Mirror and transparent designs

Screens made of transparent and translucent glass or mirrors are quite expensive and rare. Undoubtedly, a bathtub with this design looks extravagant and expensive, but finding a finished mirror or glass product is very difficult. You can make it, but it is better to entrust this business to a professional, since you will need to cut and fit thin material.

This type of screen is not susceptible to moisture, but it is very fragile and requires constant maintenance. Indeed, on glass surfaces, water leaks and salt accumulations are especially noticeable. When installing such structures, it is necessary to ensure that the surface is covered with a film that does not allow small fragments to fly apart.

Despite the complexity of installation and operation, such designs are finding more and more buyers. Indeed, with the help of mirrors, you can visually change the geometry of the premises, just slightly change the angle of reflection.

How to choose the right screen

When choosing a screen for your bath, you need to pay attention to several aspects. First, you need to consider the area of the room.

After all, if a bath in a small room has a screen with detachable doors, then they will complicate its use. In a tiny room, it is best to make sliding panels. You also need to understand that fragile glass and mirror screens are not the best choice for an apartment in which small children live.

First, you need to consider the area of the room. After all, if a bathtub in a small room has a screen with tear-off doors, then they will complicate its use. In a tiny room, it is best to make sliding panels. You also need to understand that fragile glass and mirror screens are not the best choice for an apartment where small children live.

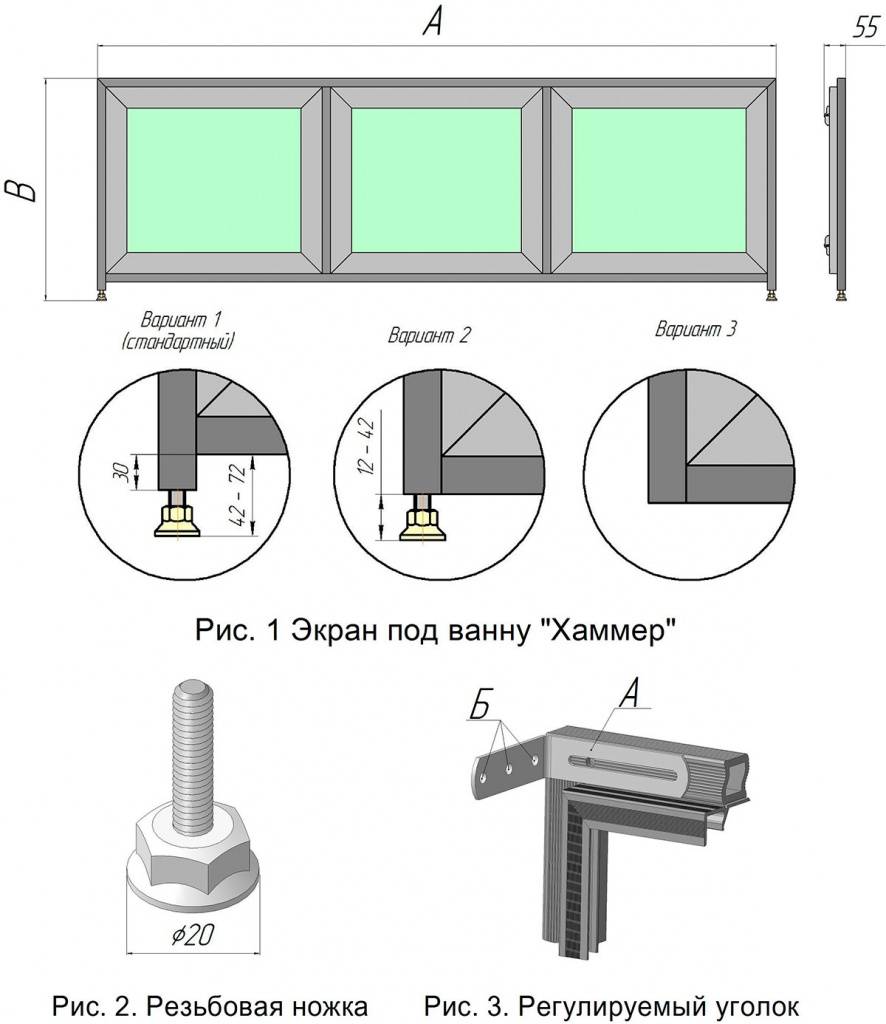

Before going to the store for a finished screen or material for its manufacture, you need to very carefully measure the dimensions of the bath itself: its length, height, width. If a side panel is required, then you should also know its estimated dimensions.

When buying a finished structure, you need to check whether the rollers on the guides are in good order, whether the legs of the screen are adjustable in height. How are joints made on plastic panels

All this is important, because a pleasant appearance is what a person aspires to.

You need to understand that if there is no good hood in the bathroom, then the wooden frame under the chipboard and MDF screen will sooner or later deform and collapse from the moisture accumulated over the years of operation. Therefore, the hood must be taken care of in advance or moisture-resistant materials must be used.

Before installing with your own hands, you should carefully consider the design - its functionality and appearance. Only then should one get to work. In this case, the result will delight the owner for many years.

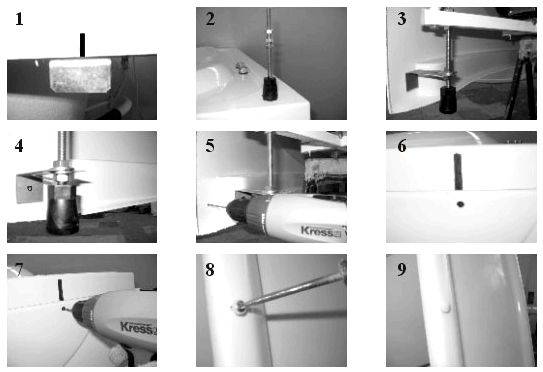

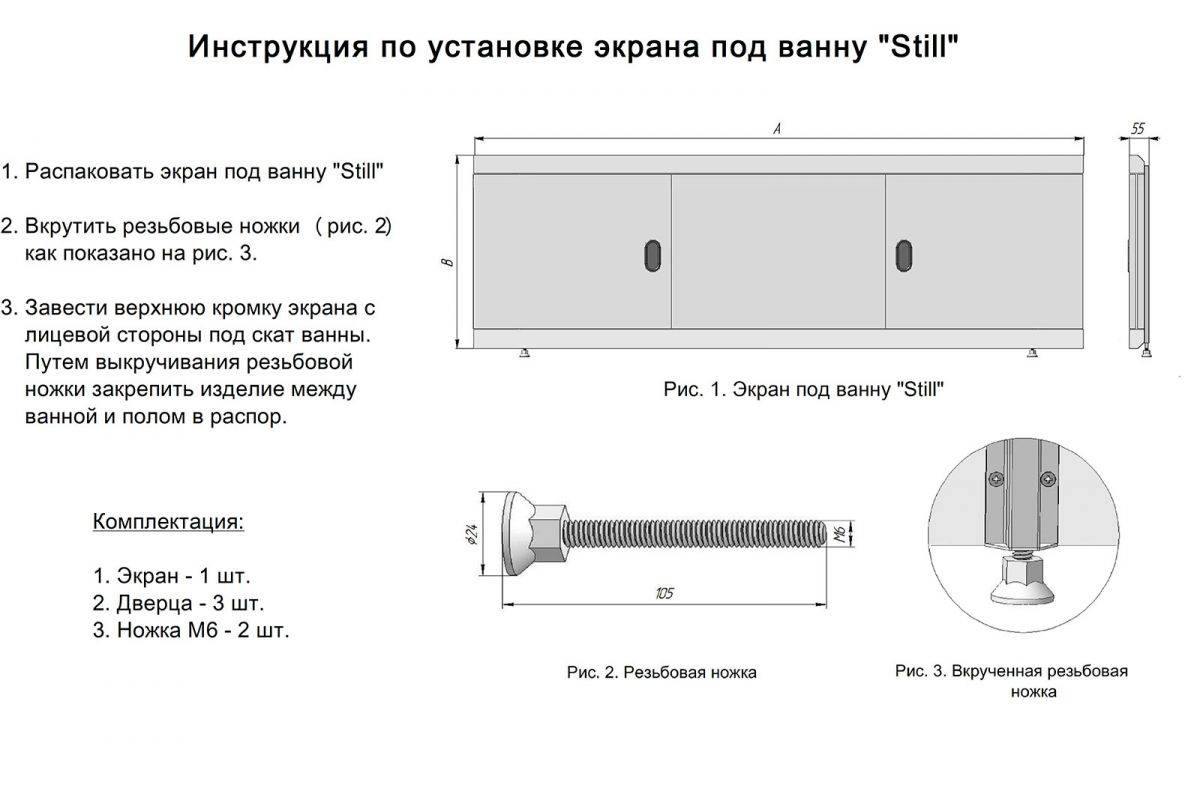

How do I install pre-built models?

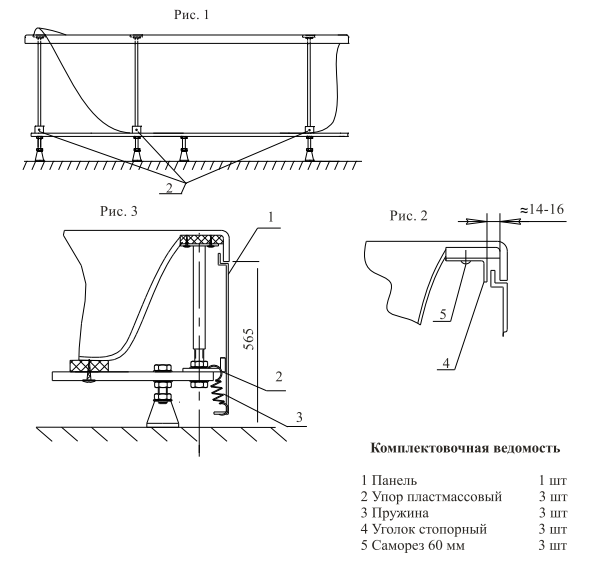

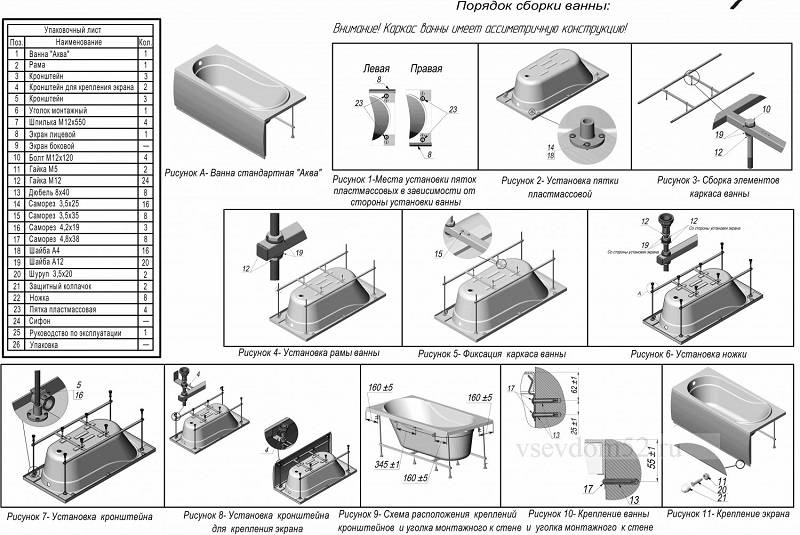

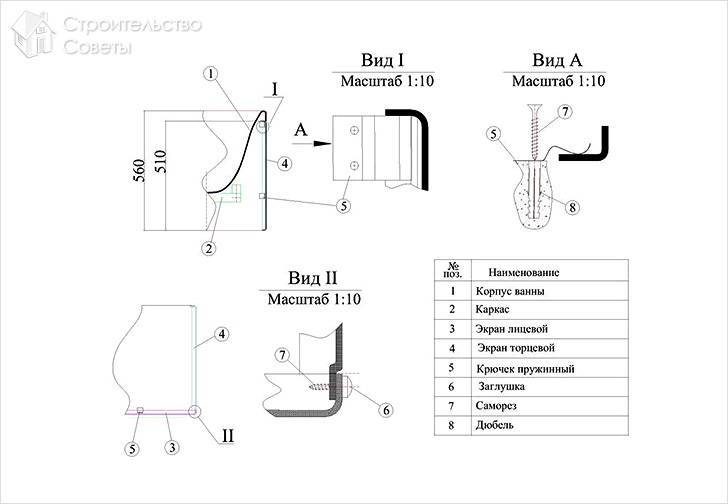

If there is no experience in installing screens, then it is recommended to purchase ready-made models. The choice in favor of this option is explained by the fact that such products exactly correspond to the dimensions of the bath and are equipped with the necessary parts. It is recommended to fasten the elements of the future frame with self-tapping screws with a diameter of 10 millimeters or more.

During the installation process, it is necessary to strengthen the frame with wooden bars. The latter will increase the strength of the structure being erected. The frame is not recommended to be installed close to the bath. This arrangement will complicate the installation of the panels.

Checking the contents and quality

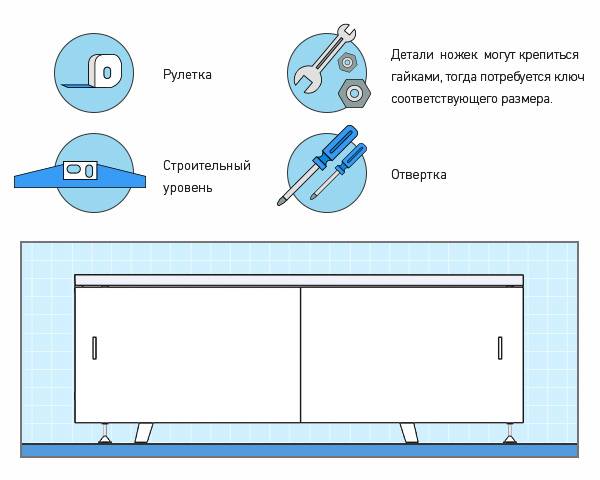

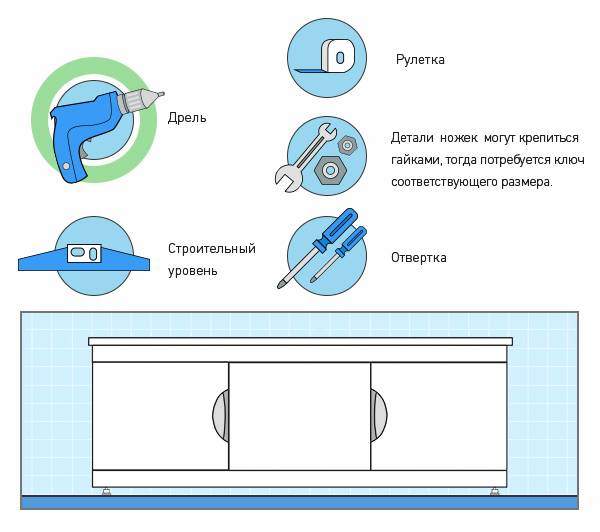

The complete set depends on both the design features and the material.Basically, such products are sold together with guides, fasteners and profiles, to which the panels are fixed. To assemble the screen, you will need a hacksaw (jigsaw), a screwdriver, a drill, a tape measure and a pencil (felt-tip pen).

Problems with the quality of finished products usually arise when acrylic bathtubs are purchased along with protective structures. The dimensions of the latter often do not coincide with the dimensions of the bowl. It is recommended to refuse the purchase of such products.

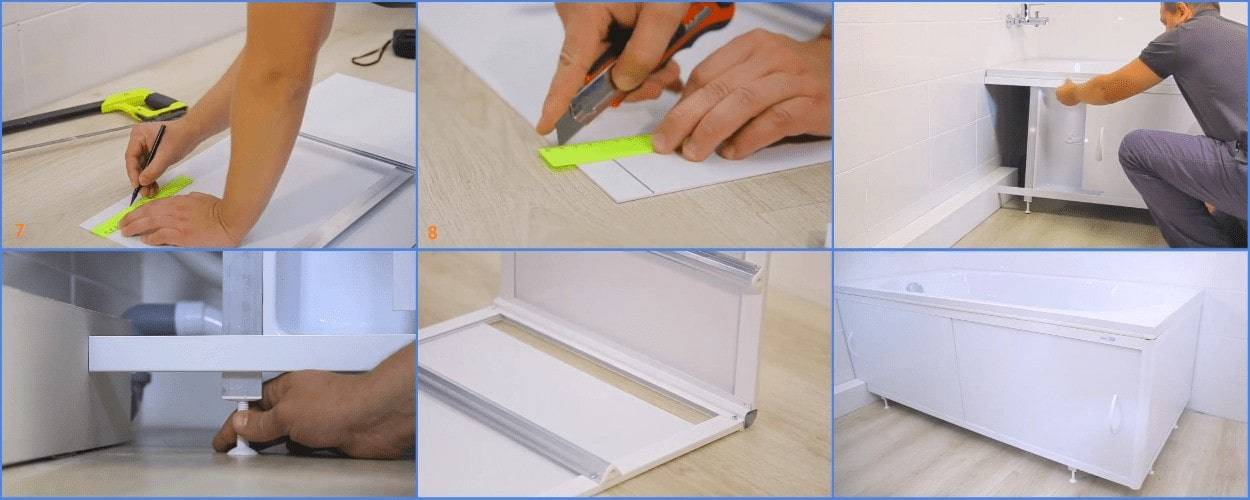

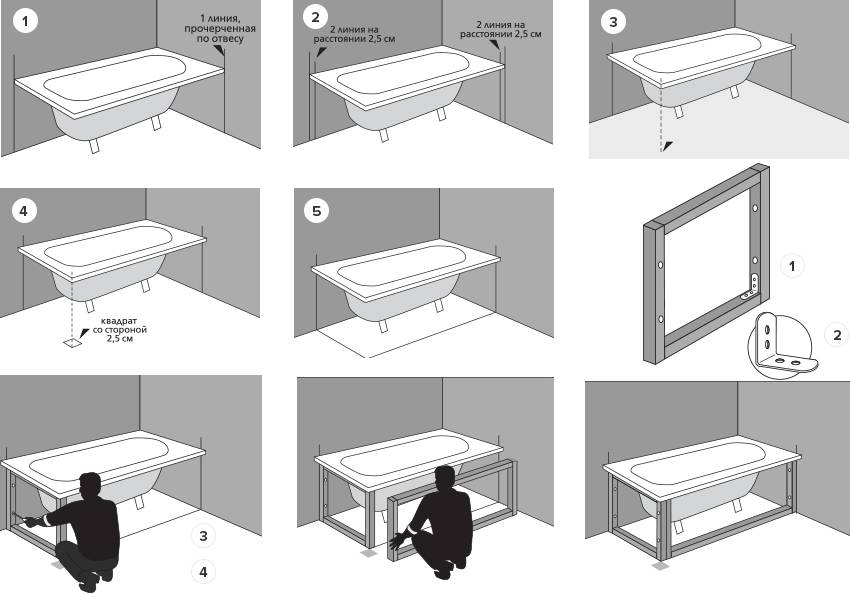

Measurements and markings

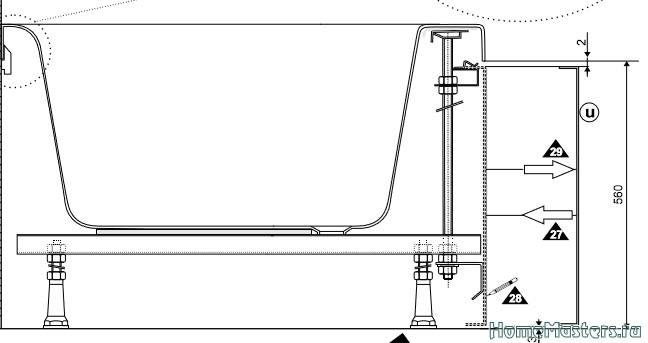

The installation of the protective structure begins with the determination of the dimensions of the future structure. For this, the height and length of the bath bowl are measured at several points. When determining the last parameter, it is necessary to take into account that the upper guide profile will be solid, while, like the lower ones, it will consist of several parts interconnected by means of vertical struts.

To find the correct screen size, you need to step back from the top edge of the bowl by 2.5 centimeters and measure the length of the bowl from this point.

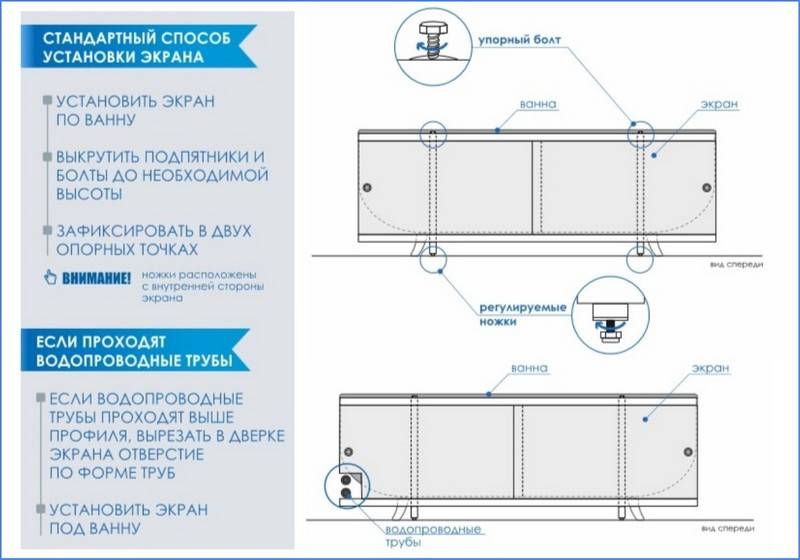

Adjusting the feet

To exclude the penetration of moisture under the bowl, it is necessary to adjust the legs before installing the panels so that the bath fits as tightly as possible to the future screen. This procedure should be carried out after installing the frame.

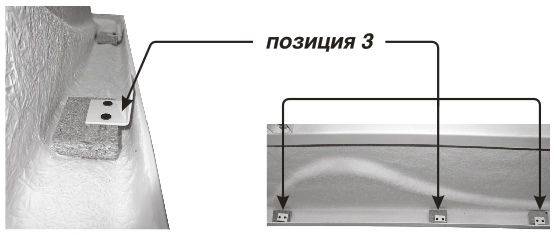

Fastening the frame under the bath rim

The frame is fixed with dowels, nails, according to the attached instructions. It is recommended to check the correctness of the installation with a level. This also applies to the installation of a profile in the form of the letter "Ш", which comes with a set of panels, complemented by sliding doors. The number of stiffeners (vertical strips) is determined depending on the size of the bath. Standard bowls require at least three profiles. At each stage of work, it is necessary to strictly maintain the level.

Installation of panels

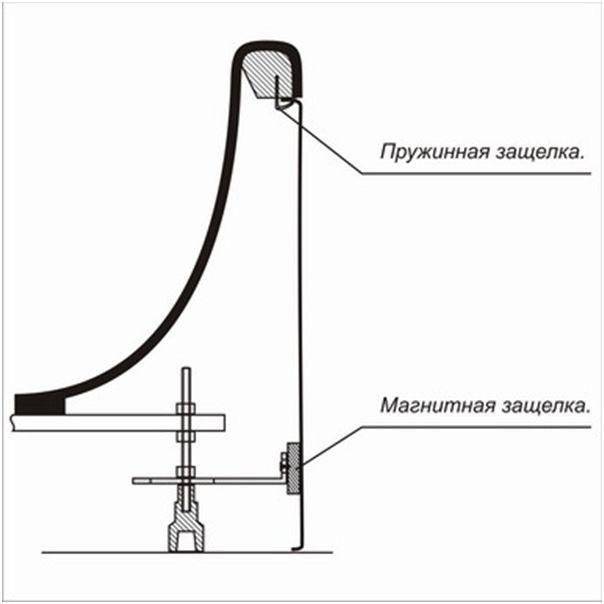

To fix the panels, the latter must first be brought under the upper guide, and then under the lower one. After that, it is necessary to re-tighten the legs of the bathroom so that the edges of the bowl fit snugly against the installed material. When performing these works, it is also recommended to measure the vertical by level. If a structure with sliding doors is being installed, then first you need to install the upper guide and insert the panel. After that, the lower profile is attached on both sides.

Seam processing

At the end of the work, it is recommended to treat the joints with a sealing compound. This also applies to the area of contact of profiles and panels to the floor. The sealing layer will protect against moisture penetration under the bowl.

MDF panels

You can install a screen for an acrylic bath without a frame, while the materials for the shield must be dense and moisture resistant. These are MDF boards. In fact, this is a chipboard familiar to everyone, which differs from chipboard in smaller fractions of wood and resistance to moisture due to modern glue.

MDF is almost two times thinner than chipboard, it is well cut, therefore it is great for building a screen for an acrylic or regular bath.

The main difference between an MDF screen and a thin plastic screen is the way it is opened. Due to the thickness of the slabs, they cannot be made sliding - the storage places under the bathroom open, as in a regular cabinet (by means of a hinged door). However, this feature gives the structure a monumental and expensive look. At the same time, installing a screen under an acrylic bathtub differs little in time from a simple device. MDF structures are sold ready-made with standard dimensions. They can be made on site using a jigsaw and door hardware - hinges, handles, edging.

MDF is not afraid of moisture, so it will work for many years without deformation and destruction. This screen is easy to clean with common detergents. This device has only one drawback - it is much more expensive than a thin plastic screen.

Original screen bezel

Original screen bezel

The screen under the bathroom can be made as a drapery or covering from fabric and other similar materials. The main thing is to choose quick-drying polyester fiber fabrics.

- Polyester materials work well in a humid environment.

- Membrane fabrics prevent the formation of fungus, allowing the space underneath the bathtub to be ventilated.

- Waterproof nylon materials - ideal for screen cladding.

- A good solution is to cover the frame with artificial leather.

- It is permissible to install panels with any finishing solutions that can withstand dampness.

Installation technology for a ceramic bath curb

Ceramic curbs are composed of straight, corner and end elements. The number of straight elements is calculated based on the dimensions of the bath / shower tray, corners and ends with a standard placement for a bathtub, two are required, for a shower tray, there can be one corner. Take the number of straight elements with a small margin - for pruning.

It is advisable to inspect all elements before laying. If there is a need (they do not fit exactly, there are differences in thickness, etc.), you can work on the back side a little with a file. It is better not to use a grinder - the chance is too great to harm more than fix it.

Layout options

Installation methods

The installation method of the ceramic curb depends on the wall finish and the size of the gap. If it is a tile, you can use a waterproof adhesive. If the tile is embossed or the wall is simply plastered, the installation on glue does not date the required level of tightness. In this case, mount the ceramic bath curb on a special tile adhesive for wet rooms. It is sold in bags in a dry form, before use, some of it is mixed with water until smooth.

The colors can be different, but more often they use white - to match the color of the bath

Sequencing

The whole process consists of a sequence of steps:

- The surface is cleared of deposits and dust. If there is mold, remove it, treat the wall with an antibacterial compound, and let it dry.

- If the gap between the bathroom and the wall is more than half the width of the existing curb, it must first be repaired. Better - make the formwork from below and fill it with cement mortar. The second way is to attach moisture-resistant plasterboard in two layers. If the shelf turns out to be large (more than 5 cm), it must be made with a slope. It can be about 5%. So you can use the shelf (put something on it) and the water will not stagnate on it. If necessary (if the border does not cover it all), the tiles are first laid, with which the walls are finished, after which the installation of the ceramic border for the bath continues.

- Start from one of the corners. Set the angle, then two adjacent straight line segments. A layer of glue is applied to the back of the curb and leveled. Installed in place, pressed against, leveled.

-

Then continue laying to one side. End elements are installed on the sidewalls.

The process of installing a ceramic bathroom curb is not much different from laying tiles. The actions are the same. It is necessary to align the elements in two planes - so that both the edges and the plane go smoothly and without drops.

Typical mistakes

The main installation errors regarding fixing the sanitary ware to the wall are:

- the springy material of the legs of the frame or gaskets under them - a crack is formed between the wall and the side of the bowl;

- lack of a hatch - access to the siphon for its maintenance is blocked;

- the size of the bracket is too large - the board has a free play, is not completely pressed against the tile;

- instead of brackets, adjustable fasteners, brackets are used - these elements provide support for the bowl, but do not fix it completely in the horizontal plane near the wall;

- incorrect location of adjustable fasteners - there is no access to tighten the nut, anchor;

Standard screens usually interfere with the manufacture of blind screens, both from brick, tongue-and-groove block, and from drywall. The home craftsman removes the frame, but forgets that his lower frame is designed to support the bottom, increase the strength of the bowl structure.

Therefore, this frame should be correctly replaced with other constructive solutions - brickwork, timber under the bottom. This will prevent the structural material from buckling, peeling off under the weight of the user and water.

Thus, fixing an acrylic composite bathtub to the wall exclusively solves the problem of immobility of the sanitary ware in the horizontal plane. This can be done either by fixing the side to the wall with home-made, factory fasteners, or by screwing the legs of the standard frame to the floor, or by building a screen made of brick, gypsum board, tongue-and-groove blocks.

Install mortgages

If the bathtub is supplied with a factory screen in the kit, then all the necessary fasteners are already provided in the design. If not, you will have to mount mortgages in the front side, to which the screen frame is then attached.

To do this, you need to cut off a piece of a wooden block and glue it on the inside of the bead with silicone sealant or foam. If the bowl adjoins not three walls, but only two, one more block should be fixed at one of the free sides.

Some acrylic bathtubs already have ready-made inserts in the form of pieces of timber along the perimeter of the sides. If you see such pieces of wood, then you can do without additional inserts.

Benefits of using

Installing panels that cover the space under the bath bowl helps to solve several problems:

- create a single space in the bathroom;

- hide household chemicals;

- cover communication pipes;

- reduce the likelihood of water and objects penetrating into hard-to-reach places under the bath bowl.

The solution of these problems is facilitated by a variety of both designs and design of screens.

Aesthetics

The screen allows not only to hide the legs of the bathtub and water supply and sewage pipes, but also to decorate the bathtub. Such products made of plastic look especially attractive. Such panels are often decorated with various patterns that are applied using photo printing technology.

Functionality

Screens serve several purposes. The main one is to hide engineering communications. However, not only this task is performed by such structures. Screens prevent water from entering under the bath, thereby providing additional protection against leaks. In addition, these products hide household chemicals from pets and children.

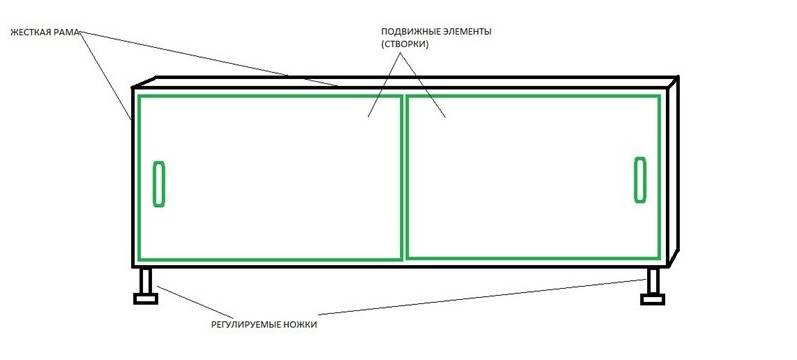

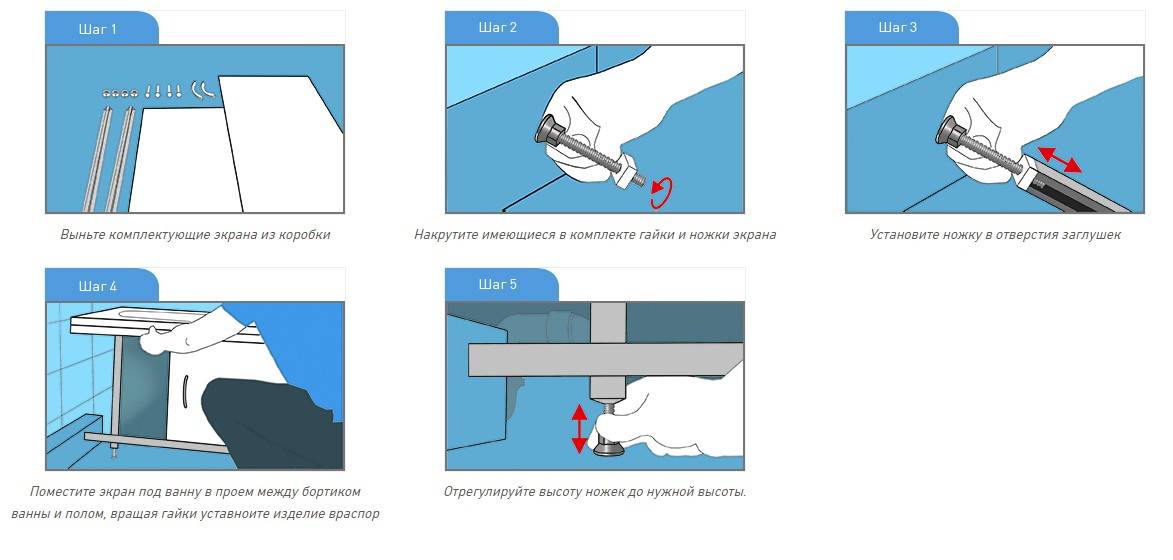

Installing a purchased screen

Installation of the screen under the structure

Installation of the screen under the structure

Finished models are equipped with frames, fittings, fasteners.

If all dimensions are selected correctly, then it is enough to use a tape measure, a building level and a screwdriver. Before starting the installation, it is worth filling the bath with water. If the screen is installed simultaneously with the bath, then this condition is optional.

The installation scheme for all structures is similar:

- Measure the niche again and place the attachment points. If the panels do not fit a little, then they are trimmed.

- Install the frame. Fix the frame under the bathtub and align the W-shaped profile if the model is sliding.

- Adjust the legs. They are unscrewed so as to fix the frame as much as possible between the floor and the side.

- Fix the frames under the bath rim. After firmly fixing the frame, polyurethane foam is placed in the space between the edge of the frame and the side. This provides additional rigidity to the structure.

- Panels are placed on the frame. Swing doors are hung on hinges, and sliding doors are inserted into the guide profile. Handles are screwed to the doors.

- The seams are processed. The joints are lubricated with a sealant. This provides protection against moisture penetration.

The installation of the screen on an acrylic bathtub is slightly different. Usually these models are equipped with screens in advance.

How to make a do-it-yourself bath screen

The process of hand-made manufacturing of the product is carried out as follows:

- To create a frame, you need to acquire a ceiling profile, and to fix it with wooden bars, given that their installation should be carried out in a vertical position relative to the bath.

- Next, you need to press the block tightly to the surface of the flooring and fix the profile using self-tapping screws.

- Having finished with the frame, you can start working on the screen hardware. The first step is to glue the plastic guides into the profile.

- Next, you should install the panel itself, which will perform the function of the screen. It can be made of plastic, glass, lining, plaster and more.

- Finally, it is necessary to cut out the panels from the above materials, taking into account the dimensions of the screen, and carry out their installation.

Installation of a homemade structure

Tile construction

Tile construction

You can make the screen yourself as follows:

- The attachment points are marked.

- All necessary measurements are taken.

- A frame is made of metal and its elements are fixed according to the marking.

- Panels are cut out of a suitable material and fixed to the frame.

- Cladding is carried out.

If the installation process takes place on an acrylic bathtub, then the fasteners are mounted directly on the side, but the cast-iron bathtub cannot be drilled, as this will ruin the product.

When installing the sliding screen, you can use the removable handles on the suction cups. This is an additional safety measure that will help hide household chemicals from children.

Screen making materials

A do-it-yourself bath screen is made from:

- galvanized profile, sheathed with sheet material:

- moisture resistant plasterboard;

- moisture resistant or film faced plywood with a thickness of at least 10 mm;

- GVL (a good choice, since it is absolutely not afraid of moisture and does not deform);

- bricks;

- aerated concrete 50 mm thick;

- plastic panels and guides for their installation (this option is exclusively decorative, suitable only for cast iron or steel baths).

All these structures, except for the last one, need finishing. Most often it is porcelain stoneware or ceramic tiles, the same as those laid on the walls of the bathroom.

The most common version of a homemade bath screen is made of profiles and drywall. In order for the structure to be reliable and not to bend under loads, the profile must be taken with a thick wall, it is possible - reinforced. Also a prerequisite is good quality galvanizing. If possible, you need to take branded profiles so that there are no problems later - after all, high humidity in the bathroom is the norm.

Frame made of galvanized profile for sheathing with sheet material

The sheet material for the frame must be moisture resistant. This is a prerequisite. And even in this case, before installation, it will not hurt to prime it with a composition that increases its water-repellent properties. It's not bad if this composition is also antibacterial - protection against mold and mildew will not hurt.

Brick screens are made mainly for acrylic bathtubs - so that part of the load can be transferred to the brick wall. Although, if desired, the frame from the profile can be made with sufficient bearing capacity - to make double reinforced racks.

If it is decided to make a brick screen for a bathtub, it must be ceramic, red. It is better not to take silicate because of its hygroscopicity. Ceramic bricks are also hygroscopic, but their absorption capacity is less. To minimize possible problems (coloring from high humidity), it is advisable to cover the masonry from the inside with a layer of plaster. It is not easy, but if desired, it is possible - to apply the solution as the screen is being erected. Special care is not required, the main thing is to protect the brick from moisture.

Bathtub brick screen ready for tiling

Another version of the screen under the bath, which you can make with your own hands, is from aerated concrete. This material is easy to process. The required relief is formed easily, even with a sharp piece of iron, and the block is cut with an ordinary saw. For all that, the blocks have a good bearing capacity. So this material can also be used for a homemade acrylic bathroom screen. In addition, the blocks are large, so this small wall folds very quickly.

Laying the screen under a foam concrete bath

Plastic screen under the bath

Features with a curved bath

Often, the screens installed for the bowls in the bathroom are rectangular, because standard baths are also rectangular. However, in recent years, plumbing on the domestic market is so diverse that you will not surprise anyone with a corner bath. For such models, the rectangular option will not work. A curved design is required. You can purchase it based on the parameters of your corner bowl or create it yourself by following our instructions.

That is why experts recommend opting for plastic. It is a moisture resistant material that bends easily and holds its shape perfectly. We also note that today plastic is sold in a variety of colors, which makes it possible to give the bathroom a special appeal and charm.

Universal screen for a semicircular bathtub

First, you need to fix the plastic guides on the floor, so that they repeat the bend of the bath in an ideal way. Applying “liquid nails” to the upper part of the bowl, wooden blocks are fixed, which are used to fasten the upper rail from the metal profile. Then, with the help of a knife, the sashes of the current size and shape should be cut out of the plastic sheets and fixed at the bottom and top of the starting profiles. The bottom joint is masked by using a floor plinth.

If you have no desire to cut the model out of plastic yourself, just buy a ready-made structure and fix it under the bowl, as described above. The main thing is to clearly match the bend of the screen to the bend of the bathroom itself.

Screen selection nuances

Before you put the screen on the bathtub, you must purchase it in advance, having carefully thought out which model is best for you.

When making a choice, you need to take into account:

- appearance;

- durability;

- functionality;

- price;

- the complexity of the installation.

If the screen is fastened under the bathtub in order to close communications that have an unsightly appearance, you can consider the option of installing simple removable or stationary products with a hidden hatch.

When the active use of the space available under the plumbing is planned, the home craftsman will need to figure out how to install a sliding screen with doors under the bath. This most convenient option in operation is universal for bathrooms of any size. As for the swing doors, it is convenient to use them exclusively in spacious bathrooms.

When starting work such as assembling a screen for a bathtub, it is necessary to prepare the fittings, but it must be made of corrosion-resistant materials, otherwise the product will soon lose its original attractive appearance. It should be borne in mind that plastic components wear out quickly and are of low strength.

In turn, parts made of galvanized steel retain their inherent qualities throughout the entire period of operation. When purchasing all the elements, you need to make sure that they are of high quality, they have a smooth movement of the doors and there is a snug fit to the frame.

The decorative design of the structure should correspond to the style of the bathroom in texture and color. In small bathrooms, mirror products look advantageous, since their reflective surface expands the surrounding space.

The front panel image and photo print must match the interior. For example, a screen with a floral print in a nautical room would be out of place. The image of the inhabitants of the sea or the waves is ideal.

When there are a lot of contrasting and bright elements in the bathroom, it is better to install a monochromatic screen and vice versa, for a bathroom finished in soothing colors, a product with a large colorful pattern is well suited.

When making a choice before putting the screen under the bath, it is advisable to pay attention to the manufacturer of the product. The most popular models among consumers are TM OSM, Vannbock, MetaKam, as they differ in the variety of materials and colors used.

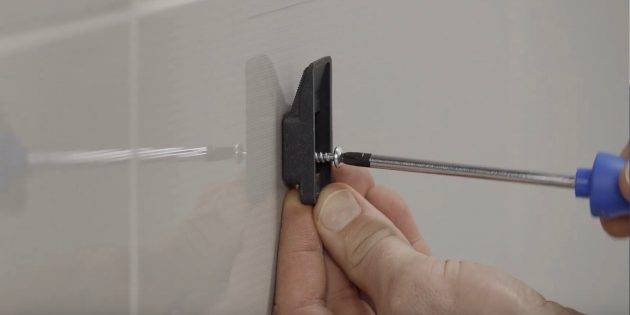

Mount the wall mount

Massive cast-iron bathtubs stand confidently on legs and do not require additional fixation. But light steel and especially acrylic for reliability are also attached to the wall.

Acrylic and steel bathtubs

Such baths are most often fixed with brackets in the form of hooks on which the bowl is hung. Also used are home-made stops made of a metal profile for drywall, which perform the same function.

In both cases, the fasteners are installed on dowels, for which holes are drilled. Using the top line of the bath, mark the holes for the stops in such a way that they are strictly under the edge of the sides and evenly distribute the load.