A method that involves placing a patch

This method is somewhat different from the past. The crack is smoothed with sandpaper. The surface must be degreased. For this, acetone or gasoline is suitable. A boot knife should be prepared. With its help, the edges of the surface are cut. The cutting depth is one millimeter

In each direction, it is important to retreat a step equal to five millimeters.

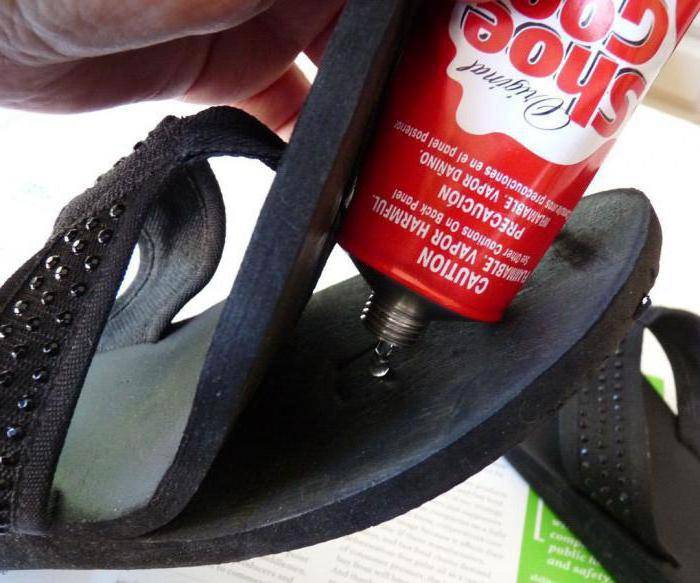

The next step is to measure the depth of the crack and add 1.5 centimeters to the resulting number. If you have an old bicycle camera, then you should not throw it away. It can be used to cut a great shoe sole patch. You will get a rectangle that closes the crack along its length. The strip for the patch is protected with sandpaper. After that, this section is degreased. The strip is processed from all sides with glue. One side is completely smeared with glue, the other is almost completely processed, you need to leave only dry edges. The indent will be 4-5 millimeters.

After the work done, it is necessary to fold the sole so that the crack becomes visible. The edges should be coated with glue

It is important that the edges of the broken part of the sole do not stick together. The rubber strip must be placed exactly in the crack space

After that, the surface should be fixed with special glue with quick coupling. This method is great for repairing shoes and boots. You can glue almost any shoes yourself.

Cracked sole repair methods

The option for repairing the sole depends on the shape and material of its manufacture, the depth of the fracture, and the nature of the damage. Most often they use several methods:

- by gluing and subsequent sewing;

- using a piece of rubber from a bicycle tube;

- using a soldering iron and nylon;

- using special shoe glue.

No protector

If the broken sole does not have a protector, it is possible to repair it at home using the express method, after which the shoes are put on after a few hours. This requires:

- Sand the sole with sandpaper.

- Bend it in half so that the crack opens as wide as possible.

- Degrease the repair site with acetone.

- Apply quick dry glue to the fracture and bond tightly.

- Make shallow cuts across the seam with a boot knife for zigzag stitching.

- Sew the sole with a crochet hook, placing the seam and knots in the slot.

With protector

When repairing a sole that has a protector, it is necessary to apply an additional outsole, which experts call "prevention."

The procedure in this case is as follows:

- Clean and dry the sole.

- To facilitate access to the crack, carefully cut off the protector.

- Treat the repair site with acetone.

- Glue parts of the crack with a quick-drying compound.

- Suture the fracture.

- Make an outsole pattern by choosing a material that has the thickness of a cut tread.

- Degrease the sole and outsole.

- Cover them with glue and wait 15 minutes.

- Apply a second coat and wait 20 minutes.

- Warm up (activate) the glue with a hair dryer.

- Connect the sole and "prevention" and put under the press.

How to seal small cracks

If, during the care of the shoes, small cracks are noticed on the sole, it is worth making repairs, although so far they do not cause inconvenience, they do not leak. On the grooved sole, the cracks after degreasing are poured with glue using a small brush or the nozzle of the dispenser, after which the composition is allowed to dry for a day.

Sealing sneakers in a toe

Damage to the toe area on sneakers is quite common. In order to repair sports shoes, perform the following algorithm of actions:

- The damaged area is cleaned, degreased, treated with sandpaper.

- A patch is cut out of rubber or polyurethane in the shape of the sole, having a different thickness.

- Glue is applied and pressed with a press. The thicker part is applied to the site of injury, less to the sole.

Prophylaxis

The sole does not need to be rebuilt if the shoe is handled with care. To extend the life of your favorite model, you need to take preventive measures. They are as follows:

- To avoid abrasion of summer models, soles must be glued to their base. With a sedentary lifestyle, stickers 1 millimeter thick are considered the best option. For frequent walking on asphalt, it is better to give preference to two-millimeter rolls.

- It is recommended to install protection with high wear-resistant and heat-insulating characteristics on winter shoes. Such measures will also prevent slipping on a smooth surface in icy conditions.

- To prevent moisture from getting into the seams of demi-season shoes, its soles must be treated with water-repellent shoe aerosols. The budget option is castor and linseed oil.

In most cases, the sole of a shoe will crack if not properly cared for. Regardless of the type of model, all wet products must be dried in a timely manner. In this case, the use of heat sources is not allowed. It is best to let the boots dry on their own at room temperature. Also, shoes should be regularly cleaned from dirt and dust. However, it is strictly forbidden to wet the products abundantly.

Knowing the reason why the sole has burst on the shoe, and how to restore it at home, you can solve several problems at once. First, no longer make those mistakes that led to the deformation of the product. Secondly, having carried out self-repairs, you can significantly save money.

To avoid abrasion, you need to stick the soles

To avoid abrasion, you need to stick the soles Install anti-slip protection on winter shoes

Install anti-slip protection on winter shoes Treat with water-repellent shoe sprays

Treat with water-repellent shoe sprays Regularly clean from dirt and dust

Regularly clean from dirt and dust Timely dry

Timely dry

How to glue the sole at home using improvised means?

After choosing the glue, you can try one of the ways to repair the soles of your shoes if they are cracked. To do this, you need to carefully follow the instructions and follow the technology. Otherwise, you will not be able to achieve the result. Follow the algorithm:

Clean your winter shoes from dirt, dry everything thoroughly so that no wet marks remain.

Inspect the work surface for integrity. If the leather on the sole is cracked in several places, it is recommended to completely tear it off and stick it on. Also consider the surface texture

This is very important as the procedure will be different for different types.

Clean the surface from the remnants of the old adhesive. Rub with alcohol to degrease the surface.

Take what to glue the sole

Apply to surface according to package directions. The adhesive layer should not exceed a few millimeters.

Wait a few minutes for the surface to set. Press down on the sole so that there are no untreated areas.

Now leave the shoes under high pressure. To prevent it from warping, put pieces of newspaper inside. You can use clothespins to secure the seam. Do this carefully so as not to damage the leather on your boots.

This is a cold technology for gluing winter shoes. The hot methodology is as follows - you need to warm up the adhesive and carefully press the surface of the shoe. After that, you can wear your favorite pair of shoes in a few days.

Sole repair recommendations

Before starting work, the sole must be cleaned, dried and degreased. For degreasing, use a special solution, gasoline or acetone. After processing, the product is dried again.

Pick up the load so that the shoes do not deform.A block in the shape of the letter L with an additional weight is optimal. Keep the product under pressure for at least ten hours.

The adhesive is applied up to three mm thick, then it is kept for ten minutes and only then the parts are glued together. Choose only high-quality and proven glue. A suitable option would be the classic Moment glue, polyurethane or epoxy sealant. Alternatively, you can use special rubber shoe glue or shoe glue.

According to experts, polyurethane glue will be the best tool due to its strength and elasticity. It provides a secure fit and can restore any kind of shoe. In any case, these are toxic compounds, so ensure safe handling. If the product gets into the nose or eyes, immediately rinse the mucous membranes with running water.

Be careful when working, as the adhesive can spoil the material of the products, especially if these are suede boots, leather or patent leather shoes. The glue is difficult to wash off. Now let's figure out what to do if the soles of your shoes are cracking.

How to repair shoes if the sole is cracked

There are many options for restoring a damaged product. The simplest is to stick a piece of rubber or other suitable material on the crack. But this method is not suitable for all types of shoes.

You can also glue the cracked soles with special glue. In this way, small cracks that are near the heel can be eliminated. Better in the part with the least stress. Also, the damaged area can be replaced.

Classic renovation

This method is suitable for outsole made of plastic rubber or polyurethane. Special skills and knowledge are not needed here. The product must be glued and properly sewn.

The repair is carried out as follows:

- Pour glue into the crack, which dries quickly. Press well.

- Draw a zigzag on the sole.

- Cut with a boot knife.

- Sew the cracks with short stitches along the slits.

- The edge of the nylon thread can be lightly scorched with hot fire.

Partial replacement of the damaged area with a patch on a smooth sole

If cracks appear, for example, on the sole of dress shoes.

The repair is carried out as follows:

- Pour literally a couple of drops of glue into the crack and hold the sole under a press for a while so that the glue adheres well.

- The area requiring repair must be degreased. Acetone is suitable for leather material.

- The crack is sanded with sandpaper.

- Next, the shoes are placed on the material of the future sole, the shape of the sole is outlined, then the workpiece is cut along the line.

- Process the workpiece and get rid of irregularities.

- Apply glue to the sole in an even layer. In this case, it is recommended to use a spatula so that the product lies flat (the same operation is carried out with a new heel), then dry the glue.

- Apply the glue again, and only then glue the patch.

- With the help of force, you need to press the patch. Care must be taken to ensure that the material does not budge.

- Press down the shoes with a load and leave for a day. The glue should harden.

Repair of a product with a high tread

Shoe repair is carried out in the same way as on a smooth sole. But instead of a dense additional material, a small piece of rubber is used. The thickness of the patch should be less than the tread or at the same height. This method is suitable if the crack is longitudinal or transverse.

Repair of sports shoes

Most often, the sole is erased from sneakers and sneakers, as it is more exposed to mechanical damage. For repairs, the method of gluing two pads is used.

- 2 patches of different thicknesses are cut from rubber or polyurethane.

- Shoes and material are pre-degreased. You can use sandpaper.

- The thicker material sticks to the crack, while the smaller material sticks to the whole sole.

- A load is placed on top of the shoes and left for 24 hours.

The most common and unpleasant reason for people turning to shoe shops is a torn sole. No one is immune from such a problem, but the listed methods will help restore the product at home.

The main thing is not to deviate from the instructions and do not forget about the precautions. Also, in order for a new couple to serve for several years, proper care must be observed.

Gromova Anna, professional in the shoe business. The owner of a small shop and workshop for the restoration and repair of shoes.

A crack in the sole of a shoe is not such a rare occurrence. This situation is especially unpleasant when the product warranty has already expired. And although it will not be possible to make high-quality repairs at home, it is possible to partially revive the shoes. Sometimes repaired boots or boots can be carried for a few more months.

Next, we will discuss methods for self-repairing a cracked sole.

How to glue the sole of the shoe?

To prevent the repaired pair of shoes from falling apart on the very first day, or, even worse, not deteriorating at all, you need to choose a glue that is suitable for repairing shoes. Below are adhesives that you can safely use:

- "Desmokol" - transparent adhesive with polyurethane, intended for gluing PVC, repairing leather and suede products, including for gluing shoe soles. This composition has earned the trust of professionals and is sold in specialized stores.

- Clay "Moment Marathon" specially designed for repairing shoes. Possesses water and frost resistance, as well as elastic and resistant to negative environmental influences. Not suitable for bonding a range of materials (styrofoam, polyethylene, polypropylene, plasticized PVC). Consumers love this adhesive for its ease of use. In a day, the shoes are ready for use.

- Epoxy resin (B7000) - after drying, the composition turns into a durable elastic waterproof layer, which is great for shoes that by their nature are in motion all the time. When repairing shoes, it gives minimal shrinkage, but it may take 1-2 days to completely dry.

- "Nairit" adhesives or "Shoemaker" they contain polychloroprene rubber, tackifier and organic solvents. Designed primarily for shoe repair. These compounds adhere well the leather upper of the shoe to the rubber sole (except for polyurethane), and are also suitable for gluing insoles, lining and other elements. It will be possible to wear the repaired product only after three days.

- Kenda farben and Bonikol - special compositions for the footwear industry from European manufacturers. They guarantee reliable adhesion. Suitable for gluing leather and leather substitutes, as well as heels, insoles and cork.

What do you need to repair a sole at home?

How to properly glue the sole with your own hands at home without the help of a master, as well as what you need to have on hand during the repair process, you will learn from this section of the article. Here you will also find recommendations regarding the order of work to eliminate gaps of varying complexity.

It is important to remember that all work should be carried out in a well-ventilated room and away from heat sources.

You also need to take into account that the process of repairing a sole at home is a very dirty job, and it also requires concentration and enough time. It should be remembered that you only need to glue a clean sole.

To do this, the entire shoe, and especially the sole, should be washed and dried dry, and only then proceed with its repair.

It should be remembered that you only need to glue a clean sole. To do this, the entire shoe, and especially the sole, should be washed and dried dry, and only then proceed to repair it.

To fix the problem with the sole, the home craftsman will definitely need patience and:

- boot knife;

- sandpaper from "three" to "zero";

- gasoline or any other composition for degreasing;

- special glue;

- awl;

- matches or lighter;

- hair dryer or heat source;

- outsole of the right size, a piece of rubber or hard leather for the sole instead of the cut (damaged) area;

- pencil or felt-tip pen

- boot hook;

- nylon threads.

Also, every home craftsman will need a heavy object that will act as a load, which will speed up the gluing time and improve the quality of work.

In some cases, you may need a mini-grinder or a conventional angle grinder.

Be responsible for the choice of glue! After all, the final result of the work will depend on its quality. On sale in the household departments, choose shoe glue, and be sure to read the information about whether this substance is suitable for gluing the material from which the sole is made.

You can also use a generic product.

If all of the above tools and materials are available, then you can start repairing the broken sole. Do not hope that the repair done by yourself will cost less than fixing the problem in the workshop, because all the necessary tools and substances will need to be purchased at the retail price.

We get rid of the hole on our own

How to glue the soles of winter or autumn shoes? As an improvised means, glue "Moment

", Epoxy sealant" Crazy handles

", Means with polyurethane" Desmokol

". Each glue is accompanied by instructions that you need to be guided by when working.

It should also be borne in mind that these funds are toxic. In case of contact with mucous membranes, they must be immediately washed off with a stream of running water.

Work algorithm:

- Since winter or autumn shoes in most cases have honeycomb soles, you will first have to deal with honeycombs. The rubber that covers them will have to be removed to such an area in order to remove all accumulated dirt from the holes. Sometimes the honeycomb is accessed from the side of the insole, which has to be completely removed when cleaning the holes;

- Honeycombs need to be covered with small pieces of micropores and filled with silicone sealant, sealing well;

- Before you glue the cracked sole, you will need to wait for the sealant to dry and harden;

- Next, a piece of rubber or micropores is cut out, which enters the hole - if it is bulky, or small holes are pressed in with a mixture of micropores sawdust and sealant;

- The sole is cut out of thin rubber to the size of the shoe, glued with the help of an already prepared adhesive over the entire area of the shoe;

- Put shoes or boots under the press.

How long it takes for the glue to dry completely is indicated in the instructions.

How to seal a hole in the sole of summer shoes? You should act according to the same algorithm, only there will be less hassle.

If the sandals are adhesive, then it is better to purchase a rubber sole in the workshop, and glue it on your own using rubber glue. This can be done when the shoe has a solid base. Sometimes soles are attached to summer light shoes only along the contour. In this case, the sandals will have to be thrown away.

Repair of sports shoes

How to glue the soles of sneakers when a hole appears in them due to stepping on something sharp? If the training process takes place in the gym, you will not have to give up your favorite pair of sneakers.

From domestic adhesives, it is best to use epoxy, designed specifically for shoes. Its cost is low.

The edges of the hole in the sole must be thoroughly cleaned and degreased with a solvent. When everything is dry, a properly diluted epoxy is applied.

If the hole is large, it is necessary to put a fiberglass mesh into it - it is called a serpentine.While the glue dries, it is better to seal the place of the hole on the outside with masking tape - so that the sole remains flat.

The ideal adhesive is the American Seamgrip adhesive. Rubber boats are glued to them. If you manage to get it, it won't take long to part with your favorite pair of sneakers. This is the only glue that completely solves the problem of how to glue a rubber or polyurethane sole.

But if there is an opportunity to purchase glue of this brand, then it is unlikely that there will be money to buy shoes. Its cost is quite high.

Imported epoxy mixtures of the Done Deal type are better than domestic adhesives, but the durability of sneakers when using them cannot be promised.

How to glue a torn skate sole? It all depends on the material from which the sole on the skates is made and the location of the hole.

Cheap skates are mounted almost on cardboard, and any epoxy glue will help to cope with the problem if the hole in the sole is not in the place where the blades are attached. In this case, the boots will have to be thrown away. The torque will reduce all efforts to zero.

You will have to do the same with expensive skates - even the most expensive glue will not be able to secure the blades firmly after repair.

You can still try to glue holes on the side of the boot or on the toe, but a deformed boot does not guarantee stability. Home repair of sports shoes should be done only in case of minor damage.

Expensive skates with leather soles are glued with special shoe glue for repairing leather goods. If the place to be sealed is thoroughly degreased, the hole is filled with a mixture of leather scraps, and the integrity of the sole is restored.

When repairing expensive sports shoes, it makes sense to purchase expensive glue. Quality athletic shoes cost more than packaging with adhesive.

You shouldn't even think about how to glue the soles that are cracked across the shoes. It is impossible to cope with the repair at home. And you shouldn't trust private shoemakers who promise to solve the problem by installing prevention. After such a repair, you only manage to reach the door of the shoemaker's shop. When repairing, a complete replacement of "spare parts

».

Do we glue the sole at home?

To glue the sole on your own, you need to follow a simple instruction:

- Thoroughly clean damaged boot and dry thoroughly.

- Carefully inspect the sole, if it comes off in several places, it is better to tear it off completely and re-stick it. In addition, some shoes have honeycomb soles, and these require a special approach.

- With a spatula, clean the surface from old glue and degrease (with acetone or alcohol).

- Apply sole adhesive to both surfaces according to the instructions. Most often we are talking about a thin layer of glue - no more than 3 mm.

- Wait a few minutes and press the sole tightly against the shoe, so that there are no voids between them.

- Secure the boot in this position for at least 10 hours. You can put a load on top, having previously stuffed the boot tightly with paper or newspapers so that it does not lose its shape. The second option is to fasten the seam with clothespins, just be careful not to scratch the skin.

The described method is called cold. The hot method differs only in that the applied composition must be left to dry completely (for about half an hour), and then warm it up with a hairdryer and press the surface firmly for 20 seconds. You can wear repaired shoes in two days.

Video instruction:

Combo top repair

On sneakers with a combined upper made of synthetic material with foam padding or natural and artificial suede, the fabric in the toe, where the shoe touches the toes, is most often damaged.On the outside, this area can be protected by a rubber insert around which there is a mesh, which is typical for running shoes.

If minor damage appears on the front of the shoe, it is allowed to sew a patch. In the presence of large holes, it is required to rip up the seams, adjust a piece of strong nylon fabric in size and shape and sew it into place.

Ways of gluing summer and winter shoes

For spring and autumn, demi-season and winter shoes, a honeycomb or lattice sole design is often characteristic. If the sole burst on such products, as well as with prolonged wear, it gradually wears out. Voids form inside, the heel can fall through.

To restore such products, you must first remove the rubber that covers these honeycombs. To do this, tear off the insole, carefully clean each hole from dirt, debris, cardboard and glue residues. Then the empty honeycomb is filled with small pieces of micropores and filled with silicone sealant.

Reconditioning continues when the sealant has dried and hardened. Prepare new insoles, saturate with sealant or glue, glue to the sole of the shoe and press down with a load for the time specified in the instructions for the adhesive.

For summer shoes, sneakers, sneakers and other light footwear, you can buy a separate thin rubber sole and glue the products with rubber glue. This method is suitable if the products have flat soles. When gluing rubber to leather shoes, make a 45 degree hem first.

In order for the rubber to adhere firmly and permanently to the polyurethane or nylon base of the shoe, first cut the template out of cotton fabric to size and weld it to the base using a hot iron. Then glue the new sole.

After repairs, it is important to look after the shoes and take care of the pair. Wash and dry items regularly

Which shoe cream is better to choose, see here.

How to fix a hole in the sole of your shoe?

If the hole in the sole is small, then it can be effectively sealed with ordinary glue-sealant. For these purposes, silicone is better suited. Cut off its nose so that it fits perfectly into the hole of boots, shoes or any other shoe that needs repair.

From the inside (under the insole), press on the area of the hole with a piece of leather, plastic or other material. Fix up with the plantar part. Squeeze the sealant into the hole so that it completely fills it. After drying, it firmly merges with the rubber, due to which the hole is reliably eliminated and you can not be afraid of wet feet.

If it is large enough (it appeared as a result of wear), then it can be sealed with a special polyurethane shoe using thick super-glue. These parts are sold in shoe stores.

Anna Markovich

I must say right away: when solving a problem, how to glue a cracked shoe sole, you should simultaneously tune in to buy a new pair. It is impossible to carry out high-quality repairs at home. The sole is subjected to constant stress, and even the most durable ultra-modern means will not be able to provide insulation for the foot for a long time.

For factory repairs, the sole is repaired by replacement. Very often, during this process, the shoes lose their shape, their appearance becomes unpresentable. If there is no possibility of acquiring a new pair, or there is nothing to get to the shoe store, you will have to think about how to glue the burst shoe sole.