Laundry imbalance

Uneven distribution of things most often occurs when there are too few things in the car, or these are too small things or, on the contrary, large.

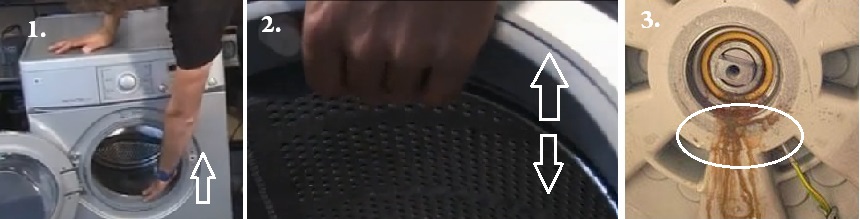

To eliminate the cause, you need to open the drum of the machine, and spread the laundry on the drum with your hands. If necessary, drain the water first through the drain filter or emergency emptying hose, otherwise the door will not open. You can also avoid imbalance if you put both large and small things mixed in the drum of the washing machine, of course, taking into account the type of fabric and color.

Removing a foreign object

Do not operate the washing machine if a foreign object gets between the drum and tub. It is quite simple to understand that something has hit the drum. You need to turn the drum from side to side by hand when the machine is turned off and without laundry. Metal objects such as coins, bra-bones, pins, metal buttons, rivets will clink, you will not confuse such a sound with anything. In addition to metal objects, debris can get stuck in the tank, for example, seeds that have not been shaken out of a pocket.

Removing a foreign object is not easy. In some cases, the item cannot be reached without removing the tank from the machine and disassembling it. Moreover, the tanks are non-collapsible, which complicates everything. Various methods of retrieving objects, for example, a bone from a bra, are described in an article on our website.

Checking and replacing bearings

Knocking bearings are usually preceded by a squeak. Therefore, you need to listen to how the washing machine works. If you suspect bearing wear, do not operate the machine. The part may break so that the machine cannot be repaired.

Knocking bearings are usually preceded by a squeak. Therefore, you need to listen to how the washing machine works. If you suspect bearing wear, do not operate the machine. The part may break so that the machine cannot be repaired.

Bearing breakage can be determined by turning the drum from side to side by hand and shaking it up and down. If you find a backlash and hear a knock, then definitely the bearings need to be changed. Bearings have a lifespan of approximately 5 years, so repairs may be unavoidable. Replacement refers to a complex repair, so most often they turn to a specialist for help. But if you want to repair the equipment yourself, then read the article How to change bearings in a washing machine.

Shock absorbers and FPS

If the washing machine knocks and vibrates at the same time, then faulty shock absorbers may be the reason. Thanks to the shock absorbers, vibration that occurs at high speeds is damped, and if they have worn out from time to time, then the tank with the drum will swing like a pendulum, and extraneous noise will appear.

In addition, it is not so difficult to do this in almost all washing machines, with the exception of Samsung and Hansa appliances. To replace a part in these machines, you will have to pull the tank out of the case; in all other cases, replacement is done without removing the tank, the detailed instructions for which are presented in the video below.

If the mains filter is the cause of the drum knocking, then it must be securely fastened to the machine body. It is located behind the back of the case. To remove and fix it, you need to remove the top cover, find the torn filter and fix it to the side wall on the holders using self-tapping screws.

Thus, in order to understand why an automatic washing machine knocks, you need to listen to it well and spin the drum with your hand. Even if it is not possible to name the one hundred percent cause of the breakdown, then at least it is definitely possible to limit their range. And only after that, seek help from a specialist.

Washing machine jumps during washing - reasons

The vibration of the machine during spinning can be triggered by various reasons, the most common of them are discussed below.

Incorrect installation of the washer

Improper installation on the floor is one of the common reasons that the washing machine makes a lot of noise and jumps during the spin cycle.

Ideally, the washer should stand without tilts and distortions, all legs should touch the surface. The floor should be level and smooth, but not slippery. If these conditions are violated, the automatic machine at high speeds begins to swing towards the slope, shake and make a loud noise.

Uneven distribution of laundry in the drum

The washing machine jumps during spinning when the laundry is unevenly distributed over the drum. It can clump together, for example, when small items end up in a pillowcase. In this case, the entire weight of wet laundry falls on a small section of the drum, as a result, the machine swings strongly in the direction of movement of the resulting lump.

Also, the operation of the equipment may be disrupted due to overloading if the weight of the contents exceeds the permissible value according to the instructions. Then the drum cannot turn at the required speed, and the whole mass of things exerts continuous pressure on the lower section. When underloaded, the laundry sharply throws over the entire available area, which also shakes the washing device.

Shipping bolts

The shipping bolts are the fastening mechanism that protects the tank and shock from wobbling, wall bumps and damage during transit. The device works even if the fasteners are not removed, but the washing machine shakes and rumbles, and its parts wear out faster.

Faulty spring or shock absorber

Shock absorbers, like springs, are designed to dampen tank vibrations that occur when the drum is spinning. Over time, especially with frequent overloads of the machine, these parts wear out.

The shock absorbers are located at the bottom, directly under the drum, they are clearly visible if you turn the washing machine over. Usually there are 2 or 4, depending on the model. The springs are located in front of and behind the tank. When they are worn out, broken, or the mountings have fallen off, the machine begins to sway and knock, as the tank sags.

Foreign objects

While scrolling shirts and dresses in the washer, small details often come off them (buttons, decorative bows, patches, bra bones, pieces of wool, etc.). Torn pieces are clogged between the tank and the drum, causing the technique to tremble.

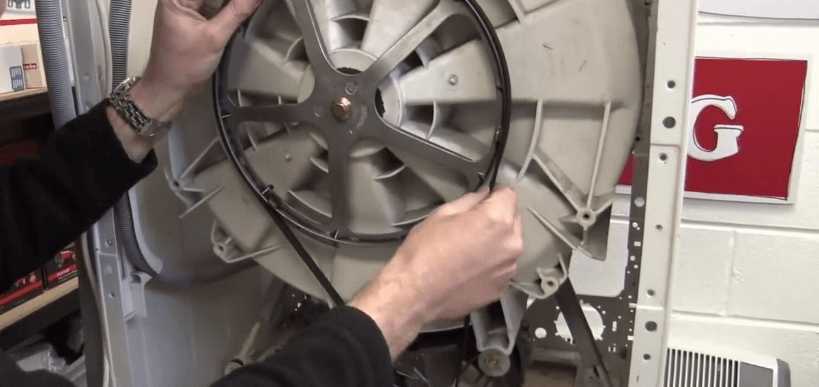

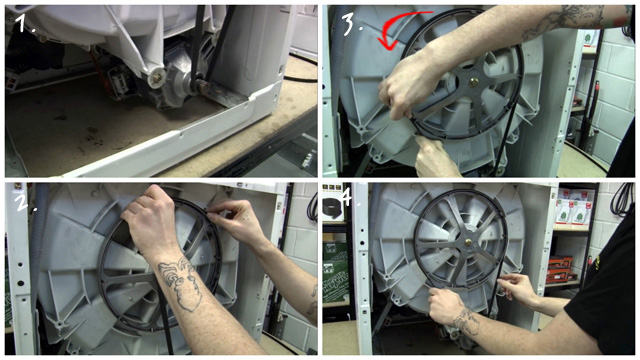

Belt loosening

In a number of machines, a special belt goes from the motor to the drum. When power is applied, the motor rotates and, with the help of this coupling drive, begins to spin the drum. Sometimes the belt wipes, flies, or its tension becomes weaker, which makes the movements uneven and shakes the structure.

Bearing breakage

Bearings are metal or plastic parts that connect the pulley to the drum. There are usually two of them: internal and external. They differ in size, distance from the drum and workload.

Under the influence of liquid and a humid microclimate inside the washing machine, the bearings begin to oxidize, and then rust and wear out, they can completely collapse. At the same time, the drum freely swings to the sides when moving and rotates non-uniformly, turning with difficulty in some areas. In the most severe cases, it is completely jammed, water begins to flow from under the machine.

On average, bearings remain operational for 7 years. It is not recommended to use equipment with such a breakdown, since fragments of the part can completely break the washing machine.

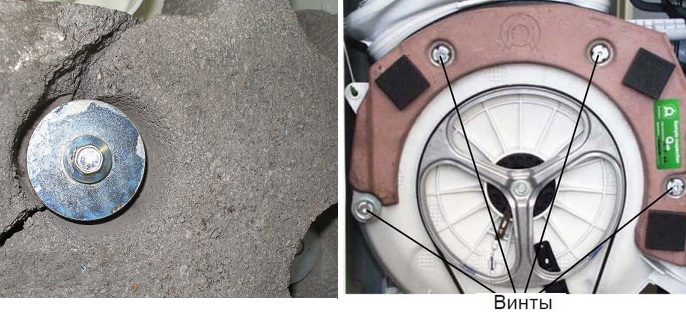

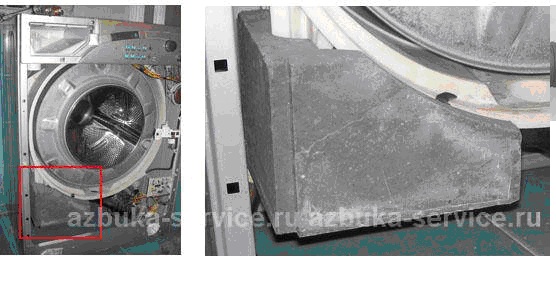

Counterweight failure

Counterweights are two heavy concrete or plastic structures that sit in front of the drum and behind it, next to the springs.They are also used to dampen vibrations while driving and to ensure the stability of the entire structure. As a result of wear, they can crumble into several parts, or fastening bolts can fly off them.

Problems in the operation of the electric motor

Most often, the problem that causes the shaking of the machine does not lie in the engine itself, but in the loosened mountings of the electric motor. It is located on the side of the back cover of household appliances. Fault detection in the electronic circuit of the device is available only to technicians with special equipment.

Why is the drum wobbling in the washing machine?

A slight play in the drum is not a breakdown. Such work is laid down by the manufacturer. If he began to stagger more than before, then this indicates a problem.

You can diagnose the problem yourself, but we recommend contacting a wizard. In this case, you only win:

- If this is a breakdown, then our technician will immediately fix it.

- If this is NOT a breakdown, then unnecessary diagnostics and cleaning will not damage the washing machine.

If you want to diagnose the problem yourself, then stock up on the tool, patience and our algorithm:

Open the hatch cover of the washing machine, grab the drum and wiggle it in different directions, twist. If you hear a knock or rattle, then the breakage is obvious. If, when manually scrolling the drum, you feel that it is going hard, then there is a high probability of bearing failure.

Switch on the machine and set the spin program at maximum speed (1000-1400 rpm). If it is noticeable that the drum, as it were, flew off the axis and, then it is either the bearing is out of order, or the shock absorber.

Stop the car and look under it. If there is a problem with the bearing, then most likely there will be a puddle under the washer (since water seeps through the movable element on the back wall of the tank). Read more here:.

If there is a knock, but there is no water, then the shock absorbers are probably broken.

It is important to understand that if one shock absorber breaks down, then all are subject to replacement.

Without disassembling the washing machine, nothing else can be found out.

A loose drum is a clear reason to take any measures to eliminate the malfunction, since breakdowns associated with this can subsequently damage other components of the device. But do not rush to contact the service center, first try to find faults. You may be able to fix them yourself. We recommend that you study our reviews, in which we looked at the error codes of the self-diagnostic system of washing machines, in order to quickly identify and eliminate some malfunctions in time, for example, "Hans washing machine codes" or "Whirlpool washing machine codes".

If you do not understand technology at all, then it is better not to try to disassemble the washing machine. Such actions can only exacerbate the problem, and repairs will cost much more.

When the drum at the washing machine dangles, then most often the washing machine hums during spinning and vibrates strongly. You can feel the "bumpiness" by moving the drum to the sides

.

There are two reasons for this malfunction:

- the bearing is worn out or crumbled.

- Shock absorbers "died".

How to determine what is out of order? Very simple.

Bearing problem

To determine this malfunction, it is enough to move the drum in different directions with your hands. Backlash (strong or weak) indicates bearing wear. Usually this problem is accompanied by strong hum and slight vibration.

The bearing is a durable part, but still has a limited lifespan. This element fails due to two reasons: wear or water ingress into it. The latter causes corrosion of metal parts, which in the shortest possible time turns the metal into non-working. The bearing life is often 7-10 years.

If you find such a problem, then do not wait, but replace all bearings as soon as possible or take the unit to a workshop

... It is not recommended to use faulty equipment.

Shock absorbers broke

To identify this problem, you will also need to dig with your hands in the typewriter, but do not move the drum, but slightly pull it towards you and release it. If it does not fall into place, but begins to swing / dangle, then this is a clear sign of failure of the dampers / shock absorbers.

Shock absorbers serve to cushion vibrations during spinning. If even one element breaks, strong vibrations occur and noise may occur. The washing machine has two dampers and two springs. They must be changed in pairs.

Breakage of shock absorbers leads to increased wear of all mating units in the apparatus, including the bearing. Therefore, it is recommended to immediately fix the malfunction at home or contact a service center.

An object has got into the tank

A grinding noise in the Indesite washing machine can be triggered by a solid foreign object that has gotten into the tank. This problem is much more serious than the previous ones, since the system at one point can simply jam. To remove the cause of the noise, you must turn off the machine from the network and start disassembling it.

So, after the machine is de-energized, try to get the foreign object through the hole for the heating element. To do this, do the following:

So, after the machine is de-energized, try to get the foreign object through the hole for the heating element. To do this, do the following:

- disconnect the washer from the building utilities;

- provide yourself with free access to the rear wall of the case;

- remove the back cover by unscrewing the mounting screws;

- disconnect the contacts of the heating element;

- remove the retaining nut;

- grasp the heater and gently swing it out of the tank.

After removing the heating element from the housing, stick your hand into the free opening and try to get a foreign object. If the cavity is too narrow for your hand to penetrate, use a flashlight to illuminate the hole and use the wire to extract the desired object. When you succeed in carrying out your plan, you can reassemble the washing machine in the reverse order and install it in its original place.

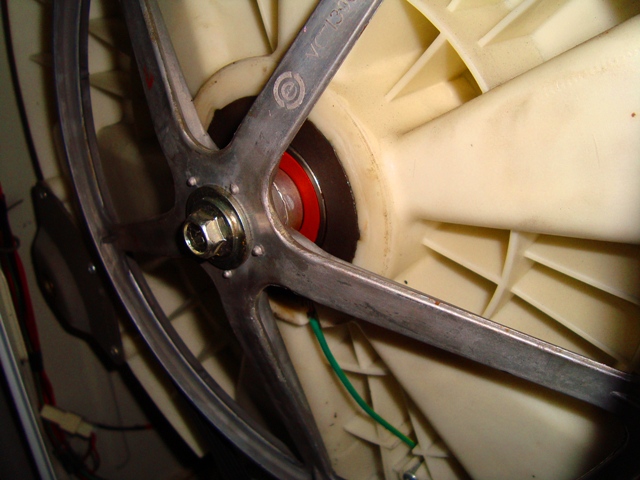

There are rarely cases when a knock in washers appears due to the destruction of bearings. You can check them by removing the back wall of the case. Take a close look at the center of the pulley. If the bearing is defective, grease will leak from there. Such a smudge is very easy to see with the naked eye. Having found this malfunction, it is better not to start replacing parts yourself. Repair belongs to the category of complex, so it is better to invite a specialist to carry out the work.

We eliminate breakdowns

Repairing washing machine bearings is a rather complicated procedure.

- First, you need to properly disassemble it in order to get to the tank and remove it. The problem is that different washing machines from different manufacturers have to be disassembled differently - this complicates matters.

- Secondly, you need to properly disassemble the washing machine tank.

- Third, you need to properly remove the broken bearings without damaging anything. All of this creates problems. For more information on how to change bearings in a washing machine using the example of models from LG, read the article on replacing bearings in an LG car?

Suspensions or shock absorbers are somewhat easier to replace, however, there are pitfalls in this business. In some models of washing machines, the shock absorbers can be reached through the top wall and through the bottom of the cabinet. This is very convenient as it saves a lot of time and effort needed to remove the panel, front and back walls of the machine.

In this case, you only need to unscrew the fasteners holding the shock absorbers, remove them, and then screw on the new ones. If only one shock absorber has failed, then everything still needs to be changed - this should always be done. In most washing machine models, you can only get to the shock absorbers if you dismantle the front wall. How should you proceed in this case?

In this case, you only need to unscrew the fasteners holding the shock absorbers, remove them, and then screw on the new ones. If only one shock absorber has failed, then everything still needs to be changed - this should always be done. In most washing machine models, you can only get to the shock absorbers if you dismantle the front wall. How should you proceed in this case?

- Remove the top wall of the washing machine by unscrewing several fasteners and pulling it towards you, and then up.

- Remove the powder drawer and the plate covering the drain filter.

- Unscrew the fixing elements holding the control unit and remove it by first unhooking the wires.

- Open the door of the washing machine wide open, then take a screwdriver and dismantle the door locking device by unscrewing the two fasteners and disconnecting it from the sensor.

- Take an awl and gently hook up the clamp, which is located on the rubber cuff. Place your fingers on the cuff and carefully pull it out.

- We unscrew the fasteners in the area of the powder cuvette, under the control unit, in the upper and lower right corners of the machine body and remove the front wall. Access to the shock absorbers is open, we change them in the order described above.

We have described the process of replacing such parts in the most general form. The whole process is described in more detail in the article How to change springs and shock absorbers in a washing machine?

Summing up, we note that if the drum of a “washing machine” that has served faithfully for many years is staggering and knocking, it is highly likely that its shock absorbers or bearings are worn out. What to do? This situation should not be allowed to take its course, it is necessary to urgently check the drum and repair the faulty units. Good luck!

Why does the drum shake

Bearings damaged.

Shock absorbers have broken.

The crosspiece cracked.

A foreign object is stuck in the tank.

These reasons cause increased backlash in the machine.

To correctly diagnose the problem, pay attention to the features of the looseness, the size of the gap

How to check backlash

Roll the empty cylinder with your hands. If it squeaks while driving, touches the tank, it means that the bearing is loose. A broken bearing will also cause dripping during washing.

Pull the drum towards you, release. If it staggers, sways, falls out, sinks, spontaneously separates from the cuff - shock absorbers flew.

When the drum moves, the body shakes, twists sharply, it seems that the machine “went off the rails”? Most likely, the cross is cracked.

Movements are smooth and noiseless, but something rumbles and rattles on the walls? It looks like a small object is stuck in the tank. If you know how to handle tools, you can eliminate these troubles at home.

Breakage of one of the components of the washing machine

One of the reasons for the noise in the washing machine is the clamp of the activator. In order to eliminate this problem, it is enough to pull out the laundry and disassemble the activator. You need to make sure that there is no deflection. It is worth trying to fix the gap between the disc and the tank. Check the suitability of the actuator axis.

Washing machine activator.

If the electric motor hums, but does not rotate, then most likely the activator assembly is skewed, and the disc itself clings to the divider, grate or bottom of the washing tank.

An unscrewed surge protector can also create extraneous sounds during operation. It protects the machine from power surges. To eliminate extraneous noise, you need to fix the filter, in some cases it is worth replacing the mounts.

Breakage and replacement of bearings

If the washing machine rattles during spinning, as well as an iron grinding and vibration, it is most likely that the shaft bearing has failed. If the unit has been operating for more than one year, then this is normal and after a complete replacement of bearings and oil seals, it will work as usual.

If there is no experience in disassembling and assembling washing machines, then it is better to seek help from a specialist. This breakdown is accompanied by an almost complete disassembly of the equipment. If mistakes are made, then irreparable damage is possible, after which the unit will be useless and cannot be repaired.

If the bearings were not replaced on time, and the washing machine squeaks, hums and rattles as before takeoff, then you will have to change the crosses (the parts that hold the drum). And this significantly increases the cost of repairs.

Replacement of bearings.

Damage to shock absorbers

The shock absorber is located at the bottom of the household appliances and is designed to reduce vibration during operation. To check the performance of a part, you need:

- Remove the top cover by unscrewing the screws.

- Press down on the top of the tank until it sinks 6 to 7 centimeters.

- Let go abruptly.

- If the tank has returned to its original position, then everything is fine. If it remains bent or has risen more on one side and less on the other, repair is needed.

The main signs of breakage before "opening":

- In the "wash" mode, the unit squeaks and knocks.

- The drum is spinning tightly (perhaps there is no lubricant in the shock absorber).

Repair of parts in such cases is not always justified. The repaired part, as practice shows, does not last long. A complete replacement of the damaged parts or the entire part is recommended.

Self-repair will require skill, attentiveness and caution. To get to the shock absorber, you need to get to the very bottom of the car

All parts must be removed carefully so as not to damage adjacent elements and wiring.

Shock absorber.

Causes of knocking

If the device is new and the owner has previously read the instructions, the likelihood of such a problem is reduced. But even with proper use, over time, the washer can malfunction.

Common causes of knocking during spinning:

- the washing machine is not installed correctly;

- the laundry is unevenly distributed;

- breakage of the spring;

- the shock absorber is out of order;

- the counterweight has deteriorated.

Appliance not installed correctly

A new automatic washing machine is usually already complete with special transport bolts. They are designed so that the elements of the device do not deteriorate during transportation. When starting the product, the bolts must be removed, otherwise the appliance will make a lot of noise, knock or jump around the bathroom during washing.

This is not the only problem that can arise during installation. The machine may be placed unevenly and vibrations and knocks will occur during spinning. You can check how level the device is using a level. After a flat installation position, you can use the silicone pads. They will prevent the problem from arising in the future.

Uneven distribution of laundry

If the drum knocks in the washing machine, there may be a

solution. Do not fold the same size for the next wash. This will prevent the formation of a lump and the tank will not knock on the walls when the machine is wringing out.

Spring broke

Springs and dampers can also cause knocking during drum rotation. The spring wears out over time and fails. Due to a poor spring, the tank does not hold well from above, so the metal drum warps and hits other parts of the machine. Shocks can lead to more serious problems over time if the spring is not replaced.

To fix the problem, disassemble the washing machine following the algorithm. First, prepare tools with a dielectric handle. Also for this you will need:

- set of open-end wrenches;

- pliers;

- Phillips and slotted screwdrivers;

- dielectric gloves.

Disassemble the instrument for spring replacement with extreme care to avoid damaging parts.

- De-energize the machine, drain all the water and turn off the tap that is responsible for supplying / shutting off the flow of water into the device.

- Remove the upper part of the case: unscrew a couple of self-tapping screws on the back wall and pull the cover towards you. The spring and counterweight can now be removed.

- Change the spring and put back the washing machine.

The shock absorber is out of order

The tank begins to skew due to the lack of proper support from below.Especially when the motor picks up speed during the spinning process. In the event of such a problem, a leak may appear. We will have to replace two shock absorbers at once so that the load on them is uniform and one of the elements does not deteriorate.

To change the shock absorber: remove the top cover, control panel and remove the front panel. Now you can get to the shock absorbers. Unscrew the bolts from the bottom and drill out the latches that hold the shock absorber. Install new ones, where there will already be latches in the kit and assemble the device.

The counterweight has broken

At the bottom of the washing machine there is a weight - a counterweight that dampens vibrations. If you use the machine for a long time, the mount may become loose. The weight will begin to beat against the body and rattle during spinning.

Check the lock and tighten the counterweight bolts if necessary. Then the beating will disappear. If the counterweight is broken, purchase a new weight.

Other problems

There are other reasons for the knocking and grinding noise in the washing machine when spinning. A coin or button may have fallen into the drum and interfere with normal rotation. You just need to remove the obstacle by disassembling the machine.

The surge protector may also come off. Screw it back on, replacing the fasteners if necessary.

Self-repair of washing machines is quite real and does not take much time. But in case of serious breakdowns and lack of experience, it is better to contact a specialist.

What to do if the drum knocks in the washing machine

This problem is common with older machines. In them, when washing and spinning, things do not straighten, but get lost in a coma. In order for the centrifuge to stop knocking, when loading the laundry, lay it out evenly without overloading the drum. It is also advisable to wash bedding and clothes separately.

Sometimes, when using the machine, small objects, for example, a bone from a bra, a button or a small thing that could fall out of pockets, fall out through the holes in the centrifuge into the space between it and the outer tank. In this case, in order to remove the foreign object, if it cannot be reached through the door cuff, the device will have to be disassembled.

Be sure to read:

The washing machine draws in water and drains immediately: the main causes and their elimination

If mistakes were made during the installation of the equipment, then this is especially noticeable in the accelerated mode of operation. In this case, it is necessary to check the correct positioning of the unit and make the necessary adjustments. In order to determine whether the car is level, you can use the level. If distortions are found, it can be moved to a smoother surface. On some models, the position can also be adjusted using the twist-in and twist-out legs.

Shock absorber wear

To fix internal breakdowns, you will most likely have to contact a specialist. The springs that provide the drum with smooth rotation deteriorate from prolonged or heavy use, which causes excessive knocking. Replacing the cushioning mechanism will solve this problem.

Counterweight breakage

Another problematic part, due to which the washer begins to knock, can be a counterweight - a special weight designed to balance a movable structure during operation. If noises and rattling occur during the washing process, then the reason may lie in the loosened mount of the balancer. To eliminate this drawback, it is necessary to disassemble the body of the washing machine and adjust the position of the counterweight.

Bearing wear

The mains filter is a typical element of all models. It is located behind the rear cover and serves to equalize the electrical voltage. When the washing machine is in operation, this part can come off and knock on the body and internal parts. For repairs, the back panel is removed, after which the filter is screwed into place with new fasteners.

Be sure to read:

The washing machine does not heat the water during washing: reasons and their elimination, why it heats up for a long time

It is not recommended to try to repair serious malfunctions at home, as there is a risk of damage to the fasteners, tank cross and other parts. However, if you notice excessive noise or shaking during washing, follow these steps:

- Switch the machine to spin mode and after it has drained the water, open the drum and take out some of the laundry. Then turn it on again. If the knocking and vibration stopped, then the problem was overload.

- Start the machine at idle speed, then start the spin program. If the centrifuge continues to rattle, then the problem is most likely a malfunction of the internal mechanisms.

- Fold back the hatch collar and inspect the space between the tank and the drum. If there is a foreign object, try to remove it.

- Open the filter opening by first placing the tray. Clean it from small debris.