Features of choosing a washing machine

There are several features of the choice of washing machines, which it is recommended to familiarize yourself with in advance

When choosing a technique for washing clothes, pay attention to the following:

The size

This is the main parameter that people pay attention to in the first place. The choice of the dimensions of the washing machine directly depends on the size of the bathroom

If the room is small, it is better to purchase more compact models.

Boot type. Washing machines differ from each other in the type of load. Frontal models are popular, which have a special door in front for loading and unloading clothes. Among the advantages of front-type washing machines are their compactness and ease of integration into furniture.

Power consumption level. Washing equipment models may differ from each other in terms of power consumption. Economical equipment has class A +.

Roominess. An important parameter is the capacity of the vehicle. If you often have to wash a lot of things, it is better to purchase a spacious washing machine with a volume of 10-15 kilograms.

Drying. It is recommended to buy models that are equipped with an additional drying function. This is a useful function, thanks to which the washed clothes dry many times faster.

Wall-mounted sink without support: how to fix it?

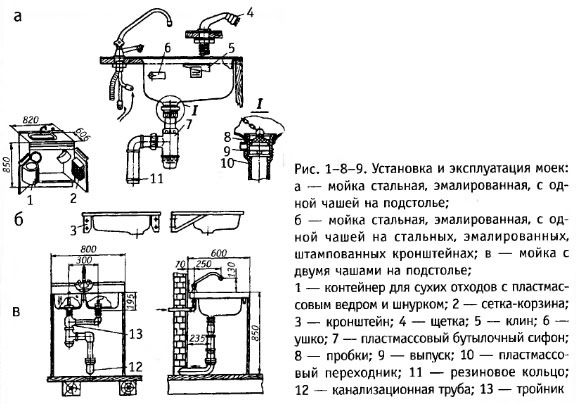

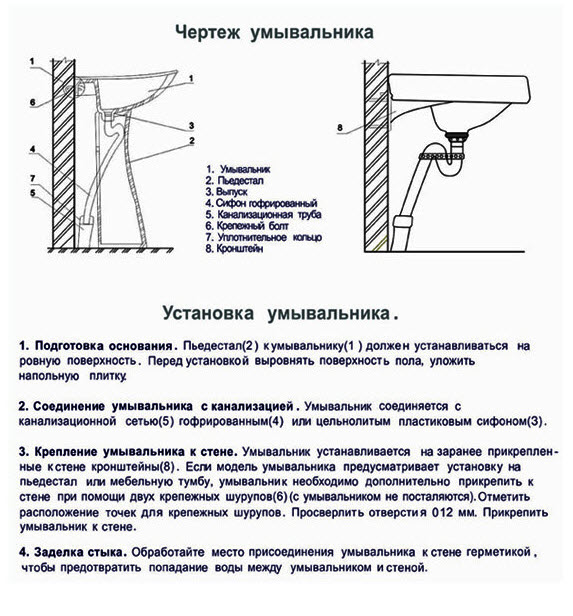

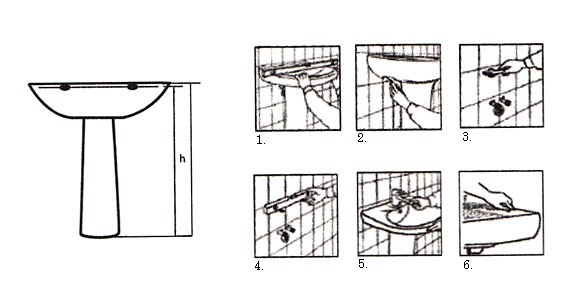

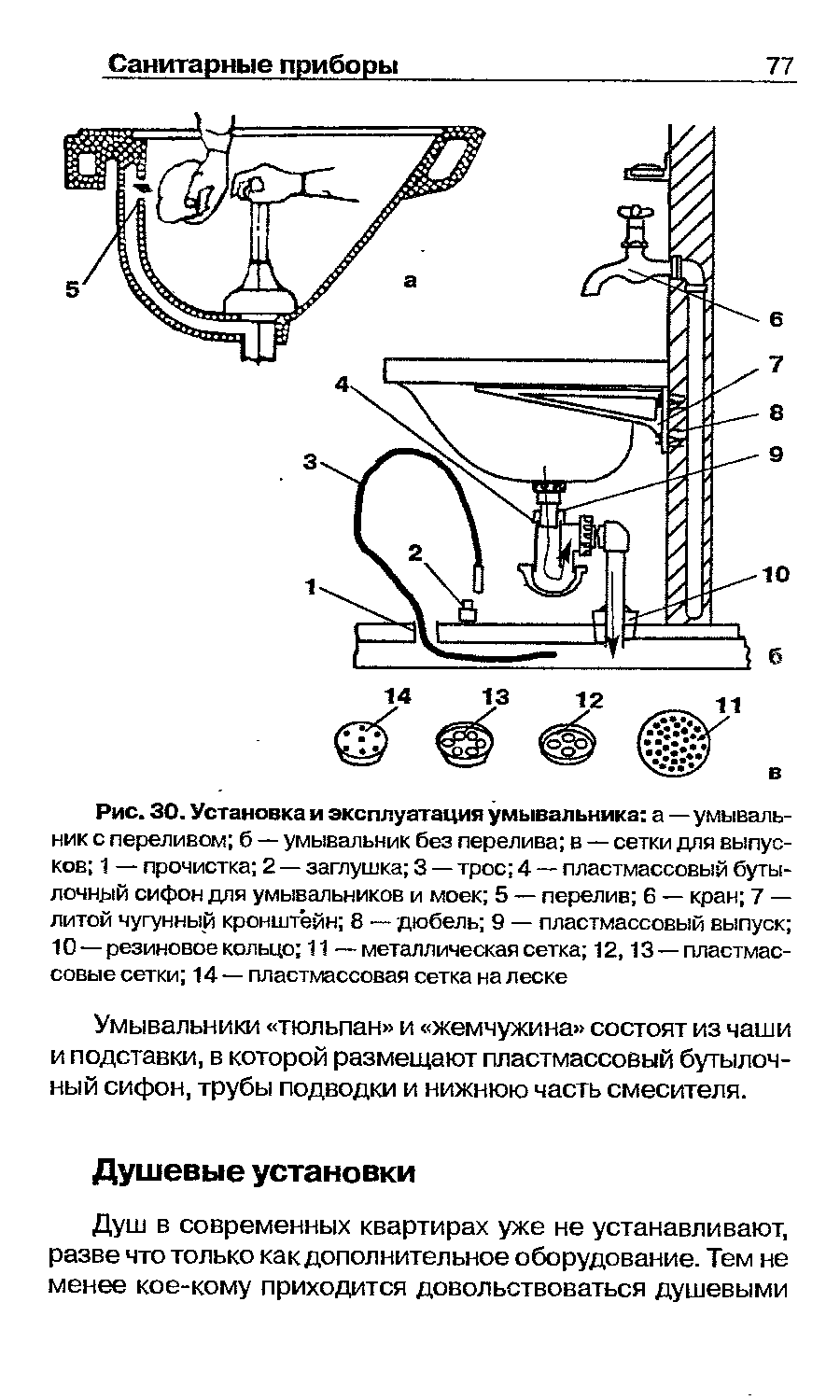

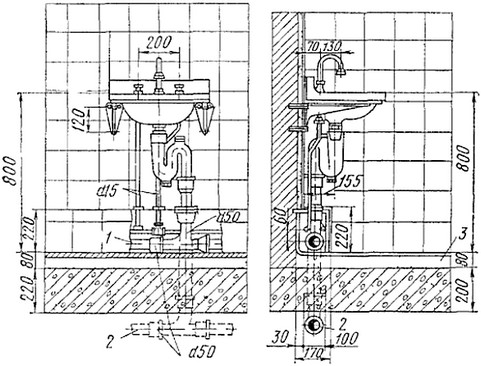

In the absence of a leg, the sink mount will experience dynamic loads, so two pins cannot be dispensed with here. Install the water lily on special brackets. It can be either the simplest steel corners or fanciful chrome-plated brackets. There is a variety of sinks with two round channels inside the sides, with which the bowl is put on two pipes, rigidly fixed to the wall.

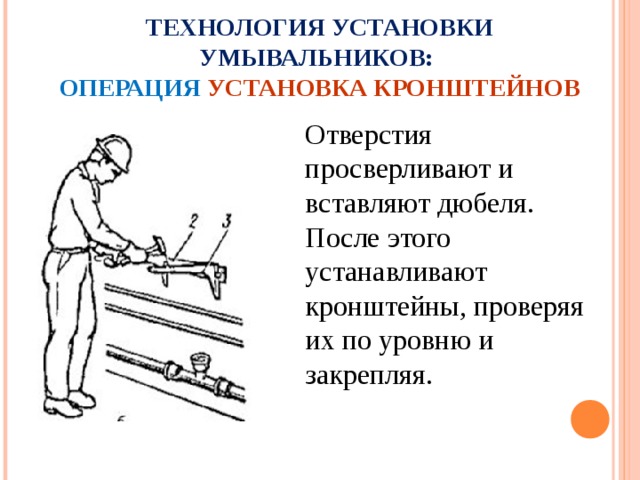

Again, the main difficulty of the installation comes down to determining the installation height. After carefully measuring the tailgate, you need to transfer the markings to the wall and place the brackets on it. The easiest way to mark the centers of the holes is "live" by attaching the bracket to the wall in its normal working position.

The most advantageous mounting technique is to first fix both brackets to one point, then check the horizontal level of the installation with a rack level. The initial fastening is carried out in the oval-shaped adjustment holes. After the horizontal position is confirmed, the main fasteners are marked, the brackets are rotated or removed slightly to allow access for drilling, and then the installation is completed.

Please note that if there are voids behind the wall cladding, the fastening must be carried out into its load-bearing layer. Therefore, when finishing the bathroom, it is necessary to provide for mortgages in the frame, which will not allow the wall to "leave" under the influence of the clamping force of the fasteners

Preparatory work

When equipping the restroom with plumbing, special attention must be paid to the choice of the size of the sink. Preference should be given to compact products that have an aesthetic appearance.

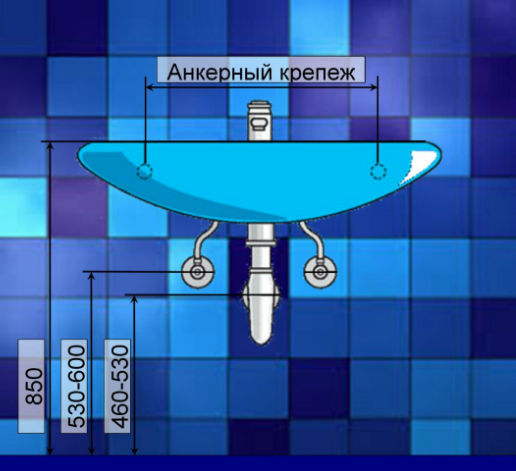

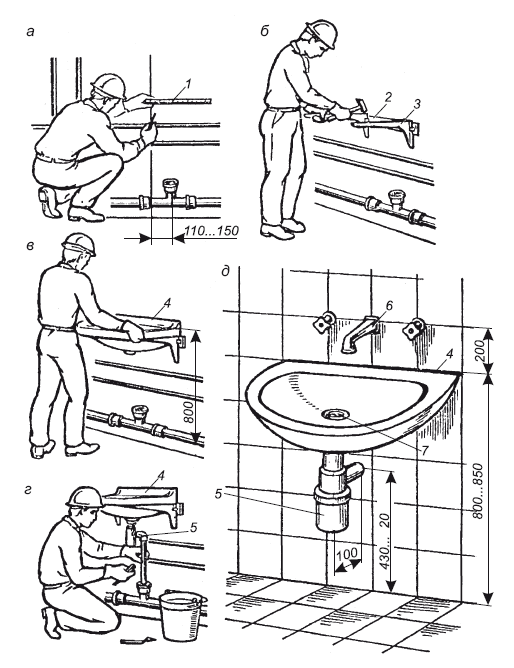

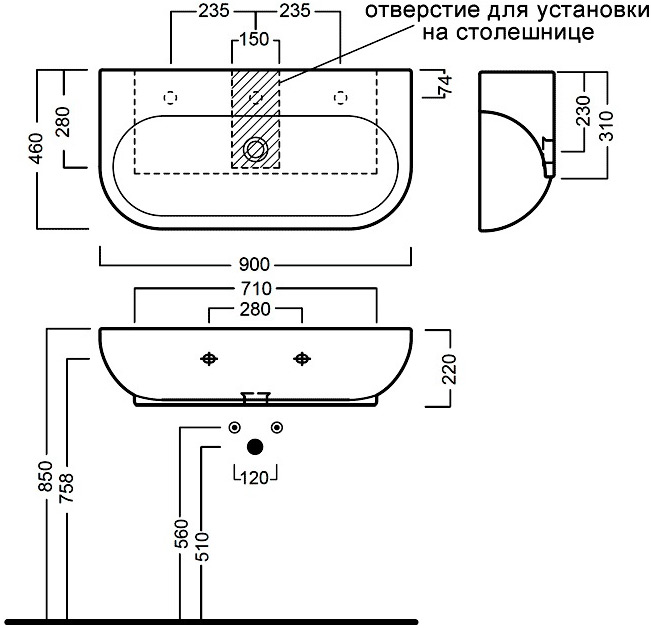

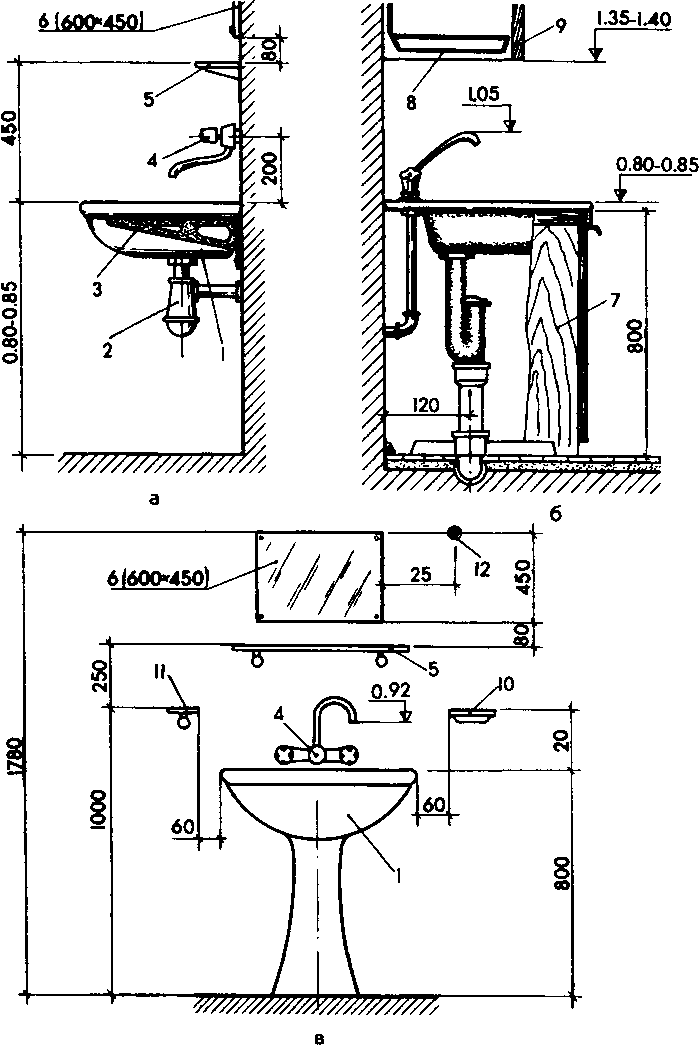

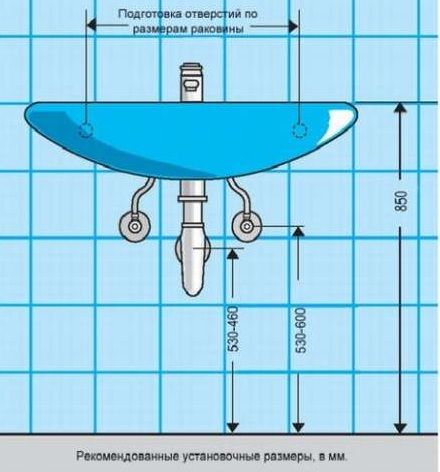

However, it is important that the dimensions of the device allow covering the spray spectrum of the water flow. The optimal size of the sink is 65 cm, and the height of the appliance from the floor to the surface of the bowl is at least 80 cm

The optimal size of the sink is 65 cm, and the height of the appliance from the floor to the surface of the bowl is at least 80 cm.

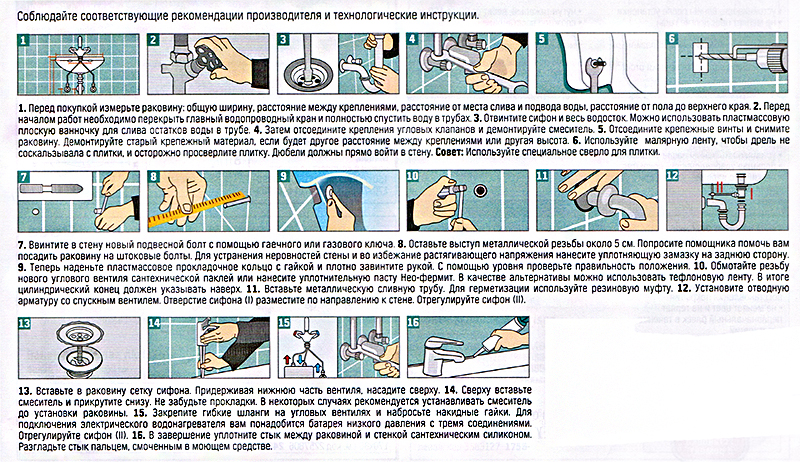

The installation of the sink begins with the preparatory work in the room.

There are three main stages:

- shutdown of the water supply riser;

- determination of the height of the sink attachment;

- preliminary fitting of the product and selection of a permanent location.

Wall-mounted washbasins are usually installed without touching the floor. Therefore, when determining the site for fixing the washbasin, it should be possible to connect it to the water supply and drainage communications.

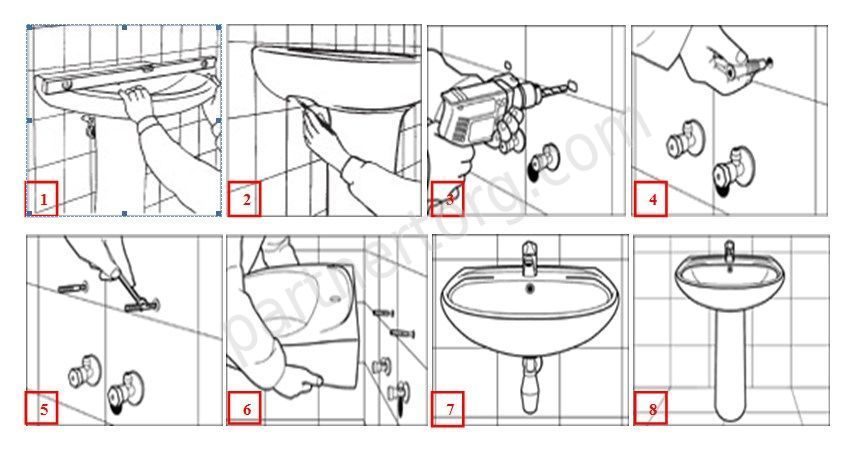

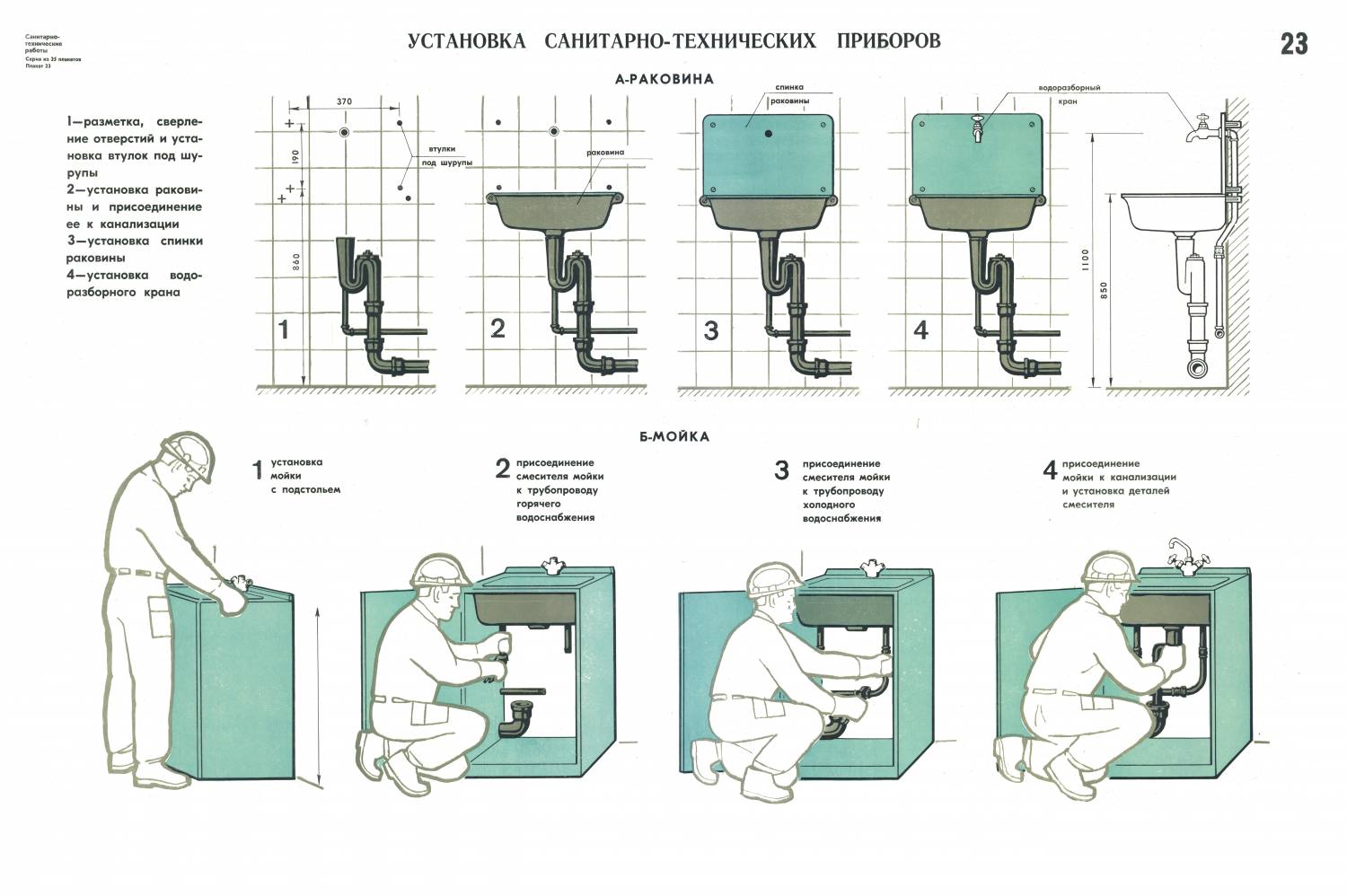

Step-by-step sink installation

installing a sink in the bathroom

installing a sink in the bathroom

Do-it-yourself sink installation includes:

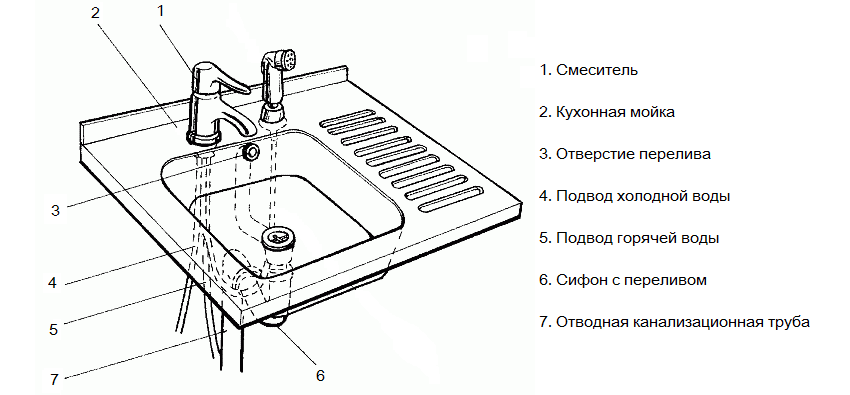

- Preliminary stage. For the work to be successful, the sink model must be docked with taps designed to supply water, both cold and hot, as well as connected to the sewer.

-

Decide on the location of the sink. Recommended dimensions of free space, which are: width - 70 cm, height from the floor - 80 cm, depth - 110 cm.

- It is required to shut off the water supply.

- Dismantle the old sink.

- Marker should mark the places where the brackets will be installed, intended for attaching the sink.

- Drill holes, the diameter of which should be slightly smaller than the diameter of the dowel screws required for fixing the brackets.

- The dowel screws must be screwed into the wall and the brackets must be hung.

- Install the sink and secure it.

- Connect a flexible hot and cold water supply to the sink.

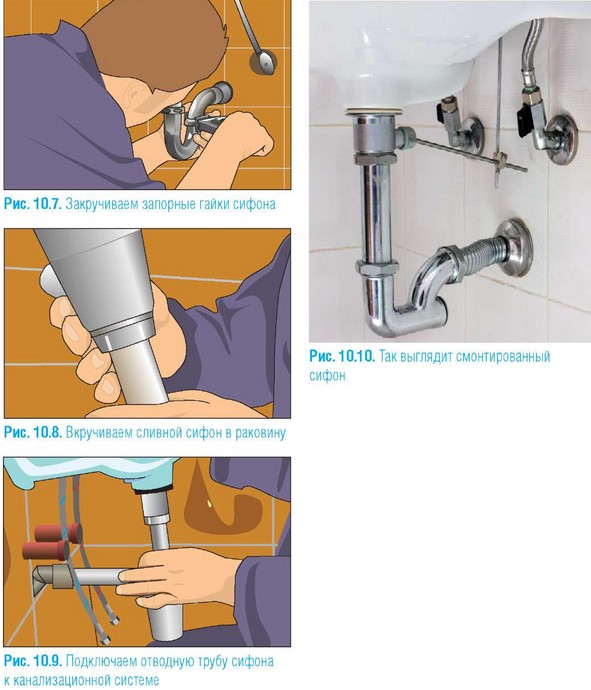

- Connect the siphon to the sewer pipe using a special branch pipe, usually corrugated.

- Check the tightness of the connections. For these purposes, you need to turn on the water and check the reliability of all connections.

How to connect the sink to the water supply

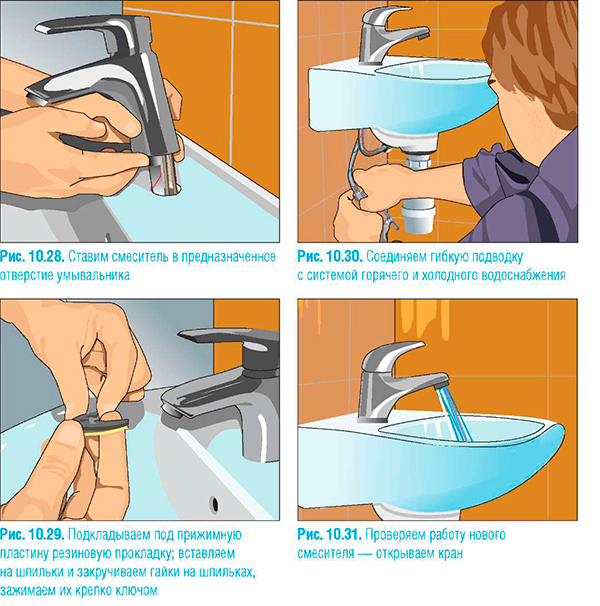

First you need to mount the mixer and it is more convenient to do this before the sink is already fixed to the wall - all the elements of the mixer must be located under the sink. How to connect a mixer:

There is a hairpin in the mixer kit - you need to screw it in.

We connect the hose for hot / cold water

We tighten the hoses with an open-end wrench, but here it is important not to overdo it - it is very easy to rip off a shallow thread, after which you will have to buy a new mixer.

The mixer is installed on the sink.

On the back of the mixer, attach the fixing pins, gaskets and a pressure washer. The nut will have to be baited by hand.

Tighten the nut on the back of the mixer with a wrench.

Please note: when installing the mixer, you need to pay attention to its "spout" and if it is not rotatable, then you need to immediately direct it to the middle of the sink, even before fixing all the structural elements. It remains only to check the presence of rubber seals inside the nuts and connect the hoses to the water supply

After everything is finished, you need to open the water and check the tightness of all connections. In case of leakage, tighten the fastening nut more

It remains only to check for the presence of rubber seals inside the nuts and connect the hoses to the water supply. After everything is finished, you need to open the water and check the tightness of all connections. In case of leakage, tighten the fastening nut further.

After the mixer is installed, it is necessary to fix the sink to the wall. This is done as follows:

- the sink is put on the fasteners mounted in the wall;

- inserts are installed, which can be rubber or plastic;

- fixing nuts are installed and secured.

Please note: if a sink with a pedestal or stand is installed, then when fixing it to the wall, the total height of the structure must be taken into account.

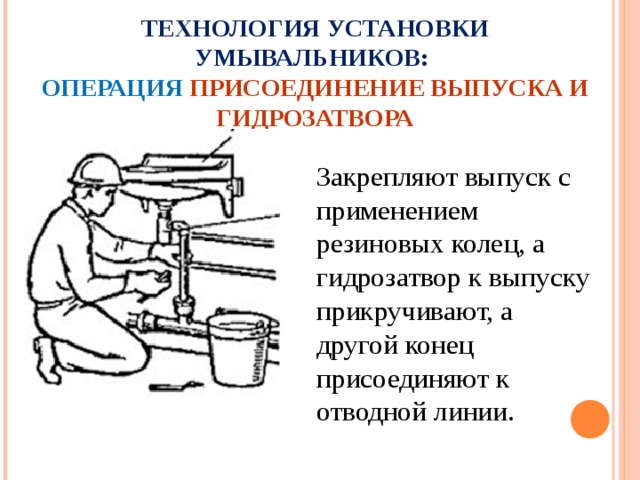

Plumbing connection

When the sink is installed, it remains to mount the mixer and the siphon. Part of the problem is eliminated if the nozzles for connecting the mixer are walled up in the wall above the sink, which is typical for water lilies and the joint use of a mixer for a sink and a bath.It is enough just to screw the mixer nuts onto the nozzles, not forgetting to put the O-rings.

If the mixer is installed in the back of the bowl, it must be pre-assembled. There are threaded holes in the lower part of the mixer; flexible hoses need to be screwed into them. After that, the mixer is installed in the hole in the sink and tightened from below with a wide nut. The ends of the hoses are packed using FUM-tape on the threaded branches of the hot and cold water supply.

Another version of the mixer is possible, when a spout and two taps are cut into the sink separately - the so-called three-point installation. In this case, a rather complicated wiring of the connecting hoses is hidden under the bowl, so the sink must be removed. The water supply is carried out to each tap separately, while the taps themselves are connected to the hidden body of the mixer with thin bellows pipes.

The sink faucet is installed in a standard way. After assembling the body of the device, it must be attached from below to the drain hole of the bowl, after placing a rubber O-ring. A mesh is inserted into the top of the bowl, which is attracted to the body by a long bolt. It remains only to put one end of the corrugated hose on the drain outlet, and lower the other into the socket of the drainage system, into which a rubber sealing collar is inserted.

How to assemble with your own hands. Instructions

To assemble a sink with your own hands, it is not enough to buy materials and components. It is necessary to follow a certain sequence of actions and have a ready-made design diagram on hand.

The assembly includes the following steps:

- we prepare the details;

- we collect the curbstone;

- we install a siphon and a tap;

- sink installation;

- connection to communications.

Preparation of parts according to the scheme

Before starting the assembly, it is important to prepare and check all the parts according to the existing diagram. If this is not done, the assembly will have to be stopped to search for missing parts, which will affect the time of installation work and the quality of the final structure.

Assembling and installing the curbstone yourself

To assemble and install a curbstone in the kitchen, you will need:

- plywood for the back wall;

- base material, cut according to the drawing;

- fittings;

- facing tape in a suitable color.

Installation of a crane and a siphon

A tap and a siphon are mounted on the sink, before placing it on the cabinet. This is necessary to ensure the convenience of work, since it is long and not practical to connect the necessary elements while under the sink.

Installing a washbasin on a vanity unit

Algorithm of actions when installing the sink:

- we fix the plastic corners to the upper ends of the side walls;

- on the edge of the walls on which the sink will lie, a layer of sealant is applied, which acts as an attachment;

- install the sink and press it against the main structure.

Connection to communications

We connect the sink and siphon to the communications and check the build quality for leaks. If everything is fine, we use the car wash as usual.

Cabinet material

After the type of the future pedestal has been determined, it is time to move on to the choice of the material from which it will be made. It will affect the durability of the structure and its practicality.

Requirements

When choosing a material suitable for building a structure, the following parameters are taken into account:

- practicality;

- moisture resistance;

- aesthetics;

- wear resistance.

Moisture resistance

One of the key parameters that directly affect the life of the sink. If its resistance to moisture is minimal, get ready to remodel your kitchen in the near future. The most common moisture resistant materials:

- laminated chipboard;

- plastic;

- aluminum;

- wood massif.

Practicality

Do not chase outlandish materials that are not suitable for use in high temperature and humidity conditions.Remember that the main thing in a sink is practicality and functionality, while visual appeal fades into the background.

Wear resistance

The wear resistance of a material is determined by its ability to resist constant exposure to external factors, expressed in:

- friction;

- blows with blunt objects.

Aesthetics

Each kitchen owner wants the headset, in addition to being durable, to have an attractive appearance that harmoniously fits into the interior. Of course, you should not sacrifice the practicality of the material for the sake of a beautiful wrapper, but there is no need to make a sink from an uncouth piece of wood either.

What is used

As mentioned above, as a common material for sinks that meets all the requirements, the following are most often chosen:

- Chipboard;

- MDF;

- wood massif.

They have their advantages and disadvantages, which should be discussed separately.

Chipboard

Chipboard is an abbreviation that stands for laminated chipboard. The principle of its manufacture is similar to the production of chipboards. The only difference is the coating with a special film, which includes:

- paper;

- melamine resin or special varnish.

Such material is resistant to moisture and temperature extremes.

MDF

For the first time the material appeared on the market in America, in the forgotten 1966. It includes wood chips, which are pressed into a monolithic sheet under the influence of high temperatures. Positive material properties:

- water resistance;

- fire resistance;

- resistance to harmful microorganisms.

Solid wood

Solid wood is understood as a material consisting of a single piece of wood. Solid wood structures have the greatest durability and practicality, losing to their competitors only in price. Some types of wood, before being used for construction purposes, must be treated with special agents in order to increase resistance to any type of impact.

Types of sinks by mounting method

According to the method of fastening the sink, there are the following types:

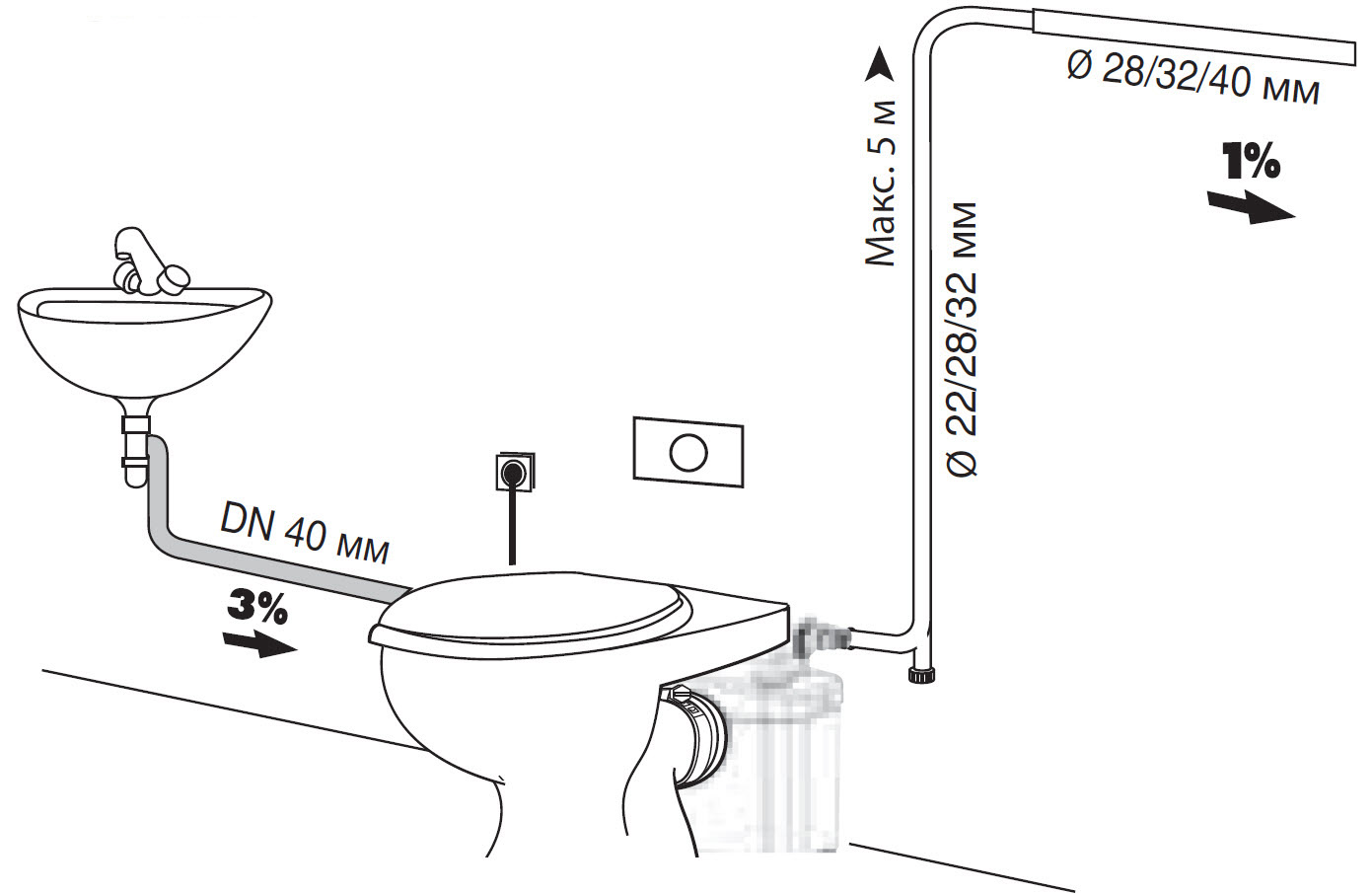

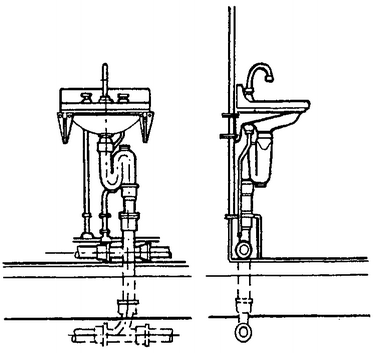

- Suspended (console). They are attached to the wall using brackets or other fasteners. The main disadvantage is that the plumbing fittings and the siphon remain visible. The advantage is space saving. There are also wall-hung flat sinks under which a washing machine can be placed.

- Shells on a pedestal (tulip). They differ from suspended ones in that they are equipped with a special stand, which serves as an additional support, and also hides the siphon and other communications.

- Overhead. Placed on a flat table top. These sinks often have no tap holes.

- Built-in. Built into furniture (bedside table, cupboard or separate tabletop).

Hanging washbasin with brackets

Installing a sink over a washing machine

Washing under the sink has a significant advantage: efficient use of free space. In this case, the washing machine can be installed in a bathroom of any size. Above the sink, it is quite possible to fix a cabinet with a mirrored door, which allows you to use all free areas without harming the interior of the room. Thanks to the wide assortment of sinks, you can choose bathroom fixtures of any color and design.

Placing the sink above the washing machine saves space and clearly organizes the bathroom space.

However, in no case should we forget about the disadvantages of this option.

In particular, when installing a sink over a washing machine, the following deserves attention:

- Installing household appliances close to a water source is quite dangerous. Specialists in working with electrical appliances warn about this.

- Stagnation of water in the sink and in the siphon due to the peculiarities of the shape.Most often, the depth of such sinks is shallow and has a drain hole in the back. For this reason, there are difficulties in water drainage, and due to stagnation in narrow slit drains, blockages are formed.

- Difficulties with the selection of component parts. In particular, we are talking about a special flat siphon, which rarely appears on the market. A similar situation arises in the case of other elements when they fail. For this reason, it is recommended to purchase sinks with a full complement of components, otherwise it is better to completely abandon the purchase of sinks.

- Not very convenient operation. Installing the washing machine under the sink limits the range of movement to some extent. For example, while washing, you should stand at a certain distance from the machine in order to avoid hitting the panel of the household appliance. For some people, washing away from the sink is uncomfortable.

Material

When choosing a washbasin, attention should be paid to the material of construction. There are ceramic, glass, metal models on the market, as well as sinks made of natural or artificial stone

Ceramic

Ceramic sinks are environmentally friendly, resistant to scratches, chemicals, temperature changes, easy to care for, and pleasant to the touch. The disadvantages of porcelain stoneware sinks are considered to be their considerable weight, which creates inconvenience during installation, fragility of the structure and relatively high prices.

Artificial stone

Sinks made of artificial stone are moisture-resistant, resistant to chemicals, high temperatures, environmental safety, a wide range of different colors and shapes, long-term preservation of their original appearance when used correctly. The disadvantages are the high cost, heavy weight and fragility of budget models.

Natural stone

Products made from natural stone are carved from large pieces or joined together from several parts. Sinks are made of granite, marble, onyx, basalt, travertine. Stone products are durable, strong and functional. The disadvantages are the high price and heavy weight, which complicates installation and transportation.

Glass

Glass sinks may seem fragile at first glance, but in fact, thick tempered glass can withstand temperature fluctuations and mechanical damage. They are easy to care for and retain their integrity for many years.

Metallic

Metal sinks are made of cast iron, steel, copper, bronze. They are popular for their low prices, ease of installation, functionality, and practicality. The metal has high strength and resistance to temperature extremes. Disadvantages are the susceptibility to the formation of limescale and the need to ground the sink if there are electrical appliances and sockets nearby.

Tools and materials

In addition to the sink and materials for the sink, it is necessary to prepare the tools with which the products will be installed in the kitchen. You will need:

- sandpaper;

- lumber;

- self-tapping screws;

- antiseptic;

- putty and primer;

- jigsaw;

- fittings;

- drill;

- screwdriver;

- roulette;

- screwdriwer set.

Lumber

Lumber is purchased according to the sink drawing. The durability and practicality of the structure will depend on the quality of the lumber.

Sandpaper

Useful when processing wooden sink parts. Using sandpaper allows you to:

- Make the material more attractive in appearance and pleasant to the touch.

- Removes splinters and sharp corners, which can hurt household members.

It is advisable to purchase paper of coarse, medium and fine grain, for high-quality and consistent processing of the material.

Antiseptic for lumber processing

To increase the durability of wood and enhance its protective qualities, the surface of the sawn timber is treated with special antiseptic agents. Necessary:

- Provide protection against moisture, as the parts of the sink are in constant contact with it.

- Increase resistance to high temperatures.

- Protect wood from the harmful effects of microorganisms that appear in large quantities in the kitchen due to their comfortable environmental conditions.

Screws, self-tapping screws

Not a single construction site can do without them, especially when it comes to working with wood. With their help, wooden structural elements and other parts used in the assembly process will be connected.

Putty and primer

Putty is necessary to eliminate wood defects, expressed in the form of chips, cracks and irregularities. The substance evens out the treated surface, increasing its attractiveness.

It acts as a connecting element, increasing the durability of the structure.

Fittings

Hardware refers to ancillary structural parts used for final assembly. Accessories include:

- door hinges;

- pens;

- guides for drawers;

- latches;

- closers;

- locks.

Electric jigsaw

An irreplaceable thing when working with wood, allowing you to cut out a part of the desired size and shape. Significantly speeds up the assembly process. When working with a jigsaw, you should be careful and do not forget about the safety rules.

Note! It is recommended to stock up on spare jigsaw blades, as they tend to break at the most inopportune moment

Drill

Another auxiliary tool, the presence of which will significantly speed up the assembly process of your sink. It is difficult to do without it; if the drill is not at home, borrow it from the neighbors.

Screwdriver

Effective replacement for conventional screwdrivers, making the work of the assembler faster and easier. This is an optional tool and can be replaced with a regular set of screwdrivers.

Tape measure, ruler and pencil

An irreplaceable trinity, without which it will definitely not work to install a sink. Of course, you can measure the dimensions by eye, but the final result will definitely not please you.

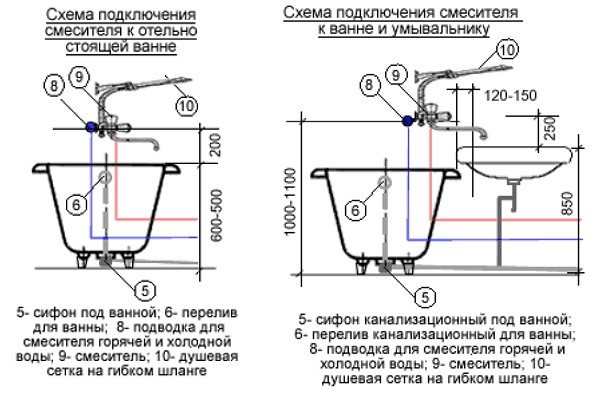

Wiring diagrams

Washbasin attachment methods depend on its design. And if a sink with a pedestal pedestal (tulip) or a bowl built into a bedside table do not leave much room for creativity, then you have to tinker with a simple outboard design or some modern developments.

It is always worth considering the factor that a typical faience sink and its counterparts weigh a lot, so the fastening must be reliable and durable. Moreover, many people have a persistent habit sometimes to lean on the edge of the sink, which significantly increases the load on the suspension system.

It is also always necessary to take into account the location of water outlets, sewage and the installation of household appliances (for example, a washing machine). All this should not block or interfere with each other. In rare cases, corrections are made for design features (for example, a stucco border runs along the perimeter of the bathroom at the height of the standard sink installation).

Usually the hardware is included in the scope of delivery and sinks. In rare cases, you have to purchase it separately

It is important to remember that not all decorative elements of the sink (for example, a pedestal-pedestal) are designed for a serious load and more often work as a regular decor, masking a drain siphon or water supply connections

Do not neglect the rubber / silicone cushioning pads installed at the contact points of the mounting bolts and the sink. Sanitary ware is a durable and reliable material, but rather fragile.

Subtleties of installation on drywall:

The usual installation algorithm is as follows:

- Determination of the optimal sink height. Marking its position using a building level.

- Sink assembly.

- Mixer installation.

- Siphon connection.

Pedestal sink

The pedestal sets the height of the sink installation (in addition to masking the siphon), so everything ultimately comes down to choosing the installation location, aligning the device vertically and horizontally, determining the optimal locations for fasteners, marking the fastening holes and installation itself.

Moidodyr

Usually the bedside table under the sink also serves as a supporting base. Therefore, such a sink is the easiest to install. True, it is worth worrying in advance that the sewerage and water supply outlets do not interfere with the installation of the curbstone. It is also worth remembering that some models have legs that allow you to adjust the installation height in a small range, which is extremely convenient. The installation of a suspended moidodyr is somewhat more complicated and, in general terms, repeats the installation of a conventional remote sink. The only difference is in the used fastening system - you will need special brackets.

Installation issues of water sockets:

Water lilies

When installing small-sized external sinks, designed for the installation of washing machines under them, you should ensure that after installation there are no problems with either the placement of the washing machine or its connection to water and drain. The drain is never done at floor level. The optimum height is 600 mm from the floor. This should also be taken into account when installing siphons. The water lily sink is allowed to go beyond the dimensions of the washing machine, but the opposite situation should be avoided - it is very inconvenient to use the sink. There must be a gap between the sink and the machine - taking into account the vibration of the device and possible dismantling.

A video on the installation of the sink can be viewed here:

Installation instructions for the sink on the wall

After determining the dimensions and installation location of the device, they begin to measure and mark the future structure. This makes it possible to ensure the correct mounting of the device to the wall plane of the room.

For this purpose it is necessary to perform the following steps.

- Draw the central contour. At the selected height, using a level, mark the upper border of the plumbing fixture and install it along its line.

- Measure the thickness of the sidewalls of the sink. This indicator is necessary to determine the resistance to pressure of the brackets, which determines the strength and durability of the entire structure. The measured value is laid down from the central horizontal and fixed with a mark on both sides of the bowl.

- Connect all the marked marks with a fastening line. This action allows you to determine the required height to install the support-brackets.

Remember, it's more efficient to markup to two people. At the same time, one person should hold the shell at the central horizontal, and the second should mark from below the places to which the mechanism will be fastened.

After the structural planning, they proceed to the installation of plumbing equipment in the room.

Mounting the sink on the wall

This process consists of the following steps.

Tipping the ceramic bowl. In this case, special brackets should be fixed on the side walls of the sink.

Designation of places for the installation of fasteners. For this purpose, the device is applied to the horizontal and, through the recesses on the back side, the necessary marks are put down

In this case, it is important to control the coincidence of all lines and places for the brackets.

Installation of fixing fittings. At the designated points on the wall, holes are drilled and dowel screws are hammered

Then, the fastening pin is carefully screwed into the prepared places.

Installation of support brackets. After fixing this mechanism, a sink bowl is installed on it.

Installation of a ceramic appliance. The joints of the device with the wall must first be outlined, and then processed with a drill. After preparing the necessary holes, the sink is finally mounted in a permanent place.

Connecting the device to the water supply and sewerage system. For this purpose, the siphon outlet pipe is connected to the socket of the drainage network, then the mixer device is mounted and the water supply is connected.

Checking the reliability of the fasteners. The final stage in installing the bowl to the wall is its final adjustment to the horizontal level and additional fixation of all fasteners.

After the installation work, the sink is tested for tightness. For this purpose, when the valve is turned on, the water pressure is changed and the joints are carefully examined. If leaks occur, tighten the fastening nut with a wrench.

Remember, it is advisable to install plumbing fixtures to the wall only if the wall surface is a solid and reliable structure.

If this requirement is not met, it is important to create a supporting frame

So, before carrying out installation work, you should take into account the wiring of plumbing equipment, the existing interior of the room, as well as the needs and desires of the whole family. However, when embodying an extraordinary design in the washroom, do not lose sight of the main purpose of the design - functionality. For this reason, they initially acquire a bowl of the correct size, and then they begin to connect the equipment.

A well-executed installation of the device will guarantee a reliable, comfortable and long-term operation of plumbing elements.

Robust cabinet for durability

Surface-mounted and recessed sinks are installed in cabinets with opening or sliding doors. In this case, the back wall of such a cabinet must be open. In order to assemble the cabinet correctly and reliably, you need to know several features of mounting.

Surface-mounted and recessed sinks are installed in cabinets with opening or sliding doors. In this case, the back wall of such a cabinet must be open. In order to assemble the cabinet correctly and reliably, you need to know several features of mounting.

The bottom line is that such structures do not provide for additional reinforcement and bulkheads, as this can interfere with the sewer pipes and the installation of the sink itself. In this regard, the pedestal does not have additional stiffening ribs, which will affect its service life. Moreover, if you install an overhead sink, it won't even have a countertop. Instead, the entire top of the cabinet will be occupied by a steel sink panel. It will also negatively affect the strength of the structure.

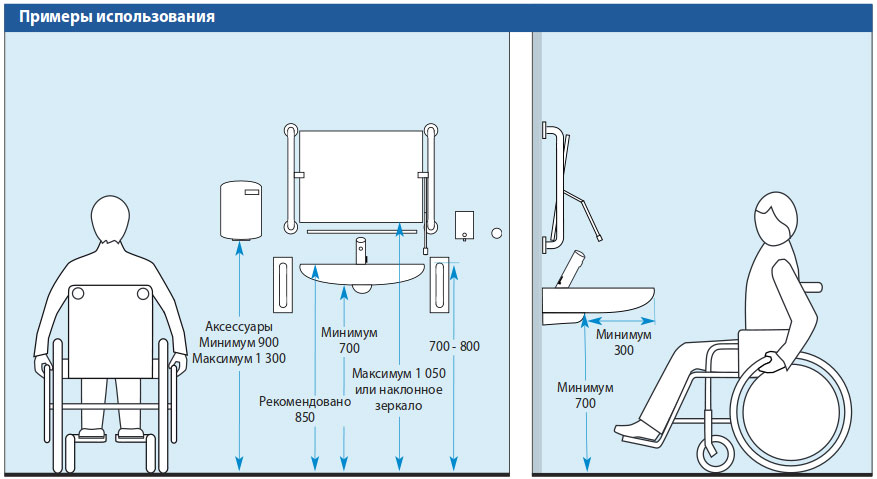

Standard issues

All standards take into account the physiological parameters of a person, which are determined by height, gender, age. Accordingly, the existing differences do not allow setting a single value that is equally convenient for all occasions. Therefore, there are three main standards that allow you to more or less accurately correspond to the target audience.

First of all, it is important to remember that all distances are indicated from a clean floor, therefore, without knowing this parameter, it is useless to build any calculations. In total, there are three averaged categories in which the average height of a person corresponding to a specific age is taken as a standard.

- Older age. Sink rim height 800 mm.

- Average age. From the top edge of the sink to the clean floor 700 mm.

- Younger age. Sink at a height of 600 mm.

It is not always necessary to strictly adhere to these values, but you should not deviate greatly from them either. In a private home, of course, there is more freedom, but when installing sinks in kindergartens, hospitals, schools and similar objects, the given parameter should be kept as strictly as possible.

In any case, even when installing a sink in your own house or apartment, you should not go beyond 750 - 850 mm from the clean floor to the upper edge of the appliance. Practice shows that even a slight deviation creates noticeable discomfort.