Natural stone

This is the most successful material. Today, the following natural stone is most commonly used for paths.

- Granite. The stone contains field twine, mica, quartz. Its distinctive characteristics: high strength, resistance to moisture, frost. It perfectly withstands up to 200 thawing-freezing cycles. In addition, it has a variety of colors, ranging from a gray shade to a dark red palette. This is the most preferred natural stone for paths in the country.

- Slates. Such rocks are characterized by a layered structure. That is why such a stone is most often found in the form of slabs. Most shales are porous. Therefore, the material needs additional processing with special compounds. Quartzite shale is closest to granite in terms of operational properties. It is he who is most often used for paving paths.

- Shungite. Such a natural stone is a good option for decorating a site. There is a layered material and a monolithic one. The latter has a whole list of advantages. It is high density and strength, resistance to frost, chemical attack, abrasion. But its color palette will not please with variety. Shungite can be black or various shades of gray. Sometimes the stone contains inclusions of pyrite or quartz. They provide amazing surface veining in golden or white colors.

- Sandstone. This stone is very popular, just like granite. But sandstone is somewhat inferior to it in hardness, although it also belongs to durable materials. It is easy to process. Thanks to this property, the stone can be easily given the required shape. Sandstone will delight you with a varied range of colors of light yellow, pink, gray-green, fawn tones.

- Quartzite. It is a quartz slate containing mica. It is characterized by high hardness and strength. Such properties create serious difficulties in stone processing. Usually the material is reddish, white, gray or greenish in color. In addition, its hue varies with lighting. It is durable and surprisingly beautiful, which is why it is often used for paving paths.

Stone paths

The technology for making a path from natural stone is not complicated, but it requires painstaking work and the use of physical force.

You need to mark the section for the track with your own hands with the help of pegs and a cord.

Pegs and a cord will help fence off the front of the work

Pegs and a cord will help fence off the front of the work

The width of the garden path can be from 40 cm, the sidewalk - from 80 cm, depending on the number of people who will walk there, the main entrance is provided with a width of 3 m. The slope of the territory must be at least 2 degrees. The sidewalk can be made convex, then the water will flow from it to all edges, and not in one direction. It is necessary to think over the drain or drainage system in advance.

A layer of soil is removed from the marked area. The depth of the chosen soil depends on the function of the territory. For pedestrian and bicycle paths, remove about 300 mm:

- 200 mm for a crushed stone and sand pillow;

- 50 mm on a concrete base;

- 50 mm for stone and mortar.

Crushed stone and sand alternate in layers of 50 mm. The slab for this purpose should be 20 to 35 mm thick. For a road that involves the movement of cars, the depth of the trench should be at least 500 mm:

- on a sandy base 300 mm;

- on a concrete screed 100 mm;

- the rest for facing material and adhesive solution.

In this case, the cobblestones must be at least 40 mm thick.

Before making a stone path with your own hands, it is advisable to distribute and mark them. When laying stones, the excess can be cut off with a grinder with a special cutting wheel (sold with a stone mark). In order for the boundaries of the site to have smooth edges, it is necessary to make a formwork.

Distinctive features of the material

First of all, you need to figure out what exactly the flagstone is, which is often used to create pretty garden paths. These are flat slabs of natural stone, the thickness of which can vary from twelve to fifty-five millimeters. The shape of stone plates can be almost any - square, rectangular, oval, round.

Depending on the source material, there are several types of flagstone. The most in demand are granite flagstone, flagstone-slate, and also limestone-sandstone.

The widespread use of limestone stone in landscape design is due to its many positive features, each of which will be considered separately.

Smooth and non-slip surface

Stone plates have an absolutely flat surface that does not slip when moisture or snow gets in. This ensures the safety and comfort of moving along the garden paths.

The degree of moisture absorption of limestone depends on the initial density of the stone and averages about 6%.

Ease of handling and styling

The limestone processing is not difficult. Natural stone is easy to cut, grind, polish and engrave. Laying out tracks from this material is also very simple. This is done using the standard method, without bordering.

Garden path with your own hands from stone slabs master class

Garden paths made of stone slabs on a concrete base are very popular among owners of large personal plots. This track looks very prestigious, easy to install and unpretentious to maintain. The only negative is that it will take quite a lot of time and effort to create the track. But the result will fully justify itself!

For a walkway made of stone slabs, the base is very important. It must be made very firmly so that the plates hold firmly and serve for a very long time.

The instructions for creating this garden path are quite simple, but a few small nuances should be taken into account:

- The stones of the path should be higher than the ground level so that water does not accumulate on it and flow down

- Not all stones are suitable for creating a taco track - for example, marble will make it very slippery

- The path should be fenced off with a curb so that over time it does not start to collapse.

With the help of a simple master class, even the most inexperienced builder can make such a track!

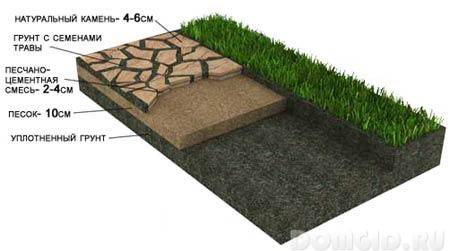

Laying sandstone on sand

An excellent summer cottage option that does not require large costs.

Instead of excavated soil, the preparation of the path is covered with sand 5 cm in height, moistened with water, and compacted.

The next layer is done before masonry work, it consists of dry cement and sand in a ratio of 1 to 7.

The cake is rammed, then prepared plates are laid on top of it.

Once the sandstone has been placed, the gaps are re-filled with the mixture, filled with water.

During the drying period, avoid mechanical stress on the track.

After 2-3 days, after the mortar settles in the seams of the masonry, fill them again.

Natural stone for paths - step by step instructions for paving

When you get tired of picking up stones, you can proceed to the most interesting part of the process - namely, laying them. Do not forget to prepare all the tools you need for this process - a trowel, a bucket and a few dry rags.

Step 1: Site preparation

If you have dry-laid on a concrete screed, carefully remove the sandstone to one side in order to maintain order. Prepare the glue in advance for lubricating the stones themselves - correctly mixed glue will not contain lumps and will remind you of liquid sour cream in density.The selected tiles should be smeared with glue with a stiff brush on the side that will be applied to the ground. While they dry out a little, sweep the concrete base properly, you can even vacuum it - dust can significantly spoil the installation process.

Step 2: glue the stones

So, you have prepared the material for styling. Apply the glue mixture prepared in advance to the site with a trowel, namely its economical version. It should be applied carefully, even if in excess, but in no case leaving empty spaces - water will definitely get into them, and at subzero temperatures this can lead to chipping of the tiles from the concrete base.

Lay flagstone No. 1 on top of the mortar and press down thoroughly. For more confidence, it doesn't hurt to even push your feet on him. You must squeeze out as much glue from under the stone as possible - in this case, it will lie firmly on its base, leaving no voids under it. Gently collect the excess glue back into the container with the mixture.

Glue the second tile in the same way. Dashes and symbols will significantly speed up the process. When joining, first press on the side that is in contact with the already laid stone, and only then press on the other side. The second option is also possible - lay the sandstone at a short distance from the "neighbor" and, pressing on it, simultaneously move it towards the already glued tile. In this case, excess glue will appear in the gap between them. You cannot leave them there - remove with a trowel and wipe the stone with a rag, since washing the glue will be a very difficult task.

After laying several tiles, you will feel yourself in such a thing as paving with natural stone with your own hands, a real master. Make sure that there are no differences between them, with the help of an adhesive mixture you can always raise the tile to the desired level. You will not find more difficulties in laying natural stone.

Step 3: After styling

It will take several hours for the glue to set well. And the very next day, you can take a stiff brush and clean the area, sprinkling it generously with water. It is acceptable that the glue in the gaps is washed out a little, forming depressions. The surface of the tracks must be sprayed with water for a few more days, until the glue completely hardens. Surely, you will like the look and color of wet limestone - in order to achieve a permanent effect, you can cover garden paths made of natural stone, made with your own hands, with polyurethane varnish.

Drawing and marking of the place

Before starting construction work on the site, you need to draw up a project. When creating a drawing, you should take into account the location of the main buildings, lawn, garden and other design details. You can place tracks along well-trodden paths. To simplify the work, you can hire specialists, but then the construction will cost more.

When drawing up a drawing on your own, it is advisable to take into account certain points:

- you need to draw a site plan with all the buildings;

- in order to save money, it is advisable to lay paths in the shortest possible way;

- don't skimp on width. It should be sufficient for 2 people to pass at the same time (1–1.2 m). But doing more broadly is also irrational. The size of the sites is chosen arbitrarily, based on the wishes and capabilities of the owners;

- to make it more decorative, you can experiment with the shape of the paths, but you should take into account the main directions of movement of households around the site.

After drawing up the drawing, it is time to start marking, for which you will need stakes, a rope (or twine), a tape measure and a hammer.

When laying the contours of paths, several nuances are important:

- it is not advisable to hammer the stakes at large intervals. If the tension on the rope is weak, the distance should be reduced;

- in marking smooth turns, a compass of 2 stakes and a rope will help (1 stake is hammered into the center of the circle, and an even arc is drawn with the second);

- it is easier to make a step on the terrain differences. This technique will look more aesthetically pleasing, and will help to lay the flagstone better;

- too straight paths with right angles conceal space.

Paving methods

It is necessary to foresee in advance whether it will be a simple walking path or a wide access road. Taking into account the purpose of the place of movement and the characteristics of the soil, it is chosen in what way the flagstone paving will take place.

You can bridge in one of the following ways:

- on a sand base - suitable for paving simple narrow walking paths that do not experience heavy loads;

-

on a sand and gravel base - it is used on clayey unstable soils, paths on such a basis will last longer, they are not afraid of heavy loads;

- on a concrete base - suitable for the installation of narrow paths and wide access roads, the base will withstand almost any load.

Paving a path on a sandy and gravel base

How to pave paths on a sandy base? Before starting work, it should be borne in mind that such structures are not able to withstand colossal loads. In this way, it is appropriate to lay narrow walking paths.

Sequencing:

- using pegs and a rope, you need to mark the paths according to a previously prepared drawing;

- dig a trench along the markings with a depth of 5 cm more than the thickness of the tile;

- fill the sand with a layer of 5 cm at the bottom of the trench;

- the sand must be lightly watered with water, it must be wet, but not wet;

- lay the stone on top in random order, leaving a small gap between the tiles;

- fill the gaps with sand.

How to lay flagstone on paths on a sand and gravel bed? The technology of work will be slightly different:

- mark the paths with pegs and twine;

- dig a trench 10 cm deep, curbs can be installed on the sides;

- fill the trench with gravel 5 cm high, and on top with sand with a layer of 5 cm;

- spill sand with water and tamp;

-

lay a stone;

- fill the space between the tiles with fine gravel.

If the path runs over the lawn, then the green lawn grass will be appropriate in the gaps of the laid flagstone. For this, the space between the tiles must be covered with lawn grass seeds and watered well.

Laying limestone on a concrete base

How to pave flagstone onto a concrete base? It is enough to perform several sequential actions:

- mark the paving area;

- dig a trench at least 40 cm deep;

- install a formwork that repeats all the bends and turns of the future track;

- the soil must be tamped, then covered with a layer of gravel 10 cm high;

- lay a reinforcing mesh;

- in a special container, knead the concrete and pour it over the prepared trench, leave it to harden for several days;

- lay the flagstone on a layer of assembly glue.

When laying on concrete, arm yourself with a brush with metal bristles and a rag, with their help you will need to remove the glue that protrudes between the tiles when laying. This must be done immediately, until the composition has frozen.

Knowing how to lay limestone on paths can turn your site into a truly paradise, where there is a place for relaxation, children's games and barbecuing.

Gravel walkway

This design is also not very complex. Consider how to lay out a stone track.

- Initially, you should outline the territory. The following dimensions are recommended: pedestrian path - at least 80 sq. cm, front entrance - 3 m.

- Dig a trench along the pre-marked pegs. Its depth is 20-30 cm. Just as described above, level the surface and compact the soil.

- Curb blocks should be installed along the sides of the dug trench. Plank formwork can be used. They should be fastened together with self-tapping screws.From above, the structure is covered with a primer.

- Laying geotextiles. This will protect the path from unwanted vegetation.

- A "pillow" is poured into the trench, which contains the same layers of sand and gravel. Its thickness is approximately 30 cm.

- The layer is poured over with water. Rammed.

- The limestone can now be laid. It is recommended to leave a minimum gap between the stones.

- All joints are carefully filled with sand. You can add a little rubble.

- If the path will be used frequently, it is recommended to apply a thin layer (2-3 cm) of thin concrete on top. This layer will protect it from premature aging.

Benefits of natural stone

The main advantage of the material is environmental friendliness and safety, which is very important in the modern ecological situation, where a person is surrounded by dirty air and water, harmful radiation and products. Natural stone, unlike artificial analogs, does not emit chemicals during temperature extremes

Natural stone, unlike artificial counterparts, does not emit chemicals during temperature extremes.

The material is characterized by high strength and durability, not subject to deformation under the influence of moisture and other climatic changes.

Another advantage of natural stone is its aesthetic appearance, the material is widely used in finishing works, recently laying natural stone on paths is widespread.

The assortment of shades and textures offered by nature itself can satisfy the most demanding client.

The most suitable material for paving paths is flagstone, since it is distinguished by its durability, versatility, ease of installation and operation. The technology is not complicated, laying natural stone on the paths does not require the use of complex equipment or materials.

Sand pillow

The cheapest is a sand pillow. It has relatively low strength and reliability, but is suitable for tracks that will not be subject to high loads. It is not recommended to use in case of high ground water level and in case of moving ground.

The preparation of the sand cushion is carried out by scattering the material in an even layer. In this case, it is recommended to add water from time to time, because this will simplify the ramming process.

Natural stone laying

The technology of laying natural stone allows you to do it yourself. At the same time, the installation features depend on the thickness and configuration of the stone. Among the features of the work carried out, the following can be noted:

- Smooth paving stones are placed close to each other, the minimum clearance is maintained. Crevices between individual stones can cause erosion of the base.

- Work begins with laying out 1 row, the length of which should be no more than 1 m.

- The next step is to create a transverse row, gradually creating sites with an area of 1 m².

- The correct position of the paving stones should be checked periodically. For this, the building level is applied.

- When individual stones settle, a solution is poured. The protruding elements of the created track are easily knocked out with a rubber hammer.

- After all the tiles have been laid, the joints formed are sealed with a cement-sand mortar. For this, the prepared mixture is scattered over the surface and spread with a brush. After 3 days, the operation is repeated. The voids should be filled in order to exclude the possibility of sediment penetration under the material.

If uneven tiles are used, then they are selected in such a way that the seams are minimal. Too wide gaps are filled with sand and filled with water.

Laminate paving methods

The main options for paving slabs: dry mix and glue.

By the type of equipped base, laying on a bed of sand, gravel or reinforced concrete is subdivided.

For a garden path, a sand base is quite enough, because there are no large load requirements for it.

The stone for laying should be taken within 5-8 cm thick, the larger the slab, the better.

A layer of crushed stone is added if there is clay soil on the site, so the track will receive an additional margin of safety.

On a gravel base, too thick pieces of limestone are not needed, 4-6 mm is enough.

Masonry joints can be filled with sand and gravel mixture or soil with lawn grass seeds.

In the latter case, the distance between adjacent pieces of sandstone should be increased.

The method, where the basis of reinforced concrete is assumed, is suitable if the flagstone is laid with your own hands in places with a large load on the surface. Sidewalks and driveways, basement around the building.

The material acts as a cladding glued to a solid base.

Do-it-yourself brick brazier

For arranging a full-fledged recreation area in a private courtyard, a brick brazier is one of the best options. This design has many options for execution, and also differs in a lot of other positive characteristics ... "More"

Substrate preparation and installation

In order for the paving stone not to move at the time of its operation, the base should be properly prepared. There are 3 main technologies:

- Concrete.

- A combination of cement and sand.

- Sand.

Planning and layout

It is recommended to start work with the planning and marking of the site, which will allow you to determine the required amount of materials. Other recommendations:

- The path must be located at a sufficient distance from trees, because roots can compromise the integrity of the base.

- The width of the path should be no more than 1.2 m. It is recommended to choose a multiple size of the paving stones, which will reduce the amount of work.

- It is recommended to give simple track shapes, because with complex ones, you have to spend a lot of time trimming the stone. Due to the high hardness, this is quite difficult to do.

- The slope must be created in such a way that the sediment is diverted away from the structures.

The marking on the site is carried out using a peg and a thread. It allows you to maintain high accuracy during work.

Drainage layer design

Heavy rainfall can create a lot of problems. water washes away the base. Therefore, experts recommend creating a high-quality drainage layer:

- The top layer of soil is removed taking into account the markings carried out.

- The recommended depth of the trench to be created is 30-40 cm.

- A layer of sand is laid at the bottom of the trench, which is well compacted.

- The next step is to lay the geotextile, with the canvas overlapping by 10 cm. This layer is required to reduce the likelihood of weed growth. it lets water through only in one direction.

- The drainage layer is represented by a layer of gravel, the thickness of which is 10-15 cm. The material of the fine fraction is selected, which should be tamped. The layer is covered with non-woven textile.

excavation

excavation

The installation of the curbstone is carried out after the creation of the drainage layer. The height of the curb is adjusted by adding sand. Most often, it rises 5-7 cm above the ground.

Concrete base device

The main load will fall on the concrete base. It is created as follows:

- A layer of sand 3-4 cm thick is poured.

- The curb is often used as formwork. If necessary, it is possible to limit the spread of the concrete solution by fixing the sides made of boards around the perimeter.

- A layer of concrete 10-15 cm thick is poured into the created formwork. If a car drives on the surface, the base is reinforced. It takes about 72 hours to dry the composition.

- After the concrete has gained hardness, a cement-sand mixture is poured onto the surface. The selected tile will fit on it.

Concrete subfloors are expensive.However, if the technology is observed, the track will last for a long period.

Cement sand base

A universal option is a cement-sand base:

- To begin with, a layer of sand with a thickness of 7-10 cm is created and compacted.

- Dry cement is scattered, which is rammed again.

Interesting: dry stream in a natural stone garden photo

In landscape design, there are many uses for natural stone. The second most popular after garden paths is such an interesting view as a dry stream. Dry streams are often used as garden paths, and sometimes just as a garden decoration.

A dry stream first appeared in Japanese gardens - those who did not have the opportunity to have a real stream on the site made an imitation of it from stones.

With the return of fashion to all oriental cultures, the dry stream has also returned - now many people make such a design novelty on their own. Often the stream performs not only the function of decoration, but is also used as a path.

The dry stream will perfectly fit into any garden and will become a "highlight" of any site. If you have not yet decided how to decorate your summer cottage or personal plot, be sure to consider this option!

Laying limestone on the facade walls

Reliable laying of limestone on the walls is not possible without preparation of the base, it is necessary to clean it from the remnants of the old coating, level it, prime it and reinforce it with a mesh.

Newly built buildings must stand for 6 months, only then can the cladding be dealt with.

The terms were reduced to a quarter, with a stress in the masonry less than 0.5 MPa.

The very laying of limestone on the facade begins with sorting the stones.

For finishing the aisles, external and internal corners, pieces with a pronounced right angle are selected.

Plates with one or more even edges are the main masonry material, but the largest plates are used for finishing the bottom row.

Try to trim the sandstone only in exceptional cases, so the façade will look more organic.

The bottom row starts from the corner, all subsequent ones come with a dressing.

The adhesive is applied to the back of the plate with a notched trowel, the plate itself is pressed against the wall with force to remove air from the solution. Grouting is performed simultaneously with installation.

As you can see, laying limestone on walls or paths is a painstaking process, but not complicated.

You can easily cope on your own, without the involvement of specialists.

DIY brick barbecue

DIY brick barbecue: photos and drawings with step-by-step instructions. Household plots are an excellent place not only for decoration, but also for the formation of areas for relaxation and pleasant pastime ... "More"

What tools and materials will be needed

Getting started with flagstone stone, you need to prepare the necessary tools and related materials. Let's take a closer look at each of them.

Mallet

A mallet is a small carpenter's hammer, the striking element of which is made of durable rubber or wood. With this tool, you can achieve the most tight fit of stone slabs to the base.

Master OK

A trowel or trowel is a tool necessary for uniform mixing and subsequent application of a cement bonding mortar. Made in the form of a small paddle with a handle.

Level

With the help of a building level, stone slabs are laid with maximum accuracy relative to the ground surface without errors.

This indispensable tool can be made of metal, wood or plastic. Its important elements are barrel-shaped measuring cones filled with liquid - they are called "level eyes". A widespread model is a level model with two "eyes" - a horizontal 180 degrees and a vertical 90 degrees.

Border

Garden paths made of limestone stone are most often made without a border. However, it is also possible with a low curb made of vertically arranged small stone slabs.

Bulgarian

To cut stone slabs, you need a grinder (grinder or angle grinder) with improved dust protection and adjustable speed.

Crushed stone

High-quality crushed stone combines well with flagstone, making the garden path more effective and durable. There are three main types of crushed stone - shale, granite and gravel.

Roulette

To mark garden paths, a construction tape is used, which combines the properties of a compass, a calculator and a marker.

Stakes and cords for marking

The marking of the future garden path is performed using pointed pegs made of wood. They should be driven into a depth of at least 300 millimeters. Then, stretch a marking or chopping line, also known as coated thread, over the entire inner surface of the stakes.

Shovel

With the help of a shovel, a trench is dug at the place where it is planned to equip the future garden path. The depth should be an average of 30 centimeters.

Metal brush

A hard-bristled metal wire brush is required to remove rust, salt deposits and other imperfections from the flagstone stone surface.

Vibratory plate for compaction of soil

A vibratory plate or vibratory roller is an indispensable tool when laying tracks from any type of tile. Devices of various capacities are used for perfect compaction of stone plates, paving slabs, gravel, crushed stone and sand.

Concrete mixer

This device serves not only for stirring the cement mortar, but also for running in natural stone.

Sand

The composition of the masonry mortar contains sand, which can be river, sea or quarry

In addition to its origin, attention should be paid to bulk density, density and composition.

Laying limestone on a concrete base

The maximum loads are withstood by the coating made according to the technology of laying flagstone on a concrete base with reinforcement.

The thickness of the sandstone is allowed less than when mounting on a dry mix. The weight supports the base, and the stone acts as a cladding.

Paving begins with the preparation of the formwork. Then a layer of gravel is laid on the compacted bed, which is leveled and compacted.

A reinforcing mesh made of metal is placed on top, the cake is poured with a concrete solution to a thickness of 20-30 cm. The base will be ready after drying after a few days.

The stone is laid directly on the glue solution, which is applied to the base of the path and the back of the flagstone.

Pieces of material are knocked out with a mallet to prevent air build-up cavities.

The level helps to control the level, try to avoid changes in height, walking along such a path is not comfortable.

The next day, clean the resulting coating from excess adhesive solution, leave to dry, without stressing for several days.

For greater adhesion, you can cover with a covering material or lightly dampen the track during the curing period.

To reduce the consumption of glue, it can be supplemented with sand with cement, because the prices for them are much lower.

One part of the glue into two parts of the mixture, the resulting solution should not stratify into fractions, the ideal consistency is like thick sour cream.

Do-it-yourself barbecue from a gas cylinder

Often, there are old things on the farm that can be used in new ways, and sometimes, at first glance, structures can be created from them. A striking example of this is the creation of a barbecue from ... "Read More"

Required materials and tools

In addition to the selected main material for the tracks, you may additionally require:

- cement;

- water;

- gravel;

- sand.

Also learn how to make a treadmill on your lawn.

The list of tools is not wide, it can be found at almost any summer resident or owner of a country house. The kit should consist of:

- bayonet and shovel, which will be required in the process of working with soil;

- rubber mallet;

- a level that determines deviations from the correct position of individual stones;

- a grinder equipped with special attachments for working on stone;

- brushes for cleaning residues of building materials and debris;

- vibrating machine;

- ropes and stakes for marking;

- containers for mixing cement mortar.