How to close up the cracks in the laminate

There are several ways. When choosing a method, they are guided by the following rule: the greater the damage, the denser the composition should be.

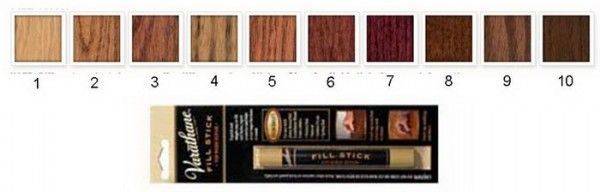

Repair pastes are produced in a wide range of shades, choose a tone as close as possible to the color of the flooring. The tool is sold in building materials stores, instructions are attached.

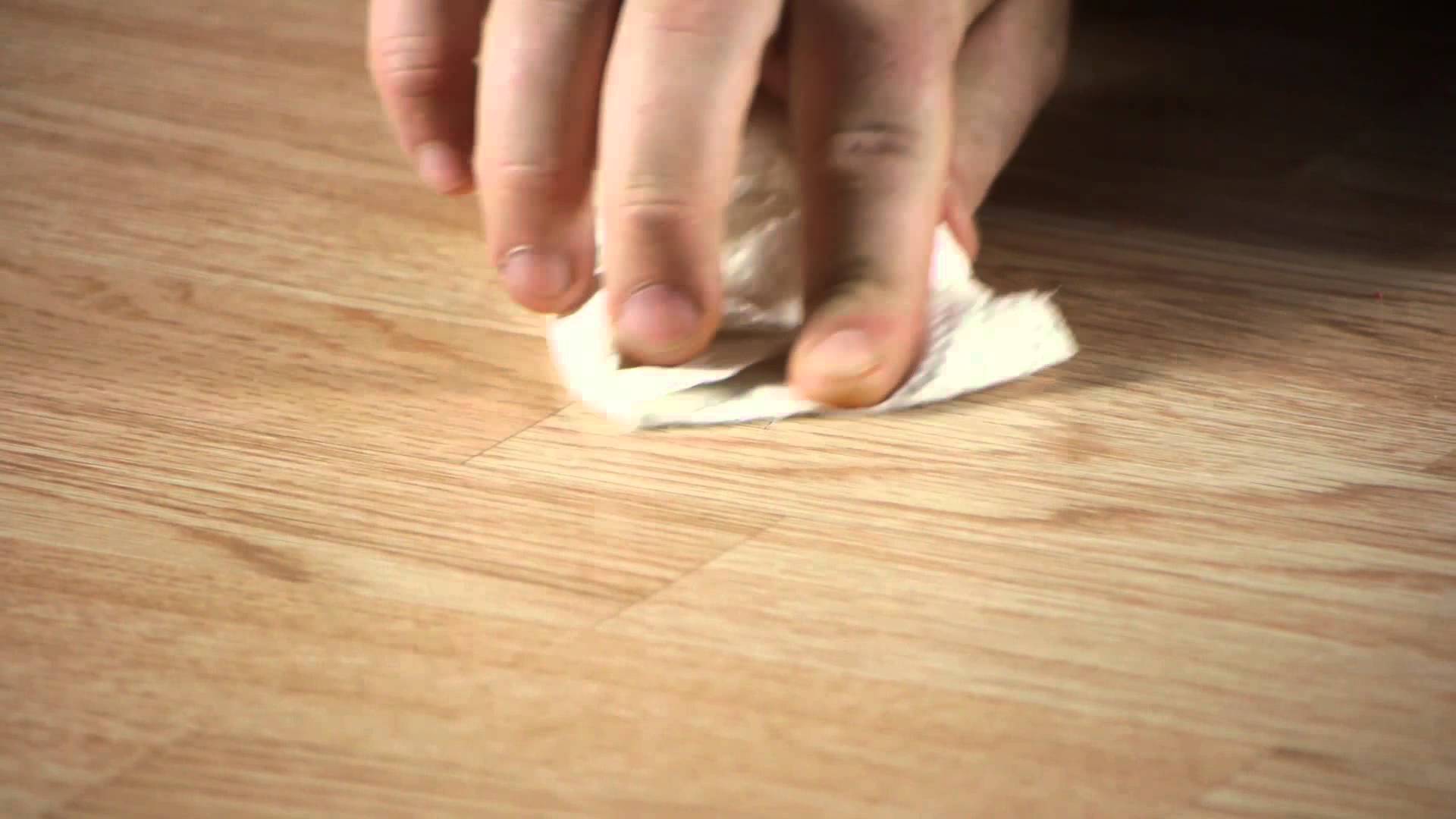

It is not difficult to use the composition. The main thing is to clean the work surface from debris and dirt. Otherwise, you will not get a strong adhesion of the paste to the board. Before starting work and after cleaning the surface, stick masking tape around the edges of the gap. This will prevent the repair compound from getting on the outside of the board. Apply the paste, smooth with a trowel and wait until it dries. Then remove the tape and wipe off the rest of the product with a thick cloth.

To repair the laminate, use wood putty. It is used in the same way as a paste. The putty is less flexible and does not tolerate vibrations well. It should not be used on those areas of the floor that experience regular dynamic stress. The composition is convenient for repairing laminate flooring near the wall and will not be used on the aisle.

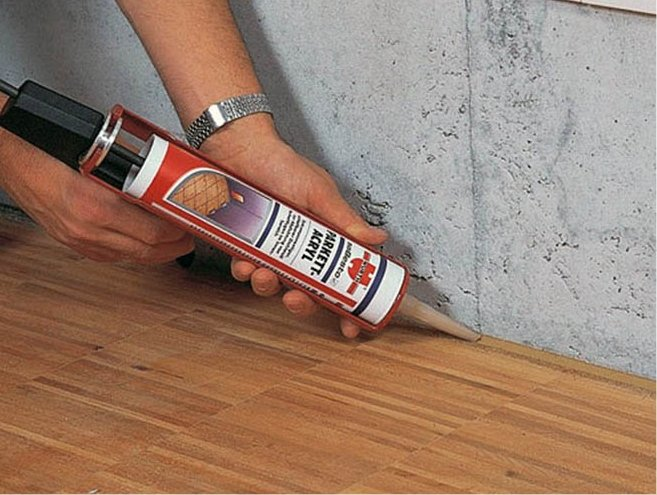

Plastic waterproof material for processing seams. Designed to be used as a preventative agent. The sealant can be applied a few weeks after the laminate has been installed. The composition is well suited if you need to cover up cracks, or for repairing minor mechanical damage (scratches, chips).

Option 4. Colored grout

Used for cosmetic repairs - filling small depressions. Colored grout is easier to use than other products, but it can only remove small gaps.

The composition is waterproof and has increased plasticity.

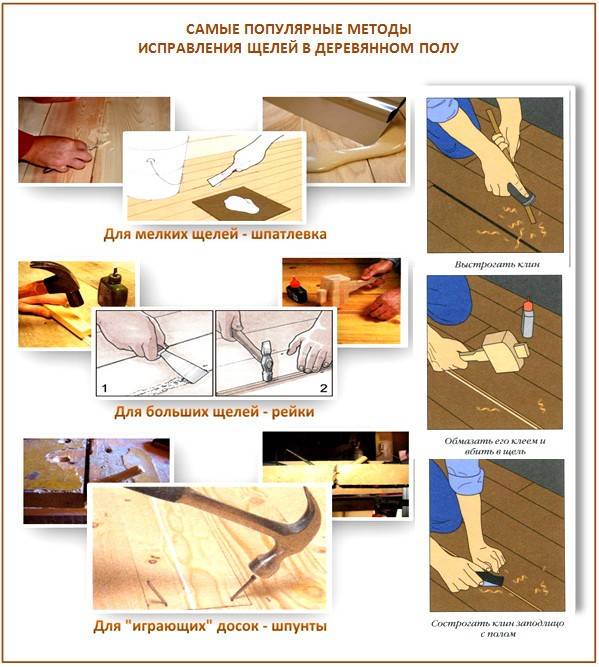

How to repair cracks in parquet

The appearance of cracks in laminated parquet can be due to various reasons:

- Initial choice of substandard parquet. Cheap board or lining can lead to defects from temperature fluctuations or from stress;

- Lamellas from different manufacturers may differ in size or shape of the locks. Such incompatibility significantly affects the connection, which over time can weaken, or stop fastening. When trying to join such lamellas, small gaps may appear.

- The most popular reason is mounting on an uneven surface. Defects are not immediately detected, since the substrate softens and absorbs for some time. But over time, it becomes denser and stops damping, while the panels diverge.

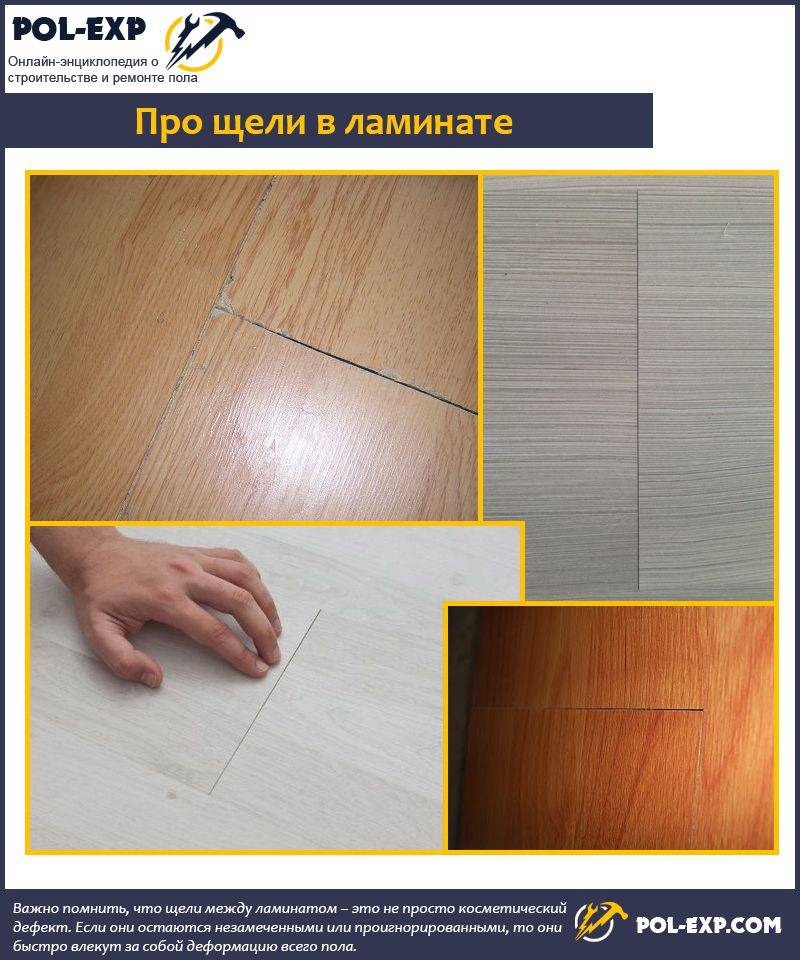

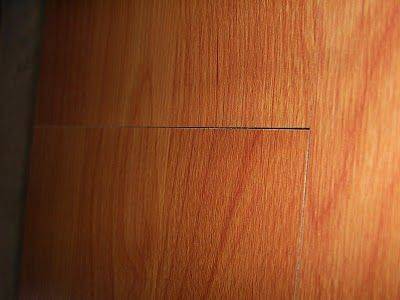

The gaps between the boards are not just a cosmetic defect. Their presence can deform the entire coating. Due to the fact that the protective film is broken and free access to the internal structure of the board is opened, without moisture-proof impregnation, the insides quickly get wet and deformed together with the surface of the laminate.

Sealing of gaps is carried out in several ways, depending on the number of gaps and sizes.

Sealing of gaps is carried out in several ways, depending on the number of gaps and sizes.

How to eliminate the cracks. If a gap forms due to unevenness of the base, it is necessary to replace the underlay. In the place of the defect, one or two boards are dismantled and the old substrate is carefully cut out. Unevenness of the substrate is eliminated and wrinkles are removed. If the volume of the damaged backing is large, then the entire backing should be changed.

Equally important information on the topic: Chips on the parquet

Not everyone knows that the durability and quality of the coating is, first of all, the merit of proper preparation and installation, as well as a well-chosen auxiliary material. There are many options to choose from:

- environmentally friendly and durable cork;

- polypropylene;

- polystyrene foam (for increased load);

- coniferous substrate, with good ventilation;

- on a foil base;

- polyethylene film;

- combined.

Which type of substrate is better is difficult to answer unequivocally. It depends on the conditions in which the coating is laid: humidity, subfloor (concrete or plank), floor horizontality, etc.

Replacing the underlay will help eliminate the cause of the uneven floor.

Replacing the underlay will help eliminate the cause of the uneven floor.

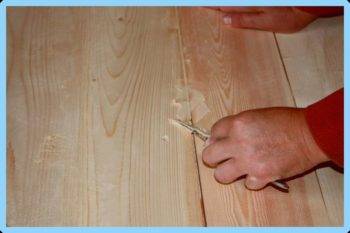

In cases where a cardinal method with replacing the substrate is not required, a cosmetic repair can be dispensed with. The slots must be sealed to restrict the ingress of liquid inside. To do this, you can use a special putty paste, the procedure is as follows:

- it is necessary to remove debris and dust from the gap,

- glue around the edges with tape,

- pick a color and apply putty,

- level with a spatula and dry,

- then remove the tape and wipe with a damp cloth.

Redecorating scratches on laminated parquet flooring can be done by yourself

Redecorating scratches on laminated parquet flooring can be done by yourself

How to remove or mask cracks

After finding out the causes of damage to the laminate, you can safely start choosing a way to eliminate them. The first situation for consideration is the most common, namely, after a couple of months, gaps between the laminate panels became noticeable on the floor. What to do in this case?

There are several ways to solve the problem. Each of the options is distinguished by its effectiveness, but it has differences in the complexity of the process:

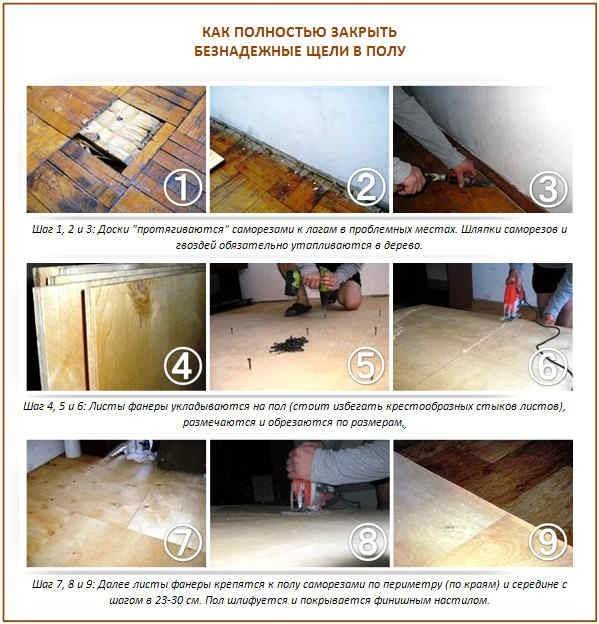

- If it turns out that the cracks have arisen due to an uneven base, then you can proceed dramatically and level the floor.

- To do this, it will be necessary to disassemble the laminate and remove the backing, which has probably already become worn out and cannot be reused. Next, you need to level the floor under the laminate. For quick alignment, you can use a self-leveling mixture. After it dries, a new substrate is laid on top and the laminate is re-laid.

Note. This method is suitable only if the panels were not coated with special glue or sealant during the initial installation.

If there is no opportunity or desire for global work, you can use a partial solution, but you still have to dismantle the laminate. Next, a denser substrate under the laminate is immediately laid and the floor covering is mounted. This will only bear fruit if there are slight irregularities.

Laminate damage

Damage classification

A high-quality laminate in itself is a durable material that tolerates mechanical stress well. But in some situations, especially if mistakes were made when laying the floor or the operating conditions were violated, the laminate does not stand up and fails.

Among the frequently occurring damage to the laminate are:

- Slots between laminate planks;

- Swelling of the laminate in high humidity conditions;

- Scratches;

- Chips, holes and other damage caused by mechanical stress.

But whatever the defect, even the smallest scratch spoils the appearance of the entire floor covering (as seen in the photo). For this reason, the faster and better the damage that has arisen is repaired, the better.

Useful information. Most cracks and scratches can be easily repaired by yourself

But before doing this, it is important to find out why the defect arose and then decide on the method of repairing the laminate.

How to remove minor scratches and scuffs

Shallow injuries are hidden with the help of means that are simple in the way of application. In this case, it is only necessary to level the surface. If the problem is solved, how to repair the chip on the laminate, consider means based on fatty components, special polishes. This method is suitable for cases when furniture or other large-sized heavy objects have been moved across the floor. Polishes are also used to eliminate the consequences of constantly opening the door when it is tightly attached to the floor covering.

Olive oil

This product helps to restore the coating by polishing. Prepare the floor before repairing the chips on the laminate.

It needs to be washed, while it is important to remove all contaminants, including fatty components. For this reason, shampoo is added to a container with water.

After washing the floor with such a solution, the area to be restored is additionally cleaned of shampoo residues. For this, water is used without additives.

Dry the surface before restoring the coating. If the humidity in the room is high and the drying process needs to be accelerated, then use a hair dryer or other heat source. You can wipe the surface with a lint-free cloth.

Polish

When all the floors in the house are covered with laminate, it is recommended to purchase a special product. A polish is a compound specially designed to protect such a floor covering. It has all the necessary properties that are important for protecting the material: moisture resistance, resistance to stress. The polish for the laminate is produced in the form of mastic, solution and aerosol.

The liquid substance is added to water, used for washing the floor. When the agent has been applied to the damaged surface, it is recommended to polish the area. After the end of the work, the properties of the laminate improve: it is protected from mechanical stress, and its attractiveness increases.

The mastic is a silicone compound. It is more effective than liquid. Laminate repair paste is applied to the scratch and rubbed; excess substance must be removed immediately. Thanks to this tool, the laminate acquires a shine, therefore it is recommended to treat the entire surface so that the coating looks attractive and does not catch the eye of individual shiny spots.

The aerosol is similar in principle to a concentrated liquid: the product is sprayed over the surface; when the slurry settles on the floor, start polishing. To do this, use a natural material, for example, a hand towel is suitable (use an old thing).

Using the WD 40

This is a universal lubricant that is used to solve various tasks (removing rust from parts, protecting against dust, etc.); such a tool is also suitable for restoring the coating. The lubricant is produced in a cylinder; The kit includes a nozzle of the minimum size, which helps to apply the substance to hard-to-reach areas.

Principle of operation: the polish is sprayed over the laminate, then treated with a rag made of natural material until the scratch disappears. You do not need to wash off the product. A brush can be used to clean the treated surface. The advantage of such a tool is the ability to protect the laminate from dust and other contaminants. Treated surfaces retain their attractiveness for a long time.

Laminate design and features of its operation

It is, in principle, possible to update the laminate flooring, but some of the nuances of the work should be observed.

It is, in principle, possible to update the laminate flooring, but some of the nuances of the work should be observed.

Before painting a laminate, it is worth taking a closer look at what it is and what is its structural difference from parquet flooring.

Laminate floorboards, despite their similarity to parquet, have little to do with them. Their main difference is the material from which they are made.

While natural wood is used in the production of parquet boards and bars, various composite materials are widely used in the manufacture of laminated lamellas.

Classic laminated board consists of 4 layers, bonded to each other by means of polymer-based adhesives.

Features of operation

In connection with such a design of the laminate, if its upper layer is damaged, all underlying layers are inevitably put under impact, therefore, damage to the protective surface should be considered not only as a decorative defect that impairs the appearance of laminate flooring.

Violation of the protective layer can cause "failure" of the entire floorboard - moisture and chemical components of cleaning agents, penetrating into the base of the lamella will lead to its deformation, delamination or fungal attack.

In order to avoid deformation of the floorboards, dry cleaning with a vacuum cleaner or broom should be limited.

But it is quite clear that dry cleaning will not be able to rid the surface of the flooring from stubborn dirt.

Moreover, a floorboard devoid of a polymer film tends to absorb dirt, and this makes it almost impossible to clean it dry.

In this regard, painting the laminate is needed not only to restore its decorative qualities, but also to protect it from adverse external influences.

In this regard, painting the laminate is needed not only to restore its decorative qualities, but also to protect it from adverse external influences.

As a preventive measure against premature failure of the laminate flooring, it is advisable to choose it in accordance with the resistance class.

For example, in rooms with increased floor load (entrance hall, kitchen, living room), a higher class laminate should be used. The table shows the classes of laminate flooring, the recommended area of their application and the approximate service life.

Reasons for the appearance of cracks in the laminate

Slots when laying laminate flooring appear for several reasons. The main ones are:

- Humidity. This problem arises as a result of seasonal changes in humidity, when materials that contain wood expand and dry out (in summer it is humid and there is no heating, but it rains, and in winter it is dry, but the heating season begins);

- leakage. It can be very different: both flooding and regular leakage from flower pots, for example. Both that, and another leads first to a local, and soon to a complete change in the geometry of individual boards and the entire floor canvas;

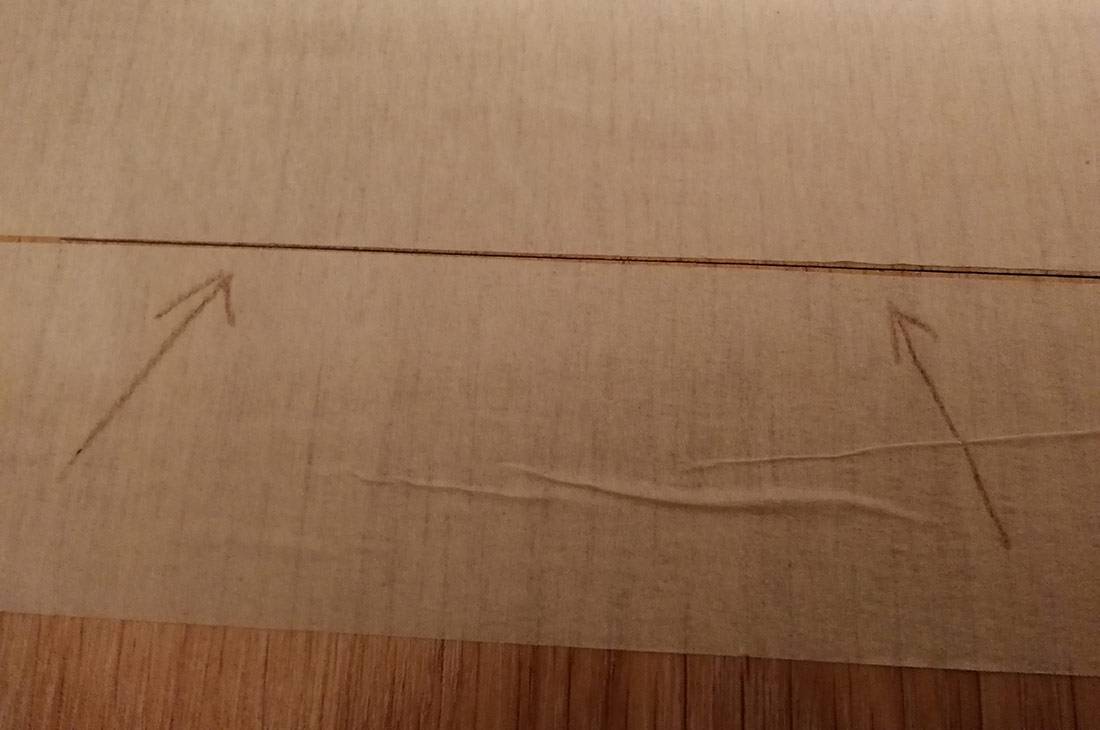

- locks. In most cases, during the installation process, the locks are not squeezed. Due to a bad connection, they start to diverge. Can this outcome be prevented? Yes, by the quality control method: all under-compressed locks have small gaps initially;

- deformation gaps, or rather their absence. During the installation of the lamellas, it is necessary to leave a deformation gap from ALL stop points and obstacles. Otherwise, due to expansion, the floor will deform, expanding across the board, or waves will appear on it due to expansion along the board.

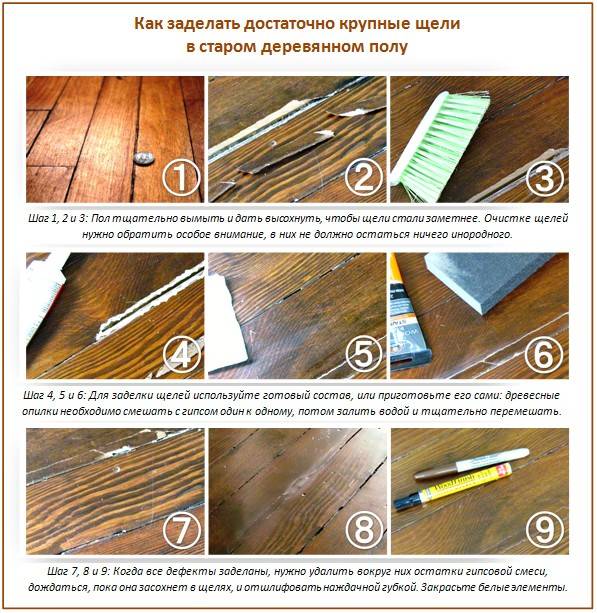

A mixture of sawdust and stucco

A good option for patching up a chip is a composition of sawdust and gypsum. Both components are mixed with water in the same amount to a homogeneous pasty state. A large chip can be pre-sealed with a tab, the role of which will be perfectly performed by a piece of wood of a certain size. The enclosed sliver is carefully coated and rubbed with a composition of sawdust and gypsum.

Instead of gypsum, you can use PVA glue:

- sawdust is mixed with glue until a homogeneous mass is obtained;

- the mixture is applied to the chip;

- after complete drying, it is necessary to remove the excess;

- align the repair site with a putty matched to the color of the laminate;

- if desired, the laminate can be varnished.

Epoxy has two components: resin and hardener. They must be mixed, observing the proportions according to the instructions, until an elastic homogeneous mass, using a drill with a nozzle. Mixing must be carried out for at least 5 minutes at a temperature of at least 15 degrees. The resulting composition is evenly applied to the pre-treated chip.

Tips for repairing lamellas

In each case, the method of restoration and the amount of work that must be performed depends on the severity of the damage: the depth and area of the chip, crack or scratch. When carrying out work, you need to adhere to the following recommendations:

- All repair work must be done immediately, as soon as a minor defect appears: it is easier to repair it this way.

- Any composition for the restoration of the laminate should be applied carefully, while grasping the edges of the damage.

- After finishing work, the laminate must be wiped with a damp cloth.

For additional protection of the laminate from damage, it can be covered with a layer of clear varnish.High-quality laminate from well-known manufacturers is a rather expensive floor covering. Therefore, you need to treat him as carefully as possible. It is best to walk on such a floor in slippers, do not move heavy furniture on it and do not drop heavy objects. In this case, the laminate will last the entire period declared by the manufacturer without breakdowns and complaints.

For additional protection of the laminate from damage, it can be covered with a layer of clear varnish.High-quality laminate from well-known manufacturers is a rather expensive floor covering. Therefore, you need to treat him as carefully as possible. It is best to walk on such a floor in slippers, do not move heavy furniture on it and do not drop heavy objects. In this case, the laminate will last the entire period declared by the manufacturer without breakdowns and complaints.

Laminate, despite the high degree of resistance to stress and abrasion, is sometimes damaged

Most often this happens when handling heavy objects, products with sharp edges, carelessly. The result is cracks, scratches, dents and chips in the laminate

To eliminate them, use improvised and special means.

We restore mechanical damage

But cracks are not the only nuisance that can happen. In addition to them, the laminate is exposed, as a result of which scratches, holes and chips appear.

To eliminate such damage, you can use the following methods:

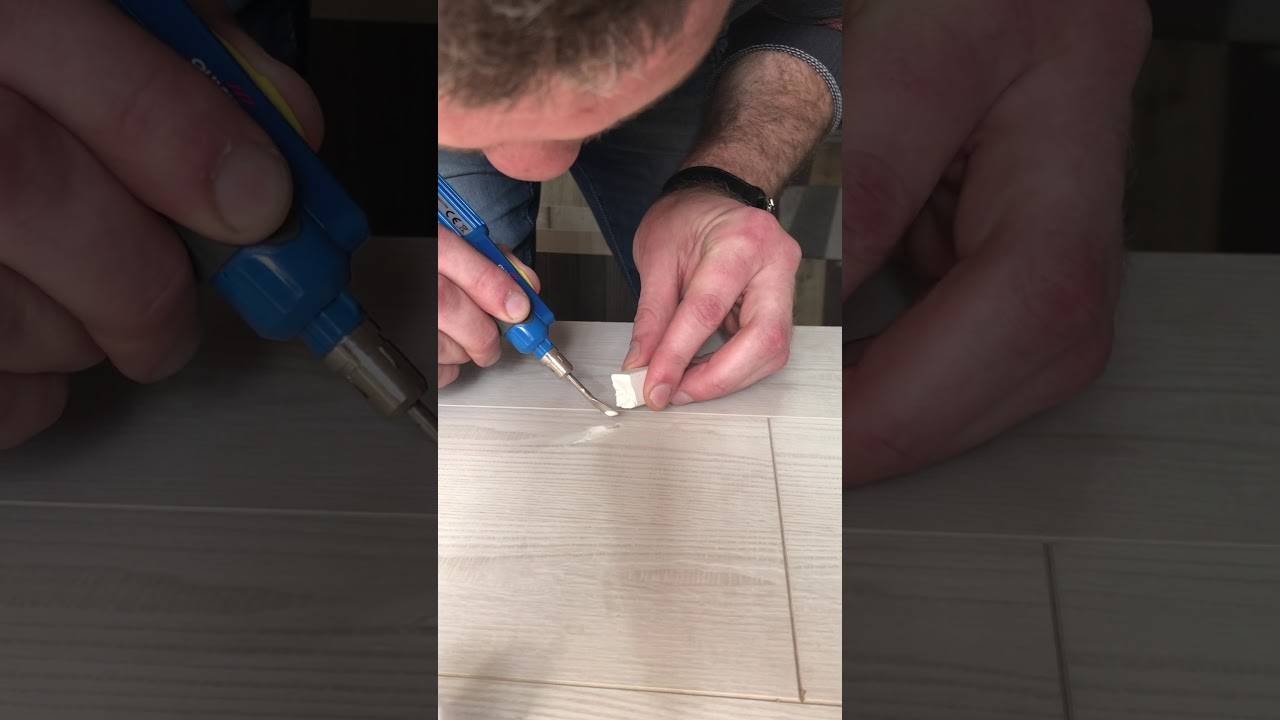

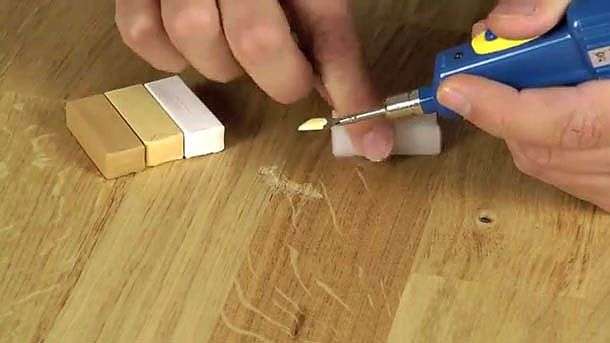

The easiest and fastest way to apply a repair compound specially designed for such purposes. The putty looks like a paste that matches the color of the laminate. For ease of use, according to the instructions, you need to apply the paste with a rubber spatula.

A mixture of crushed sawdust and gypsum can be used to repair deep cracks. In the same way, you can cover up the gaps between laminate panels.

Advice! To save grouting, a thin wooden lining is placed in deep cracks, and from above the entire structure is covered with a repair compound.

For repairing small scratches, a specially designed wax crayon is perfect. This method is suitable if only the top layer of the coating is damaged, without damaging the inner base and moisture, you can not be afraid.

Laminate repair pencil

Laminate repair pencil

Additionally, having studied the video with instructions, you can clearly see how the restoration of the laminate and giving it its original appearance occurs. In order not to be confused about what to do when faced with a problem, it is better to study in advance the material on how to eliminate the damage that has arisen (holes, chips, cracks and cracks) and how to prevent this (high-quality leveling of the base will help). As a result, we can conclude that do-it-yourself laminate repair is quite realistic and requires only accuracy and a little time.

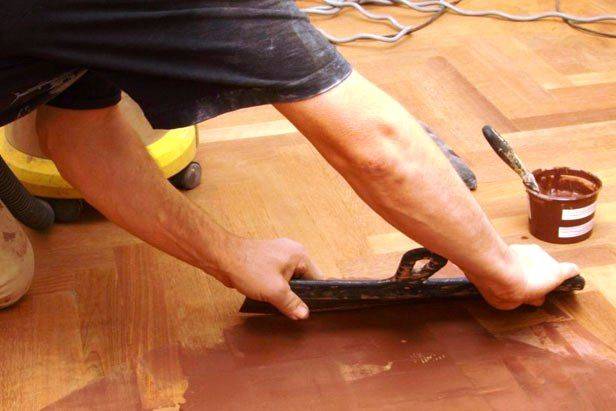

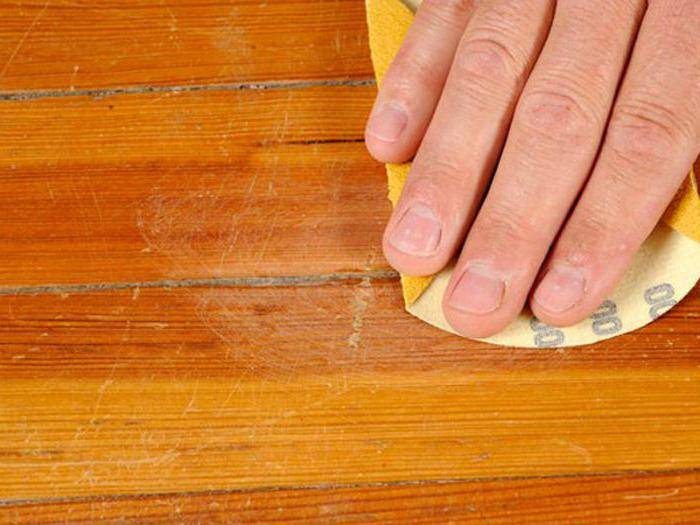

Grouting gaps between parquet rivets

Having prepared the putty, you can proceed to the solution of the next question: how to close up the cracks with your own hands. To work, you will need a minimum of tools - several spatulas of different widths, sandpaper and a scraper. The last components can be replaced by a grinder. The parquet should be leveled by scraping or sanding before puttingtying. It is advisable to vacuum the cracks - the presence of dust will negatively affect the adhesion of the putty to the wood. Wipe the floor surface with a damp cloth.

Only gaps with a width of more than 2-5 mm are subject to a separate putty - a thick layer of putty will sag and crack during drying. Having previously filled and dried such gaps, the resulting defects are eliminated during subsequent grouting. Alternatively, in problem areas, the parquet is caulked with slats of the appropriate thickness, lubricated with glue and embedded 1-1.5 mm deeper than the parquet level.

Large gap between the boards

The general grouting is carried out with a putty in the consistency of liquid sour cream, pouring it onto the surface of the parquet and evenly rubbing it with a spatula. In order to best fill the gaps in the parquet floor, the operation is repeated in each area several times, moving the tool in different directions. As the consumption progresses, the putty is poured, preventing a significant decrease in the volume of the composition accelerated by the spatula.

Parquet treated with solvent-based fillers takes only a few hours to dry.It is better to give water-soluble compositions a day to set, and only then proceed to the finishing grinding of the floor surface. All additional information about the features of working with a specific type of putty can be obtained by carefully reading the manufacturer's recommendations, and the answers to the remaining questions are easy to find in the thematic videos.

Floor polishing tool, small and handy

How to cover up the cracks in the laminate?

There are several answers to the question of how to remove cracks in the laminate. We'll look at common methods that you can apply yourself:

damages in the laminate are fought with wood putty. This sopsob can be used to close up a relatively small area of the laminate flooring. The putty composition is applied with a spatula, and then, after the surface has completely dried, it is carefully sanded with sandpaper;

a mixture of gypsum and sawdust will help remove cracks from the floor surface. The ratio of the components is one to one

In this case, it is important to achieve an extremely thick consistency of the resulting composition. Plastering is performed, as in the previous case, and after that the surface of the damage is sanded with sandpaper;

sealing the cracks in the laminate is also carried out with a sealant - grout

The process of applying the composition to the floor surface and finishing is also not much different from the use of wood putty. To achieve the visual effect of a coherent coating, use a sealant that matches the shade of the laminate. But only minor damage can be removed this way;

if you look into a hardware store with a problem how to remove cracks in the laminate, you will be advised to use repair paste. In this case, the coating adjacent to the crack, gap or other other damage is carefully glued with masking tape so as not to stain the laminate strips in vain. And only then, with the help of a spatula, they cover up all the cracks;

Covering the gap

Covering the gap

Tile and laminate joint

The combination of these materials is most often used:

- In the hallway and kitchen. The laminate does not deteriorate with water and its durability is increased.

- For dividing a room into zones.

- In doorways.

There are several ways to do the joining of tiles and laminate:

Application of grout

Tile grout is applied at the joints of the tile and the laminate. You can buy it at any hardware store. The color of the grout is chosen based on the colors of the flooring and the color scheme of the room. You can choose monochromatic or contrasting shades.

Cork expansion joint installation

For this, a strip of cork is used, which easily takes the desired shape. It can be used on smooth and wavy joints. The soft structure allows the cork to shrink and fill in narrow areas.

Application of sealant

When sealing joints, a construction gun is used, with the help of which the sealant is squeezed out of the tube into the cracks between the tile and the laminate. The components of the sealant protect the laminate by preventing moisture absorption.

The disadvantage of this method is that the sealant has only one color - brown. This color does not work with all flooring shades.

How do gaps appear between individual laminate planks?

Installation of laminated flooring is not difficult, but even with competent and high-quality performance of all manipulations over time, cracks may appear on the laid laminate. Why is this happening? Here are some reasons:

- If the room is characterized by high levels of humidity, the floor will deform over time, and gaps will appear between the individual planks.

- In the event of flooding by neighbors or spilling liquid, if it is not wiped off immediately, cracks may appear in the coating.

- If you do not "press on" the locks during installation, this will lead to a loose fit of the individual laminate strips to each other.

- If, when laying the laminate flooring, no special deformation gaps are provided, it will swell or gaps will appear.After all, this distance is specially created for further linear expansion of individual strips. This situation will not necessarily happen, but still professionals recommend cautioning yourself, and do not forget about creating deformation gaps.

Expansion clearances

Expansion clearances

- Slots appear when laying laminate flooring also because the strips are mounted on an uneven plane. And if the preparatory work for leveling the base is done poorly, during operation, discrepancies are formed between the laminate boards.

- If you saved money and used poor quality material, this could also cause deformations and gaps between the individual planks of the laminate flooring.