Malfunctions

In this situation, there may be several malfunctions.

Level sensor defective

Quite often, in some washing machines, the level sensor tube can become clogged. This happens during washing. Hair, threads, or some debris can get caught in it. Such blockages make it difficult for this part of the machine to work properly. That is, water is poured into the tank. But the heating element is not activated. And all because the module is misinformed and does not give a command to heat up.

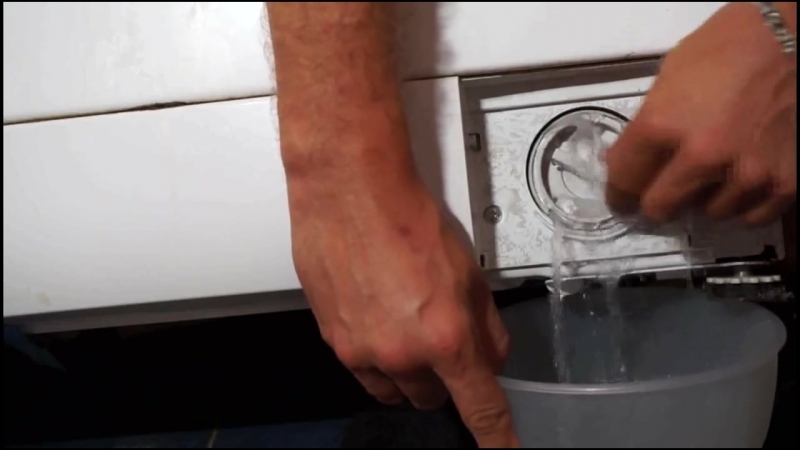

In order to fix this, you can clean the tube or replace the sensor. You can learn how to make this replacement yourself from the video:

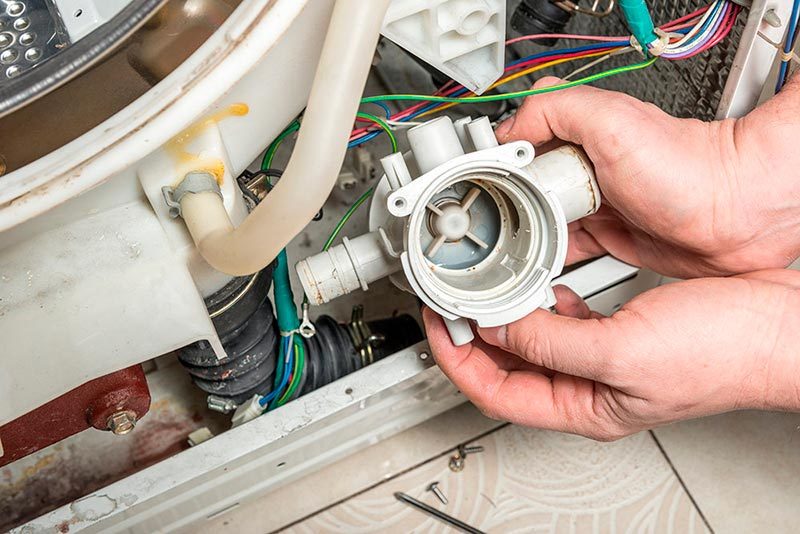

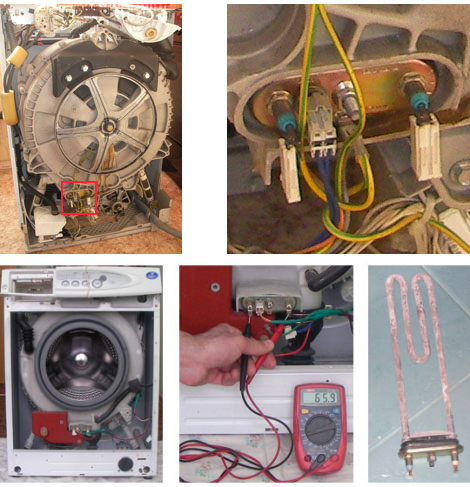

TEN (heating element) open circuit

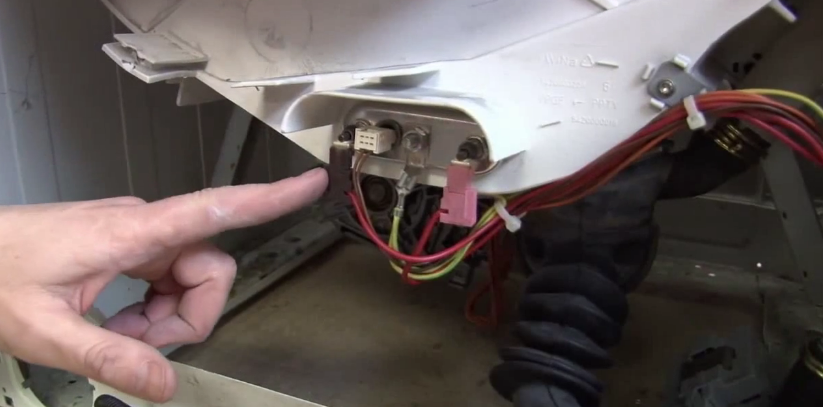

Another possible breakdown is an open circuit of the heating element. In order to check the condition of the circuit, you need to make sure the integrity of the wires that are adjacent to the heating element. In a number of washing machine models, the wires leading to the heating element are located next to the machine body. This arrangement can negatively affect their safety. During washing, spinning and other operations, the machine produces vibrations. And the wiring can simply fray. If you find this malfunction, then you must either solder the broken wires, or replace them with new ones.

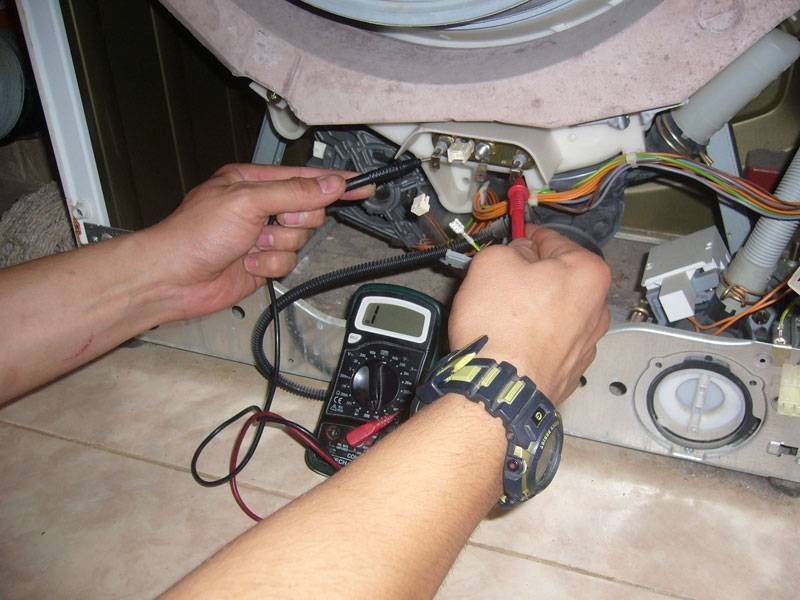

The most frequent breakdown that causes the lack of water heating in the washing machine is the failure of the heating element itself. In order to check the serviceability of this part, it is better for us to use a tester. Having called the heating element, we can establish whether it is working properly or not. If we are convinced that the reason for the incorrect operation of the machine in the heating element, then it should be replaced with a new one. The replacement process is pretty straightforward. A person without special skills can cope with it. To carry out the entire operation, you only need to remove the back cover of the washing machine body. Then, loosen the fasteners of the part, take it out and install a new one. You can find out how this is done in the following video:

Care must be taken when removing and replacing this part. Since pulling out too abruptly and incorrect installation can damage the plastic tank.

When buying a new heating element, you need to be very careful. After all, an unsuitable part may not replace the old one, interfere with normal operation, or even break your household appliances. In order to find a new heating element, we advise you to use the Internet. This is the easiest way to find and order the necessary spare part in your city.

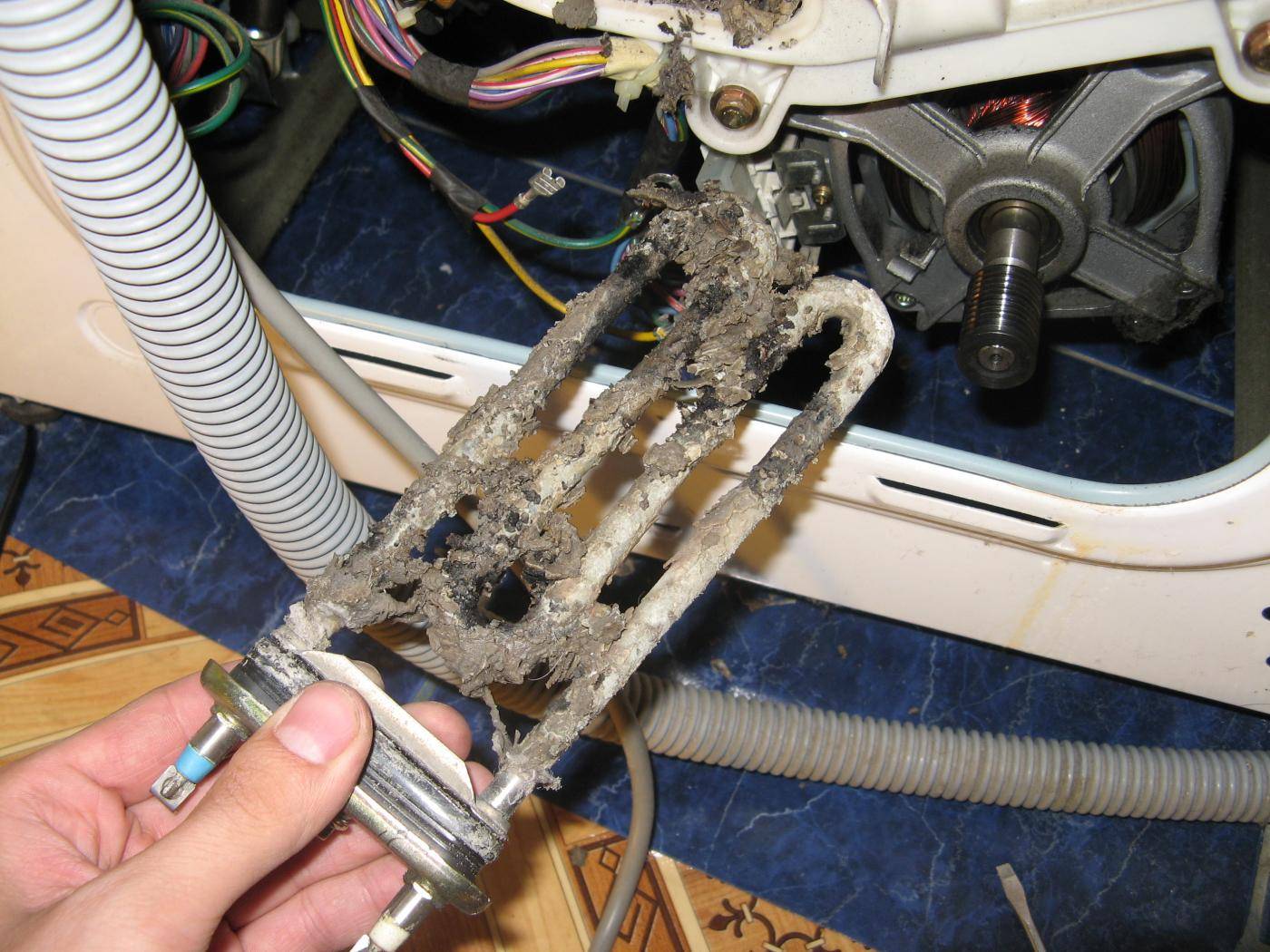

Limescale or increased water hardness

Scale on the heating element of the washing machine can occur due to the high concentration of magnesium and calcium salts or rust in the tap water. Scale build-up can affect the heating of the water. Since it impairs the function of the heating element. In order to avoid such troubles, you can use special means to maintain the machine in good condition. For example, a colgon. Or install a filter that will soften the water.

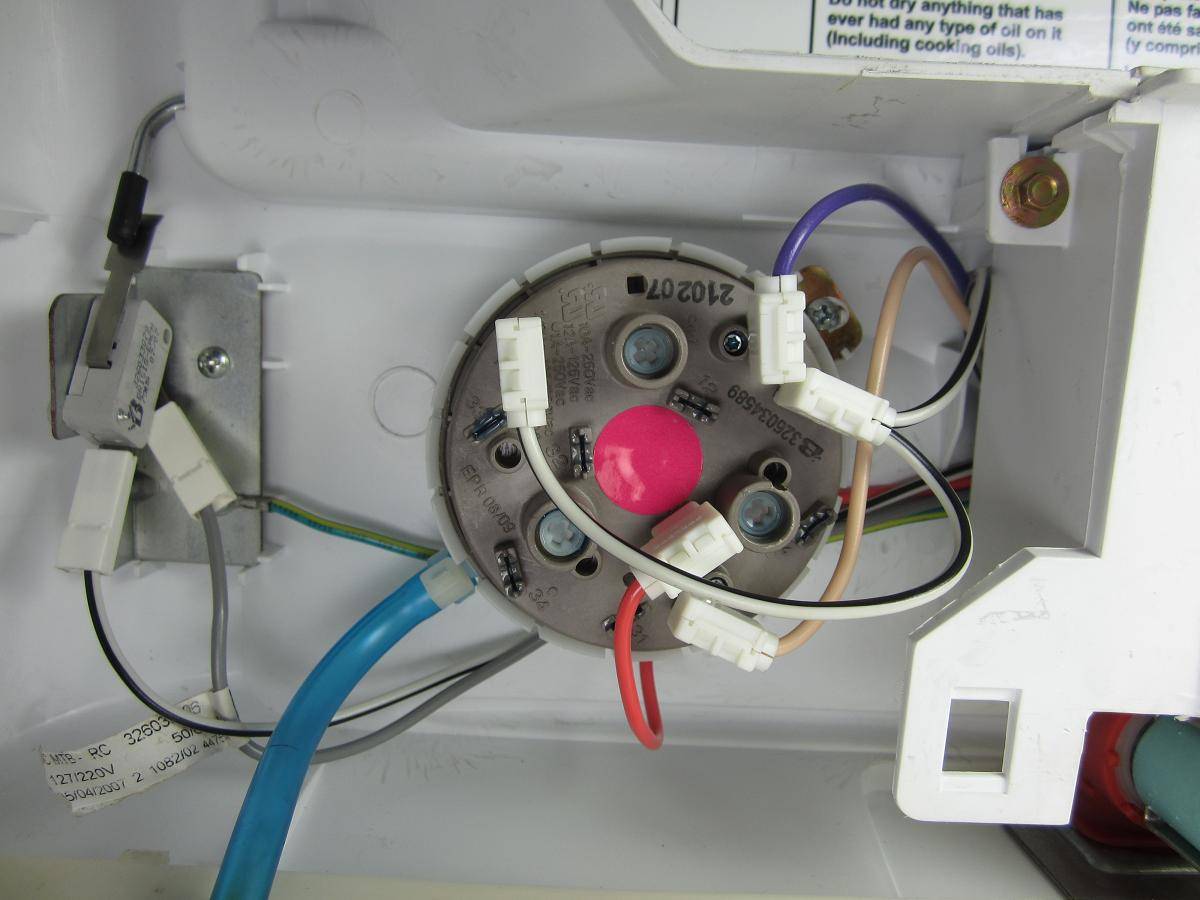

Broken heating sensor

It should inform the control module about the moment when it is necessary to activate the heating device. And if it stops working, then it needs to be changed. To do this, watch the video instruction:

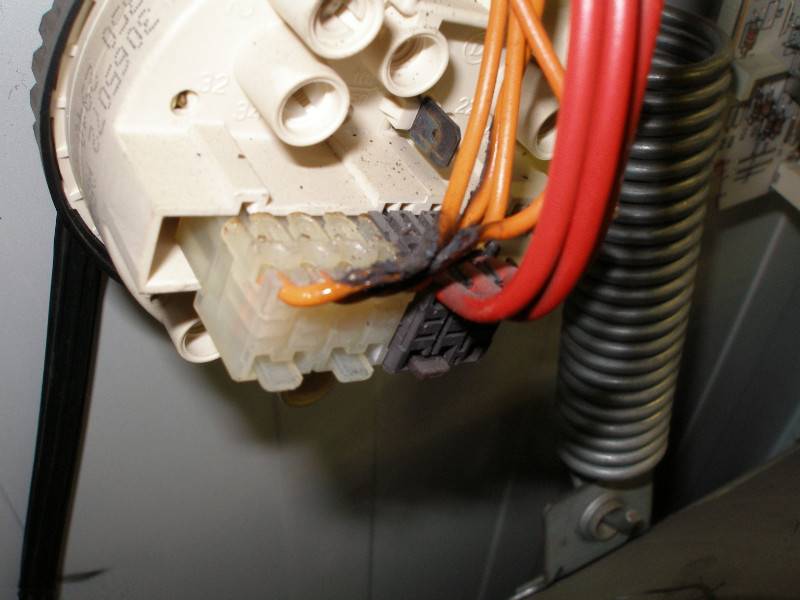

Breakdown of the programmer or heating element relay

The programmer forms part of the control module. It can break for a variety of reasons. For example, contact connections will be charred. A module is a rather expensive and very difficult part to repair. Not every repair service will undertake to restore it. Most often, in this case, you need to replace the module.

We do not recommend replacing the control module yourself.If you do not have the appropriate skills, then it is better to turn to specialists.

How do I fix the problem?

Having found out the reason why the water in the washing machine does not heat up, you can start to eliminate it. To do this, follow these steps:

- clean the pressure switch tube or replace it;

- solder damaged wires and then insulate. Or just replace them with new ones;

- get rid of limescale on the heating element. To do this, it must be boiled in water with the addition of citric acid;

- install a new heating element instead of the old faulty one;

- replace the temperature sensor;

- repair or replace the control module.

Replacing the control unit is a rather complicated process. Therefore, it is better to entrust this work to specialists.

So, if the water in the machine does not heat up, then you need to find out the cause of this malfunction and try to fix it yourself. If you have any difficulties, it is advisable to seek help from a professional. If this problem occurs with the equipment under warranty, then you need to contact the service and not try to fix it yourself.

So, we give 5 reasons why the washing machine does not heat the water:

1 Incorrect connection of the washing machine

Sometimes, in cases where they save on the quality of connecting the washing machine, there is a problem of unauthorized water leaving the sewer system. In such a situation, the water in the tank simply does not have time to heat up to the required temperature, since warm water is constantly draining into the sewer and automatically refilling a new cold portion.

2 Wrong wash program selection

The washing machine does not heat simply because this washing mode is currently selected. How is this possible? This can be a banal carelessness, which manifests itself in the choice of the wrong program. Or it may be some feature of the choice of programs for a particular model. It's just that in some models it happens that the choice of the washing program and water temperature is carried out by different knobs / switches. For example, you have set 95 degrees with the temperature selection knob. But the program selection knob was set to a mode providing a temperature of only 60 degrees. Usually, the selected program has priority and the separately selected temperature mode of 95 degrees is simply ignored. Read the instructions for your washing machine if in doubt.

3 Burned out heating element (tubular electric heater)

It's simple - the water does not heat up, because the heating element is out of order - the main character in this business, so to speak, there are several reasons for failure - voltage surges, short circuits, factory defects, age (heating elements with our water quality serve on average 3-5 years). In this case, the replacement of the heating element by an experienced specialist will help. Call the master in Kazan: +7 (953) 402 66 00.

4 Faulty thermostat (water temperature control sensor)

The thermostat, depending on the model of the washing machine, can be located either in the heating element itself, or separately on the surface of the tank. It monitors the temperature of the water and gives signals to heat the water if necessary.

5 Defective control module (programmer)

What could happen to him? Anything, starting with bad contacts (for example, microcracks on the tracks) on the board and ending with the "rally" of the firmware. As a result, the module (the main brain center of the washing machine) begins to malfunction, and along with this, the entire operation of the washing machine is disrupted. In some cases, the module can be repaired (on site or in a service center), and in some cases, only replacement with a working one is possible.

We have covered 5 main reasons why the washing machine does not heat the water. This malfunction can be successfully eliminated by our experienced washing machine repair specialists.

Of course, you can decide to fix the machine yourself, but is it worth spending your precious time mastering the skills of repairing a washing machine? You don’t study hairdressing when you want to get a haircut and don’t turn into a dentist when you have a toothache? Our masters will carry out diagnostics, determine the exact cause of the breakdown, and then make high-quality repairs and give a guarantee.

Trust us and get a good service with a guarantee for the work done. Call right now and we will solve the problem with water heating as soon as possible. Tel: +7 (953) 402 66 00

The washing machine does not heat the water

How to identify a faulty item

When warm water is drained periodically, the siphon effect is eliminated by correctly connecting the washing machine to the drain system. This is done by installing a check valve.

If the water does not heat up at all, then remove the back or side panels to check the connection of the heater to the wiring.

The spin mode exposes all parts of the washing equipment to special loads. This leads to the separation of the elements.

Heating element diagnostics

Breakage of a tubular electric heater is the most common reason when the machine washes with cold water. In good conditions, the heating element works for 5 years or more. But the presence of hard water, low-quality detergents, non-observance of operating conditions lead to the occurrence of scale. The result is overheating and burnout of the heating element.

SMA are equipped with wet-type electric heaters, with a capacity of 1.5 to 2.5 kW. It is indicated on the case of washing equipment or operational documentation. To diagnose the performance of the heating element, you will need a tester.

Step-by-step instructions for diagnostics:

- Disconnect the wire terminals from the electric heater.

- Place the tester in measuring mode up to 1000 ohms.

- Touch the electric probes of the multimeter to the contacts of the heating element.

If the multimeter reads "0", this means that a short has occurred inside the electric heater. "1" or infinity indicates a break. Both cases require replacement.

The breakdown to the case is checked by testers in the "buzzer" mode. One probe is connected to the heating element, the other to the body of the electric heater. If there is no sound, there is no problem. When there is a sound signal, the heating element should be replaced.

Temperature sensor diagnostics

When the heating element check has shown correct operation, you should pay attention to the temperature sensor. Small metal cylinder located in the electric heater housing

A small metal cylinder is located in the electric heater housing.

For diagnostics:

Disconnect the electrical wiring of the device and remove it carefully. Its resistance is measured with a multimeter

The device data is memorized. Place the sensor in hot water and measure. When the difference in information is large, the device works properly. If there is no difference, you need to replace it.

For a Bosch brand, the type of temperature sensor may differ.

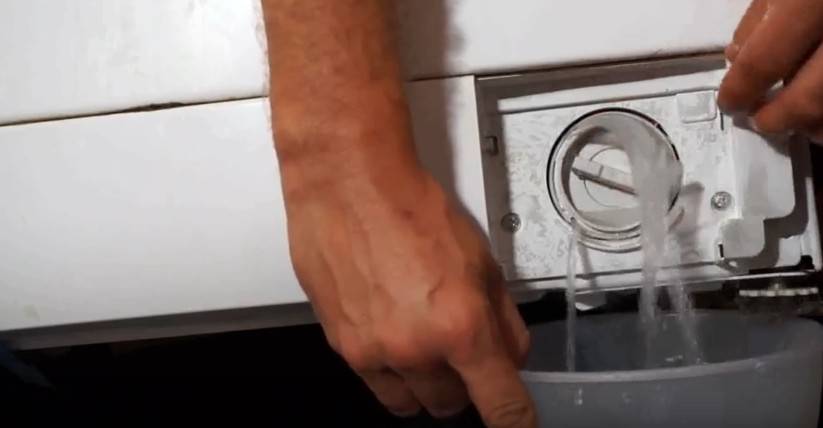

Checking the pressure switch

With a working heating element and a thermistor, the next element to be checked is a pressure switch. When it is clogged, there is no signal that the tank is full of water. Due to this, the control unit does not give orders to turn on the heating element and open the intake valve.

How is the performance of the water level monitoring sensor diagnosed:

- the washing machine is turned off from the network;

- unscrew the back or front panel, depending on the model;

- remove the heating element, having previously disconnected the wires;

- inspect the pressure switch;

- remove and clean the water sensor tube;

- check the tightness of the part and warm-up.

The pressure switch relay is clogged with small debris. If there is no external damage, the CM is collected back.

Electronic module check

The lack of water heating can be caused by a malfunction of the control unit, programmer or electronics breakdown.

Burnout of the electrical part occurs from voltage drops in the network.Mechanical damage to electronics - the consequences of vibration loads. All this leads to an error in the electronic control unit.

The identification and elimination of damage to the electronic module is entrusted to a qualified technician in the service center.

Scale check

Hard water and rust particles will build up deposits on the electrical heating element. After inspecting the part for scale:

- put the heating element in a lemon for half an hour;

- cleaned with a special tool;

- change to a new one.

For prophylactic purposes, periodically drive away CM with citric acid or vinegar.

The presence of scale contributes to the rapid breakdown of equipment and increased energy consumption.

Checking the connection

If after checking all the parts turned out to be in good order, but the water does not heat up, check the correct connection of the washing machine to the drain.

- turn off equipment from the network;

- check hoses;

- clean filters;

- install a ball valve, after wrapping the thread;

- the drain hose is placed at a height of 50-100 cm from the floor.

The drain must be carried out through the siphon of the sink, the bathroom into the sewer drain.

What should you look out for first?

To make sure that the problem is caused by the lack of heating, and not by bad powder or clogged filters, you can gently feel the glass of the hatch: 15–20 minutes after the start of the program, it should be warm. If the hatch is cold, it is necessary to exclude factors not associated with breakdowns, namely:

-

Correct connection. When the owners install the machine themselves, the problem of unauthorized outflow of water into the sewer often arises. To maintain the required water level in the tank, the machine is forced to start pumping, and the heating element does not have time to warm up the newly filled volumes to the required temperatures. Bringing the conditions for using the machine in accordance with the standards allows you to quickly get rid of these troubles.

-

Correctness of the choice of the washing program. Due to the user's carelessness or due to the complexity of setting the parameters of the cycles, the machine can start the modes using cold water. Read the instructions and try other modes.

If, according to these two indicators, everything is normal, the reasons why the washing machine does not heat the water during washing should be looked for inside the device. There are only a few of them: problems with the heating element, damage to temperature or water pressure sensors, as well as failures in the control unit.

Limescale on the water heater and increased water hardness

Scale is one of the most common reasons why heating elements do not heat water well. Lime deposits are the result of washing with water with a high content of calcium, magnesium and rust. Neither cars of famous brands such as Bosch, Samsung, Electrolux, nor economy-segment models from Indesit, Candy, LG, Ardo, Zanussi or Beko are insured against such problems.

To prevent the heating element from crusting, manufacturers recommend adding various softeners when washing. It is possible to increase the efficiency of using these substances by means of special polyphosphate, salt or magnetic filters installed in front of the injection hose. They effectively trap even small particles and prevent contact of the electric heater with unwanted inclusions.

If a lime crust has already formed on the heating element, then it must be removed. Depending on the thickness of the layers, this can be done by washing with professional cleaners or by physically polishing the heater tube. Craftsmen have adapted to clean the heating elements with citric acid, but this method has a rather low efficiency.

Temperature sensor breakage

The thermostat (water heating sensor) is a small element that, depending on the model of the washing machine, can be located inside the heating element or on the surface of the tank. If it is damaged, the system receives incorrect signals about the temperature in the drum and does not give the command to heat the water.

Checking the health of the thermostat:

-

Remove the sensor from the body of the machine, use a multimeter to measure its resistance

-

Put the part in hot water and repeat the measurements

Significant differences in readings indicate normal operation of the device. If the received data is identical or very close, it is worth talking about a component breakdown. The thermostat cannot be repaired, it is replaced with a new one.

Breakage of the water level sensor

The role of the water level controller in the washing machine tank is played by the pressure switch. In the event of its malfunction, the control unit does not receive a signal about the need to terminate the water intake process. At the same time, the drain valve is triggered, and the excess gradually flows into the sewer. In such conditions, the water does not have time to warm up to the required temperatures. The problem is eliminated by installing a new pressure switch.

Breakdown of heating element

The service life of an average heater is 3-5 years. In case of voltage surges, closing contacts or due to a factory defect, it fails ahead of time. Checking the health of an element involves ringing out with a multimeter. No tension? So the answer to the question why the washing machine does not heat the water can be considered found. The problem is solved by replacing the part.

Breakdown of the control unit

What if the heating element is working properly, the sensors are normal, but heating does not occur? The source of the problem should be looked for in the control unit. There are a lot of options for module breakdowns: microcracks on the tracks, contact tap-off, software failures - in total, about a dozen probable problems, which can only be identified as a result of in-depth diagnostics using professional equipment. Depending on the severity of the damage, repairing a washing machine involves updating the thermal paste, soldering connecting wires, updating utilities or replacing an unrepairable programmer.

We test the heating element

In case of problems with water heating, the first suspicion always falls on the heating element. This is logical, therefore, it is recommended to start diagnostics with it. To get to the heater, it is necessary to disconnect the washer from the power supply and water supply, move it away from the wall and turn the back panel forward. Then we unscrew the self-tapping screws holding the "backdrop", remove it and look for the element. It is located in the lower part of the case directly under the drum.

Having removed the panel, it is easy to find the rounded "chip" of the heating element, as well as the thermistor and the wiring connected to them. However, you will first need to remove the drive belt from the pulley to ensure easy access to the heater. Then we take pictures of the location of all connections and proceed to diagnostics:

- disconnect the supplied wiring;

- switch the multimeter to "Resistance" mode and set "200 Ohm";

- we bring the probes to the terminals of the heating element;

- we estimate the indicators.

A working heating element displays a minimum value of 26 ohms, a maximum of 28 ohms. If, instead of the norm, the device issued "1", then the heater has suffered due to an internal breakage of the winding. A result of "0" will indicate a short circuit that has occurred. In the extreme two cases, it will not be possible to repair the element - a replacement is necessary.

The next step is to check the case for breakdown. We transfer the tester to the buzzer mode and apply the probes. If a squeak is heard upon contact, it means that a current leak has been recorded - you will have to change the heating element.

The heating element changes simply. It is enough to dismantle the old device by loosening the central nut and disconnecting the thermistor. Difficulties arise when the existing rubber gasket deforms, increases in size and "blocks" the heater. In this case, it is necessary:

- liberally lubricate the WD-40 cuff;

- wait 15-20 minutes;

- collect residual grease;

- swing the heater and pull it out of the seat.

When replacing, it is important to choose the right analogue. The main reference point will be the marking embossed on the heater body

The serial number of the existing Atlanta will also help. It is even better to bring the dismantled heating element to the store and find a replacement on the spot.Before installing a new heater, it is recommended to thoroughly clean the seat from dirt and scale. The machine is assembled according to the instructions described earlier, only in the reverse order.

Causes

There are various circumstances that lead to a problem with the washing machine. We'll have to figure out what exactly we have to deal with. You need to consider each reason and try to determine which element failed.

The main types of breakdowns:

- The heating element does not heat the water to the required temperature. This appliance works on the same principle as a boiler. On average, it lasts from 5 to 10 years. The term depends on how often the washing machine is used. This part is not accepted to be repaired, it must be replaced.

- The temperature sensor is not working. It is he who activates and deactivates the heating element. If the element does not function properly, then heating will not occur.

- Defective pressure sensor in the area of the tank. If it does not send a signal to the ECU that the tank is filled with water, then the heating will not turn on.

- The heating element is not energized. This most often happens if a cable break occurs.

- Breakdown in the control module assembly.

It is worth taking a closer look at how to troubleshoot an LG washing machine. If there is no experience in repair, then it is better to immediately call the master. He will diagnose and quickly fix the problem. You can try to fix the washing machine yourself, following the instructions.

Scale has formed on the heating element

Even if the heating element is a worker, he also may not perform his tasks. The problem lies in hard water, which is high in magnesium and calcium. Because of this, scale appears on the heating element, and the water does not heat up. Thermal insulation leads to the fact that the heating element constantly overheats. As a result, it fails.

This problem is quickly eliminated. To do this, you need to use one of the products that are used to clean the heating part. The correct solution is to pour about 100 g of citric acid into the powder tray. There is no need to put laundry in the drum, and the wash should be started as it is. You will have to choose a mode of 60 degrees Celsius, and the time should be about 1.5 hours. As a rule, this is enough to remove limescale.

Broken wiring

If the water stops heating, then we can assume a break in the wiring that goes to the heating element. To understand what you have to deal with, you have to inspect the wiring inside the AGR. If the wires are frayed, then they will need to be soldered and insulated. It also happens that the problem is not found. In this case, the wiring will be in good order, but the control unit will fail.

Heating element does not work

When the water does not heat up during washing, you will have to check if there are problems with the heating element. To do this, use a multimeter. With its help, you can understand what problem you have to deal with.

What to do:

- Disconnect the machine from the network.

- Remove the back cover of the AGR.

- Find the heating element, which is most often located under the drum.

- Remove the wires connected to the heater.

- Measure the resistance with a multimeter, which must be between 24 and 40 ohms.

If there is a fault, an open circuit will be shown. The burned-out part will need to be replaced with a working one. To do this, remove the fastening nut and remove the heater. After that, a new element is installed, and a wire is connected to it and a wash is carried out to check. You need to make sure that the rubber gasket does not leak, and the water heats up.

Electronic control unit defective

Sometimes it fails, which causes a lot of problems. We have to flash microcircuits, carry out reprogramming. It happens that a malfunction appears due to breakage or oxidation of contacts. Such problems can only be determined by a master, because it is difficult for an ordinary person to identify them.

Temperature sensor problems

Although LG machines are stable, their temperature sensor may break.It is he who controls what the temperature in the tank should be. If the LG washing machine does not heat the liquid at all or does not bring it to the desired mode, it can be assumed that there is a problem with the sensor. With the help of a multimeter, you can understand if it is functional.

Instructions:

It is necessary to remove the cover of the CM body.

We'll have to disconnect the wires from the sensor.

The thermistor must be carefully removed and replaced with a new one.

Connect the wires to the sensor.

If you do everything right, then the problem will disappear. The main thing is to find out why the LG machine does not heat the water, and what to do in a particular case. If you cannot cope with the task yourself, you should contact the master.

How the washing machine works

Many housewives do not get tired of at least mentally thanking the creator of an automatic washing machine. There are many benefits, ranging from time savings to high quality work done. This is the very case when household appliances perfectly replace a person.

There are many models on the market, from simple functional mechanisms to complex devices with an electronic control system. However, the principle of operation is approximately the same for everyone:

- the laundry is put into a special drum;

- the corresponding washing program is set;

- water is supplied to the machine;

- water is heated to the required temperature using a tubular electric heater;

- the drum rotates according to the set parameters for washing, rinsing and spinning.

Washing machine device diagram

Washing machine device diagram

The cycle of the machine is from 30 minutes to 3 hours, provided that the laundry is pre-soaked and washed at a maximum temperature of 90 ° C. That is, it is practically a digestion, familiar to everyone from childhood. The more intensive and longer the most frequent wash programs, the higher the risk of premature failure of certain components.

The massive replacement of old Soviet cars with modern models began to occur in the mid-90s. The basic service life of the units is no more than 10 years. But our people manage to operate the equipment longer, squeezing the maximum out of it.

Therefore, pioneering specimens are not uncommon in bathrooms and kitchens. As a rule, these are products from the manufacturer, released at the main production facilities. Their quality is higher, which explains the durability. However, what if an almost new car breaks down? And how to find the cause of the failure?