Additional tips and tricks

In order for the device to serve as long as possible, it is recommended to follow these rules:

- It is forbidden to dry laundry on an oil heater. It will dry out rather quickly, but it will cause damage to the device. This is due to overheating of the elements of the device.

- The surface of the oil heater can be hot. To prevent accidental burns, it is recommended to put a special protective shield on the device.

- Wipe off dust from the device as often as possible. This will help prevent overheating and increase heat dissipation. In addition, dust can cause bad odors in the room.

- It is forbidden to use such a heater in rooms with high humidity.

- The device dries the air greatly, therefore it is forbidden to use it in very small rooms.

- The device may only be used in an upright position. If the unit has been stored horizontally, it should be held vertically before turning it on. This will allow the oil to flow downward, eliminating the risk of overheating the heating elements.

- It is forbidden to use adapters to connect the heater. This will create an incomplete contact. As a result, the device can be switched on and off periodically. As a result, it will simply fail.

- It is not recommended to leave the device turned on when leaving home. Do not place the device near upholstered furniture or curtains.

> Oil cooler repair has a number of features. To achieve success in this matter, it is necessary to clearly identify the causes of the breakdown and follow the basic recommendations.

Share link:

How an oil heater works

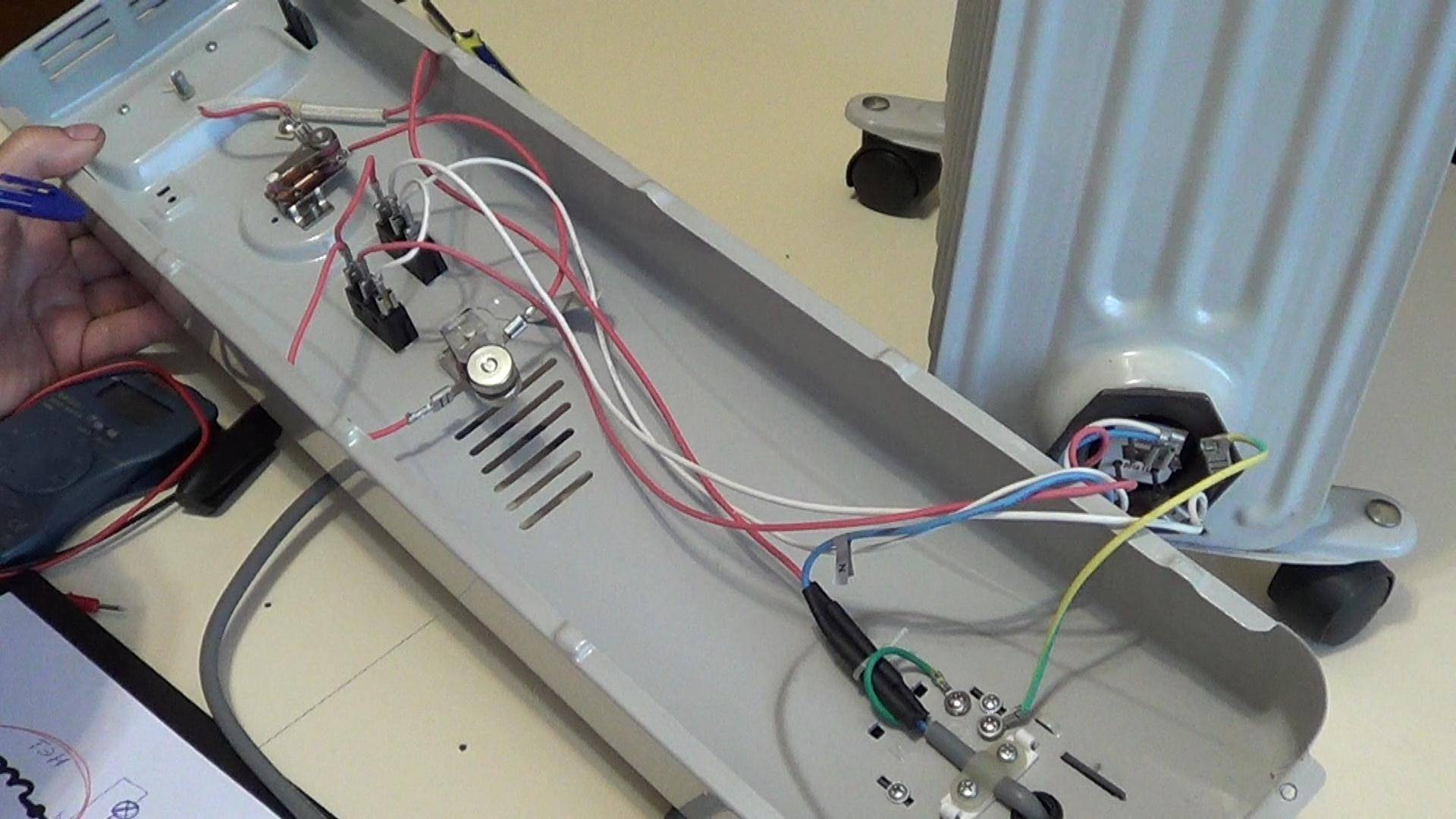

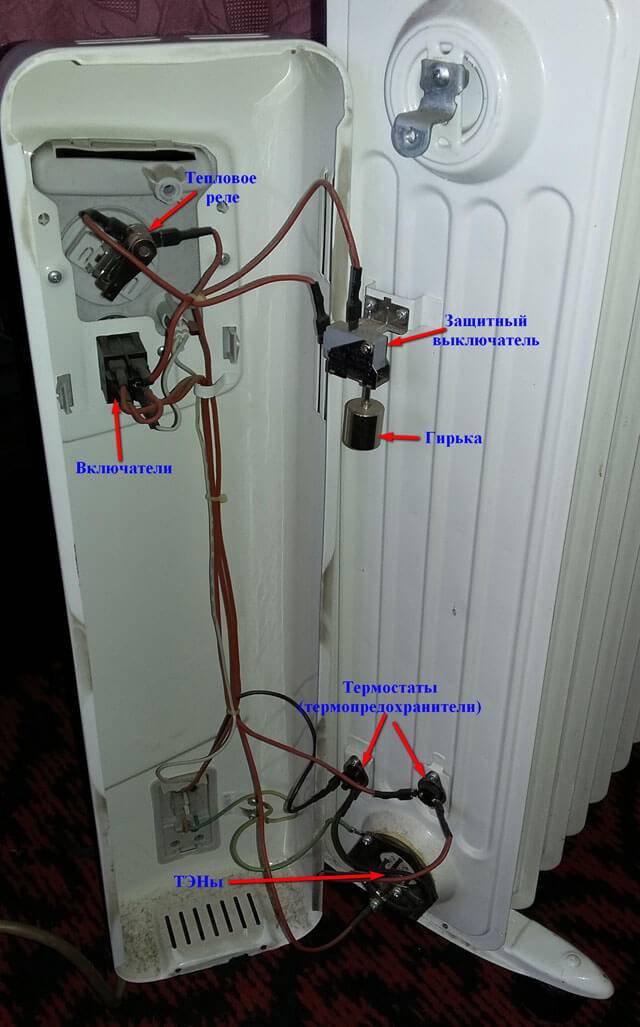

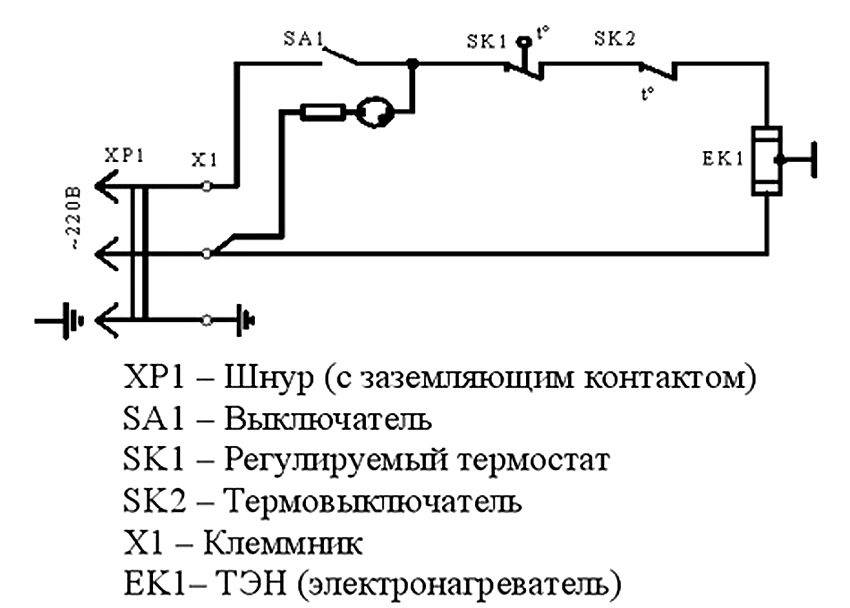

To determine a breakdown, it is worth knowing the principle of operation of the device. It includes the following components:

- Body - it includes an accordion with technical oil. In addition, most devices contain a small amount of air.

- Heating element - present at the bottom of the device and is responsible for heating the oil. Usually this device includes 2 spirals. This is required to adjust the power of the device.

- Control and safety unit. A thermostat is located on top, which does not touch the body.

- Fuse - used to turn off the device in case of failures. First of all, it is required in the event of an oil leak. Fuses are disposable or reusable. The first option has a wire version, the second is considered bimetallic.

- Switches - several wires fit to each of them. This is phase, zero, ground.

How an oil heater works

To determine a breakdown, it is worth knowing the principle of operation of the device. It includes the following components:

- Body - it includes an accordion with technical oil. In addition, most devices contain a small amount of air.

- Heating element - present at the bottom of the device and is responsible for heating the oil. Usually this device includes 2 spirals. This is required to adjust the power of the device.

- Control and safety unit. A thermostat is located on top, which does not touch the body.

- Fuse - used to turn off the device in case of failures. First of all, it is required in the event of an oil leak. Fuses are disposable or reusable. The first option has a wire version, the second is considered bimetallic.

- Switches - several wires fit to each of them. This is phase, zero, ground.

Signs of breakage and damage to the oil cooler

Indirect signs that the oil cooler does not work correctly are the following.The car stopped accelerating quickly and the maximum speed decreased significantly. At the same time, the power unit heats up to a higher temperature with a standard coolant and its quantity.

This indicates that oil leaks have appeared in the engine, and most likely the radiator is to blame. This happens as follows: when a leak appears in the radiator, lubricant begins to enter the combustion chamber or into the exhaust system. When the engine is running, the leaking oil begins to ignite, creating additional heating, which entails burning out and breakdowns of parts. This creates short-term vibrations that are not characteristic of a correctly working motor. Vibrations can be especially pronounced in the initial stages of engine operation after stopping. Lubricant, when it enters some of the combustion chambers of the cylinders, creates additional detonation, which is vibrated throughout the entire power unit.

Visual inspection reveals that the radiator is swollen. This is due to a malfunction of the internal oil circulation. In this case, only the replacement of the swollen element is necessary.

Useful tips for operating the heater

In order for a household appliance to serve you for a long time, and you are not faced with repairing a heater, you should adhere to several rules for its use:

Do not dry laundry on a heating device. Undoubtedly, it will dry quickly on the body of the unit, because its surface can heat up to 100 degrees. But this can also lead to damage to the radiator, since the heater will not be able to give off heat to the room through a blocked access, and all internal parts will overheat. If you want to dry clothes in this way, then you need to purchase a special device that is attached to the radiator from above and is designed specifically for this purpose.

If, for example, you plug it into a power outlet, and in response there is silence - neither the light indicators work, nor there is any heat. It feels like he's dead. What are the reasons for the breakdown of oil heaters? Can you fix it yourself?

At one time, I had the opportunity to work in the workshop for the production of oil radiators, namely, to test ready-made radiators for their performance. You can repair the radiator with your own hands if you do not need to replace the thermostat itself. In order to repair a radiator, you must first determine the cause of the failure. And this requires at least minimal knowledge of electrical engineering, the presence of an ohmmeter screwdriver. First of all, you need to make sure that the socket and plug of the heater are working properly using an ohmmeter or indicator. If everything is in order in this part, it is necessary to check the control unit by removing the panel covering it. Using an ohmmeter, we check the absence of a short circuit between the live parts of the radiator. Contacts in the control unit may be loose or burned out. In this case, we tighten the weakened contacts with a screwdriver, clean the burned out contacts and fix them, not forgetting to insulate them first. Once again we check the absence of a short circuit and close the panel. Only after that we try to connect the electric radiator to the network. Unfortunately, you did not specify which brand of oil cooler. But in any case, if the cause of the breakdown is the failure of the thermostat, it is more difficult to repair it yourself. It is also difficult to repair a Chinese-made oil cooler. It is better to dispose of it than to repair it. If the thermal relay fails (very fragile and unreliable), then it must be replaced if you find a suitable one on sale.

Of course, you can fix it with your own hands (after all, somehow they are repaired by the master). There are three main breakdowns of oil heaters: 1. TEN is out of order; 2. The thermostat is out of order; 3. The body switch is out of order.All breakdowns are eliminated by replacing the failed elements. It happens that the contacts on the thermostat are stuck and the repair consists in cleaning the latter. But this is less common. Usually the thermostat crumbles altogether.

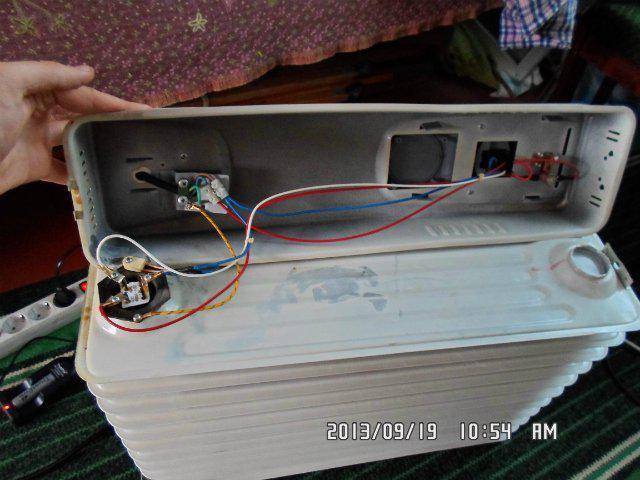

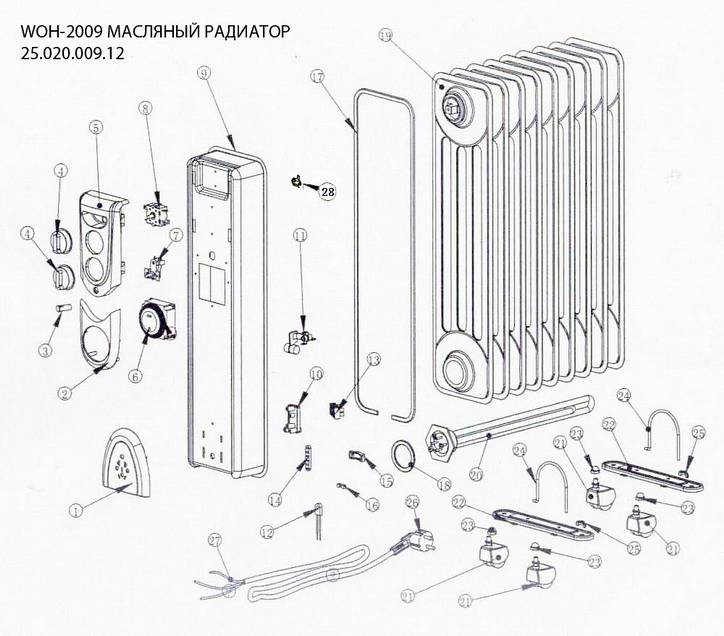

Heater structure

Before proceeding with the repair of any electrical devices, it is important to study the device of the product and the principles of its operation. After reading this information, it will not be difficult to disassemble the oil cooler.

The constituent parts of the heating equipment are:

- metal body;

- heating element (heating element);

- Control block;

- connecting wires.

In the case of the device there is oil, which is heated after turning on the heating element. In the process of operation, the walls of the radiator heat up, and from them the entire room. When certain temperatures are reached, the control unit is triggered, as a result of which the heating element is turned off. These cycles are repeated as long as the product is connected to a power source. As a result, a constant temperature is maintained.

How the oil heater works and how it can be repaired, see this video:

Features of the device

Before you understand the various intricacies of the device of this category of heating equipment, you must first understand how, in general, it works. The scheme of its device, in principle, is not overwhelming and includes such components as:

- a body made of metal;

- Control block;

- wires for connecting various elements;

- a heating element.

The lower end part of the accordion assumes the presence of a heating element, to which an area is attached where all the electronics of the device are located. There is no pump here, and the operation of the device is carried out using the process of natural recirculation of the oil liquid. In addition, the presence of a thermal fuse should be noted. Its main function is to exclude the possibility of a fire if the container suddenly leaks and the oil leaks out. And also it does not allow the oil to heat up too much if the temperature switch suddenly breaks. When talking about thermal fuses, they are usually of two types:

- wire - considered disposable;

- bimetallic - considered reusable.

This is interesting: Which heater is better and more economical for an apartment?

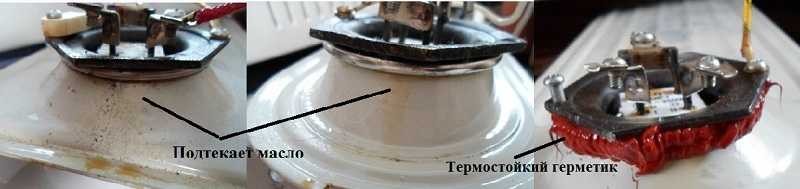

Fault 5

Leakage of mineral oil from the housing of the electric radiator along the weld.

Cause: Violation of the tightness of the weld.

Inspect the appliance and, having identified the location of the oil leak, place the appliance in such a position that this place is at the top. Minor cracks, pinhole holes can be soldered with soft solder such as POS-61 or POSSu 40-2 with F38N flux, consisting of hydrochloric acid diethylamine (20-25%), phosphoric acid (20-25%) and glycerin. You can use a different acidic flux, such as # 200.

File the defective section of the weld seam with a file, clean it with sandpaper and wipe it with a napkin soaked in gasoline. Run a soldering iron on the cleaned surfaces and solder the crack or pinhole.

If the defective section of the seam is long and it is not possible to eliminate the leakage with soft solder, it is possible to restore the tightness of the oil cooler body by brazing (L63 brass using a mixture of borax and boric acid with an equal ratio of components as a flux) or by welding. In both cases, it is better to contact an oil cooler repair shop.

In conclusion, we recall that household electric heaters of any type cannot be used in rooms with earthen, reinforced concrete, metal floors (sheds, garages), in rooms with high humidity (bath, cellar), as well as in rooms where flammable liquids and gases are stored.

When choosing the power of heaters, as well as their number, one should proceed from the fact that for every 4-5 m 2 of the floor of the room, approximately 0.5-0.7 kW of electric heater power is needed.

Share on social media networks:

Reliable classic heating devices, which are oil heaters, fail very rarely. But still, sometimes breakdowns do happen. Repairing oil radiators sometimes does not require any special skills, so you can often do it yourself at home. How exactly and in what case it is worth doing this - we will figure it out in this article.

Repair of the casing of oil heaters

Holes in the casing result from corrosion of the heater walls or from mechanical damage from the outside. This breakage will be visible visually. The device must not be operated in this state. Those who decide to take on the repair of the heater with their own hands should remove all the oil from the device and rinse the inside of the tank with alcohol. Refrigerator repair equipment should be used to repair the tank, and copper-phosphorus, brass or silver solder should be selected as the soldering agent.

Before soldering the case, it is imperative to clean the damaged area, cover it with an anti-corrosion liquid, and after it dries, degrease the surface with alcohol. The next step will be the soldering itself. To do this, the solder is applied to the place of damage and heated with a torch according to the principle of hermetic brazing of refrigeration equipment.

It must be remembered that synthetic oil cannot be combined with mineral oil. Mixed oils should not be mixed. Therefore, if you are not sure which type of oil was filled, it is best to replace the oil completely. If the type of oil is known, according to the passport data, it just needs to be topped up.

After a complete repair of the oil heater, it is necessary to fill the oil inside to 90% of the capacity, leaving 10% space for the air cushion (when heated, the oil tends to expand, and the air will contribute to this process). In the absence of an air cushion inside the housing, it may burst due to increased pressure.

Oil heaters are massively used by summer residents for heating rooms in winter. They are efficient and do not burn oxygen, but the danger is that their body gets very hot. If misused, a number of problems can arise that are difficult to fix.

Operating conditions

Caring for an oil heater, first of all, consists in correct operation, compliance with all rules and conditions.

- During operation, the surface of oil heaters can get very hot, up to about 100 degrees. If there is no special protective screen, then you can easily get a severe burn. Often there is a great temptation to hang wet laundry on the device to dry, rightly believing that it will dry in a moment. Of course, it will dry out, but it can also damage the device. Wet laundry hung to dry does not allow the device to give away the body in the room, therefore it cannot be cooled. Because of this, in turn, its internal components begin to overheat. The result is a breakdown. If you are so anxious to use the heater to dry your clothes, buy a special attachment that attaches to the top of the device so that you can lay out wet clothes without damaging the device.

It is advisable to wipe off dust accumulating on the heater as often as possible. This also saves the device from overheating and increases its heat output. In addition, dust burning on the heater can cause an unpleasant odor.

Do not install the device in damp rooms. Oil radiators are not intended for use in bathrooms or showers. The most ideal place for such devices is spacious, dry rooms.

It is undesirable to use oil radiators in small rooms.The truth is that it becomes worse for the owners of the device themselves. In a small area, the device simply cannot function correctly. Therefore, very often there is a lack of oxygen in the premises and too dry air.

- The oil heater should only be operated in an upright position. Even its storage in the summer, when there is no need to use additional heat sources, should only take place vertically. If it turns out that the device has been lying in a horizontal position for a long time, let it stand before turning it on. This is necessary so that the oil completely flows down, and the heating elements do not overheat due to a lack of conductor heat.

It is not recommended to use adapters for connecting a radiator. This usually happens when the socket in the room does not have a euro plug. If such a need has arisen, then it is better to buy a really high-quality reliable conductor. Most often, you can find cheap options in stores. When connecting a device with their help, the contact is incomplete. As a result, the device turns on and off. This will not end with anything good for the heater; it may simply burn out.

As you can see, in order for the oil heater to work well and for a long time, no extra efforts are required. Prevention during the operation of the device will only benefit. Proper care can increase the life of the appliance.

Another important point: never leave the radiator turned on when leaving the house and do not place it near upholstered furniture or curtains. In general, everything that can catch fire with ease. And all the more, there is no need to put the device in close proximity to your own bed, because you can simply forget about it and get completely unpleasant sensations in the morning.

Device device

Oil cooler Watt WOH-80

The components of an oil heater are:

- Hermetic body in the form of an accordion, consisting of two panels welded to each other. Technical oil is pumped inside, and in almost all models small amounts of air remain. But this does not harm the device, because oil, when it comes into contact with air, does not create conditions for corrosion. If there was water instead, the probability of rupture of metal structures would be very high.

- In the lower part, a heating element is inserted into the device on the side. It is with its help that the oil and the radiator itself are heated.

- A control and safety unit is installed next to the heating element. Its main and important element is a thermostat with a fuse. The first is responsible for setting the required temperature regime, and the second is for the safety of operation. If, for any reason, oil begins to flow out of the housing, the fuse will work and stop the supply of electricity to the heating element.

Today manufacturers use disposable wire-type fuses or reusable bimetallic pills. As for the control relays, in oil heaters they are similar to an electric kettle, and not to irons. In the design, the relay hangs in the air without touching the device case.

- Each device has two switches. Three wires are suitable for each - a phase, zero from the heating element and a wire from a thermal relay. Three wires are required for the backlighting of the switches to work.

The electrical circuit of an oil heater is practically the same as in irons, electric kettles and other heating devices. It is simple yet reliable. Usually, all these heaters have two heating elements, and when both are turned on at once, the power consumption increases greatly. But at the same time, the time to reach the operating temperature increases. If the temperature in the rooms is low, then even with two heating elements turned on, the device can work without turning off.

The metal case, which covers the power and safety unit of the device, has ventilation slots at the top and bottom. If you close them, the device will not suffer from this, but it will be difficult to work. It will turn off faster, but not turn on so soon. Therefore, it is recommended not to hang items to dry on the radiator. If this happens, try not to cover the ventilation gaps.

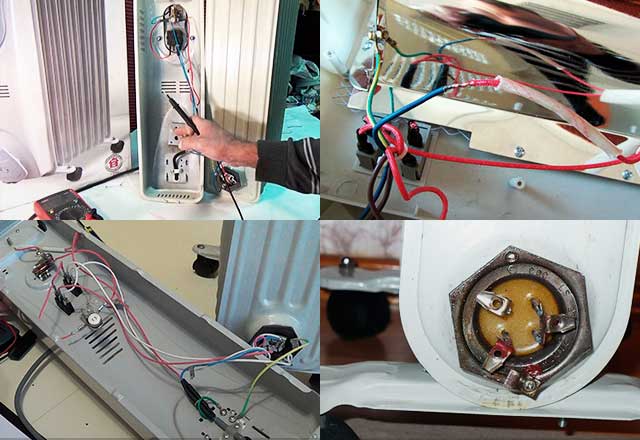

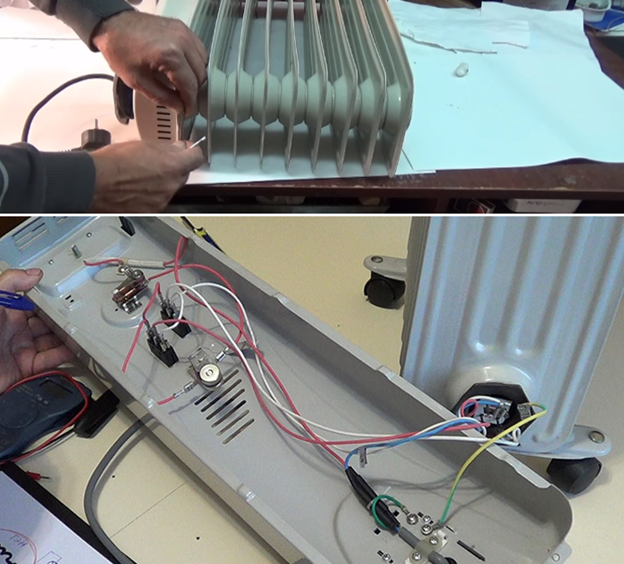

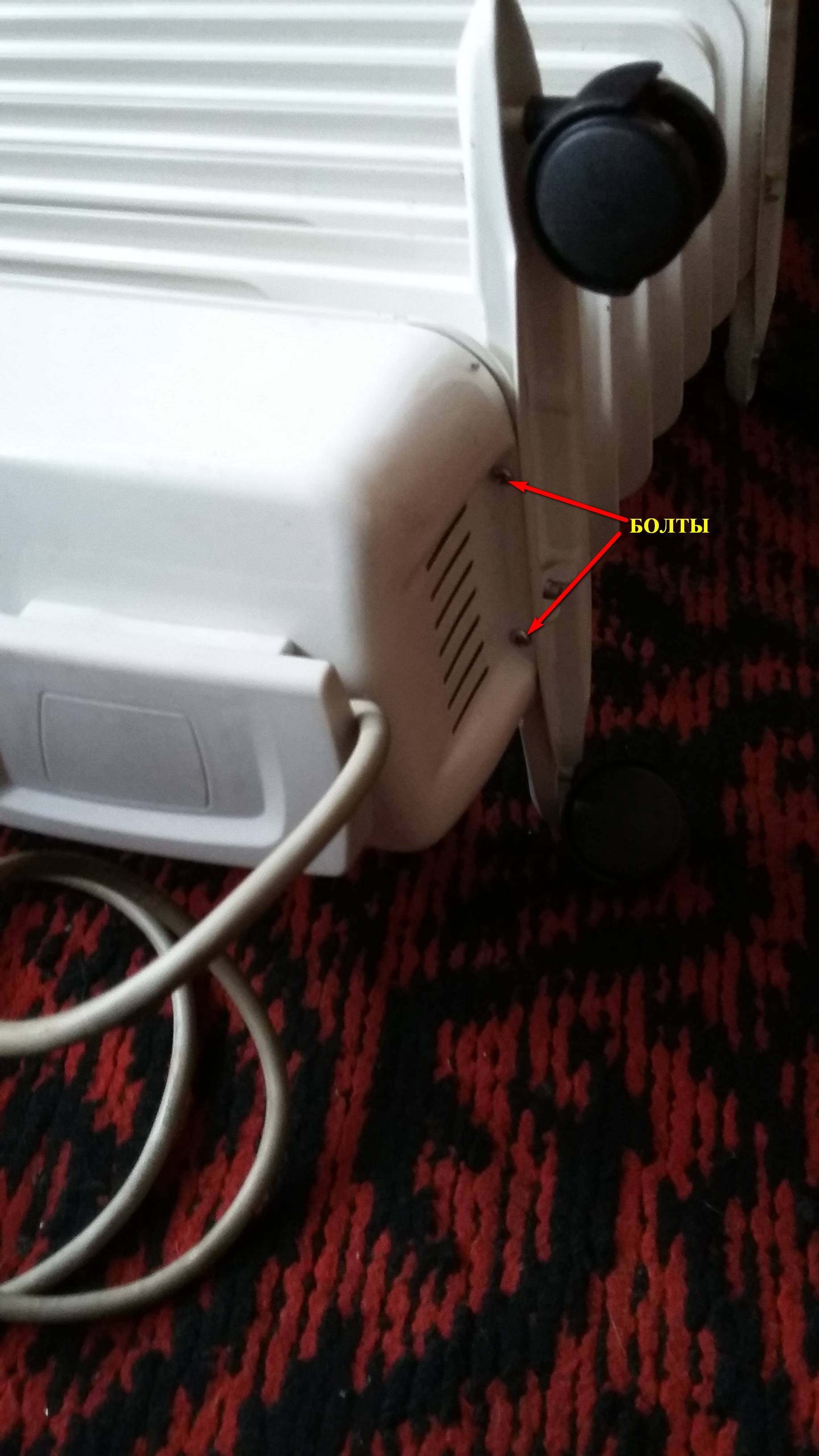

How to disassemble a radiator

To repair the heater, you need to identify the cause of the breakdown. For this, it is recommended to disassemble the device. To begin with, it is worth preparing everything you need:

- an item for prying a plastic panel - it is desirable that it has a wedge-shaped shape;

- screwdriver;

- alcohol or cologne;

- tester;

- sandpaper;

- soft napkin;

- brush;

- file.

Before starting disassembly, the device must be disconnected from the power supply. It is strictly forbidden to connect the disassembled device. All models of heaters are different, therefore there is no standard algorithm for the procedure. However, there are several options for solving the assigned tasks.

But most often, a spring latch is used as a retainer for the plastic panel. In this case, you should touch the surface with a plastic object or a product made of another material. This must be done very carefully to avoid damaging the case. You will be able to feel the area where the latch is located. If you press harder on this area, it will be possible to bend it.

If you have little skill in analyzing the technique, it is worth photographing the entire process of shooting. It is recommended to lay out bolts and nuts during disassembly. This will help reassemble the instrument after the process is complete. Experts advise not to rush to disassemble the device. Some problems can be identified without looking inside the device.

The device of the simplest oil cooler

To find the cause of the breakdown, you first need to navigate the design of the device. It consists of the following parts:

Frame. It is a sealed accordion with technical oil inside.

- At the bottom of the device, a heating element is built on the side. This element also heats the oil. Often it consists of two spirals, which makes it easier to adjust the power of the device.

- The control and safety unit is located nearby. At the top there is a thermal relay, and so that it does not touch the case.

- There is also a fuse in the device, which in the event of a malfunction (for example, oil leakage) turns off the device. Such elements can be disposable wire type and reusable (bimetallic).

- The design has two illuminated switches. Three wires are suitable for each: zero and phase from the heating element and grounding.

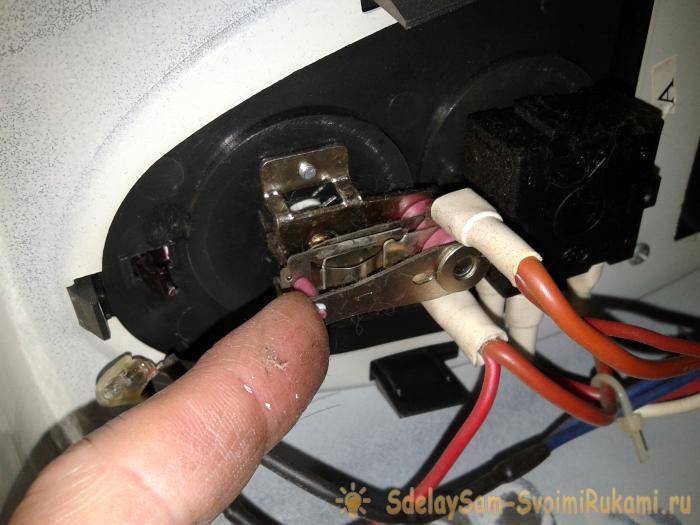

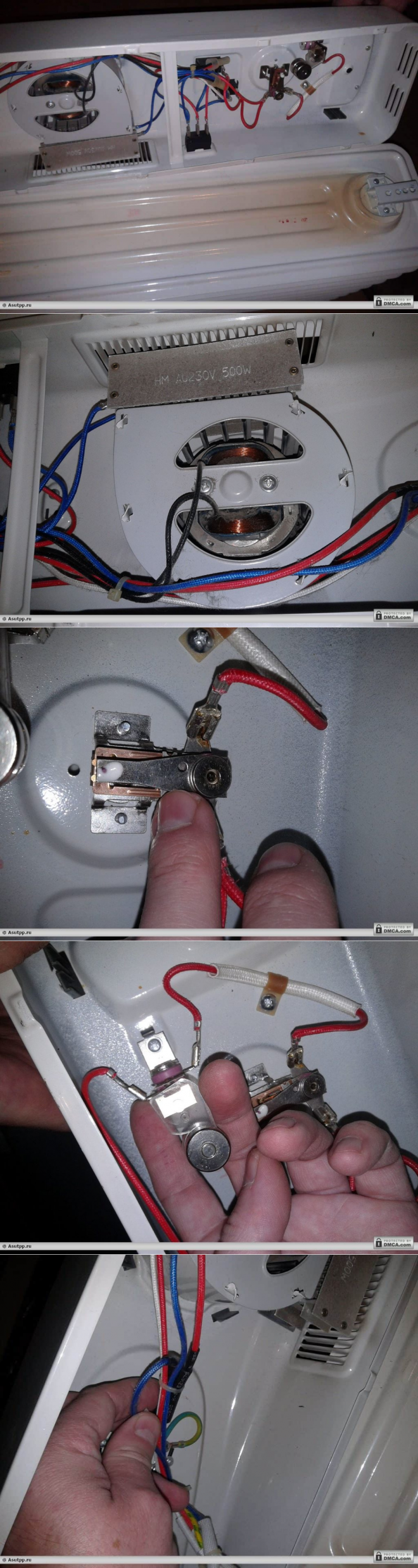

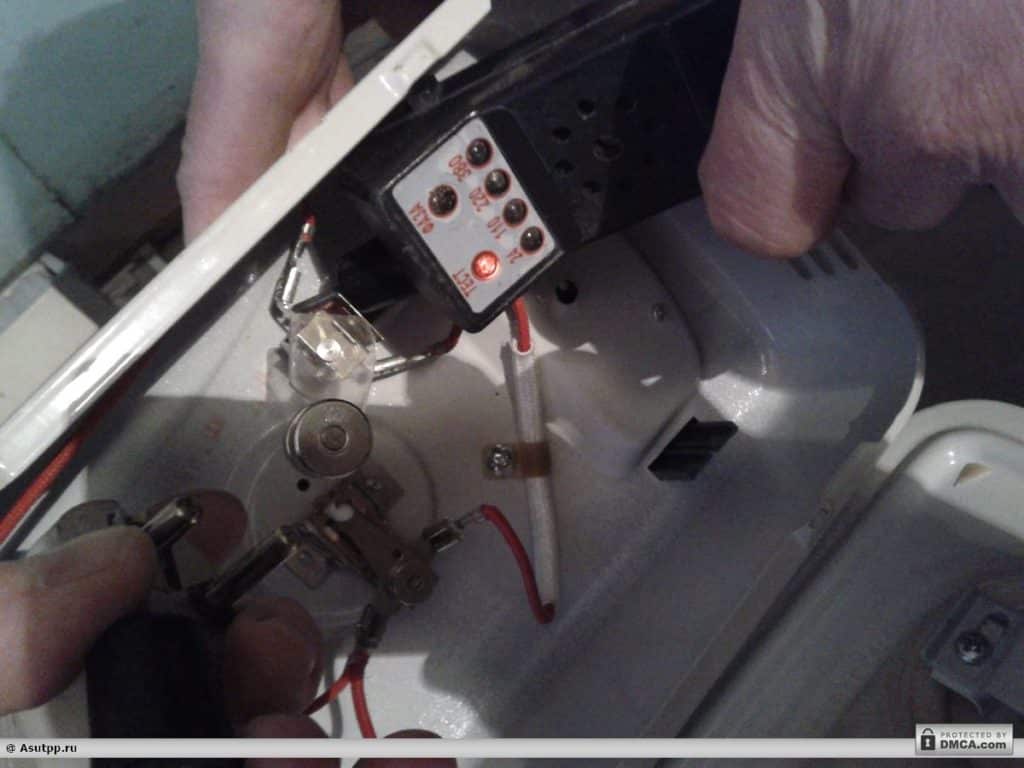

Thermostat

If everything is ok with the conductive cord, you need to move on and inspect the thermostat for a possible short circuit. It is best to do this initially with the PSU cover removed. In order to get to the thermostat. The anchor of the device should be slightly raised so that in no case the thin plate is bent, there are contacts under the plate, they must be carefully examined. (See also: What are the most economical heaters)

If they are black, it means that a short circuit has occurred, the device can be reanimated by cleaning the contacts with sandpaper to a shine. After cleansing, for a more effective result, it is better to wipe the contacts with alcohol.

How to repair a heater in case of suspected bimetallic plate breakage? The bimetallic plate is located in the same thermostat. Therefore, you first need to disassemble the thermostat, and only then take out the plate. In such a situation, the repair is only one complete replacement of the bimetallic plate.

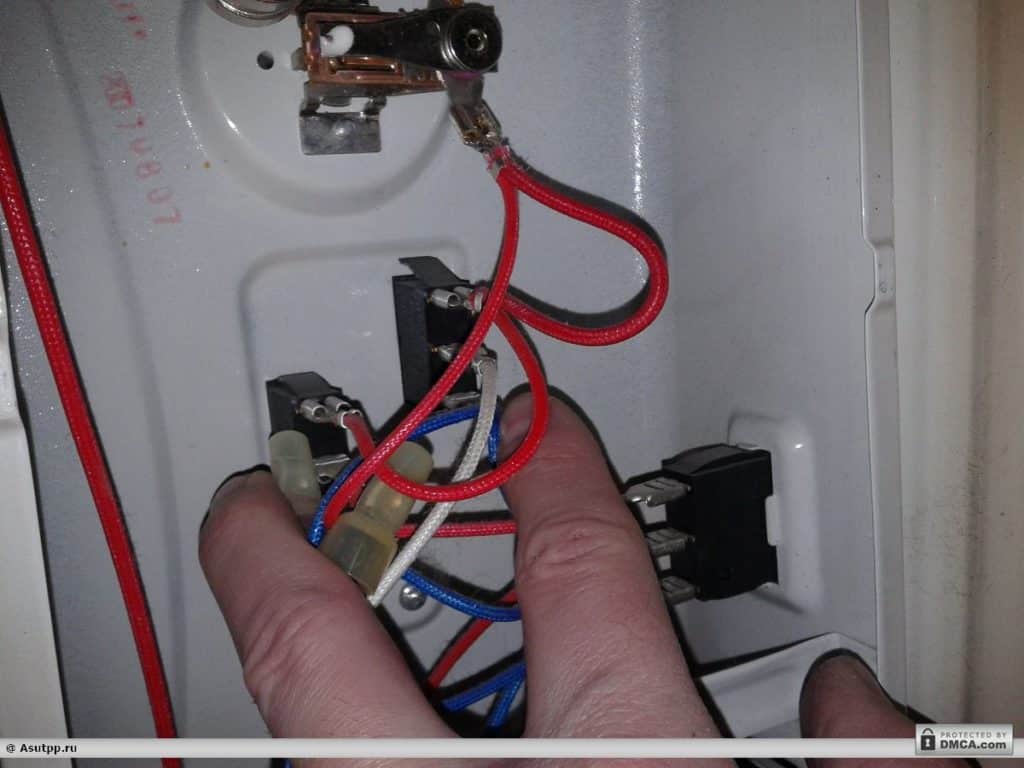

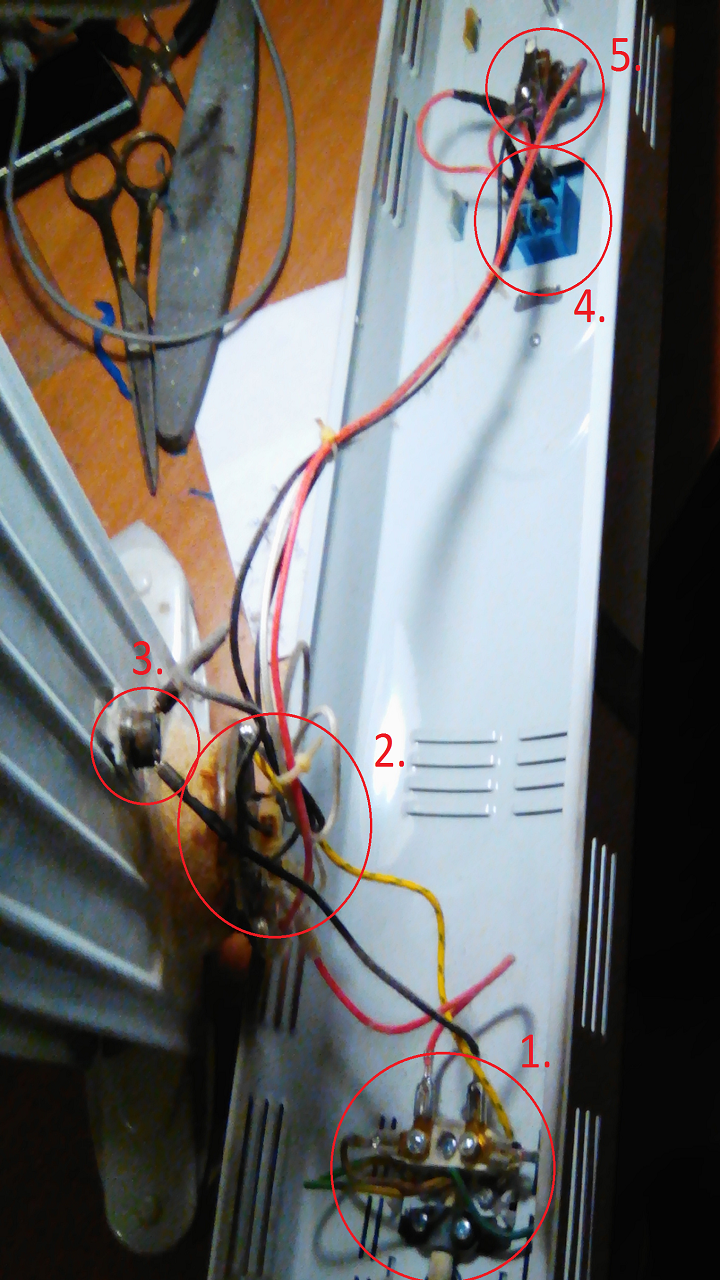

Fault 3

The electric radiator did not turn on after an emergency shutdown by the thermal limiter, its red button is unusually high. After pressing, it returns to the same position.

Cause: The cogwheel in the thermal limiter mechanism is unsoldered or rotated.

Remove the cover from the control box, remove the panel.

On the reverse side of the plastic panel 1 (see Fig.) There is an emergency thermal limiter. It consists of a screw with a fixed contact 14 and a movable contact riveted to the elastic plate 12. In the normal state, this contact pair is closed. In case of emergency operation of the thermal limiter, the contacts are separated by a plastic plate 13 attached to the rod 5. At the opposite end of the rod there is a red button 3. Together with the rod, it is under the influence of a spring 4. In the working position, the rod is held by a plate 6 with a groove, riveted to the rod. With the edge of the groove, the plate abuts against the gearwheel 7, mounted on the rod 9 of the emergency thermal limiter sensor and soldered with low-melting solder to the bar 8. The bar itself is attached to the plastic panel 1 with two screws 10.

When the sensor rod is heated above 130 ° C, i.e. in an emergency, the low-melting solder melts and the rod 5 rises upward under the influence of the spring 4. In this case, the plastic plate 13 disconnects the contacts and the heater is turned off.

If you find that the gear 7 is sealed off or turned for other reasons, unscrew the two screws 10, remove the bar 8, the sensor rod 9 and the gear.

After sanding the end of the rod with fine-grained sandpaper, pass it through the hole in the bar. Now you need to put the gear wheel on the rod and solder it to the bar with low-melting solder, for example, type PVSO-96. The melting point of the solder should be 120-135 ° C. Attach the assembly to the panel by screwing two screws into the holes in the strip. Put the thermal limiter in the working position, for which press the red button 3 and, using a screwdriver or tweezers, make sure that the teeth of the wheel 7 enter the groove of the elastic plate 6 and lock the rod.

Now remove the elastic movable plate 12. Having unscrewed the screw 11, inspect the movable and fixed 14 contacts. Having found burn or corrosion, restore the serviceability of the contact pair, as you did when eliminating the malfunction caused by cause 4. A slight decrease in the thickness of the contacts can be easily compensated for by carefully bending the elastic plate 12. If the total thickness of the contacts has decreased by more than 0.5 mm, you need to loosen the nut on the front side of the plastic panel and, by unscrewing the screw 14 with a fixed contact, compensate for the decrease in the thickness of the contacts.

Then securely tighten the nut on the face of the panel. Make sure that the contacts are tightly pressed and the contact pair is closed.

Having restored the serviceability of the emergency thermal limiter, try to establish the cause of its operation. Check and, if necessary, adjust the thermostat of the electric radiator, as you did when troubleshooting fault 2 caused by cause 1.

Assemble the control unit, check the operation of the oil cooler.

Oil heater does not work. Causes and elimination of breakdown

In some cases, you can fix the oil cooler yourself. Consider the main breakdowns of such devices and the algorithm for subsequent actions.

Extraneous noise

Often, after the heater has been dropped or has been tilted for a long time, it starts to emit a crackling or hissing sound during operation. This is one of the cases when there is no need to disassemble the device. Air and oil have moved inside the unit during improper positioning or as a result of an impact.

Remedy - It is necessary to place the instrument in an upright position for a few days. After this, the problem should be eliminated by itself.

Electrician

If the device does not respond to plugging in, does not heat up and does not even light up the indicator light, then first try connecting the power cord to a different outlet.The reason may be a faulty outlet. If it is the radiator that breaks down, then using a multimeter, you should check the health of the electrical part of the device.

Troubleshooting:

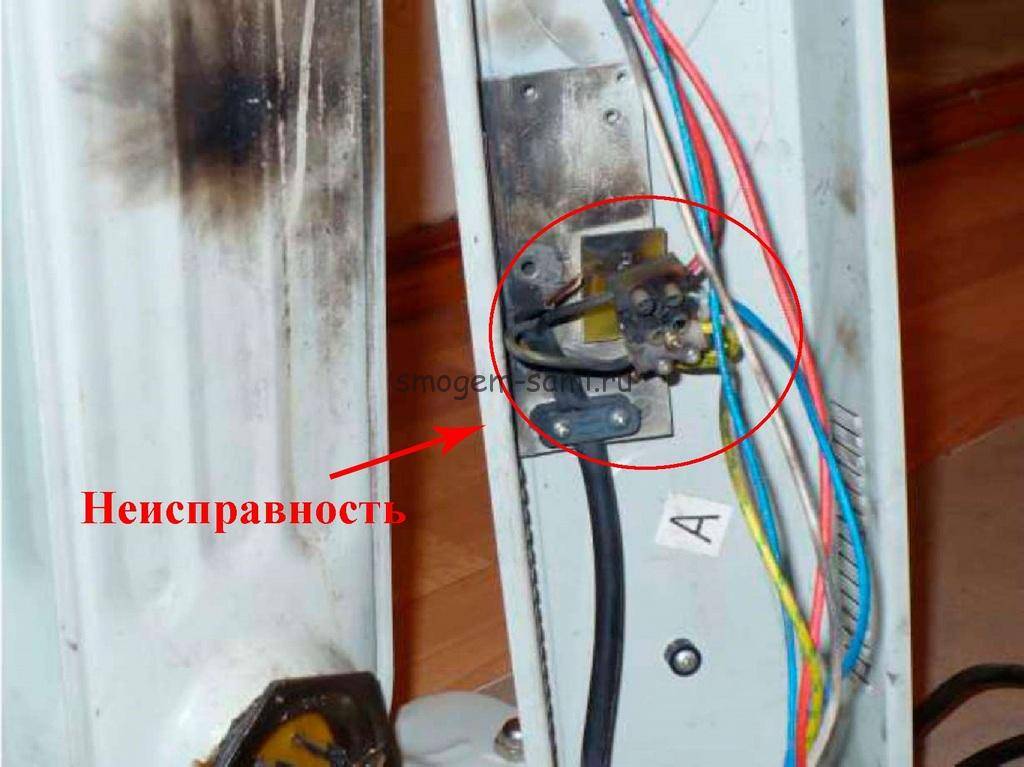

- Check outlets and plugs. Inspect for a short circuit between the elements of the heater, because often the cause of such a problem is burnout at the wire junction.

- A de-energized radiator must be checked for the operation of all buttons on the switch. This can be done with a multimeter or tester. In the on position, there will be a short circuit at the ends, and in the off position, nothing.

- Also, using a multimeter, you need to check the thermostat. There should be no short circuit, and the resistance should be small.

The rest of the breakdowns associated with this problem can be detected only by disassembling the case:

Inspect all contacts in the control unit - they can oxidize, burn out or weaken. In this case, the repair of the oil heater is reduced to treating the contacts with alcohol. Loose contacts should be tightened with a screwdriver, oxidized ones should be rubbed with sandpaper and insulated.

Thermal fuses

There may be several of these important parts in a heater. If one of them becomes unusable, then the device stops working.

Remedy - Ring the bell to find the defective fuse. The non-working part must be removed, the wires must be insulated and connected.

Bimetal plate

The plate can be deformed during operation. This often causes oil to leak from the device. In this case, replacement of the damaged element is required.

Troubleshooting:

- Disassemble the temperature controller.

- Set the heating temperature to minimum.

- Remove the regulator handle from the screw, unscrew the nuts and remove the frame.

- Remove the deformed plate and install a new one.

Oil leak, tank repair

If you notice oil leaks from the heater, it means that the tightness of the case is broken.

Troubleshooting:

In this case, the repair of oil radiators is a responsible business and not always justified. If you nevertheless decide on such actions, then you need to do the following:

- Drain the oil.

- Seal the tank using not tin solder, but silver, brass or copper-phosphorus. To do this, use a burner.

- It is necessary to thoroughly clean the edges of the seams from rust so that they firmly "seize".

- During work, the inside of the tank should be filled with water. This will prevent fire. Dry the reservoir after finishing work.

- After the repair of the tank is successfully completed, the oil should be changed. Use transformer oil for this. It must be remembered that mineral oils are not compatible with synthetic oils.

Breakdown of heating element

This part of the oil cooler cannot be repaired. If it breaks down, then it can only be replaced with a working one. And this is only possible if your heater model has a removable heating element.

Debugg:

If you can change the heating element in your radiator, then you should choose a new one, preferably copper, which would be identical in power to the old one.

Drop or position sensor

This part is a weight that ensures the safety of using the heating device. At a certain angle of inclination of the radiator or its fall, the sensor turns off the device.

To check if this element is working properly, put the heater on the floor and ring the contacts.