What should be the glue

A compound with increased adhesion characteristics is able to glue firmly, the seam of which will be reliable and elastic. Additionally taken into account:

- operating temperature of the glued part;

- indoor humidity;

- the load on the glued surfaces;

- what elastic properties the part should have after gluing;

- chemical aggression towards the treated surfaces.

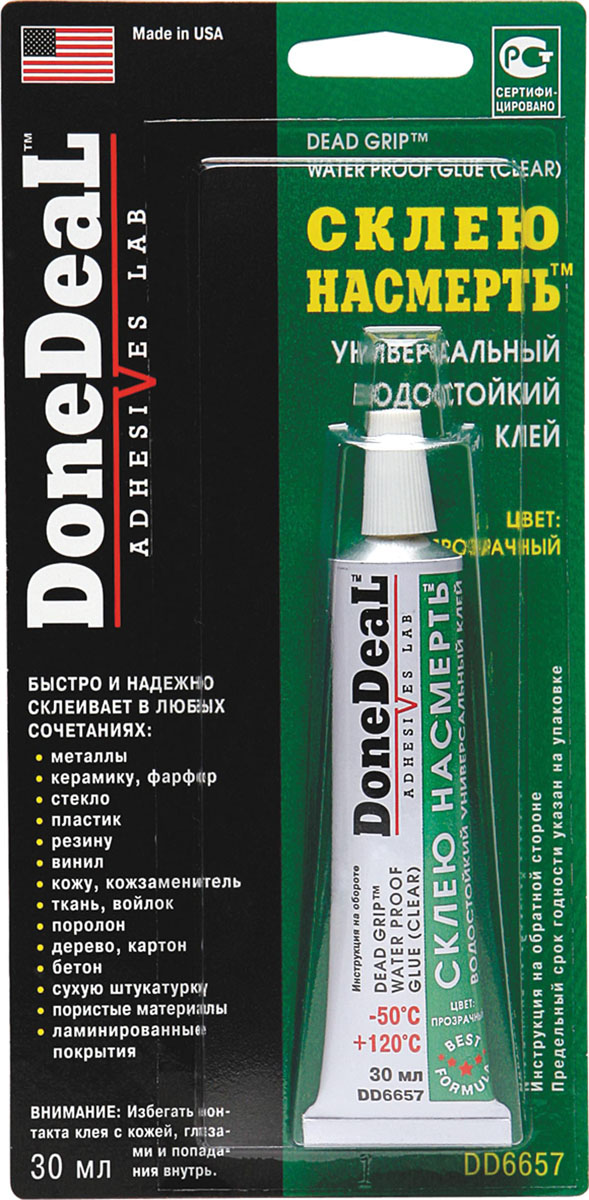

The instructions must be read, the manufacturer must indicate in it that the composition is suitable for rubber, metal alloys. After drying, a high-strength, water-resistant seam should form, retaining strength at low, high temperatures.

For gluing parts in cars, it is worth buying products like "liquid rubber", they create a single plane with the treated surface, which makes the seams visually invisible. When gluing silicone rubber, a mixture is used, the packaging of which says that it is for elastic materials.

What are used as solvents and fillers

Before using the glue, it is necessary to familiarize yourself in more detail with the components from which it is made.

Chlorine compounds

Most rubber mixtures contain chlorine-containing compounds. Manufacturers try to add the minimum amount of such components, as they are characterized by a high level of toxicity. Therefore, when choosing an adhesive for further work, you need to familiarize yourself with its composition and make sure that it does not contain many compounds in which chlorine is present.

v class = 'code-block code-block-12' style = 'margin: 8px 0; clear: both; '>

Eticelate with nephras

Many adhesive liquids are made with the addition of nephras and ethyl acetate. This chemical compound improves the quality of the mixture and increases its adhesion. Therefore, experts recommend using glue containing refined products mixed with acetic acid.

Latex with water content

Latex is added to almost all adhesives. However, this element is added to cheap rubber glue not in pure form, but together with water. The addition of liquid to the latex negatively affects the adhesive properties of the product and makes the connection less reliable. Because of this, such an applied rubber mixture adheres to the surface at times worse.

Resin and polystorole

In adhesives, which are characterized by increased strength, polystyrene with resin is often added. Therefore, in order to more reliably glue the surfaces, it is recommended to use just such means. However, buying glue with too much polystyrene and resin in it is not worth it. A large amount of these components negatively affects the elasticity of the joint.

Sulfur, amines and metal oxides

Adhesive mix firms often add metal oxides, amines and sulfur to them. It is thanks to these substances that the vulcanization process takes place, during which the plastic rubber turns into rubber. The amount of additives directly depends on how much rubber is contained in the glue.

Consistency stabilizers

Some inexpensive adhesives will gel over time and bond less well. Most often, this problem appears if there are no consistency stabilizers in the composition of the product. These include diethylamine or ethanol. These components maintain the liquid consistency of the glue.

Adhesive selection

What glue is better to use, what are the selection criteria? If you need to firmly glue metal to rubber, you should look for a product with enhanced adhesion, which gives a reliable seam, while elastic

It is also important to consider a number of factors:

- humidity and temperature in the rooms where the gluing will be made, and then the operation of the product;

- load on the surfaces to be glued;

- the need for high aesthetic properties of the finished product;

- the degree of chemical aggressiveness of the adhesive, taking into account the type of metal.

When buying, it is important to clarify in the instructions or on the packaging that the manufacturer guarantees the suitability of the composition for rubber and metals, alloys. Universal means are far from always suitable for such a complex joint, as well as for joining other dissimilar materials.

After drying, the seam should not flake off from the base, must be heat-resistant and not change the strength under the action of low temperatures.

For cars, it is often advised to buy products such as "liquid rubber". They can perfectly glue rubber surfaces, as if becoming part of them, therefore they are invisible from the outside. The water resistance of the glue is another important point when choosing; this property is required by almost every user, especially a car owner. If necessary, you can buy glue that will allow you to operate the parts even under water.

When joining rubber and metal, it is important to exclude corrosion, therefore, there is always a note on the safety of the composition on a high-quality glue. A separate type of adhesives is considered to be means for silicone rubber, which is soft, pliable.

On the tube of such glue there is an inscription “for elastic materials”.

The best brands for bonding

How to glue metal or other complex materials to rubber? For this purpose, it is worth purchasing only proven formulations:

- 88CA. Resin glue on organic solvents, contains phenol-formaldehyde resin, nefras, ethyl acetate. Perfectly fits both painted material and concrete, glass, wood, suitable for dissimilar substrates. The composition is waterproof, does not flake off from the action of moisture, after drying it does not give off toxic fumes. Does not interact with metal, therefore does not provoke corrosion.

- U425-3. The properties are similar to those described above, since they have a similar composition. It is used for bonding with subsequent vulcanization, if required.

- 4NB-UV. The glue is oil-resistant, waterproof, but withstands heating only up to +60 degrees, while it is frost-resistant - it is not damaged from freezing to -40 degrees. They can glue rubber, rubber-fabric materials, metal. Such a composition forms a very elastic seam, has a residual stickiness. It is ideal for repairing various rubber products, boats, chemical protection suits.

- Radical. This glue can serve even in sea water, does not deteriorate from the action of salts and alkalis, therefore it is popular among fishermen (it is used to repair any boats).

- The moment is rubber. Suitable for hard and foamed rubber, provides high strength, resistance to water and oils, elasticity of the glue line.

Also, for complex surfaces, adhesives such as Super-NN, Rogneda, Loctite Super Fast are often used. Some users make rubber adhesives on their own in order to save money. To do this, soft rubber is crushed and filled with aviation gasoline to completely cover the mass. After 2-3 days, the liquid is filtered off. After keeping it warm for another couple of days, the glue will be ready.

Popular manufacturers

Choosing the right composition from a wide range of these products can be difficult, but you can follow the advice of professionals.

Pay attention to the porosity of the rubber. The larger it is, the more viscous you will need the glue.

For absolute waterproofness, it is wiser to use a bituminous compound, however, polyurethane is suitable for sealing the joints between the slabs.

To create coatings in natural conditions, it is better to stop your attention on an adhesive base that is resistant to frost and temperature extremes.

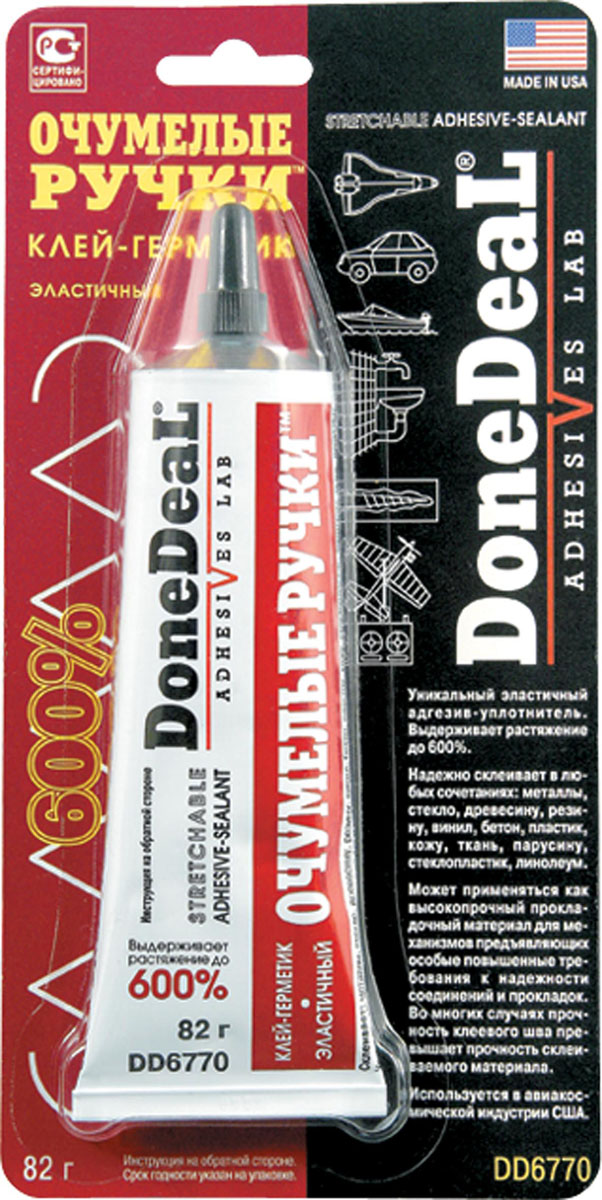

For elastic sports flooring, the shock-absorbing characteristics of the glue are important - these are compositions with a coefficient of elasticity of more than 600%.

For working with natural rubber, only special types of adhesives compatible with this material are suitable.

Several well-known brands offer high-quality adhesive mixtures for crumb rubber products.

-

Domestic chemical company "Avenir", engaged in the development and production of polymer products, including polyurethane types of glue for rubber and other materials. The Avenir trademark is a high quality with unconditional environmental friendliness of polyurethane products, the creation of innovative compositions with increased strength and wear resistance characteristics.

-

A very popular manufacturer of polyurethane binder for rubber crumb is the German company Huntsman, which produces glue with optimal viscosity and good compatibility with various substrates.

-

The Russian company "Yupak Vostok" manufactures, in addition to injury-free rubber tiles, high-quality types of one-component polyurethane adhesive compositions for simple and reliable installation of coatings.

-

The Gambit company is a manufacturer that is constantly improving its products, guaranteeing their high quality. The advantageous features of such a modification as "Gambit M" are well known - the glue makes it possible to obtain seamless monolithic coatings and, moreover, is resistant to low temperatures.

It might not hurt to take a look at some of the certified products sourced from these countries.

Useful Adhesive Tips

In order to glue a rubber product with high quality, it is worth adhering to the main recommendations of specialists:

Individual substances become thick with prolonged storage. To avoid this, it is worth checking the expiration date before purchasing.

Before fixing the elements, it is recommended to clean the surfaces from dust and dirt.

Degreasing of elements and thorough drying are of no small importance.

The adhesion characteristics of the material increase significantly if they are cleaned with emery paper before applying the composition.

First, it is recommended to sand the surface and then degrease. It is best to use a solvent that evaporates easily.

This category includes gasoline and acetone.

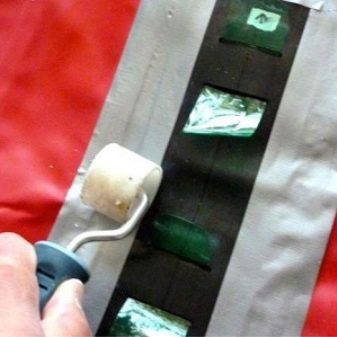

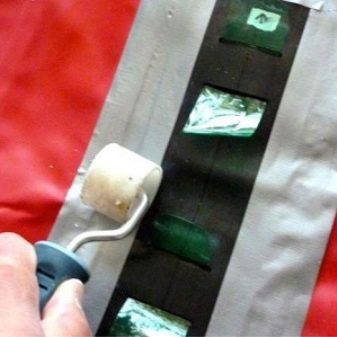

It is recommended to apply the substance with a brush. For a thick mass, a spatula is suitable.

The thickness of the adhesive layer must be at least 2 millimeters.

If stains or excessive amounts of glue appear on the surface of the product, it is recommended to remove it. This is done with a knife or spatula.

It is recommended to keep the area to be glued under pressure for several hours.

Low moisture parameters lead to a slowdown in the drying of the glue. A good composition sets within half an hour. Finally, it solidifies after 2 days. There are many effective rubber adhesives out there today. To achieve good results in fixing products, it is worthwhile to properly prepare the surfaces and strictly adhere to the instructions for applying the substance.

Share link:

Usage Tips

The algorithm of actions specified in the instructions for the adhesive should be strictly observed. A number of funds lose their properties if a person, when using, deviates from the norms that are spelled out in them. To get a really high-quality seam, especially if patches are glued, the surfaces to be glued must be cleaned with coarse-grained emery. After that, they need to be cleaned with acetone or solvent and dried well. So that the load on the adhesive is not so strong, you can pull off large tears before gluing using nylon threads.

For spot repairs, it is best to use a liquid patch. If you need to repair boat accessories, it is better to use one-component adhesives.

If repairs are carried out onshore, then it is better to give preference to road tubes.

In addition, it will be important to observe the temperature regime and use glue for repairing a PVC boat only at temperatures above +15 degrees. Avoid direct sunlight on the adhesive

When applying the adhesive, bends and various kinds of bubbles should be avoided. If you need to glue the places where there are folds, then it is better to entrust this to professionals.

If glue gets on your hands, then it can be removed with acetone or gasoline. It is enough to apply a small amount of them to the area where the adhesive has gotten, and wipe it off with a rag. After that, you need to wash your hands very thoroughly with soap and dry them with a towel.

For information on how to properly use PVC boat glue, see the next video.

Adhesive characteristics

To repair boats made of polyvinyl chloride, you need to use an adhesive composition that is designed for PVC products. In addition, it must have the following characteristics:

- Moisture resistant. Since the operation of the product is carried out in water or repairs can be carried out at high humidity, the glue must withstand the effect of water on it.

- Elasticity. When inflating the pontoons of a boat, the material experiences a high surface tension. Therefore, the adhesive composition must have high elasticity in order to avoid the destruction of the seam.

- Heat resistance. During operation, the boat may be exposed to heat from the sun or other source; therefore, the glue should not soften under the influence of high temperatures.

- Strength. Must have high tensile strength.

- Durability. The glue joint should not lose its strength characteristics after a long period of use.

- Drying time. The short curing time is one of the advantages of the adhesive. This feature is especially important for field repairs.

Advice. Experts recommend installing patches with an air humidity of no more than 60%. Otherwise, at high humidity, the quality of the glue line is significantly reduced.

When gluing the patch on a rubber boat, choose special adhesives that are designed for PVC products. But when working with such substances, you must remember that they are flammable and emit harmful substances for human health. Therefore, all work must be done in a well-ventilated room or outdoors.

Instructions for use

When working with the material, solvent vapors will be released from it, therefore, ensure good ventilation in the room. Some brands of adhesives are quite fluid, it is worth additionally purchasing a thin brush. To improve the adhesion of the surface to the material, all the parts to be glued must first be sandpaper and degreased, remove dirt and dust. Ideal working conditions - the temperature is not lower than +15 degrees, but not higher than +17 degrees.

Hot application instructions:

- apply one layer of the composition, leave for 10 minutes;

- grease the details with a second layer, leave for 30 minutes;

- warm up the surfaces to + 85 ... + 90 degrees using a burner with liquid fuel, press them down (use of open fire is strictly prohibited);

- leave products for 3-5 hours (as indicated on a specific brand of product).

The cold method requires similar preparation - degreasing, removing dirt, wiping dry. Then the material is applied to the surface, left for 10 minutes, after which a second layer is applied. Then the parts are immediately connected and left to dry for a day. There is no need to rush - the quality of adhesion will completely depend on the drying time. It is not necessary to fasten the shoes with a load, the glue will cope with the task without weighing it down.

Views

The distribution of adhesives by type is carried out according to two distinctive features: by the volume of the dry residue and by the composition of the rubber itself.According to GOST, the volume of dry residue can be from 6-8% to 8-12%. Glue, if it contains from 6 to 8% of the dry residue, is known as grade A (more elastic composition), and when the indicator is from 8 to 12%, then it is glue released under the brand B.

The most used classification is according to the characteristics of the rubber contained in it.

The most common types of rubber products are:

- Natural rubber compounds. This substance contains sulfur. This glue is chosen for gluing parts made of cardboard, leather or fabric. Suitable for carpet.

- Chloroprene composition. For the implementation of vulcanization, divalent metal oxides are included in it. The composition is very good in terms of connecting qualities, and therefore it is chosen for gluing metal and other elements.

- Adhesive with the inclusion of nitrile butadiene rubber. Sulfur also acts as a vulcanizing element here, but only with the addition of thiuram. This adhesive is waterproof and is selected for a variety of popular materials.

- Silicone glue. Its hardening occurs only under the influence of tetrabutoxylane. It is rarely used, as it can only glue homogeneous rubber.

- Styrene butadiene adhesive. It has a weak gluing ability and therefore is bought only for production, for example, for the production of scotch tape. Other artificial rubbers can also be the basis of this kind of glue, but their use is limited.

Adhesives for rubber are divided according to their intended purpose: for industrial and home use (for gluing various coatings at home). Industrial glue is used in manufacturing, it is produced in huge volumes, and it is applied to coatings using special tools.

Such compositions are glue 88, 88 H and 88 CA. They are found in the construction industry - for the installation of various finishing surfaces, in the automotive industry - for gluing rubber products, in the production of furniture and any footwear. This product is suitable for gluing rubber and gluing it to metals, paper, wood.

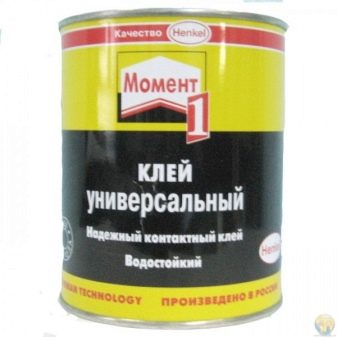

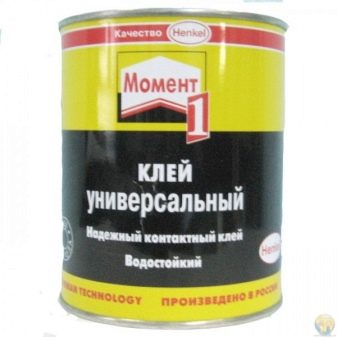

Quick-drying universal glue "Moment-1". It is better to choose it for gluing rubber, wood, metals, leather and felt, plastic and glass, as well as ceramics. This high-strength composition is very toxic and quite flammable, therefore it can be used only in air or in a room that is ventilated, while keeping the composition away from open flame.

It is applied in the thinnest layer on two completely dry elements, which are first of all cleaned and degreased, then they are kept for about 15-20 minutes until completely dry. After that, both surfaces are strongly pressed against each other for only 10-15 seconds.

You can also often find such a type of rubber glue as liquid rubber - a transparent polyurethane glue-paste for repair work, protecting surfaces and their high-quality waterproofing. This composition is distinguished by its resistance to wear and tear, flexibility, it completely fills the existing gaps, and is not afraid of temperature changes.

It is also worth mentioning the rubber adhesive sealant - this is a high-strength adhesive that is needed for high-quality repair of seals in doors and windows. It hardens very quickly, adheres perfectly porous and non-porous materials.

Types of glue used, features, advantages and disadvantages

Based on the numerous observations of experienced anglers, the following types of adhesives have proven themselves well:

PK - 2 glue is ideal for bonding most types of rubber, in particular for repairing PVC products. Advantages: high degree of resistance to water, atmospheric changes, forms a reliable elastic seam.

Glue for PVC fabrics "Master" from a German manufacturer, made on the basis of Desmocoll rubbers, is positioned as a professional universal and waterproof agent."Master" is intended for gluing products from leather, plexiglass, rubber, PVC, paper, cardboard, fibrous fabrics.

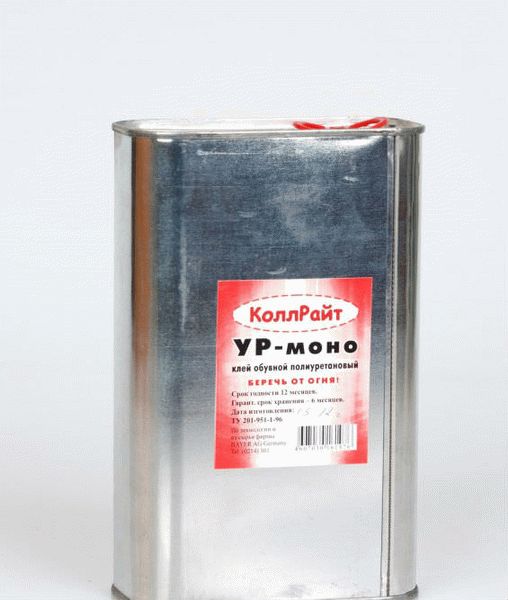

"UR - mono" from the category of one-component compositions, is used without additional hardeners, has a high degree of water resistance, has good resistance to ultraviolet rays, and has low toxicity. Most often, it is used to repair PVC coatings.

"Vinikol - 1520" from a series of polyurethane compounds, the main purpose - gluing surfaces made of synthetic materials, including PVC boats. The product has a fairly high resistance to hydrolysis.

"From polyvinyl chloride 900I" - polyurethane glue, its scope is extensive: balls, plastic awnings, air mattresses, swimming pools, rubber soles, PVC fabrics. The composition has good resistance to various oils, gasoline, water and acids.

Penosil Fix Go is marketed as cold welding, based on two epoxy substances. Advantages: instantly hardens, does not cause difficulties during processing, ideal as an emergency aid for gluing PVC surfaces. Penosil Fix Go has a very strong binding capacity.

"Kernil" is very popular among consumers, the positive qualities of the glue include: super strength, reusable, capable of withstanding loads up to 250 kg / cm2, firmly glues dissimilar surfaces.

How to increase your fish catch?

For 7 years of active fishing enthusiasm, I have found dozens of ways to improve the bite. Here are the most effective ones:

-

Bite activator. This pheromone supplement attracts fish the most in cold and warm water. Discussion of the "Hungry Fish" bite activator.

- Increasing the sensitivity of the tackle. Read the appropriate manuals for your specific tackle type.

- Pheromone-based baits.

Rubber glue Gost

For gluing products from fabric, leather, rubber, cardboard, rubber glue made from natural rubber is often used. According to GOST, it must form an elastic glue seam, leave practically no stains, and does not require degreasing the surfaces.

After applying an even layer of the mixture, after a quarter of an hour, a second layer is applied, and after another couple of minutes the surfaces are pressed tightly and after a day the glue should finally set. The composition is available in containers of various capacities: 1, 50, 100, 200 kilograms.

Natural rubber glue

Rubber glue is superior in strength and quality to instant super glues. It is easy to use, easy to transport and allows for quick repairs.

Advantages of rubber based glue:

- A wide range of processed materials.

- Good elasticity of the glue line.

- Long-term stickiness - the glue retains its adhesive properties for a long time, which is convenient when working with large areas.

- Non-toxic, when drying and under the influence of high temperatures, the glue does not emit substances hazardous to health.

- The adhesive composition is produced ready-to-use.

Rubber glue can be used to hold wood together. Under the influence of moisture in the air, it instantly freezes. In the process of drying, the composition swells and provides a high-quality connection of cellular materials and excellent filling of the glue seam.

It is applied to a wooden surface in small quantities, the products are connected and left for four hours. Work with it should be carried out in a well-ventilated area and away from open flames.

Gasoline with rubber glue

Rubber-based adhesive is a mixture of organic solvents and natural rubber. Gasoline is used for its preparation.

- First, the rubber is cut into small pieces and filled with gasoline, which causes the swelling process.

- Absolute dissolution of rubber is achieved only with the gradual addition of gasoline. As a result, a homogeneous solution should be obtained.

- Before gluing, the surfaces to be treated are well sanded or degreased. To do this, you can use ether, acetone, WFD thinner.

- Then the mixture is evenly applied with a brush. Oiled products are dried for thirty minutes at a temperature of eighteen to twenty degrees, then joined, starting from one edge. This must be done as accurately as possible, since it will not work to peel off the already glued sections and adjust the position of the seam. When processing fabrics and leather, they should be smeared several times, while each layer should be completely dry.

The glue is used when covering heels, gluing a rim, pasting a welted insole with a cloth.

Glue for rubber crumb

In the construction of sports and playgrounds, crumb rubber is often used. Only with its help can you create a safe and durable coating for active sports. The main advantages of the material: high shock absorption and complete elimination of the possibility of sliding.

Polyurethane glue for crumb rubber will help to create such a coating. It allows you to get the perfect surface, which, even during intense sports activities, will remain strong and provide maximum comfort of use.

Manufacturers offer one- and two-component composition for crumb rubber. They differ from each other only in the presence of a hardener. The most commonly used adhesive is one component. A small amount of moisture, which is already present in the air, is sufficient for it to harden.

Glue for rubber crumb

The result is an elastomer that is resistant to any external influences. It is used to create various coatings on sports and playgrounds, walking and jogging tracks, inside medical institutions.

The rough surface guarantees reliable grip under any load and a high level of safety. Before starting work, it is necessary to carry out the necessary calculations in order to accurately determine the price of the mixture for rubber crumb and its quantity. Working with a polyurethane compound requires full compliance with all manufacturer's recommendations.

The glue must meet certain requirements:

- Laying coverings is possible only in warm weather.

- The working temperature ranges from ten to twenty-five degrees.

- The humidity level is not more than 70 percent.

The binder mixture hardens within three to five days, after which the coating is ready for use.

The author of the article is Kristina Sekushina

Instructions for use

To tightly glue a vacuum or other rubber product, you should follow the instructions for use of the substance. It is forbidden to use such a composition in rooms with a temperature of less than +5 degrees.

To increase the efficiency of fixing parts, it is recommended to prepare the surface before applying the adhesive. To do this, they are cleaned of impurities - dust and dirt.

Before applying the composition on the surface, it is recommended to walk with an abrasive material. This increases the adhesion of the elements. To remove foreign objects, use a soft, lint-free cloth. Degreasing agents, such as acetone, are suitable for removing oil or grease stains.

It is worth applying the substance with a brush. If the mixture is very thick, it is recommended to use a spatula. Its shape and width are chosen individually. The layer thickness must be at least 2 millimeters. Usually it is selected taking into account what parts are planned to be fastened. So, to fix rubber shoes or a spoon, 1 millimeter of glue is used. Gauze is laid on top, pressing it with a spatula. This layer acts as a reinforcing element.

After a quarter of an hour, it is recommended to apply a layer of glue again. To improve the connection, all elements should be placed under a press and left for a couple of hours. It is recommended to remove excess adhesive. The maximum gluing efficiency is achieved after 1-2 days.

Moment glue for boats and PVC products

Specifications

-

Type: Glue

-

Works: Outdoor, Indoor

-

Scope: Universal, For wood, For furniture, For windows, For floor

-

Country of origin: Russia

-

Packing: Box

Description

Adhesive for boats and other PVC products is suitable for both professional and DIY repairs. The glue line is transparent. The compound is resistant to water, oil and gasoline. Suitable for gluing in various combinations of soft and hard PVC, rubber, leather, metal, fabric.

Polychloroprene glue

- a one-component compound designed for bonding inflatable boats, wetsuits and rubberized materials. Not particularly suitable for PVC, but without fish, as they say ...

- Waterproof

- Elastic

- High strength

- Quickly sets

- Provides seam durability

- Durable

- Heat resistant

Polyurethane glue

for boats, PVC has the same qualities as polychloroprene, it differs only in transparency and in that it does not turn yellow.

You should not use Moment and similar adhesives when repairing their PVC boat, despite the fact that many advise using them. The tightness and strength of such an adhesive in this situation is questionable. And durability too. But to clean it off from the place of gluing in order to apply a new adhesive composition will be more than problematic. Most likely you will have to glue on it, and this reduces the quality of the patch.

Two-component adhesive for pvc boats Bostik Vinycol 1520 (Bostic Vinycol 1520) is based on polyurethane (with the addition of wax) in an organic solvent.

This PVC adhesive can be applied with a brush and dries quickly. Vulcanized Bostic adhesive for PVC boats is highly resistant to water and moisture. It is just intended for the production of inflatable boats.

How to protect yourself from rain, wind and spray? Making a PVC boat awning

TOP 6 best glue for rubber

There are several factors to consider when choosing the best rubber adhesive for a particular situation:

- Material characteristics (thickness, flexibility)

- Conditions under which gluing will be performed

- Product operating conditions (temperature, load, vibration exposure)

Before working with glue, you must familiarize yourself with the technique of its application. Following the instructions will allow you to get the most out of the adhesive.

Glue 88 (CA, H)

The 88 series of adhesives are available in a variety of media. For a situation in which you want to glue rubber to rubber, grades 88 CA and 88 H are suitable. Rubber glue 88 CA is easy to use for repairs. It is used both in everyday situations and in industrial conditions (construction, automotive, footwear industries) 88 N glue is the most durable rubber glue of all the products in this line, but it requires more exposure time before operation than 88 CA brand.

Advantages of adhesives 88 CA, 88 N:

- large exposure temperature range (from -40 ° C to + 50 ° C);

- water resistance;

- long residual stickiness;

- elasticity of the seam;

- fast adhesion;

- lack of toxic substances.

This rubber adhesive contains a solution of a rubber compound. Makrka 4508 has proven itself well in the repair of shoes, special protection suits, fishing suits, boats. Glues any cameras tightly. At the same time, it does not require hot processing, since vulcanization occurs during the operation of the technical device.

Of the advantages of the 4508 brand, the following are worth highlighting:

- high water resistance;

- increased elasticity;

- vibration resistance;

- good stickiness;

- creating a strong seam (when using hardeners, the seam strength is even higher)

- heat resistance (up to + 50 ° C)

Rubber adhesive grade A

This natural rubber glue is easy to use and is suitable for bonding almost any surface.The neat seam and cleanliness of the surface after gluing allows this glue to be used in decorative and design work. In small repair and construction works it is used as an elastic sealant.

Advantages of using this brand of glue:

- elasticity of the seam;

- resistance to weathering;

- resistance to oily liquids and gasoline;

- does not leave marks on the surface;

- does not require preliminary degreasing;

- dries quickly;

- transparent.

Moment Rubber

This product from the well-known Moment line is suitable for gluing rubber materials of any hardness and porosity (including foamed). Creates a strong and reliable grip that allows you to glue rubber to rubber tightly.

Possesses the following positive characteristics:

- elastic;

- waterproof;

- resistant to a wide range of influencing temperatures (from -30 ° C to + 100 ° C);

- lasting.

Radical is a particularly durable repair agent. In addition to everyday situations, it is used for gluing wetsuits, rubber boats and kayaks.

Pros of using Radical glue in repair:

- glued surfaces withstand high pressure and heavy loads;

- resistant to water (fresh and salt);

- wide range of operating temperatures (from -40 ° C to + 70 ° C).

Each glue has individual characteristics and is different for its application. Therefore, the answer to the question of which glue for rubber is the best is obvious: the one that is selected taking into account the type of product and its operating conditions.

Recommended adhesives

For the repair of inflatable boats, experts and experienced fishermen recommend using several brands of glue, each of which has its own advantages:

1. 4508 is an effective water-resistant adhesive with a high degree of strength. Due to its ability to form an elastic seam, it is used to repair rubber fishing equipment: boats, suits, boots. The glue contains a solution of polyurethane resins.

Attention! Combined use of 4508 glue together with Desmodur and Leikonat hardeners increases the wear resistance of the glued joint several times. 2

Polyurethane glue - professional two-component gluespecially designed for bonding PVC, acrylic, polyurethane, rubberized fabrics used to create awnings, banners, boats. Among the advantages of polyurethane glue, experts note resistance to temperature extremes, water, engine oil, gasoline, and mechanical stress. The use of this glue gives a thin elastic seam of high strength that can last more than 10 years.

2. Polyurethane glue is a professional two-component glue specially designed for gluing PVC, acrylic, polyurethane, rubberized fabrics used to create awnings, banners, boats. Among the advantages of polyurethane glue, experts note resistance to temperature extremes, water, engine oil, gasoline, and mechanical stress. The use of this glue gives a thin elastic seam of high strength that can last for more than 10 years.

3. "Radical" is a universal one-component adhesive capable of reliably gluing polyvinyl chloride, rubber, neoprene and other materials due to the presence of chloroprene rubber and organic resins in the composition.

Glue "Radical" can be used at subzero temperatures. Inflatable boats made of PVC, glued with this glue, can be operated in fresh and salt water, as well as in the temperature range from -60 ° to + 80 ° C, they perfectly withstand mechanical stress and pressure.

4. "Gummi" is a strong one-component adhesive designed for gluing inflatable rubber and rubber-fabric products. The main component of the glue is natural rubber. The seams glued with "Gummy" are water resistant and elastic.

5. 88 N - glue made of rubber used for cold gluing rubber products.The use of 88 NP glue makes it possible to operate an inflatable boat in fresh and salt water, as well as at temperatures from -50 ° to + 70 ° C. The seams obtained as a result of the use of glue are water-resistant, vibration-resistant, mold and mildew resistant.

Attention! According to experts, the best glue for eliminating defects in the hull of an inflatable PVC boat is glue 4508. In its absence, polyurethane glue and Gummi glue showed themselves better than others.