The drum of the washing machine is not spinning

When the drum mechanism rotates weakly, in jerks, or even stopped, then the reason may be an elementary overload. In other cases, the motor, motor brushes, or software module could be damaged. Let's consider each case in more detail.

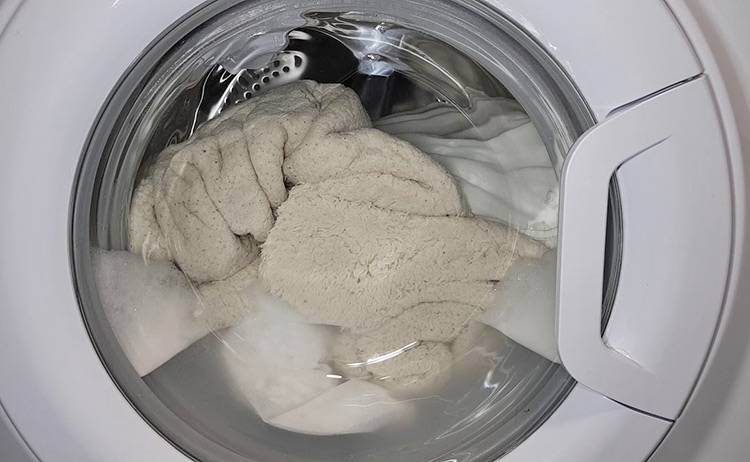

Overloading the car

If the automatic machine barely turns during washing, it is possible that you simply overloaded it or the things inside are unevenly distributed. This is the most harmless problem that can be eliminated by taking out unnecessary things.

After reducing the load, start the wash program again. If the machine works, then the worst is over.

New models of automatic machines - such as Ardo, Whirlpool, LG - are equipped with special sensors. If the load is exceeded, an error code will appear on the display or the machine will beep.

Units without sensors simply stop the wash cycle, signaling in such a way that a malfunction has occurred.

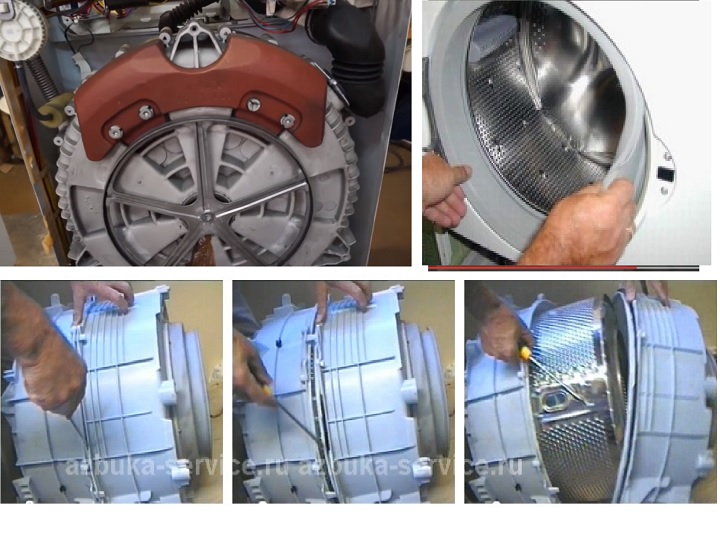

Drive belt wear

The drive belt transfers rotation from the engine to the tank. The operation of the device is disrupted if the belt becomes unusable: it stretches, frays or bursts. This can happen during active operation or vice versa during prolonged downtime.

The worn part should be replaced with a new one.

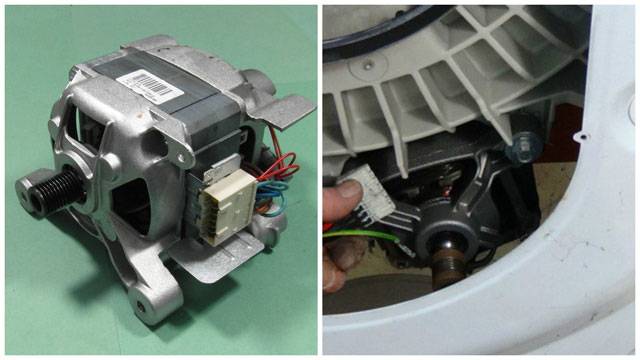

The brushes of the electric motor are worn out

Such a malfunction more often happens with outdated models or with frequently used ones. The motor brushes wear out simply because of the long time of use.

Their replacement is required. There shouldn't be any difficulties with this. All that is needed is to remove the engine and replace the worn part.

If the machine then makes a loud noise during operation, it means that the replacement of the brushes was performed incorrectly.

Engine breakdown

In this case, the drum mechanism starts spinning more slowly until it stops completely in the future. In this case, the motor stops emitting sounds characteristic of its operation. This could be:

- Breakage caused by voltage drops or leaks;

- Wear of brushes - described above;

- Capacitor Failure - Typical for older models.

The motor should be carefully inspected and additional diagnostics carried out. At best, it can be repaired, at worst, it will need to be completely replaced.

Malfunction of the program module

The program module, which controls almost all the mechanisms of the automatic machine, is also susceptible to breakdowns. Due to its wear or voltage drops in the network, the drum device also begins to jam. To fix the breakdown in electronically controlled machines, you will have to reset the programs. In models with electromechanical control, you will need to rewrite the board or completely replace it.

Advice

- Before loading the laundry into the wash, carefully check all the pockets, turn out the duvet covers and pillowcases - this way you will be sure that small things will not get inside the unit.

- Before starting a new clipper, read the user manual carefully. Observe exactly the recommendations regarding the volume and weight of the loaded laundry.

- There are special bags for washing underwear and other small things. Experts strongly advise using these bags not only for the safety of things, but also for the safety of the washing machine.

- You are not fond of using fabric softeners, bleaches, anti-scale agents, and do not exceed the dosage of washing powder. Household chemicals can damage the interior of the washing machine.

- If during the washing process the unit began to emit extraneous sounds, cancel the program and unload all the laundry from it.If the situation repeats after restarting, then the washing machine needs to be diagnosed and repaired.

Calling a foreman to repair the washing machine

Call the wizard - engine shutdown, bearing wear, or a washing machine drum off the axis never "passes" just like that. You cannot do without renovation. Such malfunctions are eliminated either with a complete replacement of the unit, or by rearranging the bearings. But this is not always possible, because in some models of Ardo, Whirlpool or Beko washing machines, the tank and the bearing are rigidly connected to each other.

The foreman decides on the procedure and technology of repair, based on the inspection of the machine after disassembly - if the problem lies in the electric motor, then it can be completely replaced, try to install new brushes or clean the collector. If your washing machine has a broken or loose drive belt, then you are faced with the easiest problem. But this does not mean that it is enough to simply rearrange the belt, because it is necessary to check the condition of the tensioning mechanism.

Finding the Cause of a Drum Malfunction

After detecting the problem, you need to follow these steps:

- Stop a running wash program;

- Disconnect the machine from the mains;

- Drain the water through the drain valve. In most washing machines, it is located at the bottom of the front panel;

- Take out the laundry.

After that, we move on to finding the problem. It is necessary to understand at what point the unit malfunctioned. The pulled out laundry will help with this. After carefully reviewing it, you can find out the following:

- Wash out soap - a problem arose during the washing process;

- Things are wet - a failure occurred during the spin cycle.

What should be the next steps? First of all, you need to check the mobility of the rotating mechanism by hand. If it rotates, even though it is tight, it means that:

- The car was overloaded with a lot of things, or they were unevenly distributed inside;

- The motor drive belt is worn out;

- The brushes of the electric motor are broken;

- The engine has broken down;

- The electronic module is out of order.

If the mechanism is jammed, then the problem is as follows:

- The belt slipped off;

- There is a foreign object;

- Bearings are out of order;

- Flaps opened in a top-loading machine;

- The capacitor is broken.

Next, you will learn how to act in a given situation: when you can try to fix it yourself, and when you need to call a specialist.

Self-repair of breakdowns

Let's consider the main common reasons when the drum of the washing machine does not spin:

An object is stuck in the space between the drum and the tub.

One of the most common causes of a washing machine breakdown is an object (something you usually forget to get out of your pockets) getting between the tub and drum.

Try turning the drum by hand - if it does not give in to rotation, it means that a foreign object is interfering with it.

This is important: be sure to unplug the power cord before starting work.

What to do? Using a flashlight, shine the drum through the water drain holes and try to understand where the object is. Next, you need to remove the item yourself through the hole for the heating element (electric heating device).

Take a note: in some models of washing machines, the heating element is located at the back, and to access it, you must remove the back panel of the case

In other models, the heater is located in the front, then it will be necessary to remove the control panel.

The filter is clogged.

When the filter becomes clogged, the washing machine automatically goes into emergency mode and stops working (usually during washing).

In the instructions for the machine from any manufacturer (Indesit, Ardo, LG), you can easily find information and where the filter is located, and how to remove it, and how to put it back in place.

Expert advice: Before opening the filter cover, cover the floors with rags or place a bowl under the filter cover. This will save you from subsequent cleaning.

Drive belt burst or stretched.

The drive belt rotates the drum.

If you use your washing machine for a long time (from 5 years), there is a high probability that the belt is stretched (during washing, the drum rotates slower) or flew out of its place (when the machine is turned off, the drum rotates easily and there is no "rustle" of the engine).

In this case, it is necessary to replace the belt with a new one (when buying a new belt, do not forget to write off the characteristics from the old one: belt length, number and size of wedges).

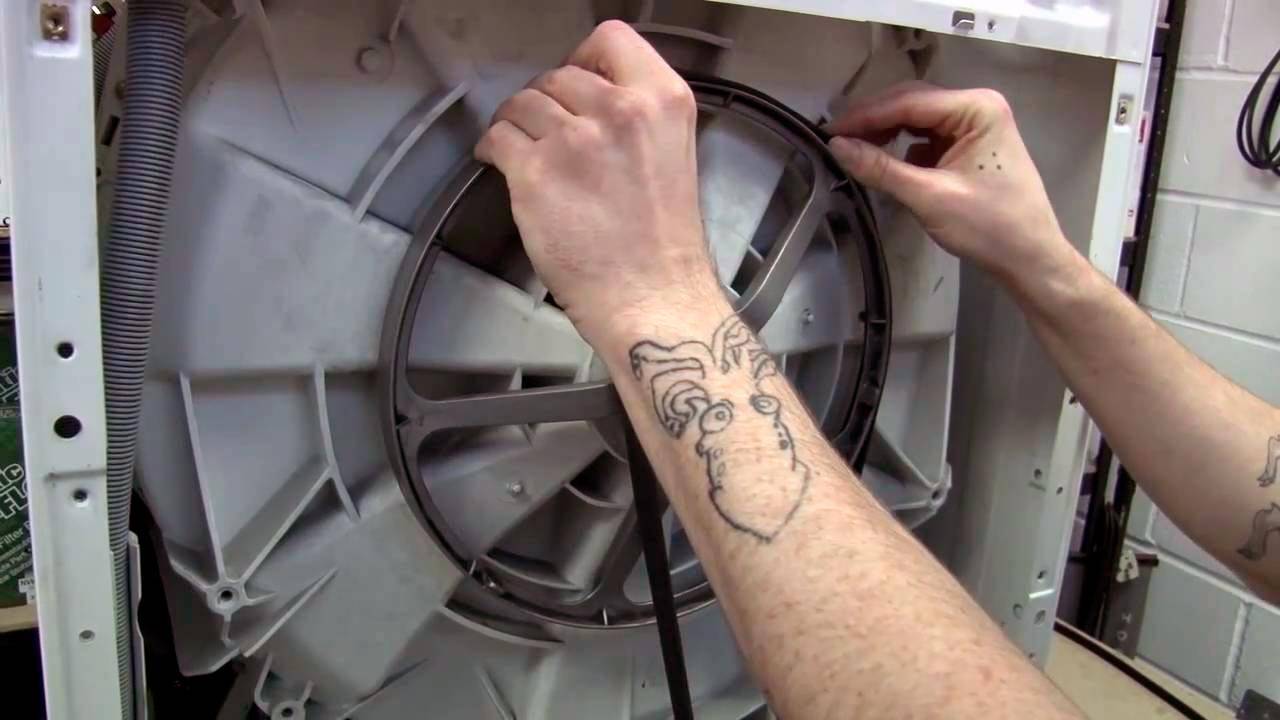

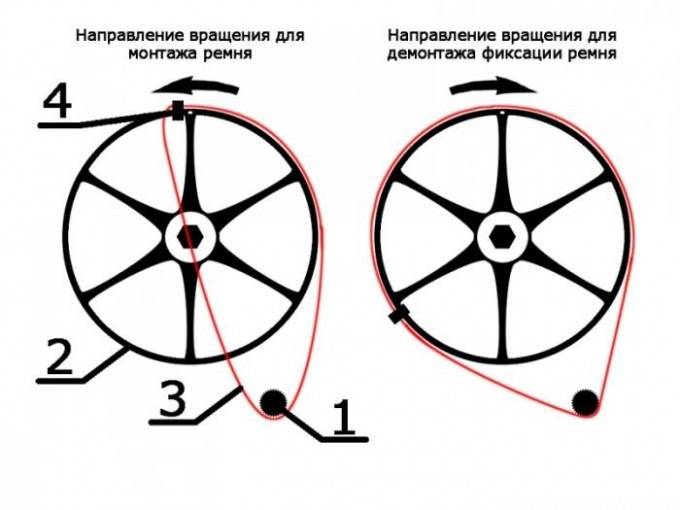

To replace the belt, you need to unscrew the back panel of the washing machine, remove the old belt, put a new one on the drum pulley and, holding it with your hand in the groove, slowly rotate the drum until the belt is completely in place.

The machine does not spin: 7 systemic reasons

When the mechanism does not move, although before that it was easily rotated by hand, the following malfunctions are possible:

- Broken belt. Elimination of the breakdown characteristic of models with a long service life is carried out by replacing the damaged product with a new analogue. This requires the removal of the rear cover. Less common is the belt slipping from the electric motor pulley, which can be easily repaired on its own.

- Failures of automation. In case of breakdowns associated with a violation of the functionality of the software module, the best solution is to contact the service center.

- Failure of the speed regulator. If the drive does not rotate during spinning, the device that controls the intensity of rotation - a tachometer, may fail.

- Burnout of the heating element, which provoked its rupture, can cause the motor shaft to stop when it cannot rotate the tank.

- Failure of the water level sensor. When the control unit does not receive a signal about the presence of liquid in the tank, the electric drive does not start.

- The wear of the brushes of an electric motor most often occurs during intensive use of equipment or during long-term operation. Replacement of defective parts is carried out after preliminary dismantling of the engine.

- Drive problems can be caused by an open circuit, short circuit, seized or broken bearing when the machine hums but does not turn the shaft.

In any case, if you have a question: what to do if there is no drum rotation - contact the specialists. Remember, not only a certain qualification or experience, but also a specific tool is required for a high-quality troubleshooting.

The design of automatic machines and possible reasons for their failure in operation

The design of modern washing machines, equipped with many modes and allowing you to clean almost any stains, is quite complex and consists of many parts. Due to their complexity, such systems are susceptible to various breakdowns. Moreover, even the most expensive models of the world's leading manufacturers easily break down and fail. Of course, the products of any Chinese manufactory are much more susceptible to similar problems, but the largest European brands are also not immune from them. Indesit, Bosch or Electrolux guarantee the quality of their products, but the operating conditions of such devices still leave their mark and contribute to their failure.

We recommend that you familiarize yourself

In such a situation, one of the most common problems that appears during the operation of equipment is the fact that the washing machine does not spin the drum. There can be a great variety of reasons for a similar phenomenon. The best solution, designed not only to save your own time, but also to preserve the design of the machine, is to call a specialist. This is the only way to guarantee its effective repair and be sure of the integrity of the device.However, such a solution requires certain material costs, which makes it not always successful. At the same time, it is possible to independently identify the problem and even neutralize it.

The most common reasons that the drum does not spin in a washing machine are violations of fairly simple principles embedded in the machine's control system. They look like this:

- the maximum weight of the laundry has been exceeded;

- the drain filter is clogged.

It is quite easy to diagnose such problems on your own, since they are obvious. In this case, the blocking of the drum is performed by the system itself, which limits the user's access to the device. These settings are set by the manufacturer and provide a kind of protection against damage to the device. In the first case, to unlock the appliance, it is enough to partially unload the laundry. In the second, the situation is a little more complicated, since the obstruction of the drain filter provides for a partial disassembly of the device. However, cleaning it can bring a positive result and ensure the full operation of the device. It is clogged primarily by small parts that fall into it directly from the drum. These can be any small items that penetrate the rubber seals, such as handkerchiefs, baby socks, or bits of lint. Therefore, you should be careful when placing the laundry in the drum of the machine, as this is the only way to avoid clogging of the filter and thus guarantee the smooth operation of the device.

When the car does not spin: what to do

The most common and easiest problem to troubleshoot is overloading if the drum is not spinning. Most modern models are equipped with a built-in forced stop / failure to start system with an excessive loaded weight. The following points are indirect confirmation of this situation:

- the machine does not respond to switching on;

- after pulling out, the laundry is completely dry, since no water is collected;

- the container for things is not jammed, it is easy to turn it by hand.

In this case, do not rush to call the master, most likely, the new technique did not break. Automation simply does not turn on due to exceeding the permissible weight. Load half of the items and reactivate the wash cycle. If the unit starts to work, next time monitor the total load more closely.

Household reasons

The presence of many sensors that are sensitive to various malfunctions and, at the slightest deviation from the norm, are able to stop the rotation of the drum.

First of all, we try to eliminate the simplest malfunctions. To do this, let's try to unload the machine from excess laundry. We turn on the washing program again and monitor the result of these actions.

If the machine still does not start turning, you must disconnect the washing machine from the power source and try to open the loading door. In the case when the door does not open, but inside the car we see the presence of water, then with 95% certainty we can say that there was a blockage in the water drain system.

If the drum does not rotate even before water is collected, but the hatch door opens, a foreign body may get into the washing machine tank. When we try to turn the drum by hand, we will immediately understand whether it is jammed or not.

To eliminate the blockage of the drain system, you first need to drain the water from the tank. This operation can be done through the filter, which is located on the front panel of Samsung in the lower right corner. Gently unscrewing the filter, having previously spread a soft rag so as not to flood the floors in the room with water, drain the tank. Then, having completely dismantled the filter, we thoroughly clean it from dirt and foreign objects.

If cleaning the filter does not bring a positive result, you need to completely disconnect the washing machine from the communications.Next, you need to clean the drain pump and drain pipe. To get to these parts, the car will have to be placed on its left side. Having removed the pump and the branch pipe, we clean them from debris and foreign bodies. After carrying out these procedures, the washing machine starts up normally.

If a large foreign body enters the tub of the washing machine, the drum can jam. If we find just such a malfunction, we must immediately turn off the machine and stop all attempts to crank the drum. Otherwise, you can get even bigger problems with the operation of the machine. Further, tilting the machine to the left side, remove the drain pipe and through this hole we try to remove a foreign object with our fingers. If it was not possible to get the debris out of the tank, you will have to remove the heating element and clean the tank through this hole.

If the drum rotates freely

If rotations are present under the influence of an external force, then breakdowns are as follows:

- Belt damage (this item is not suitable for direct drive models). A malfunction is indicated by the noise from the engine running, and the laundry does not spin. The belt can be inspected by removing the back panel. The part wears out both with active use of the unit, and dries up and cracks during idle time. If the drive belt is frayed or loose, it must be replaced. Before purchasing a new belt on your own, you should study the marking of the old one. You need to find out its length and the number of wedges.

- The brushes of the electric motor are worn out. With prolonged use, the brushes are shortened and no longer reach the collector. As a result, the electromagnetic field required for the movement of the rotor is not generated. No engine noise will be heard during operation. When the brushes are completely worn out, they need to be replaced.

- A faulty wiring in the instrument itself prevents voltage from being supplied to the motor.

- Problems with the electronic module or programmer. The first is installed in devices with electronic control, the second is typical for electromechanical devices. This means that the control board does not work, which should transmit a signal to start washing. Malfunctions most often occur due to power surges in the network or in the forced manual correction of programmed operating modes. Repair consists in "flashing" the old board or installing a new one. If there is simply a failure in the module, it is enough to perform the program reset procedure.

- Damage to the electric motor. Malfunctions with this part of the unit do not occur often. Basically, they arise during operation for more than ten years. Malfunctions occur through fluctuations in the electrical network or leaks, as a result of which water gets into the engine. If a short circuit occurs between the turns of the motor winding, then the empty drum can rotate. However, when the device is started, the plugs will be knocked out immediately. A break in the winding will completely jam the machine, and it will not move at all. It is better to solve this issue for a specialist who will diagnose and repair or replace the engine.

Decoding of fault codes of the Indesit washing machine

Debugg

To access the damaged part of the washing machine, you will need to partially disassemble the household appliance. The best way to access the inside of a household appliance is to remove the back cover.

This option is ideal when disassembling LG or Ariston Hotpoint cars. On some Samsung, Indesit and Bosch models, in order to get to the internal parts, you will first need to dismantle the top cover of the household appliance. Before you start disassembling the washing machine, you must unplug the power plug from the socket, and also turn off the water supply to the device.

The top or back covers are secured with screws, which can be easily removed with a screwdriver.After access to the internal parts of the machine is opened, depending on the cause of the malfunction, a certain sequence of actions is performed.

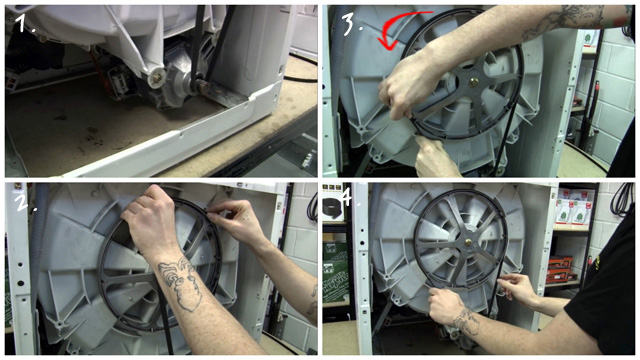

Replacing bearings

If the reason that the drum flew off the shaft is a malfunction of the bearings, then the repair of the household appliance is possible only by replacing these parts. The operation is performed in the following sequence:

- The top and bottom weights are removed. As a rule, in order to remove these parts, it is enough to unscrew 4 bolts.

- The drive belt is carefully removed from the pulley.

- The heating element is removed from the tank.

- The plastic clips of the shock absorbers are removed.

- The springs are released.

- The electric motor is dismantled.

- The pulley is removed from the rotating part.

Now access to the bearing will be opened, which should be removed using a special puller. What if there is no such tool? In this case, you can use a hammer and any elongated object of small diameter to knock the product out of the seat.

Care should be taken when removing the bearing in this way, as careless actions can damage the rotating part of the household appliance.

When the old bearing is removed, a new part is pressed into its place, after which the machine is assembled in the reverse order.

Shock absorber repair

If the drum has fallen off due to a defective shock absorber, then this part can also be easily repaired on its own. When the rear cover is removed, locate the mounts on the rotating part of the machine to which the shock absorbers are attached. On many models, there are at least four such elements, so each should be inspected for breakage.

Sometimes the spring can simply fly off the mount, therefore, to restore the device's performance, it is enough to install the shock-absorbing element in place. If the spring breaks, it must be replaced with an original product.

In some models of washing machines, a damper is used as a shock absorber. If such a part is damaged, you will need to purchase a new product or remove it from a faulty "donor" of the same model.

Replacing the drive belt

Sometimes the cause of the drum coming off the seat can be in a badly worn drive belt. In this case, you cannot do without replacing this part. It is quite simple to do this, because each product has markings, according to which it will not be difficult to choose a new belt.

The belt is first put on the pulley of the electric motor, and then installed on the wheel of a larger diameter located on the tank. To facilitate the task, you can pry the belt with a screwdriver, but even a new, not developed belt is usually easy to put on by turning the pulley 1 turn, after having previously thrown the part onto the wheel.

If the drum has fallen off in the washing machine, then it is absolutely not necessary to seek help from specialized workshops. You can save a lot if you carry out the repair yourself according to the recommendations given in this article.

Imbalance or overload

Many, but not all, washing machines are equipped with overload and imbalance detection systems. These are different problems, but when they are detected, the electronic module blocks rotation. This is done in order to prevent damage to the AGR units, which were not originally designed for such loads.

Overloading is the excess of the permissible weight of the laundry.

Imbalance is the crowding of things in one part of the drum. As a result, parasitic centrifugal forces can arise.

Do you machine wash your shoes?

Oh yes no

These problems are identified in different ways:

- special sensors;

- the rotation speed is analyzed according to a special algorithm.

Since such functions are implemented on expensive washing machines, the user is usually notified through messages or error codes that are displayed.Note that decryption is carried out using a special table or using the operating instructions.

We take out foreign objects

So, the belt is in perfect order, let's move on to checking the drum. It is likely that a small object in the form of a button from a clothing or a key fell into the free space between the tank and the drum, and the element stopped rotating. In this case, the use of the machine is not recommended, as the object may become jammed or damage the walls of the drum. In each case, the situation requires expensive repairs associated with the replacement of the internal parts of the machine.

It is easy to determine if there is a foreign object in the tank. To do this, you need to open the loading door and turn the drum manually, first in one direction, then in the other. The presence of resistance, extraneous grinding or ringing will tell you that you are on the right track. It remains only to remove the foreign object as quickly as possible, and for this difficult actions are ahead, since you will have to work with a drain filter or a hole located under the heating element.

The first sequence of actions is as follows:

- at the bottom right we find a hatch designed for draining;

- open its lid;

- spread rags on the floor;

- remove the trash filter;

- we clean the body, sleeve, pipes.

Larger items remain at the bottom of the machine tank. To get to them as quickly as possible, you will have to dismantle the back panel, disconnect and remove the water heating element. It remains, illuminating with a flashlight, to find a foreign object and get it using a wire or pliers

You will have to act carefully so as not to damage the tank body.

If the drum stops rotating and is completely jammed, the tank must be completely disassembled. We act as when replacing the bearing - we remove the panels from the top and the back, dismantle the drive, the electric motor, the dispensary with the module, counterweight elements, shock-absorbing devices and other components of the machine. After completing these works, we take out the main container, disassemble it and remove foreign objects. The difficulty arises if the tank of the machine is made non-separable. It will take four hours to cut, and it is better to entrust this work to an experienced specialist.

Study of the situation

After the preparatory process is completed, you can proceed to a detailed study of the breakdown of the washing machine. It is possible to do this on your own if you follow some simple steps. Then the breakdown is quickly determined and the repair method is assigned accordingly.

We must carefully recall the moment when the drum in the car stopped spinning. To do this, there is an option to look at the taken out laundry. For example, if the laundry is just wet and there are no traces of powder on it, then the drum probably stopped spinning during the spinning procedure.

If, however, the presence of washing powder is observed in the things that were taken out of the washing machine, then the drum of the unit stopped spinning directly during the washing of the laundry.

Now you need to twist it yourself

To do this, you need to grab the inner edges of the drum with your hand and give it centrifugal force.

If in this process the drum does not want to spin, then most likely the reason for this stop is that there is a foreign object that does not allow the drum to spin.

If the drum itself spins quite freely, then the whole snag will be in the electronic filling of the washing machine.

When determining the reason why the drum of a washing machine does not spin, it is necessary to take into account such a circumstance as an overload of the drum. Quite often, users, in an effort to wash a large amount of laundry in one process, violate the drum load.

Then he can simply stop during the wash procedure. Therefore, as a way out, you can try to divide this laundry into two parts and perform the wash again.In connection with this point, it should be noted that in the latest modifications of washing machines there is already a special function providing for the control of the weight of the laundry loaded into the drum. For this purpose, special sensors are installed. If, as a result of loading, the nominal weight is exceeded, the sensor stops washing and the drum stops spinning. At the same time, in a number of models, a visual indication also occurs at the same time, which makes it clear to the user that an overload has occurred in terms of weight.

It is necessary to pay attention to external circumstances that may affect the operation of the system. For example, a number of washing machines have a sensor that is very sensitive to water pressure readings in the supply system. If these data do not correspond to the norm, then he will react adequately and de-energize the machine.

We figure out the problem on our own

The initial diagnosis of breakdowns will be within the power of any user. To do this, follow certain procedures:

- check the maximum weight of the laundry in the instructions for use;

- check that the door is not locked. As a rule, the drum stops spinning if the water drain filter is clogged;

- we try to turn the drum with our hands. If everything is fine, and there is a problem during the automatic wash, you should look for the cause in the wires, tachogenerator device, control module;

- it is imperative to inspect the cavity between the tank of the machine and the drum for the presence of foreign objects. If everything is normal, the heating element could fail. The drum can also stop rotating due to a non-working heating element, completely blocking the washing process;

- we inspect the drive belt. It should be corrected or completely replaced with a new analogue;

the machine is disassembled and inspected to see if there are any problems with the bearings. It is quite possible that they also need to be replaced.

Repair

If you are faced with the fact that the Indesit washing unit does not rotate the drum, then most likely its drive belt has fallen off or is torn. It may seem that this is not a terrible malfunction - it would seem that there is nothing easier than removing the back wall and pulling the belt back onto the small and large pulley wheels. However, if it flies off with enviable regularity, then in most cases this indicates that you are dealing with a much more serious problem - a drum pulley malfunction.

In order to check the version data, you need to perform certain manipulations.

Switch off the washing machine and move it aside so that you can easily approach the back wall.

Open the service hatch. If the drive belt has fallen off, then you must immediately inspect the large wheel - the drum pulley. If no traces of mechanical damage are visible on it, then you can put it back on and look for a breakdown further. If the integrity of the wheel is broken, this element should be replaced with a new one, otherwise it will fly off constantly. Inspect the small wheel in the same way.

A common cause of machine breakdown is foreign objects in the drum. At the bottom of the tank, pins, rubber bands, coins, buttons, paper clips and even keys are far from uncommon. It wouldn't be so sad if these things just lay at the bottom of the drum. The problem is that they often cause the drum to jam and damage the rather flimsy tank wall.

If the cause of the malfunction is precisely in a foreign object that has fallen into the tank, then you do not need to try to push the drum and even more so to start the machine, but the object itself must be removed as soon as possible. The easiest way to do this is through the hole of the drain pipe or through the hole of the heating element. In some Indesit models, the heating element is located at the back, in this case you just need to remove the back wall, disconnect the wiring from the heating element, unscrew the fastening bolt and pull out the heating element.

If the heating element is located in front, then it will be much more difficult to remove the front wall. But if you are 100% sure that the cause of the malfunction is precisely in the stuck object, then you can take the following steps:

- lay the machine on its side;

- remove the drain pipe from the drum through the bottom;

- Catch a foreign object through the drain hole.

The drum will not be able to spin if the engine is faulty. In the collector motor, the carbon brushes may wear out, the winding may short-circuit, or the lamellae may malfunction. In all these cases, repairs must be carried out by a service center master who has the necessary knowledge, working skills and a set of tools.

Perhaps the most difficult reason for the Indesit drum to stop spinning is the control board malfunction. This reason can only be diagnosed by a professional who calls all the semiconductor contacts and draws the necessary conclusions. In most cases, the reason for such a malfunction is the failure of the control triacs responsible for controlling the motor. Although this is just one of the most common conclusions that a specialist makes after a thorough examination of your washing assistant.