How to disassemble correctly

To disassemble the iron, you will need:

- sharp knife;

- screwdriwer set;

- pliers.

Depending on the nature of the problem, a multimeter, sandpaper, insulating material, and a soldering iron with solder and flux may be required. It is recommended to start parsing with visible mounts. The first step is to unscrew every screw that comes into view. After that, remove the cover from the back.

Then you need to pull up the main part of the device, which is attached to the plastic latches. The latter are pitted with a knife

It is important to be careful at this stage, as excessive force will break the latches. If there are screws on the outside of the case, these elements must also be unscrewed.

Advice:

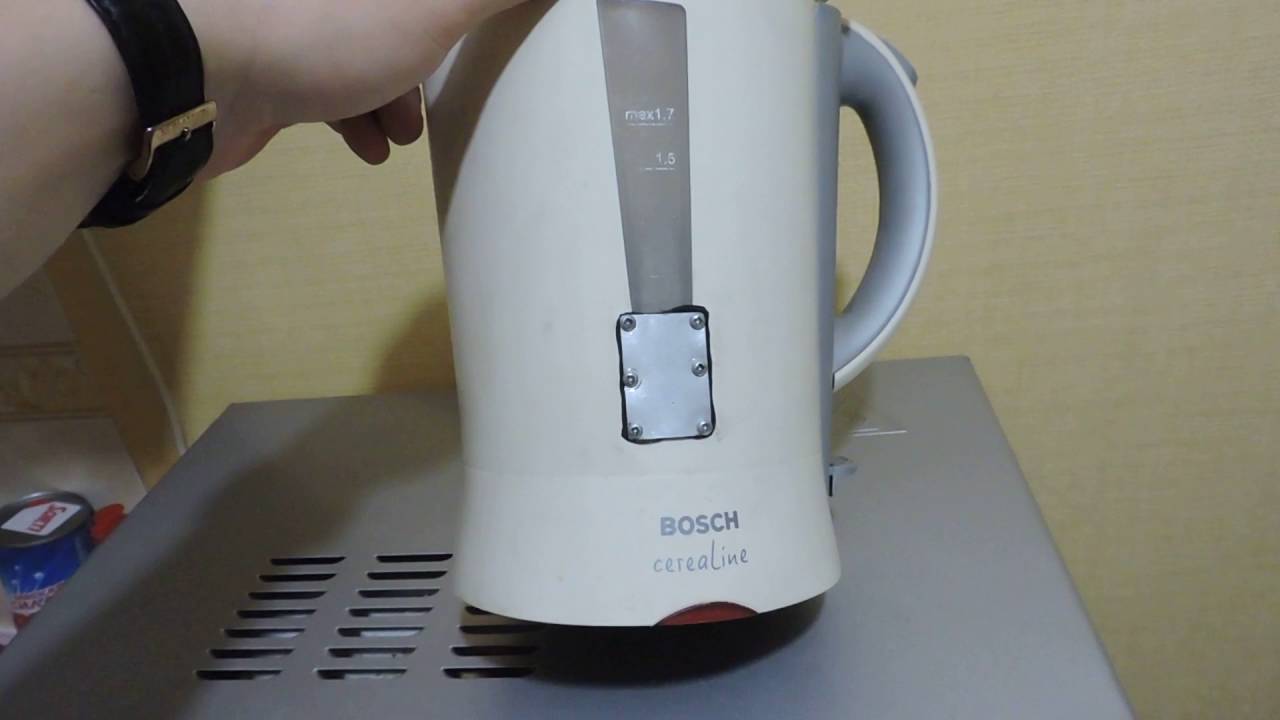

With modern teapots, the on / off button is most difficult to reach if it needs to be repaired. Remove the cover and unscrew the bolts that are at the top and bottom of the handle

Do everything carefully and carefully so as not to damage the plastic parts. Replace the LED bulb at the same time if it does not shine.

If the kettle turns off ahead of time, then in this case, do not disassemble the device completely, because the whole thing is in scale, and not in breakdown.

Use citric acid to clean the device: dissolve a sachet of citric acid in 0.5 l of water and pour it into the kettle, then turn on the device with the lid open. Repeat the procedure if necessary.

What to connect an electric kettle directly to the network

There are situations when there is no time to repair or replace a particular part. As a temporary measure, you can apply the connection of the kettle to the network directly. To do this, open the bottom cover of the case and connect the power cord directly to the heater terminals. Thus, the kettle will operate completely manually, bypassing all circuit breakers.

The power cord connects directly to the heating element

By plugging it into the socket, it will start, and by turning it off, it will stop working. It is necessary to be near such a device in order to disconnect it in time when the water boils.

Additional video on the topic:

During assembly, disassembly and testing of the kettle, personal safety measures must be observed. The mains supply must be disconnected. The flask must be dry, without water residues.

Leaking soil

Sometimes a crack can form at the bottom of the teapot. In this case, it can be repaired on its own using the same sealant. We disconnect the electrical appliance from the network, clean the case from dirt and follow the instructions.

Kettle repair:

- Get the bottom of the case there should be several self-tapping screws. We unscrew them and remove the panel.

- We remove the sealing rubber and the heating element.

- Visually inspect the bottom for cracks.

- We seal the gap with a sealant and wait until it dries completely.

- We assemble the structure in the reverse order.

- Fill in water and bring it to a boil, thereby checking for a leak.

Penetration can also be at the bottom of the teapot

If there is no visible damage to the bottom, then the rubber cushion may be the cause of the leak: we change it to a new one. Sometimes it is enough to tighten the screws, thereby removing the rift between the body and the disc. Cleaning the elements from scale, which interferes with the normal fixation of the elements, also helps.

The electric kettle is leaking - what to do?

The reasons for the electric kettle leaking during heating can be:

- Cracked hull. In this case, it is best to go for a new device.

- Damaged bottom.A similar problem often arises with metal devices, since due to corrosion, a gap forms at the junction of the bottom with the case - water flows from it. Such damage cannot be repaired.

- Crack on the water level indicator.

- Weak attachments.

- The sealing ring on the heating element is damaged.

Consider how to repair a kettle with your own hands.

Crack on the water level indicator

To determine this breakdown, disassemble the roof of the device, because your task is to get to the indicator and study it. It is necessary to check the indicator not only for cracks, but also to determine if there are any leaking joints.

If you have a plastic device, then the indicator can be presented in the form of the same plastic tube, which often dries up and breaks at the bend. It will not work to replace the indicator, but there is a way out - block the access of liquid to the tube with a screw. The kettle will boil water perfectly, the problem of the electric kettle leaking will be solved, but the device will no longer show the water level.

Weak attachments

Take a closer look at the heating element - if it dangles, then you need to firmly attach it to the wall of the kettle in order to solve the problem of the electric kettle leaking. Tighten the bolts and check the result. For this:

- Pour water into the kettle.

- Place the device on a paper towel or newspaper:

- If the paper is dry, then the problem is solved.

- If water still collects around the kettle, then it is necessary to check the integrity of the rubber gasket.

Replacing the O-ring

It is necessary to start repairs yourself only if the warranty period has expired or the kettle is purchased without a warranty. It is possible to independently decide how to glue the electric kettle or what to do if it leaks, even if the device cannot be delivered to the service department.

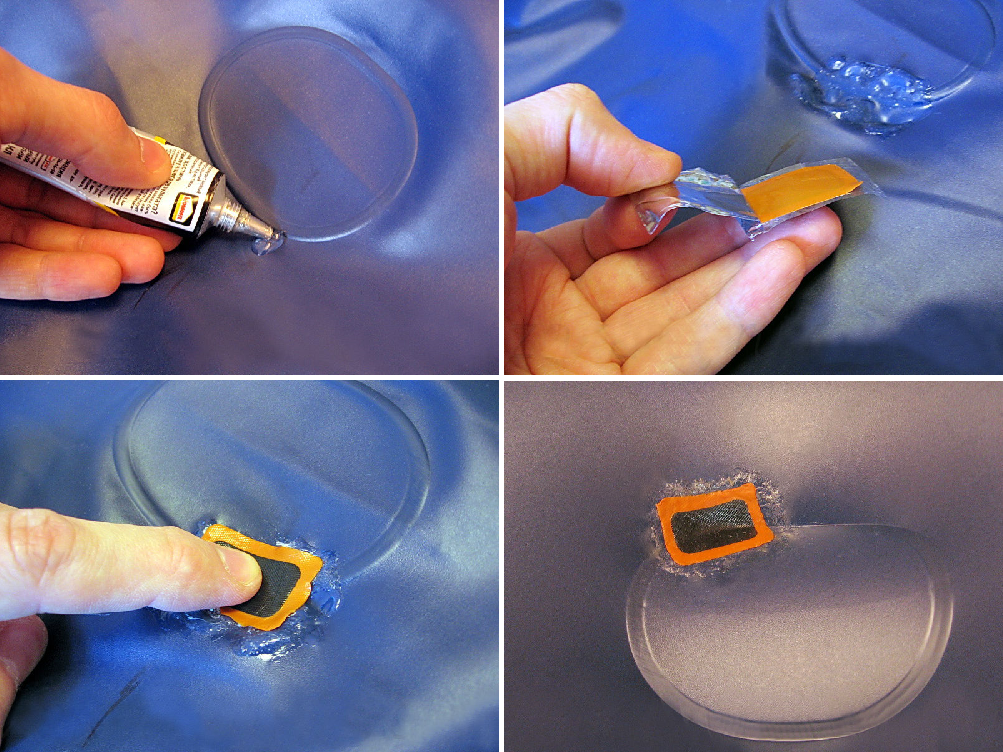

We offer the following instructions for replacing the O-ring on the heating element:

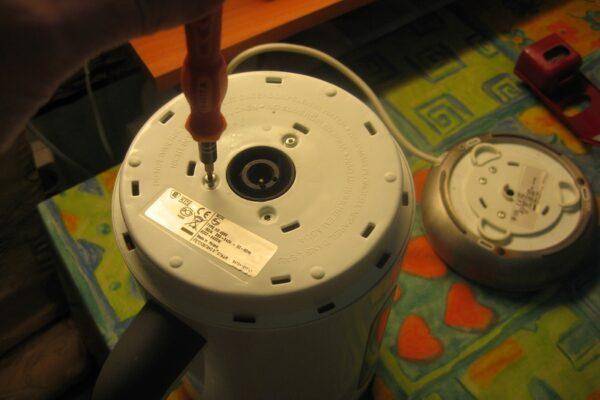

- Remove the bottom of the kettle. On some models, the bottom is fixed with three self-tapping screws - using a Phillips screwdriver, unscrew them. On other models - options are possible, so follow the instructions for the device.

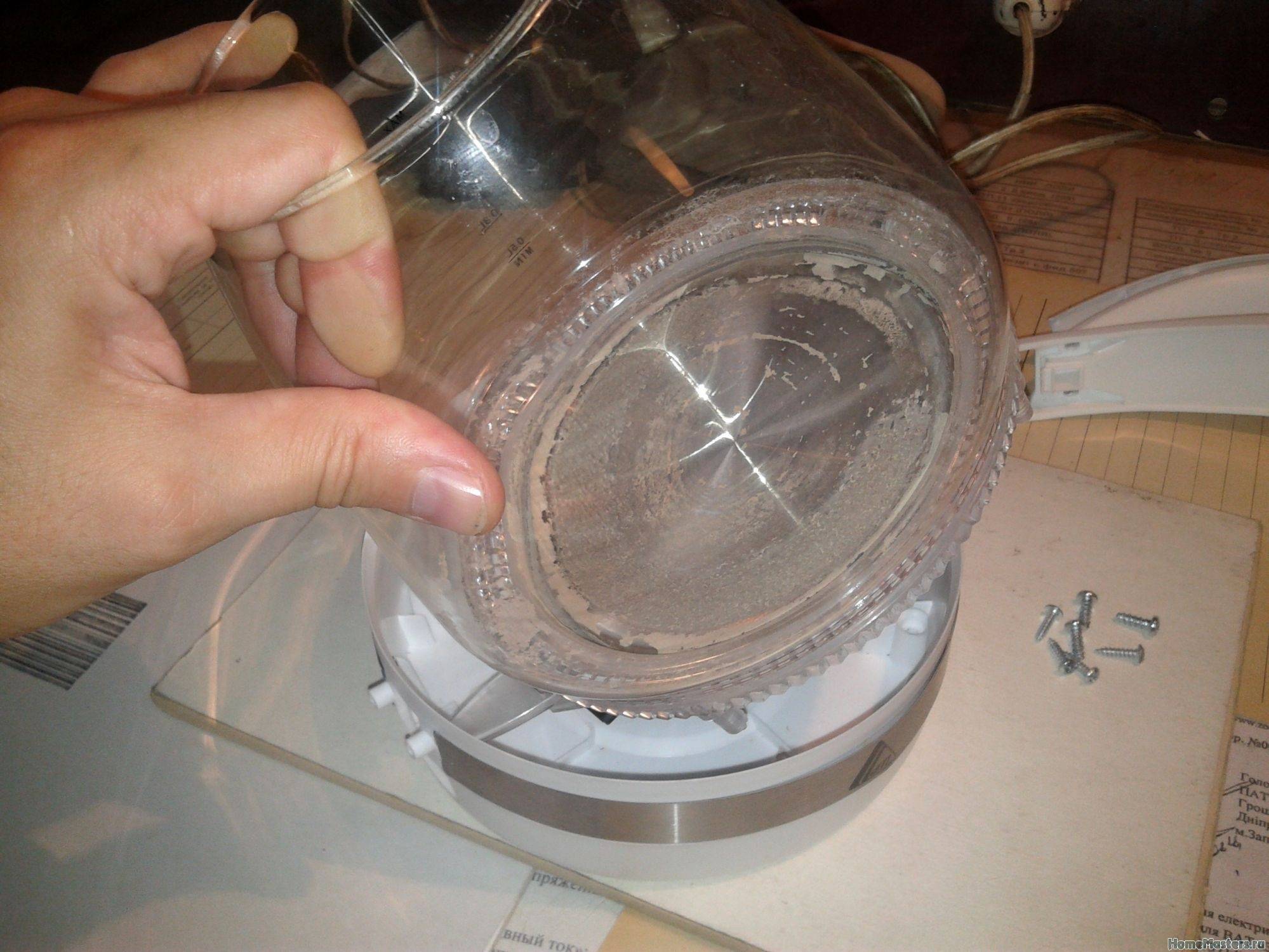

- Pull out the disc with the spacer. If the kettle is disk, then the heating element is simply inserted into the body. The tightness in this case is provided by a heat-resistant silicone gasket. This is the same gasket that holds the disc.

- Remove the spacer from the disc. Carefully inspect the gasket, disc, and housing:

- If there is a defect in the case (chip, crack), then further repairs are impractical.

- If there is no through rust on the disc, then proceed to study the O-ring. If there is a defect on the disk, then it will need to be replaced.

- In case of obvious defects in the seal, replace it. If everything is in order, then it is possible that during operation the connection between the disc and the body has been weakened (moved down).

- Wipe the gasket, disc and body from scale and limescale.

- Replace the O-ring.

- Insert the disc into the case until it stops.

- Replace the bottom.

- Screw on the bottom with self-tapping screws, but without too much zeal, do not tighten too much.

- Pour water into the kettle.

- Plug in the device and boil water.

- Check the kettle for fluidity - if everything is in order, then the device is ready for use.

Helpful hints:

- If a new electric kettle leaks a little, then wait a while (a week or two), perhaps the formed scale will tighten the microcrack.

- To prevent the kettle from dripping, descale it regularly for as long as possible and use filtered water. Then the heating element will also work longer and better, and the gasket will remain.

Although the selection of home appliances on the market is huge, if you want to repair an old kettle that is very convenient for you, then check out the simple steps to do it yourself repairing appliances.

Features of working with metal and ceramic products

Slots in electrical metal products appear at the junction of the body and the bottom. The reason for their appearance is corrosion. A corroded case cannot be restored. If the leak is associated with a defect in the O-ring, it is replaced:

- unscrew the screws with a Phillips screwdriver;

- take out the disc together with the gasket;

- evaluate the appearance of the heating element, if there is no visible damage, it is cleaned from traces of scale;

- replace the silicone gasket;

- the heating element is returned to its place;

- fix the bottom with self-tapping screws;

- the kettle is placed on a paper towel;

- pour water;

- if after 10-15 minutes the towel is dry, the kettle is turned on.

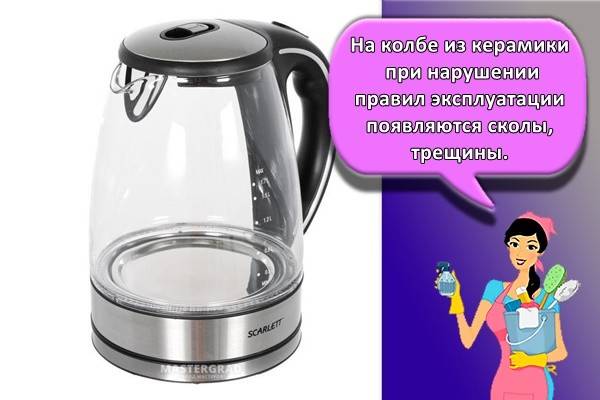

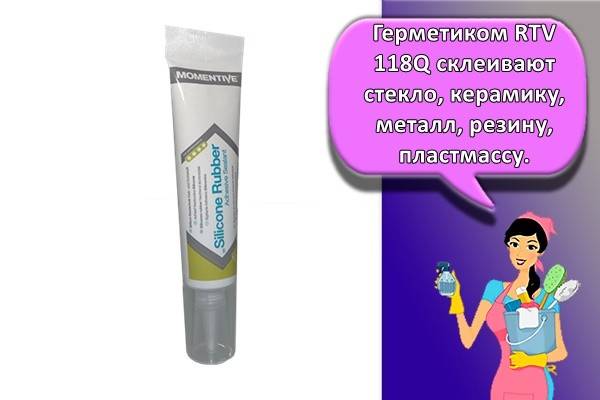

In case of violation of the operating rules, chips and cracks appear on a ceramic flask. They are sealed with RTV 118Q heat-resistant silicone sealant. It adheres well to ceramics and retains strength at high temperatures.

The adhesive is vulcanized at room temperature. It is produced in the form of a plastic paste. It is applied in a layer up to 6 mm. The surface film appears after 1.5 hours, complete drying occurs on the 4th day. Mode of application:

- the surfaces to be glued must be cleaned, degreased, dried;

- unscrew the cap from the tube, cut off the nose, cut angle 45 °, cut diameter along the crack width;

- apply the sealant evenly, without tears, to one of the surfaces to be glued;

- connect the details;

- remove excess sealant.

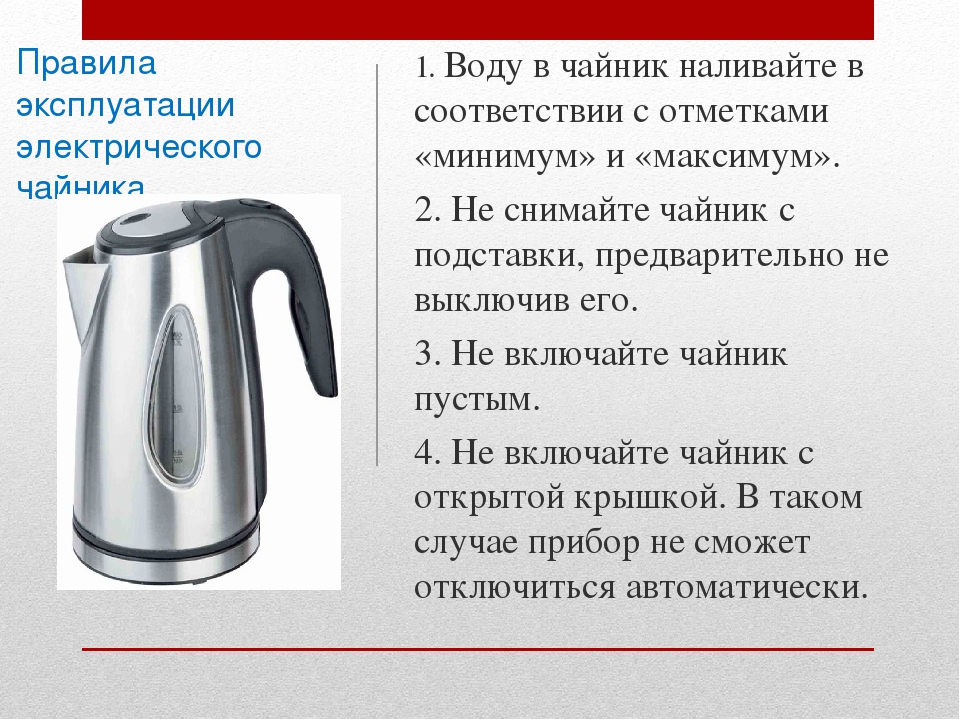

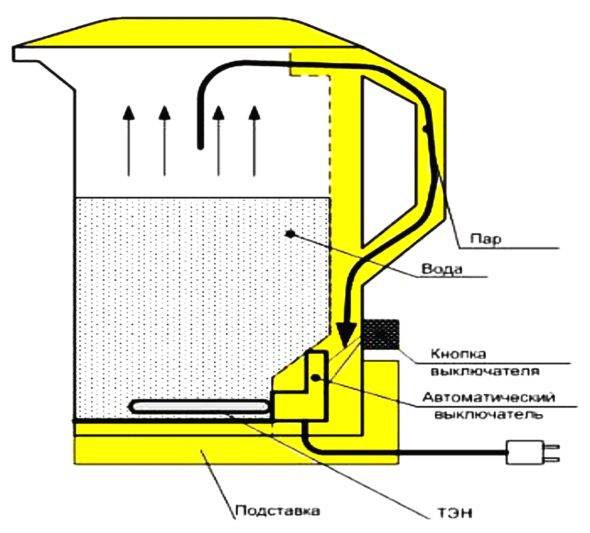

The principle of operation of the electric kettle

The device of an electric kettle, even in expensive models, is not complicated and does not differ in originality:

- A heating element located in the lower part of the housing, when supplied with electricity, heats the water.

- The heating element itself is connected to a thermostat.

- As soon as the temperature reaches the set value, the kettle is disconnected from the network.

- For ease of use, an LED light is connected to the external circuit of the circuit, which indicates that the device is working.

A thermal fuse must always be present in electrical appliances, which will open the circuit, for example, when overheating, or in the case when you forgot to pour water into the kettle.

The schematic diagram of an electric kettle itself is not complicated and is similar to an iron diagram. There are not many parts in the device that can break. The most difficult part is the thermostat, because its device depends on the specific model. If the thermostat breaks down, it is not repaired, but replaced with a new one. The rest of the faults can be eliminated at home.

Repair sequence:

- The first step is to check the cord and stand. Make sure voltage is supplied to the device. Ring the contacts with a multimeter and, if necessary, solder the contacts in the cradle. If the contact group has melted, then nothing can be fixed.

- If the cord and stand are ok, check the ring contacts on the kettle. Click the "On" button and if there is no signal, then unscrew the bottom of the device, check all the contacts inside. A defective thermal sensor or heating element will have to be replaced.

- Check the auto-off button. It is located on the handle. Due to oxidation of the contacts, this part very often fails. Clean the contacts with sandpaper, if necessary, and the device will work.

The refrigerator was brought in today!

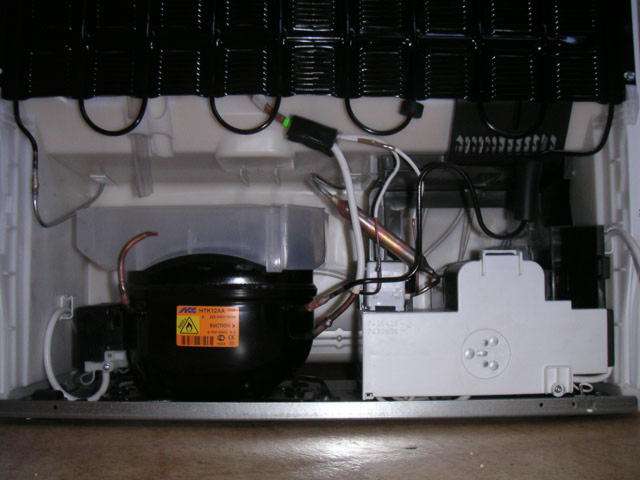

Today they brought me a Liebherr C 4023 22D / 001 refrigerator. I was pleased with the delivery - oddly enough, they brought him standing, tightly fastened with a belt to the body of a tall gazelle. They even dragged them into the apartment almost vertically, on the back of the loader. The driver only slightly supported him from behind. They unpacked it, allowed it to be inspected, but they did not even offer to turn it on for a short time. They said that it can be turned on only after 3 hours (just in case, I'll wait a day). So kudos to the delivery men - two Russian-speaking southeastern people, one of whom was also named Max. I saw what the compressor was. Firm ACC (formerly ACC were called Electrolux), compressor model HTK12AA. For reference: ACC (Appliances Components Companies) was established in 2002 and is headquartered in Pardenone, Italy. Annual production of hermetic compressors 21 million units. provided by factories: Elettromeccanica S.p.A. (Mel and Rovigo, Italy), ACC Austria GmbH (Furstenfeld, Austria), ACC Spain S.A. former Cubigel S.A. (Sant Quirze and Cervera, Spain) and finally Zanussi Elettromeccanica Tianjin Compressor Co. Ltd (Tianjin, China) is the brainchild of Electrolux. Plus three factories in Italy, Germany and Hungary for the production of electric motors.

For reference: ACC (Appliances Components Companies) was established in 2002 and is headquartered in Pardenone, Italy. Annual production of hermetic compressors 21 million units. provided by factories: Elettromeccanica S.p.A. (Mel and Rovigo, Italy), ACC Austria GmbH (Furstenfeld, Austria), ACC Spain S.A. former Cubigel S.A. (Sant Quirze and Cervera, Spain) and finally Zanussi Elettromeccanica Tianjin Compressor Co. Ltd (Tianjin, China) is the brainchild of Electrolux. Plus three factories in Italy, Germany and Hungary for the production of electric motors. The adhesion of the compressor tubes to the refrigerator circuit seemed to me insufficiently high-quality, with streaks of metal and the remnants of some substance (apparently, an analogue of rosin):

The adhesion of the compressor tubes to the refrigerator circuit seemed to me insufficiently high-quality, with streaks of metal and the remnants of some substance (apparently, an analogue of rosin): I have not yet identified any other drawbacks of the assembly, but this type of adhesion worries me very much. It looks very much like corrosion ...

I have not yet identified any other drawbacks of the assembly, but this type of adhesion worries me very much. It looks very much like corrosion ...

Most common malfunctions

The following malfunctions are typical for electric kettles:

-

Failure of the heating element. The cause of the defect is the scale formed on the heating element, as a result of which the transfer of heat to water becomes difficult, and the spiral itself heats up. Heating elements of the spiral type are most susceptible to such breakdown than disc heating elements, which take more time to form a critical scale layer. The reason for the burnout of the heating element can also be a violation of the operating rules, for example, if the kettle is plugged into the network, forgetting to pour water into it.

-

Breakdown of the button for turning on the electric kettle. There are two possible reasons for this - the formation of carbon deposits and oxidations on the button contacts, or a break in the rod connecting it to the power supply terminals.

- Leakage of the housing of the electrical appliance. This malfunction is more typical for kettles with a plastic body, as well as those equipped with a disc heating element. In the first case, a breakdown may result from the deformation of the kettle from overheating at the place where the heating element is attached, and with disc heaters, the reason is corrosion along the seam of the connection between the disc and the body of the electric kettle. Often the cause of such a breakdown is a broken seal or a cracked glass of the water level indicator.

-

Premature disconnection of the electrical appliance. This malfunction is caused by limescale deposits. The water does not have time to boil, and the heating element has already overheated and the thermostat disconnects the device from the network.

-

Failure of the thermostat. The design of electric kettles with a thermostat contains additional units and parts - a thermometer, temperature sensors, a memory unit, an electronic board and a control panel. The more parts a device has, the lower its reliability and the higher the probability of breakage of any of them. In teapots with thermostats, the regulator itself most often fails, in which the contacts are oxidized or burned.

Breakdowns allowing the kettle to be returned to the store

You can return a faulty electric kettle to the store during the warranty period, if during this period its significant deficiencies appeared, namely, malfunctions of the following nature:

- fatal breakage;

- recurring breakdown of the same unit;

- breakdown that cannot be eliminated without disproportionate costs close to the cost of the kettle itself;

- a malfunction that takes a long time to eliminate, as a result of which the device cannot be used for more than 30 days throughout the year.

There may be a wide variety of malfunctions, but the most serious of them are leaks that are not associated with mechanical damage and a leaky gasket, but that have arisen due to deformation of the body or damage as a result of corrosive processes.

The failure of the heating element can also be attributed to significant breakdowns, provided that the kettle has been properly operated and there is no scale on the heating element.

Electric kettles are household appliances that are included in the list of technically complex goods.Therefore, it is possible to return them back to the store, with the return of the money paid, only if they are of inadequate quality. When you contact the store with a written claim, you need to indicate a breakdown that is often repeated or requires costs. comparable to the cost of an electric kettle.

The seller has the right to invite the buyer to contact the service center, but if the breakdown has not been eliminated within 20 days, the store is obliged to return the money or exchange the device for a new one. The seller also has the right to appoint, at his own expense, an examination of the goods, which will determine whether the breakdown has arisen through the fault of the user or it is the cause of a factory defect. In the first case, the buyer must reimburse all the costs of the examination. In the event of a defect due to the fault of the manufacturer, you can demand not only a refund, but also compensation for moral damage. Moral damage can only be claimed by a court decision.

The device and principle of operation of electric kettles

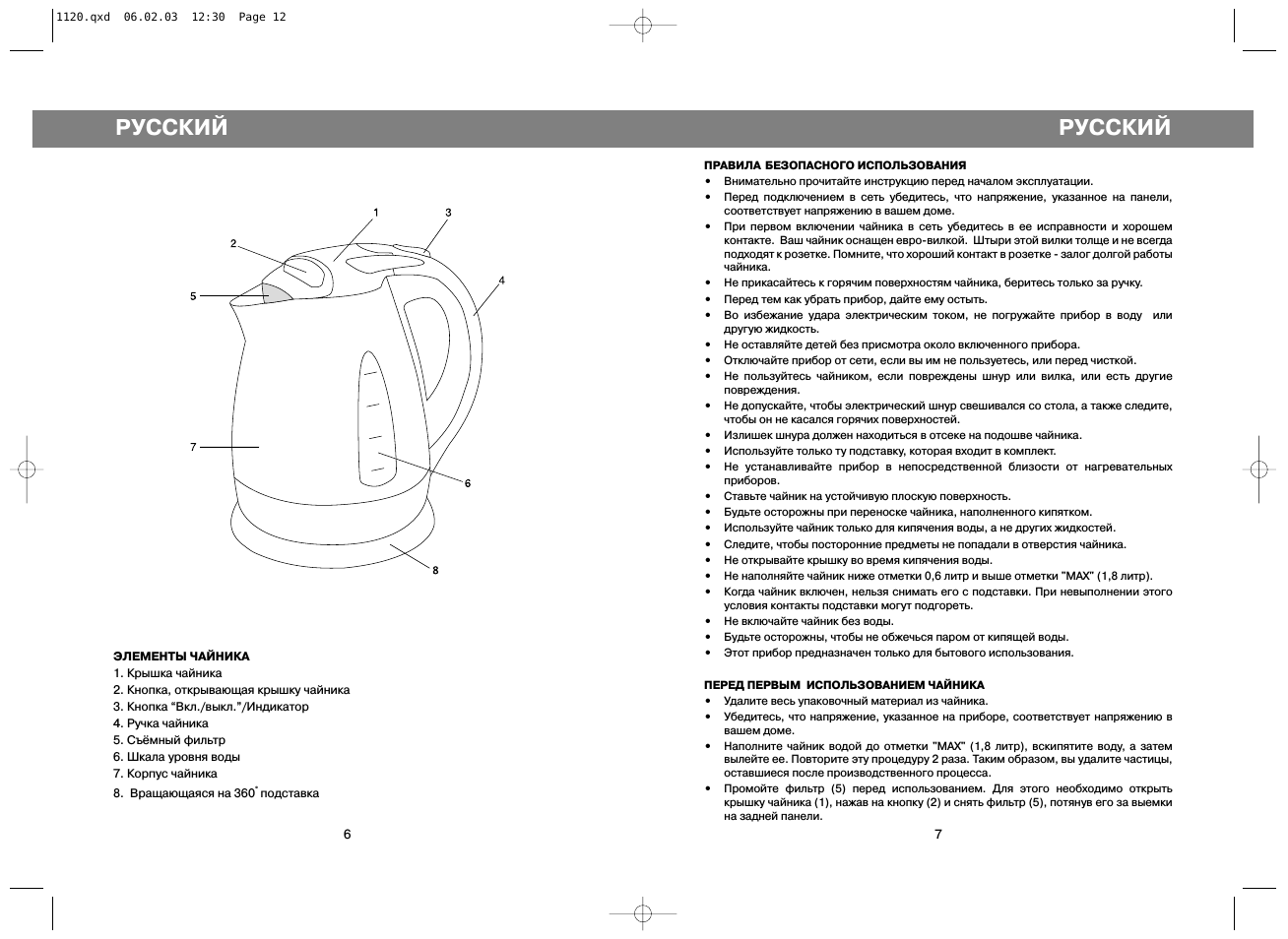

An electric kettle is a household appliance, the design and principle of operation of which can be understood even by a person who does not know much about technology. All kettles are designed the same, regardless of the model, and work according to the same scheme. They consist of the following main units and elements:

- the body, which is at the same time a flask for water (some models of electric kettles have a separate bowl placed in the body);

-

a heating element in the form of an open spiral, similar to a boiler, located right at the bottom of the water tank or (like most modern electric kettles) in the form of a disc heating element;

-

a stand (base), on which there is a connector for connecting a kettle and a power cord for connecting to a household power supply (it is available in all modern electric kettles related to cordless);

- power connector pads on the bottom of the kettle base, which can have a central (like most models) or side location;

-

thermostat, used to turn off the kettle when it boils;

- power buttons.

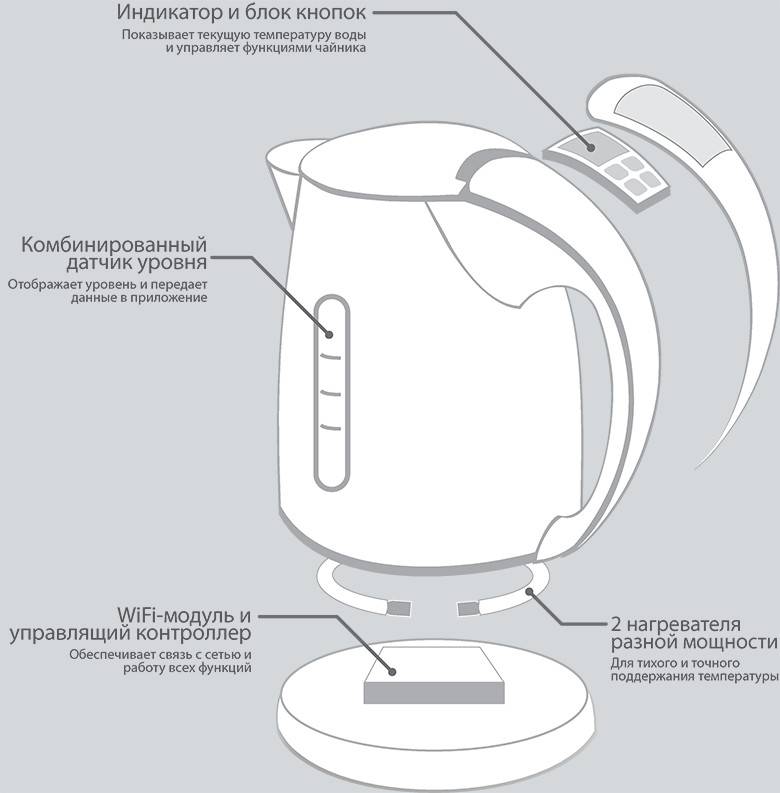

Today on sale you can find electric kettles with a thermostat, with the help of which you can heat water not only to 100 ° C, but also to any desired temperature, and even maintain this temperature regime for a certain time. This property is necessary for the correct brewing of various types of tea (black, green, white, red), each of which requires water of different temperatures from 60 to 90 ° C. An electric kettle with a thermostat is an ideal purchase if the family has a small child. Indeed, for the preparation of baby food mixtures, boiling water is not required, and with the help of such a device, you can set the desired temperature. And for adults, repeated boiling of water is very undesirable if they adhere to a healthy diet.

In this model, the control panel is located on the stand

Naturally, each model of electric kettles has its own design features, but in principle they do not differ in design.

The principle of operation of an electric kettle is also quite simple. Heating up, the heating element heats up the water in the flask until it boils. Steam is supplied through special channels to the bimetallic plate of the thermostat, made of metals with different coefficients of thermal expansion, it, bending, presses the button lever or opens the contact terminals, disconnecting the device from the network.

The diagram shows the movement of steam through the channels in the handle, but for this purpose a tube in the kettle flask itself can be used.

Breakdown reasons

Of course, the repair of an electric kettle can only be performed by a person who understands electronics and has experience with such devices. If these skills are absent, it is better to contact a service that deals with such repairs.

Before making a decision, it is very important to find out the reason for the failure of the electric kettle, its nature. Basically all damage is divided into several types

Each has its own characteristic differences:

- Cracking on the scale indicating the liquid level. It is usually made of plastic, which starts to crack due to the high temperature.

- Mechanical damage to the case has occurred. For example, cold water was poured into the kettle immediately after the boiling water was drained. As a result, microcracks may appear in weak areas, and the integrity of the case will be violated.

- The heating element is not properly fixed.

- Corrosion has formed on the bottom of the kettle. The result of this formation is the appearance of a gap between the bottom of the device and its body.

What to do if the bottom is leaking

Seeing a puddle on the table next to the kettle, they find out the localization of the leak. If it flows from below, analyze the bottom. To do this, it is removed:

- work with a screwdriver;

- unscrew the screws, there are several of them;

- remove the heating element and the gasket.

The removed parts are inspected. Determine the cause of the leak. If there is no visible damage, remove plaque from the parts, wipe them, put them back in place, firmly fix the parts by tightening the fasteners with a screwdriver. If the leak resumes, the procedure is repeated, and the gasket is replaced during assembly.

Mechanical damage to the bottom is not repaired at home and in the workshop, they go to the store for a new kettle. Corrosion is the cause of bottom cracks. It appears on household appliances with a metal body. Because of it, microcracks form at the bottom, it is through them that water seeps.

Electric kettle leaks: what to do, how to repair it yourself

The kettle, like all household appliances, sooner or later breaks down and breaks down. The causes and consequences are unpredictable. However, depending on certain signs of damage, you can still try to repair the device yourself.

What to do if an electric kettle is leaking?

In most cases, you can make repairs yourself if the kettle is leaking. However, ignorant people in electronics need to contact a specialist to get a quality kettle repair.

Finding out the reason

Before making a decision, you should first determine the cause of the breakdown and its nature. Signs of damage and their brief description will be described below:

- Crack on the scale for measuring the water level. Usually the water level is made of plastic, which can crack over time due to dryness.

- Damaged housing. Violation of the integrity of the body occurs under various mechanical influences. For example, filling the kettle with cold water immediately after draining hot water can provoke microcracks in especially weak places.

- Weak heating element attachment.

- Bottom corrosion. In this case, a gap may form at the junction of the bottom with the body.

Self repair

Now about what can be done with each considered breakdown. Manual repair of an electric kettle is possible in the following cases.

Crack on the indicator:

- Replacing the measuring glass itself will not work, but you can try to seal the crack tightly with tape or electrical tape, which will significantly reduce the loss of water.

- If the level of your kettle is a tube, then all you need to do is cut off the access of water to it.

- You can also try to seal the cracks with hot melt glue. It is enough to apply a layer of glue to the crack of the case or indicator using a special gun. Before checking the kettle for serviceability, you should wait until the substance has completely dried.

- A cheaper option is cold welding. Similarly to the previous example, apply welding to the damaged surface and let it brew. Then pour cold water into the kettle and check the tightness of the device.

REFERENCE! This method of solving the problem is effective for microcracks in the water indicator. In other cases, specialist assistance or replacement of the device may be required.

If the case is damaged:

As in the previous example, if the crack is minor, then you can try to fix the damage with hot melt or cold welding.

Weak heating element attachment:

If the lower part of the kettle is "loose", then the problem is solved by simply tightening the screws. Next, put the kettle on a napkin, paper or any other material to be wetted. After a while, the result will be visible.

If a wet spot is still formed on the paper or fabric, then only replacing the O-ring will help. Below you will find step-by-step instructions on how to do this:

- Remove the bottom of the kettle. Here the instruction with a detailed description of the equipment set can help.

- Remove the disc with the spacer.

- Remove the gasket from the disc.

Inspect the disc, housing and silicone gasket for signs of malfunction. There can be two situations here:

- If the case is damaged in place of the disc, the kettle must be disposed of.

- If only the gasket is damaged, it should be replaced.

If no serious damage is found, then perhaps the matter is in the weakening of the connection between the disk and the case. It is recommended to descale the parts and put them back in their original place.

It remains to check the result.

In what cases repair is impossible

It so happens that neither the proposed methods, nor the master are able to restore the electric kettle. In this case, the device must be disposed of and replaced with a new one. List of damages for which repair is powerless:

- Bottom corrosion. Rusted metal is a sign that the integrity of its surface has been compromised, which provoked oxidation of the bottom as a whole.

- Serious damage to the case. A broken cover or a significant part of the case cannot be repaired.

- Burnt wiring. If, during a short circuit inside the kettle, the wires burned out and at the same time melted part of the body and damaged other parts of the kettle, then such a device can be changed immediately.

An electric kettle, like any household appliance, requires adherence to operating rules. This will increase the life of the device and reduce the cost of repairing or replacing it.

Did you like it?

Loading…

Video

We hope that in the article we answered the question: how to glue the electric kettle, as you can see, glue will not help here. First, determine the cause of the leak, and then, following the tips and recommendations, proceed to action. A self-repaired device will be even dearer and closer to you. Enjoy your tea!

How can you glue a glass electric kettle

Sometimes there is no money to buy a new kettle. Sometimes there is no time or desire to go to the store. In such cases, you can revive your old but beloved kitchen gadget. You can seal a leaky flask with a substance that meets a number of requirements:

- not toxic;

- no restrictions for use in the food industry;

- withstands high temperatures;

- elastic;

- dries quickly at room temperature;

- possesses adhesive properties.

On the forums, craftsmen give advice on how and how to glue a leaking kettle. You cannot use recipes that include:

During operation, they release substances into boiling water that are harmful to health. In addition, they are not plastic, they become brittle from exposure to high temperatures.

RTV 118Q food grade silicone sealant

The lower limit of the operating temperature range is -60 ° C, the upper limit is +260 ° C. Glass, ceramics, metal, rubber, and plastic are glued with RTV 118Q sealant. It is approved for use in the food industry. It takes 72 hours to dry completely. It is convenient to use the tool. The paste is easy to apply to the glued surfaces.

OTTOSEAL S27

The lower limit of the operating temperature range is -40 ° C, the upper limit is +180 ° C. OTTOSEAL S27 is approved for use in the food industry. Glass is glued with this silicone sealant without applying a primer. It takes 24 hours to dry completely.

Dow Corning 732 clear

The lower limit of the operating temperature range is -60 ° C, the upper one is +180 ° C. It takes 24 hours for the sealant to dry completely. Times are indicated for certain conditions:

- indoor air humidity 50%;

- air temperature 22-25 ° C.

Dow Corning 732 clear is approved for use in the food industry by NSF International.

Food-safe silicone sealant "Titan"

It adheres well absolutely smooth surfaces, including colorless glass. The lower limit of the operating temperature range is -40 ° C, the upper limit is +200 ° C. It takes 24-120 hours to dry completely. The time depends on the thickness of the applied layer.

CHEMLUX 9014 food grade

The sealant glues glass, ceramics, stainless steel, plastic, aluminum. The lower limit of the operating temperature range is -40 ° C, the upper limit is +180 ° C. There are no restrictions on the duration of contact with food. The adhesive layer dries quickly.