Useful tips when changing the lock cylinder

Difficulty in replacing the larva may arise if the fixing screw gets into the hole of the larva. To avoid complications and difficulties, you should keep the fastening screw strictly perpendicular to the end of the door, slowly and carefully insert the screw into the hole until it stops, then slowly scrolling it clockwise and slightly stirring the larva itself, get into the hole and tighten the speckle bolt.

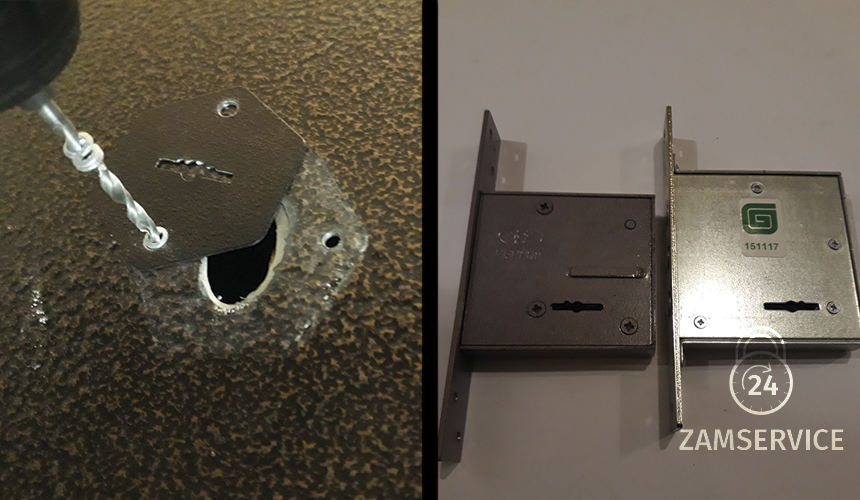

Another important point when replacing the lock is some mismatch in size.

Here you will either have to buy an identical lock, or work with a drill and a chisel, adjusting the installation place for the lock.

It is very important to ensure that the larva does not fall into the door, because it can be problematic to get it out of there, and sometimes it is completely impossible without removing the lock.

The screw should not be tightened too tightly, as the thread could be ripped off. You can tighten it like this: when the screw head is level with the metal bar of the lock, you need to turn the screw another 1.5-2.5 turns in order to securely fix the larva in the lock.

When removing the door handles, make sure that the rubber seal is not lost and that the handles are not confused in places.

A common mistake is misalignment when installing the larva.

In this case, the lock may not work properly. When installing the larva, you need to ensure that there is no distortion.

When opening the lock cover, sometimes you have to deal with rusted screws. To unscrew them, you need to lubricate them with penetrating grease, which is sold in cans.

After all the work on replacing the cylinder has been completed, check the functionality of the lock with the door open! Does the handle of the lock work, is the lock opened from the inside and with a key from the outside? Only after making sure that the lock works with the door open can you test it with the door closed! At the same time, the lock is freely and easily unlocked and locked, the locking tabs easily move in their grooves, the lock works without extraneous sounds, the key can be easily inserted and removed.

- Lubricate the lock (with any lubricant suitable for mechanisms) to prolong its life and prevent rust. You can also grease the larva. To do this, you need to drop a few drops of oil on the key and, after inserting it into the larva, turn it 3-6 times, then wipe it with a soft cloth.

- If previously there was a larva with turnkey slots from the inside and outside (a key was required to close or open the door from the inside), then you can install a larva with a "spinner", which is very convenient when unlocking and locking the lock from the inside.

- In place of a lock without a larva, you can put a lock with a larva. This will save you time and money in the future, because replacing the larva is faster and cheaper than replacing the whole lock.

FAQ:

Question: where to buy a maggot?

Answer: A maggot can be purchased at a hardware store, but the choice of maggots there may be limited. You can also order it online in the required sizes and models.

Question: which larva is better?

Answer: the larvae differ in the degree of reliability and secrecy of the key. It is better to choose a cylinder with perforated keys. It costs more, but its reliability is higher than that of ordinary larvae.

Question: After replacing the larva, the key is difficult to turn. What to do?

Answer: it is possible that the fastening screws were tightened too much when installing the larva. You can try to loosen them up a bit. If it does not help, then try to install the larva with the other side.

Replacing the lock cylinder is an important and responsible process that requires certain skills and knowledge, which are presented in this article. Correct use and care of the lock and keys will significantly extend their service life.

What tools may be needed to repair a door lock

This procedure requires the preparation of the appropriate tools. The set of these devices may differ depending on the nature of the breakdown. To repair the locking mechanism of entrance and interior linens, the following are most often used:

To fix the lock, the following are used: milling cutter, hammer, chisel, screwdriver, drills, screwdrivers, tape measure

- milling cutter (manual);

- hammer;

- chisel;

- screwdriver.

- set of drills;

- screwdrivers;

- yardstick.

A manual router is used when it is required to replace a mortise door lock. This tool allows you to make accurate sampling in a wood panel. When replacing the device, you can do without a router, but this will affect the quality of work. This device does not damage the decorative cover of the sash.

A hammer is necessary in case of unprofessional installation of the locking mechanism. The chisel is used to organize a niche in which the castle will be located. A screwdriver can be replaced with a drill, but the presence of such tools is a prerequisite. With the help of a screwdriver, the mechanism is dismantled, the opening for the door handle is organized, and the new device is fixed.

Repair of a door lock of a metal door (or any other) is carried out exclusively with the help of a step-by-step guide. To do this, you will also need to prepare Phillips and flathead screwdrivers, a set of drills and a measuring tape. Among other things, when cleaning the locking mechanism, you may need white spirit, as well as machine oil.

You will need a special tool to remove the broken key.

How to determine if it is possible to change the larva in a particular castle

The larva can be changed on all types of cylinder mortise locks (the body of the lock is hidden in the door leaf) and on some overhead locks (the body of the lock is attached to the door from the inside).

Determining whether it is possible to change the larva in the castle is quite simple. To do this, you need to look at the key to it. If the key is flat with cuts and notches, semicircular with cuts, cruciform - then replacement of the larva is possible.

If the key is round with two notched blades, then replacement of the larva is impossible. Locks with keys of this type are called suvadal.

Locks with such keys do not have larvae; locks with other types of keys usually have larvae.

Locks with such keys do not have larvae; locks with other types of keys usually have larvae.

If the lock is mortise, then it is necessary to inspect the end of the door, the metal bar where the locking tabs are extended. For locks with a removable cylinder, under the locking tabs, you can see the screw head for a Phillips screwdriver, less often under a flat one. This is the screw that secures the larva. If there is such a screw, then the larva can be changed.

If the lock is invoiced, then most often the larva can only be replaced with the lock. However, on some types of overhead locks, replacement of only the larva is possible. These are such locks as SHO-25, which was very popular in the 90s. You can understand for sure only by removing the lock from the door.

In an overhead lock, a possible option is to replace the entire lock, or to install a mortise cylinder lock with a larva instead.

It may turn out that the lock does not provide for the replacement of the larva. This happens with other types of locks, without a replaceable larva. It can be either a mortise or an overhead lock. In this case, an alternative solution is to completely reinstall the lock.

Abnormal situations and common mistakes

In the process of replacing the key core, people may encounter abnormal situations.

Boiling the fixing screw

Owners of private houses, whose front door is on the street, are often faced with the boiling of the fastening screw. This problem appears due to the ingress of water into the castle. To unscrew such a fastener, you will have to pre-treat it with turpentine or kerosene. The lock is filled with liquid and left for an hour and a half. Then you can try to unscrew the screw. If this does not help, it is poured with sulfuric acid mixed with zinc.

Broken key in the lock

If the key breaks inside the keyhole, it will not be easy to open the door. When the broken part of the key sticks out, it can be grasped with pliers and pulled out. However, sometimes the key breaks inside and it is not possible to get it with the pliers. In this case, you will have to completely unscrew the lock and change it to a new one.

Popular models of locks by type of mechanism

The most popular locks for metal entrance doors are cylinder and lever locks. Disc, rack and pinion, cruciform and other types are less commonly used.

The Ministry of Internal Affairs of Russia recommends using two different types of locks. They require different hacking methods, so it will take longer for intruders to break into the house. In addition, the chances are increased that thieves will not want to tinker with such an apartment at all.

Most often, locks with cylinder and lever mechanisms are installed in modern metal doors.

Cylinder - locks, the design of which consists of a cylinder with a cylinder and a system of pins and springs. The key to such a lock has a flat shape with notches and notches.

This is not only the most popular class of locks, but also the easiest and most convenient in terms of self-repair. Due to the design feature - the presence of a removable cylinder - a complete replacement of the entrance door cylinder lock is not required in most cases.

If you just need to change the secret, and the mechanism itself is working normally, then replacing the entrance door lock core will be the best solution. It is also not necessary that the cylinder and the lock were produced by the same manufacturer, the main thing is their clear coincidence in size. If you have to replace the lock cylinder in a metal door, the video will facilitate this task and make it feasible even for a beginner.

The lever lock is distinguished by a more complex secret mechanism, which consists of a package of plates with figured cutouts (levers).

The key to such a lock is in the form of a long round rod with one or two plates at the end. Repair and replacement of the lock of the front door of the apartment in this case is quite specific, and an amateur is unlikely to cope here. In such a situation, it is better to turn to professionals.

When to change the lock

It is not always possible to understand that the valve needs repair. It would seem that there is no visual evidence of a breakdown, and there is no need for repairs, but suddenly, suddenly, the lock becomes unusable.

Signs that can signal that the lock in a metal door needs repair are: purchase and installation of a new door leaf.

As a rule, a store door is sold without a locking mechanism. It must be selected separately. You can use the services of specialists who will quickly and efficiently select and install the lock without any problems.

However, wanting to save money, it is better to study the intricacies of this work and carry it out on your own; keys are lost. There is no such person who would never lose the keys to the house. Even if there is a duplicate, there is always a high probability that the found key can be used by intruders.

Therefore, the best option to fix this unpleasant situation is to change the lock; minor breakdowns of the locking mechanism. Even in the best, most expensive and high-quality lock, parts and functional elements wear out over time. They can be replaced individually.

But you always need to weigh the material benefits from repairing one part and replacing the entire lock. There are times when it is easier and cheaper to install a new locking mechanism than to repair an old one; replacing a lock in a metal door, which does not meet high reliability indicators. Unfortunately, it is not always the first time, it turns out, to choose and install a really reliable and durable lock on the door.

Already during operation, defects in work begin to appear, which interfere with the normal operation of the mechanism. It is better to change such a locking device to a more perfect and reliable model; the consequences of breaking.

Installing a new lock is a must if intruders entered your apartment or house.

buying a new house or apartment. You cannot be sure that when giving you the keys to the house, the old owners will not leave a duplicate for themselves. The first thing to do after moving into a new house is to change the locks.

If at least one of the listed reasons takes place, then the replacement of the lock on the entrance metal door should be carried out as soon as possible.

Why do door locks break

There are many different reasons why the lock breaks, but one of the main ones is the use of soft metals and alloys. Sometimes manufacturers use soft steel grades, copper and aluminum alloys, which can be used in the manufacture of the internal device of the lock. The main reasons for door locks breakage:

- Deformation of a door or doorway.

- Operation of the lock in conditions of high humidity or high levels of dust, which leads to oxidation or dusting of the mechanism.

- Failure of the lock mechanism and wear of the mechanism elements.

Let's study how negative external conditions affect the performance of the lock.

Doors and doorways made of PVC, aluminum and wood deform over time. Even a slight change in the geometry of the door can cause the striker to move relative to the striker. The device of the mechanism for moving the locking fittings is not intended to overcome the friction that occurs when the bolt or latch bolt interacts with the striker. For this reason, an additional load arises, which lays down on the entire mechanism and causes breakdown of the mechanism.

For this reason, breakage of crossbars and latch latches is much less common for this reason.

The use of door locks in rooms with a high level of dust, together with lack of maintenance and lubrication at the specified time, begins to experience increased internal resistance in those parts that are subject to increased loads.The door lock can break if this problem is ignored. This problem is especially acute when used when a multi-point lock is installed on the door. Rust usually affects door locks operating in high humidity conditions. Oxidation of parts of the mechanism under constant stress can cause great inconvenience during operation. Only preventive maintenance of the door lock can be a solution to the problem of oxidation of the mechanism. Prevention of lock breakage is very important, but it is not a panacea for breakage. The constant loads that the lock is experiencing are also the cause of breakdowns. A door lock can last a long time if breakdown prevention and timely replacement of parts are carried out in time.

The worst case

The worst case is for someone who detects a breakdown, being outside and not being able to prepare for replacement. First you need to try to get inside by alternative routes (for example, through a window) and try to open the entrance from the inside. If this is not possible, you will have to drill out the larva. The drill can be borrowed from neighbors or rented at the nearest rental, because before changing the cylinder in the door lock, it must be removed from there.A drill for metal is placed in the drill, it is oriented according to the location of the flag, and a hole is drilled to the middle of the lock. A screwdriver is inserted into the hole, which turns the flag. When the door is open, the fixing bolt is screwed on and the larva is pushed out of the nest. Then everything is according to the above: a new cylinder is bought and installed in the place of the old one.

Tools and preparatory work

If you decide to independently replace the lock in the iron door, then first you need to prepare all the tools:

- hammer;

- electric drill;

- chisel.

In the process of work, you will need devices

It will not be possible to do without these devices when the mechanism needs to be replaced if the keys are lost, because the core will have to be removed.

You should carefully choose the details for the lock - they should fit the existing model perfectly (it is advisable to choose products of the same brand, and then you can not worry, because all the elements will fit perfectly into the device).

In the case of buying a new castle, it is necessary to schematically display the following measurements:

- hole for the base (not present if the rack and pinion was previously fixed);

- the diameter of the holes for the handle and the lock, as well as the gap between them;

- the gap between the mounting holes;

- the gap between the outer edge of the bar and the cylinder (depends on the design of the mechanism).

It is recommended to take measurements before installing the lock

Types of castle larvae

"Sekretki" on locks of various designs have different shapes and devices. Therefore, first of all, you need to determine the type of lock. Here is a list of the most common and common types of locks.

Cylinder. A very popular type of locking device

It is difficult to burglary, which is important for ensuring the safety of property. Experts distinguish several types of cylinder locks:

key-key;

spinner key;

gear;

half-cylinder.

Disk

The rotary discs play the role of an identifying device when unlocking. It is rather difficult to find a related cylinder. Most often, the larva in such locks cannot be replaced. Completely change the castle.

Pin. Rare, but still existing locking mechanisms of the English system. It is believed that pin locks are inferior to cylinder locks in terms of reliability. However, perforated systems have been used quite successfully.

Cruciform. Not the most secure type of lock. Experienced burglars open it with a Phillips screwdriver of the right size. Nevertheless, at the end of the last century, this type of locking device was very popular. Many still serve today. It is quite difficult to change the larva in such a castle. To do this, you must completely disassemble its body. Most often, in the event of an emergency situation, the lock is changed entirely.

Complex locks. This group includes devices with a special degree of protection. As a rule, their maintenance is carried out by the specialists of the manufacturers. Therefore, it is more advisable to entrust the replacement of larvae and secrets, of which there may be several, to professionals.

It is also pertinent to note that according to the type of fastening, locks are classified into mortise, hinged and overhead. This must be taken into account when choosing a new larva, since the fastening is different for everyone. Padlocks cannot be disassembled, replacement of the larva is possible only in a workshop. Most mortise locks for household use are designed in such a way that access to the larva is possible without disassembling the case. In overhead structures, for replacement, it is necessary to remove the lock from the door.

How to choose a new lock cylinder

The best way to find a new "secret" is to unscrew the old one and purchase an exact copy of it in the store. If the lock is made by a large industrial company, then it must be marked on it. Sales personnel are usually well versed in the pictograms and symbols that represent the product number.Consultants or managers will help you find an identical or compatible bot for any lock.

If there is no opportunity to take the "secret" to the store, you need:

- Remove the larva from the castle, photograph in several projections and put in place.

-

Measure the length, thickness, and distance to the pusher tongue from the edges of the device. Another "floating" parameter is the location of the fixing hole. If the threaded hole is in the wrong place, the cylinder will not be able to fix correctly.

In addition to the size, when choosing, the material and color of the larva are taken into account. Copper or steel cores last much longer than brass or duralumin cores, but they are, of course, more expensive. The color is matched to the overall range of interior solutions.

According to the author, a core made of stainless steel can be considered the best option. This material has practically no restrictions on the duration of operation, looks great on doors and withstands burglary attempts very well. The price of an iron cylinder is lower than that of a copper one, and the surface coating (nickel or chromium) protects the mechanism from corrosion.

Standard procedure scheme

Before changing the core, be sure to study the features of the procedure.

For mortise cylinder locks

There are two types of mortise locks in which you have to change the larva.

With handles

If you need to replace the core of a lock with padded handles, you will first have to get rid of the fasteners. This is done to provide access to the lock cylinder. Then the fastening bolts installed inside are unscrewed, and the structure is removed. After removing the old lock, a new core is installed in the vacant place. It must be installed in such a way that the fixing screw falls into the fastening cavity of the lock. At the same time, it must hit perfectly, without distortions.

Without handles

Some locks are not equipped with additional patch handles. It is much more convenient to work with them, since you do not have to waste time removing the linings. You can immediately unscrew the larva and get it out of the keyhole inside the door.

The new larva is placed in place of the old one, after which the fastening bolt is fixed. It is screwed in all the way so that the structure does not dangle during use. After installing the core, they check the functionality of the lock. The key should turn right and left without difficulty.

For invoices

In some doors, not mortise, but overhead devices are used. To change them, first unscrew the four mounting screws. Then the back cover is removed, which is attached to the door surface with three screws. After that, the screws responsible for fixing the larva are unscrewed.

When they are unscrewed, the core is carefully pulled out of the lock structure. In its place, a new part is installed, which is screwed and covered with a lid.

After assembling the structure, check its performance.

With cross key

Cruciform models are used less often than others, since they quickly break. Replacing their core is carried out in several successive stages:

- Removing the lock strips. To do this, unscrew the fastening screws located at the back.

- Removing the housing cover. To get rid of it, twist the screws on the outside of the mechanism.

- Extracting the larva. There are screws under the case cover that fix the key core.

Installing a new part is carried out upside-down.

Stages of installing a new lever lock on a metal door

Before installing a new lock, you must dismantle the old one.

For this:

-Open the metal door and then open the lever lock to the end, that is, the crossbars should be pushed in as much as possible;

-Remove the key from the keyhole;

-We dismantle the door handles, armored cover plate and bolt;

-Unscrew the screws in the end part of the locking system;

- We gradually remove the entire mechanism. For convenience, the lock is pushed under the end plate;

-We buy a new lever lock and install it, performing all the steps in the reverse order. For better operation, experts recommend choosing a lock of the same design or at least the same manufacturer.

Replacing a metal door lever lock is not difficult, but it takes a lot of time and requires diligence.

Features of replacing a disc lock for a metal door

Disc locking systems are distinguished by a high degree of protection not only against burglary with a master key, but also against forceful burglary with the help of drilling.

In addition, disk locks are less likely to clog up with dust, are protected from moisture penetration, are not afraid of low temperatures and have a long service life.

Replacing the disk lock is not difficult, especially if the structure is made by a foreign manufacturer.

The problem with domestic disk-type locking systems is that their repair is not always advisable.

Therefore, in the event of a malfunction in the operation of a domestic lock, it is recommended to replace it with a new lock.

If the disk lock is made by foreign manufacturers, then if it breaks down, it makes sense to find the cause and eliminate it.

It is quite possible that for the disk lock to work well, it will be enough to replace its cylinder.

If the disc lock does not open well, then perhaps the reason is the lack of lubrication in the internal mechanism.

If the lubricant does not help, then it must be removed for diagnosis. To do this, it is enough to unscrew the end screw, and then remove the patch lock using a key.

Disk lock device

Then we unscrew 2 more screws that secure the disk and remove it.

After purchasing a new disk of the same size, it is installed in the lock, performing all the steps in the reverse order.

As practice shows, it is possible to avoid problems with locking systems and at the same time provide reliable protection for housing, if not to save on the purchase of high-quality mechanisms.

A high-quality lock does not guarantee a complete absence of breakdowns, but it will make them a rare and easily solvable phenomenon.