into a mold, after solidification, the workpiece requires minimal processing. The inexpensive cost of the material and the simple method of manufacturing parts form a relatively low cost of the finished crown and drive gear. This is the main plus of the cast iron product.

There are several disadvantages at once:

- Cast iron is a brittle material, with mechanical stress, the part can break;

- With repeated use, the teeth are abraded;

- The heavy cast iron crown makes a lot of noise during operation.

Steel

Steel is a very strong and reliable material that does not wear out as quickly as cast iron and does not burst if dropped or bumped. By the way, the steel crown makes much less noise during operation. However, it costs an order of magnitude more expensive than cast iron. This is due to the manufacturing process of the part. First, the red-hot metal composition is poured into a mold and cooled. After extraction, they are brought up on special equipment (grind and grind). In addition, the steel is hardened. All these processes increase the cost of the part, but at the same time contribute to its strength and reliability.

Plastic

A plastic crown is the cheapest of the above. It does not require large financial and production costs to manufacture. Another plus of the plastic crown is its quiet operation and its light weight. The disadvantages include the quick wear of the teeth, which are erased from friction with the gear.

Polyamide

Polyamide is a modern, durable and lightweight material that has been used in the manufacture of concrete mixers not so long ago. It is not inferior to steel in strength, and plastic - in lightness. In addition, the material is resistant to high temperatures. Therefore, it is able to withstand heavy loads in the hot summer period, without deforming and not being erased.

The synthetic material is also resistant to natural factors - it does not rust from water, does not react to the effects of many abrasive agents.Among the advantages of a polyamide crown: strength; durability; ease; heat resistance; resistance to electrical breakdown; collapsible ring design, simplifying disassembly and repair; quiet work.

Any crown, be it made of plastic or steel, is a toothed ring fixed around the drum. It drives the drum by means of a gear that transmits movement from the engine. In the course of frequent use, the teeth of the rim are erased together with the teeth of the pinion under the action of friction and vibration. However, after wear, these parts can be replaced.

Also, the following factors affect the wear of parts:

- Ambient temperature;

- Water inflow into the drive mechanism during rain;

- Penetration of sand, water or a ready change into an unprotected mechanism;

- Incorrect assembly of the device;

- Shocks, mechanical damage, falling of a filled device.

Top manufacturers

Manufacturers produce concrete mixers of different classes and power levels.

List of brands:

- Zitrek. This is a manufacturer from the Czech Republic.

- Denzel. The manufacturer from Germany guarantees high quality and reliability during operation.

- VseInstrumenty.ru is a Russian company that has been manufacturing concrete mixers since 2015. The trade mark is called Inforce.

- "Vortex". This is a Russian manufacturer cooperating with a Chinese firm.

- JSC "Lebedyansky plant". The production workshop operates in Russia. Construction finishing machines are manufactured here.

- Heat Trade. It is a reliable brand from Russia. Concrete mixers under the "Profmash" brand are manufactured here.

Rating of popular models of high-quality concrete mixers

It is recommended that you familiarize yourself with the rating of high-quality and proven units for obtaining finished cement.

Popular models of quality concrete mixers.

Redverg RD CM 63

This is a Chinese-made unit that has a compact size. The volume of the bowl is 63 liters. This model was designed for mixing small amounts of cement.

Advantages:

- low cost;

- high quality stamped crown;

- simple assembly.

Disadvantages include loud noise during operation and minimum power level. The average cost of a concrete mixer is 8500 rubles.

SBR 100

Concrete mixer SBR 100.

This model is easy to carry. The bowl and blades are connected by a soft strap, which helps to change the speed of their rotation. The solution is prepared in 2-3 minutes.

Advantages:

- crown with four sections made of cast iron;

- if the belt is damaged, it can be easily replaced;

- connection to a network of 220 V.

The bowl and structure may wobble during use. The average market value is 14,000 rubles.

Lebedyan RN 200

A new production cycle starts after the end of the previous one. This model has a powerful electric motor. The solution inside the thicket is thoroughly mixed.

Advantages:

- economical work;

- buttons for control are located on the engine cover;

- the ability to regulate the speed of rotation of the blades.

The disadvantages include high cost. The average price is 60,000 rubles.

Misom SO 351 300

The machine has a power rating of 2200 watts. The bowl prepares a solution of 300 liters. Features - low noise level during operation. The advantages include compact size, good performance.

The disadvantage is the high price. Average cost varies from 71 to 75 thousand... rub.

Misom SO 351 300.

Profmash B 180

The unit is produced in Russia. This model has an electric motor. The power level is 850 watts. The crown is made of polyamide. It consists of 4 parts. In the event of a breakdown, they can be replaced without removing the drum.

The advantages include convenient unloading of the finished mixture, the presence of wheels. The price on the construction market is 15,000 rubles.

Prorab ECM 180 A

The unit is versatile. It is used for the preparation of concrete, fertilizers, mixtures for livestock. The volume of the bowl is 180 liters.

The drum can be tilted at different angles, fixed in a comfortable position. The drive has a protective cover and wheels for moving around the construction site.

Whirlwind BM 180

The structure is lightweight, suitable for a small amount of construction work. The unit is connected to a 220 V network. The device is excellent for domestic conditions.

Electric motor power - 800 W. The crowns are made of cast iron, there are wheels for moving. All parts are qualitatively attached to each other by welding. The average cost is 16,000 rubles.

Parma B 201 E

Domestic production unit. It is used to obtain a viscous concrete solution. Advantages - a crown made of cast iron, control by buttons, the presence of wheels for transportation, the drum is fixed in a single position.

Concrete mixer Parma B 201 E.

Caliber TSE 65 220

The concrete mixer is compact in size. For 1 inclusion, you can prepare 44 liters of cement. The unit is intended for domestic use. Advantages - high build quality, compact size, low cost. The average price is 10 thousand rubles.

Prorab ECM 260

The capacity has a capacity of 260 liters. In this models are provided with a high power engine... The concrete mixer is equipped with a sturdy thickened steel structure.

Advantages:

- the crown is made of cast iron;

- a protective casing is installed around the entire perimeter;

- you can choose the model in 220 and 380 V.

The average price is 42 thousand rubles.

Zitrek ZBR 700 220 B

It was developed for professional construction, the construction of new buildings. The metal surface is treated with an anti-corrosion compound. They are characterized by a high level of power. The concrete mixer must be plugged into an outlet with a voltage of at least 2200 W. Average price $ 74,000