We increase the efficiency of the furnace

The potbelly stove is able to heat the room in just a matter of minutes. Moreover, everything that comes to hand can be thrown into the firebox: since there is no branched network of chimneys in it, and the smoke comes out “directly” in it, there is no need to fear that they will clog up.

But if an ordinary heating stove, installed in premises for permanent residence, has an extensive network of chimneys that trap heat, in a stove it goes directly into the pipe, so its efficiency is not too high. That is why it is too "gluttonous" and requires a lot of fuel.

To reduce fuel consumption, you can use the following tips from experienced stove-makers: • door to the firebox and blew in such a furnace should be as tight as possible; otherwise, the air supply to the stove will increase, and the fuel will burn out too quickly; • to regulate the release of warm smoke in the chimney it is desirable to provide a damper ; • next to the stove can be provided side metal screens at a distance of 5-6 cm from the stove, in this case, it will heat the room not only by radiating heat, but also by convection (circulation of warm air);

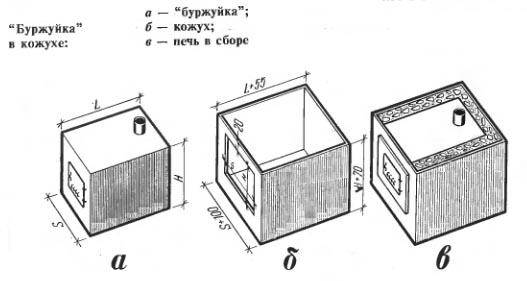

Potbelly stove in a casing

Potbelly stove in a casing

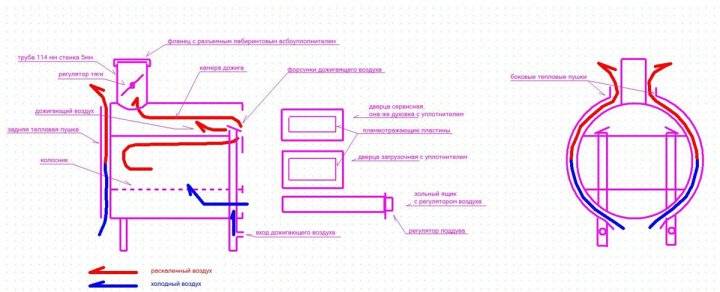

Round furnace with afterburner and casing with heat gun

Round furnace with afterburner and casing with heat gun

• to retain heat in the room, bends should be built up in the pipe; however, soot will linger in them, so it is advisable to create a collapsible structure; • the pipe can also be given a stepped shape: arrange the elbows in stages, with each step turning by 30 °; in addition, each of the knees must be securely attached to the wall with rods;

Stove with chimney elbows

Stove with chimney elbows

• chimney throughput should be less than the capacity of the furnace itself, in which case the hot gases will not go into the pipe immediately; its diameter should be only 2.7 times larger than the volume of the furnace, for example, with a volume of the furnace of 40 liters, the diameter should be 110 mm; chimney blowing with a fan - this will turn the stove into a kind of smoke cannon; • to reduce air circulation firewood in the oven should fit as tightly as possible; if it is heated with coal, stir up the resulting ash as rarely as possible; slots and latch... which will cover these slots; • to increase the heating area, it can be ribbed, that is, welded onto its body perpendicular to the furnace metal stripes ; • if you put steam on the stove buckets or metal box with sand... then they will accumulate heat and store it even after the oven goes out; sand filling or heat accumulator made of stones can be sewn up inside the metal body of the furnace;

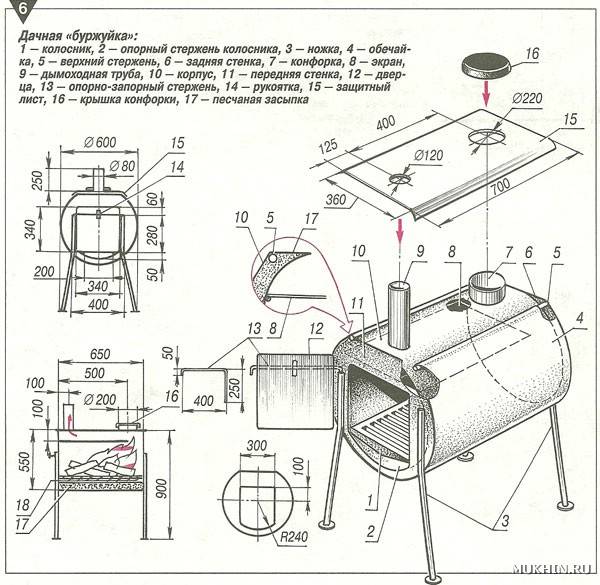

The scheme of a potbelly stove with a sand backfill, the furnace is made of a pipe with a diameter of 500 mm, its length is 650 mm

The scheme of a potbelly stove with a sand backfill, the furnace is made of a pipe with a diameter of 500 mm, its length is 650 mm

• bake, lined with 1-2 layers of brick... will keep warm for much longer;

• the volume of the furnace also matters: the more the area of its walls... the more heat they will give into the room; • bricks or sheet metal... on which the stove is installed, will help not only to protect the room from fire, but also to keep warm.

Related video: Do-it-yourself stove stove

Burzhuik schemes

The main advantage of a rectangular stove... unlike oval products made of pipes or gas cylinders, it consists in a larger area of the heated surface, so its efficiency will be much higher. The optimal size for a potbelly stove is 800x450x450 mm. A stove of this size does not take up much space and can easily fit even in a small room.

The simplest design is the "Gnome" stove, which consists of a box with a pipe welded to it

An important distinction Loginov ovens is the presence of two plates (reflectors ) in the upper part of the combustion chamber. Because gas path at the same time, it increases, the heat transfer of such a potbelly stove is significantly higher than that of a conventional metal stove.

Advice... If it is required to reduce the size of the Loginov oven, then it is desirable to change only its width. With a change in the length and height of the structure, its effectiveness can be significantly reduced.

Detailed diagram of Loginov's stove

Detailed diagram of Loginov's stove

The second life of a gas cylinder

A good idea for a small stove is to recycle containers that can withstand high heat. We have already talked about barrels, but how do you, for example, a potbelly stove from a gas cylinder or even two? These containers are good because they allow you to make yourself a stove for a country house or garage, both vertical and horizontal.

To create such a stove-stove, you will need the following tools:

- welding machine;

- grinding machine with wheels;

- drill with drills;

- brush with metal bristles;

- tape measure and construction pencil for marking;

- hammer, chisel, pliers.

Materials for making do-it-yourself stoves are needed as follows:

- 1 or 2 gas cylinders;

- Metal sheet for ash pan and hob (thickness must be at least 3 mm);

- cast-iron doors (old ones are suitable, for example, from a wood-burning stove, or made by hand from sheet metal);

- chimney pipe;

- thick metal fittings for making legs and grate.

Before starting work in a gas cylinder, open the valve and leave it in this state for at least 12 hours to ventilate the container. Another way to clean the bottle is to fill it to the top with water and then empty it completely.

Potbelly stove from a gas cylinder

Potbelly stove from a gas cylinder

For a vertical stove-stove, the gas cylinder is placed in a standard position for it, the neck is released and the markings are made for the future firebox and blower. The marked pieces are cut out with a grinder. The grate is manufactured separately - for this, the fittings cut to the required dimensions are welded in the places marked on the bottom of the cylinder.

Hinges are welded to the cylinder, on which the doors are hung. Further, the latch is equipped, which are designed to secure and raise the efficiency of the stove. A pipe is welded to the top or side of the cylinder to remove the smoke.

For a horizontal stove-stove, the cylinder is installed on the "legs" sideways. A square hole for the door and a round hole for the chimney pipe are cut in it. Instead of a grate, a number of holes are drilled at the bottom, and a rectangular container for collecting ash is welded below the cylinder. The stove is almost ready, it remains to hang the door with your own hands and install the chimney.

If desired, the complete set of vertical and horizontal stoves from gas cylinders can be expanded with a hob made of a sheet of metal attached from above.

Potbelly stove made of metal sheets

Here are the features of making a stove from metal sheets that use different raw materials for heating: mining and firewood.

Working furnace

To start working with your own hands, a metal sheet of about 5 mm is harvested (it is this width that allows the stove to quickly warm up and effectively heat the garage) and pipes (needed for the chimney and some other elements). For a more accurate understanding of the manufacturing principle, see the drawing: Drawing of a potbelly stove for processing

Drawing of a potbelly stove for processing

Getting started:

- According to the given dimensions, it is necessary to cut out the elements from the sheet, from which the furnace will be made. Try to clean cut edges as much as possible.

- A part is being prepared for attaching the components of the stove - a pipe with holes.

- The parts of the upper tank are prepared for the installation of the chimney. To do this, according to the data shown in the drawing, you need to make a hole offset to the left in relation to the cent. Also, at the bottom of the tank, another hole is made (shifted to the right) - it is intended for installing the connecting pipe.

- The constituent parts are welded to each other and a finished tank is obtained.

- The lower tank is welded in the same way. Only a hole is made to install the pipe in the center. You also need to make another hole with a slight offset - processing will be poured into it. A special sliding cover is made over the filling hole.

- The lower tank is attached to the upper one (they are welded to the connecting pipe). The structure should be strengthened using brackets.

- Do not forget to weld the legs to the lower tank.

- To increase the service life, the oven is cleaned and painted.

You attach a potbelly stove to the chimney and try to heat the garage. To do this, pour fuel into the lower tank and set it on fire. When it has caught fire, the recycling hole needs to be closed with a sliding lid.

Rectangular stove on the wood

Drawing of a rectangular potbelly stove

Drawing of a rectangular potbelly stove

This option is suitable when you need to heat the garage or sauna rooms intended for relaxation.

The features of the model, the manufacture of which we will describe with our own hands, is high heat transfer and the ability to adjust the traction force.

Our oven will measure 45x45x80. These dimensions are enough to heat an average room. Long wood will fit into it and is easy to move.

In this case, we will not give a specific drawing, and will try to explain as much as possible in words. Before starting work, we buy:

- Steel 3-4 mm thick. A sheet one and a half by two meters will be enough.

- A piece of pipe. Choose from a diameter of 90 to 100 mm. Length: 0.4 m.

- Rebar 16 mm. You need exactly 6.2 m.

- Five kilograms of electrodes.

- Four door hinges.

- A rod of steel, half a meter long and about 10 mm in diameter.

- Seven meters of corner with 40 mm shelf. The walls should be 5 mm thick.

When everything you need is prepared, we start working with our own hands in the following sequence:

- Future walls of the structure are cut from the sheets.

- The corner is welded in such a way that a frame is obtained. When performing this and the first point, you need to remember the above dimensions of the stove (45x45x80).

- The reinforcement is cut and welded to the frame at 2 cm intervals.

- The finished frame is scalded with tin.

- Along the diameter of the smooth bar in the section of the pipe that will be the chimney, you need to make 2 holes. The pipe is welded to the frame (before that, you need to make a hole under it).

- A curved bar is inserted into the chimney holes. It should be in the form of a right angle. A piece of tin of a round shape is welded to it, slightly smaller in size than the inner diameter of the chimney - it will be used for adjustment.

- The potbelly stove must have doors. They are cut straight out of the body. Loops are welded onto the removed piece of metal, with which they are attached to the furnace.

- Bolts and handles are installed on the doors, which can be made in any convenient form. The main thing is that they guarantee the maximum fixation of the door (if you do not want to burn the garage).

- When the work is finished, you can check the result of the work with your own hands and start heating the garage.

Why are stove stoves good

To begin with, it would be nice to understand the features and advantages of stove stoves.The main plus is extreme simplicity. If a gas cylinder is available, the assembly can be done in a matter of hours. The main thing is to have a welding machine available, which is impossible to do without. A cylinder, a door, a chimney - and an excellent artisanal heating unit is ready to take the first portions of firewood to give its owners warmth.

Omnivorous - a gas cylinder stove is suitable for burning any type of fuel. It can be firewood, pressed eurowood, wood waste or pellets. Throw into it everything that can ignite and burn - the potbelly stove is undemanding to the quality of the fuel. The main thing is to let her flare up, and only after that you can burn anything in her gut.

Availability - a potbelly stove from a cylinder is extremely cheap. You can use a new bottle for her or get an old one from somewhere. If you live in a rural area where there is no gas main, then there will be no problems with the search. And if you cannot get a cylinder, adapt sheet metal, an old barrel or any other suitable container for a stove.

Other features and advantages of stoves assembled from gas cylinders:

Any life-worn, but in the slightest degree, a whole gas cylinder can be adapted for a potbelly stove.

- Versatility in application - if you need a stove for a bathhouse or in a garage, use a stove-stove. Its production does not take much time, and you will have an excellent heating unit at your disposal;

- A potbelly stove from a cylinder does not need special maintenance - it is only necessary to periodically clean the ash pan and check the condition of the chimney;

- Easy to install - just mount the stove on any suitable base or weld metal legs to it;

- Ease of modernization - a cylinder oven can be made more efficient if you use some technical tricks;

- Relatively high heat transfer - thermal power, depending on the volume of the stove, will be from 2 to 7 kW (heated area from 20 to 70 sq. M);

- A stove from a cylinder is characterized by stable operation in any conditions - you just need to build a decent chimney with a height of at least 3-4 meters;

- Easy self-assembly - if you know how to work with the tool, then after 2-3 hours of work you will have the most efficient stove from a gas cylinder at your disposal;

- Several modifications for consumers' choice - the stove body can be vertical or horizontal, large or small.

There are also some disadvantages. The first of them is an unsightly appearance. But if you make some effort, then you will be able to build a nice compact potbelly stove with good external data. The second drawback is not the highest efficiency. For such units, it is about 70%, but this figure can be improved by implementing the afterburning of combustion products with secondary air.

All the main ways to increase efficiency will be discussed in the corresponding section of our review.

Simple potbelly stove from a can

The simplest do-it-yourself potbelly stove is made from an ordinary can. There is no need to talk about the durability of such a structure, but it is quickly built, easily assembled and gives enough heat.

All work consists in the installation of the legs, the arrangement of the outlet pipe and some cosmetic operations. For work you need:

- Can

- Chimney pipe

- Grate wire

- Welding machine

- Tools

Getting started

- We set the can horizontally and mark where the blower will be, which has the shape of a rectangle or a sickle. Place it under the lid

- A hole is cut in the wall or bottom of the can, equal to the diameter of the chimney pipe

- To make a grate, you need to stock up on steel wire. It is bent, carried through the lid into the inside and gently unbent so that the zigzag is in the desired position, while it remains convenient to lay chips, firewood, etc.

- The can must be fixed on legs that are cut from tubes or corners and welded

- The chimney is welded

A reflector can be mounted on the outside of the tank, thanks to which less heat generated will escape. Having welded the handles from the sides, the structure can be transferred to any other place.

Pros and cons of homemade bourgeois

Among the many advantages of such a nondescript, but useful installation, there are:

- Full autonomy and energy independence

- Work on any solid fuel, including plant residues - this saves a lot of money

- Versatility of the design, which can not only be installed in various rooms, but also used for cooking

- A simple design that you can build yourself from the materials available in the garage

- There is no need to erect a monolithic foundation and install a capital chimney

But despite the significant and numerous advantages, there are a number of disadvantages of bourgeois:

- The high thermal conductivity of the metal leads to rapid fuel burnout and cooling of the furnace

- If the wall thickness is insufficient, they will soon begin to burn out and the furnace will fail.

- You need to watch the combustion process and throw up firewood in time, control the traction

- Tarry and damp logs cause stubborn soot in the chimney

Video - another option for making a furnace

A homemade potbelly stove is a reliable and effective assistant in a cold workroom or your own garage. Its production is not difficult, and there is no need for large material investments to start work.

Good material has been collected in your article. I thought for a long time to buy a finished one or to make it myself, nevertheless I made up my mind, I did it myself. I used a 200-liter barrel of fuels and lubricants as a raw material. I was guided by a detailed drawing that I found on

The design of the stove-stove: features, principle of operation, arrangement of heat exchangers

A potbelly stove with a water circuit works as follows:

- Firewood is loaded into the firebox.

- Fire is kindled, heat is transferred directly to the water tank or the recuperator coil.

- Hot water is supplied to the heating or water supply system.

- Residual heat and combustible gases are removed from the room through the chimney.

- Ashes fall through the grate into the ash pan.

In the design of the unit with a water circuit, two principles of energy collection are used:

-

Direct collection of heat energy. The heat exchanger circuit is located inside the stove. Heat transfer begins immediately from the contact of the open flame and the boiler tubes. The water in the radiator boils and flows into the heating system. From there, it is sent to the water supply pipes. The heat exchanger experiences large temperature differences (contrast between the temperature of the water and the heat inside the oven).

-

Collection of secondary radiation from the heater. The boiler circuit is located outside the heater. Being outside, it collects the secondary thermal radiation from the heated metal surface. The degree of heating of the heat exchanger is lower than in the previous case, the temperature differences are not so significant. The water in the circuit of the device begins to heat up after the stove warms up.

Photo gallery: common types of heat exchangers

Mineral salts are formed inside the boiler. Therefore, instead of water, it is more advisable to use antifreeze or antifreeze, which contain additives that prevent the formation of mineral deposits.

The most common heat exchanger designs:

- a water tank built into the stove - a capacitive boiler;

- a pipe boiler - a tank in the form of a water jacket around a stove or chimney - a capacitive heat exchanger;

- main boilers are a coil spiral or a water conduit passing in the active zone of heat transfer.

Calculation of the main parameters of a potbelly stove with a water circuit

To calculate the dimensions of a stove with a water circuit, a drawing, drawing or sketch of the future device is required. This will help avoid manufacturing errors.

Having chosen a suitable project, we determine the parameters: length, height, width. We consider the dimensions of the combustion compartment, the length and diameter of the pipe, and the height above the floor.

The potbelly stove is characterized by high temperatures inside the boiler, therefore, metal with a thickness of more than 3 mm should be used. Or every 2-3 years to carry out scheduled repairs.

Thick-walled alloy metal is used in the manufacture of potbelly stoves.