Varieties of fireplace stoves

Constructions suitable for a summer residence made of bricks, wood, foam blocks or other material are intended for heating and cooking. How high quality can you make a cozy fireplace out of an existing stove? In the form of a partition between the recreation area and the kitchen! The layout of the system is selected according to the layout of the dwelling:

- buildings in which there are no load-bearing walls between the hall and the kitchen. It would be appropriate to build a stove or fireplace made of high-quality corner bricks. The stove is placed near the kitchen, and the fireplace system is oriented at 45 degrees in the living room. Fireboxes are arranged on the front or opposite walls;

- in rooms with uneven floors, an already equipped foundation, you can convert the stove into a fireplace using channels. The structure, which is small in weight, is set up near the cut of the walls. Consoles balance the load on the base;

- the country house during the construction process is complemented by closed fireplace structures. Systems on chain mounts are installed in the middle of the overall living room.

The shape of the product follows the style of the room. The U-shaped construct will emphasize the classic solution, and the D-shaped construct will give the space a country flavor. Rectangular or semicircular options are typical for design in the spirit of Art Nouveau.

Required thermal insulation materials

Stone wool 50 mm thick serves as a fire shield between the chimney and other building elements. It is necessary to take a responsible attitude to this moment, especially when it comes to transition nodes in the zones of interfloor and attic floors.

The fireclay core and facing parts are sometimes separated by basalt cardboard, which has a low thermal conductivity. Thanks to this heat-insulating layer, the temperature regime of the working core is maintained and the outer part of the fireplace does not overheat.

The tightness of the adhesion of metal elements to masonry is ensured with the help of sealants that can withstand high temperatures. If this is not done, there will be no good draft in the chimney, which means that the performance of the heating structure will decrease.

Drying the oven and first start-up

After the last brick takes its place, do not rush to melt the stove, this will not be done soon.

To prevent this from happening, it is required to dry the oven. The gate valve and the blower are opened. The air flow generated by the draft will facilitate the evaporation of moisture over the surface of the masonry. It is recommended to close the gate and the door at night. The procedure should be repeated until moisture ceases to form in the pipe.

It remains to dry the mortar at the depth of the masonry. To do this, you will have to start starting the oven. The device is heated with small portions of dry firewood, adding the amount of fuel per 1 kg every day. After the mass becomes equal to 20 kg, a control burn is made at maximum power, after which the condition of the masonry and seams is inspected. The absence of cracks gives a start to the full operation of the fireplace stove.

What are stoves fireplaces

When deciding how to build a fireplace stove, proceed from their capabilities and preferences.

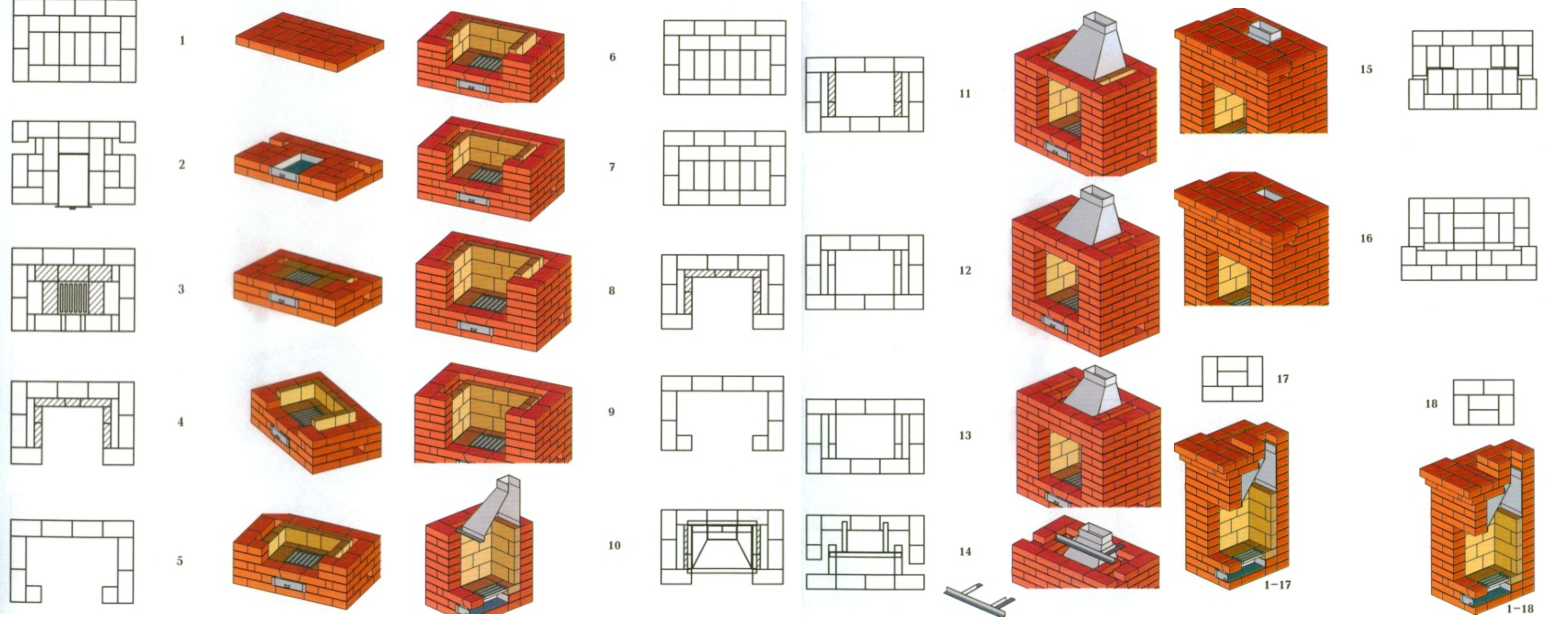

According to the design of the stove, fireplaces can be divided into two types:

- Fireplace stove with two fireboxes. This design is chosen if the area allows. Many problems associated with heating, providing a country house with hot water and cooking will be solved by a powerful multifunctional brick fireplace.It can provide not only a hob, an oven and a water boiler, but also the ability to connect to the water circuit. The fireplace can become an attachment to the heating and cooking stove, having united with it a common chimney. Thus, the structure will have two fireboxes, and it will be possible to heat the fireplace and stove at the same time, or separately.

- The stove is a fireplace with a single firebox. Suitable for a small country house. This heating device is also called a modernized "Swedish" or "Dutch". It is a modern version of a compact heating stove with an enlarged furnace compartment and a heat-resistant glass door.

The spatial layout of the structure is of great importance. The scheme of laying a stove with a fireplace largely depends on the layout of the premises.

Among all the constructive diversity, several different types can be listed:

- one-sided (fireplace and stove inserts on the same line)

- double-sided (fireplace inserts and stoves from different sides);

- corner;

- T-shaped in shape.

If we are talking about a small structure, you can limit yourself to a fireproof glass door in a single firebox.

Step-by-step technology for arranging a fireplace and stove installation

When planning how to build a heating system for a country house or summer cottage, start by laying the foundation.

Foundation construction process

You will need rubble stone blocks, cement mortar and formwork boards. Work like this:

- Create a trench at the depth of the main foundation. The width of the pit should be 10 cm more than the parameters of the stove.

- Lay crushed stone at the bottom of the pit and tamp it.

- Erect the formwork ending near the floor surface, waterproof it with bitumen, dry it.

- Lay rubble blocks on the bottom, and fill the distance between them with medium fractional rubble.

- Prepare a mortar based on 1 part cement, 3 parts sand and water. Pour the mixture into quarry and crushed stone.

- Lay out the stone and fill it with mortar again. Continue until the structure is 7 cm from the floor.

- Fill with the top layer, leave to dry for 1 week.

After hardening, arrange the waterproofing using a liquid bitumen composition.

Making mortar for laying bricks

Do-it-yourself oven is laid out on a clay-sand composition with high heat resistance. The mixture is made from clay with a high fat content, soaked in a wooden barrel. The solution is infused for 7 days, foam and debris are occasionally removed from it. After a week, the water is drained, and sand and porcelain stoneware glue are added to the clay. Cement is added in portions, trying to make the composition stick out from the trowel.

Classic scheme-ordering

Wondering how professionally you can make a functional fireplace out of an existing stove? Follow the classic masonry technology. Practicing builders are advised to make one heating unit from high-quality material without glossy shine and chips. Brick layout is done like this:

- Form the 1st row from substandard material. Level the stones as much as possible.

- The 2nd row includes the arrangement of the blower doors. Place asbestos or basalt material on the bricks, fix the door frame on the reinforcing rods, pulling them through the holes.

- 3rd row - continue fixing the doors. Pass the fired wire through the side holes of the frame and the masonry seams. Form a grate in the fireplace insert.

- 4th row - close the blower doors with bricks. Make a grate and start shaping the smoke channel. Bring it to its side, attach the latch. Smooth the solution with your hands until it is perfectly smooth.

- 5th row - install the firebox doors, securing them vertically with pins and wire.Line the space between the metal frame and the masonry with heat-resistant material.

- 6th row - put the fire door and work according to the scheme up to the 8th row.

- 9th row - close the door of the combustion compartment with a brick stone, work according to the scheme up to the 11th row.

- 11th row - install the hob. It is better to place bricks without mortar, mark the cooking place with a marker, and number the bars. Use a grinder to deepen the slab at the level of the main masonry.

- 12th row - close the doors of the fireplace insert. Lay a steel corner on top of the bricks. 13 - 15th rows are drawn up according to the scheme.

- 16-row - arrange the arch above the slab. You will need to place a corner and a strip of metal in front.

- 17th row - brickwork, next to which is a steel strip to support the arch.

- 18th row - lay the corner with bricks, install a metal sheet in place of the valves. The role of the support will be performed by a small piece of the corner.

- 19th row - make grooves of stone 5 mm more than the thickness of the main material of the valve. Check the quality of the chimney shutoff and secure the doors for cleaning.

- Row 20 - Secure the smaller steel strip above the latch. Continue laying according to the scheme.

- Row 21 - Place chimney support steel on top of the bricks.

- From the 22nd to the 26th row they work, narrowing the smoke exhaust ducts. At the end of the 26th row, a latch is made on the frame.

- From the 27th to the 28th row, they overlap the system, narrowing each level by ½ a brick block.

- After completing the work, dry the system and carry out a test - the first firebox.

A self-made chimney is located inside the building to improve draft. The vertical structure will ensure the quality of the removal of combustion products and prevent the formation of condensation. External chimneys are made of brick material or special sandwich pipes. A do-it-yourself fireplace, combined with a stove, is a guarantor of high-quality heating of the home. Only a responsible approach to construction, study of the scheme, purchase of high-quality materials will make the operation of the heating device comfortable.

Several ways to rework

If you got the stove when you bought a house as a dowry, then most likely you have no idea what kind of internal structure this device has. Therefore, partial disassembly is indispensable here. To determine which elements can be left unchanged and which need to be modified, begin to disassemble the oven carefully, removing each brick. The material that has remained intact can be reused, therefore it is recommended to fold it separately.

Already passing several rows will give a complete picture of the smoke channel arrangement. At this stage, you will have to determine whether you will leave the chimney in the same form or build a fireplace option, which is a regular vertical channel.

Having compared the diagram of a real device with the most suitable fireplace project, decide which part of the masonry will remain intact. Evaluate the possibilities of modifying the rows and then proceed to cleaning all the cavities of the body. It is much easier to clean the disassembled oven than in the current one.

Renovated brick building

Each brick should be cleaned of old mortar and soot. If necessary, you can use water. These bricks are most likely unsuitable for laying the outer layers, as modern materials are more aesthetic and attractive. But when installing the chimney, they will be irreplaceable.

In the case when it is impossible to delve into the circuit and after partial disassembly the picture is not clear, you will have to continue to disassemble the furnace. If there is a lot of damage in the masonry, then fixing them can be more time consuming and expensive than building a new fireplace. This idea forms the basis of the second method, how to convert a stove into a fireplace. It will be necessary to disassemble the oven completely to the bottom rows of the base

Dismantling should be done with extreme caution, as soot on the skin and respiratory system is irritating.

When disassembling the stove, do not regret the design. With a lot of cracks, it would cause a lot of problems.The very existence of the foundation and foundation is a huge legacy left by the fireplace stove. Having carefully examined the state of the base, you can carry out installation work on it. But verification is not only about integrity control. With the help of a level, you need to make sure that the plane is horizontal.

The remaining foundation points to the boundaries of the fireplace complex. With such dimensions, it will be possible to build not just a decorative element, but a real functional fireplace with a hob for cooking. In addition to the fact that the firebox will need to be performed according to the dimensions calculated according to the parameters of the room, immediately orient yourself with the location of the chimney so that it goes as close as possible to the existing hole in the roof of the house.

A fireplace made from a stove with its full or partial disassembly can radically change the style of the layout of the room. In some cases, the oven undergoes minimal changes. They mainly relate to the size of the firebox. Then it makes sense to keep it in its original form, decorating it with folk art painting. Naturally, modern materials are used for this, which do not leave traces and retain their appearance after long-term use.

It should be noted that with the help of such solutions, two important tasks can be solved: to equip a fireplace and to preserve the memory of Russian craftsmen in the house. After all, the Russian stove differs from the designs of other countries by the presence of a stove bench. This stove bench can be left for decoration, or it can be turned into a working fireplace unit.

Location of a brick fireplace stove

To decide where to install a fireplace stove, you need to know the layout and dimensions of the house.

Optimal solutions for the location of the fireplace stove:

- in the middle of a large common room;

- in the center of the building at the junction of interior partitions;

- in the partition between the common room and the kitchen area;

- between the hallway and the bedroom.

If you place a fireplace stove in the center of the room near (against) one of the inner walls, several rooms warm up at once. It is convenient if the heating stove, which serves as a fireplace and a cooker, will be located between the common room and the kitchen. The fireplace side will be in the common room and the hob will be in the kitchen area.

The heat shield plays the role of a warm wall if the stove is built between the living room and the bedroom.

The greater the power characteristics of the combustion chamber, the more spacious the area of the fireplace room should be.

To improve the microclimate inside the building and ensure normal combustion, an additional air supply is provided. This can be done in a number of ways. Ordinary window vents or special channels for air flow from the street will do. Their diameter depends on the type of combustion chamber. For a closed type firebox, the channel is made at least 10 cm, for open ones - at least 20 cm.

Functioning of the fireplace stove

A self-built fireplace based on a stove will combine the elements of two products. Open fireplace systems quickly warm up the room during the combustion of fuel materials. Furnaces have the ability to retain heat for a long time due to smoldering. The complex design increases the heat dissipation time and flares up quickly.

Thanks to the two fireboxes, the owners can light the stove or fireplace separately. Long flue gas ducts reduce hot gas evacuation. For this reason, fuel is saved, which is used as firewood, peat or coal.

The stove combined with the fireplace functions according to a special principle:

- fuel is loaded into a special chamber with a grate;

- air masses in the case of a stove enter through an opening at the bottom of the compartment and provide ignition of firewood or coal;

- fireplace compartment with a special convection chamber improves heat circulation throughout the rooms;

- combustion products are discharged through special channels;

- gates and dampers exclude premature heat transfer.

Two heating devices in one have increased efficiency, good pulling force due to which hypothermia is excluded.

Choosing an installation location

Before building a brick fireplace stove with your own hands, plan its location. In a wooden structure, separate the heating unit from the wall with a gasket made of asbestos, metal, ceramic tiles.

A fireplace stove in the center of a room is a great idea for zoning a space. It is better to turn the fireplace insert into the bedroom, and the cooking compartment into the kitchen. Use partitions if space permits. Make load-bearing walls from asbestos strips.

Having chosen the shape and location of the building for a brick house, "try on" it. Mark up a paper plan or sketch on ceilings, walls, and floors. Perform the necessary calculations before starting work.

Highlights when installing a fireplace stove with your own hands

The combustion chamber can be laid out of special fire-resistant bricks, or a ready-made factory metal firebox can be laid in the brickwork. If an open firebox without a door is arranged in the fireplace, the fuel burns out faster even when the smoke channel is adjusted. The door helps to slow down the combustion process, thereby leaving more heat in the room. The second plus of the furnace door is that less oxygen "burns out".

The advantages of a fire-brick firebox (and stone cladding) is that this material accumulates heat well. This means that after the fuel burns out, the walls of the stove will warm the room for a long time.

In brick versions, hot flue gases have to pass through a labyrinth of smoke ducts. In this case, heat is returned to the brickwork.

There are two types of smoke duct arrangement:

- above the combustion chamber;

- on the floor line.

The latter have special requirements for traction, but the comfort is maximum.