Problems with locking the hatch

Symptoms: water intake does not start.

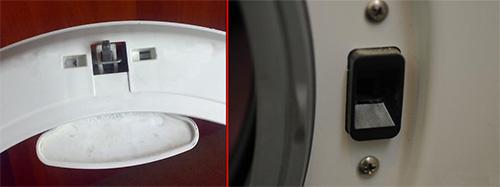

The sunroof blocking device (UBL) protects from the gulf of the apartment and possible injuries: naturally, in case of any problems with the hatch

the machine does not start to draw water. The reasons can be both the most commonplace - the hatch is not closed tightly, and the breakdown of the UBL.

To begin with, make sure that the hatch is really closed and that no clothing has hit the target that interferes with the tight closing of the hatch.

Check that there is no skewing of the machine door or a hook on it. Bolts are provided to adjust the door level.

Also check the metal bar that holds the hook: it might just fall out. Both the lock and the managers can break

electronic elements: it is better to entrust a qualified person to accurately determine the cause of the malfunction and to eliminate it qualitatively

specialist.

Control module malfunction

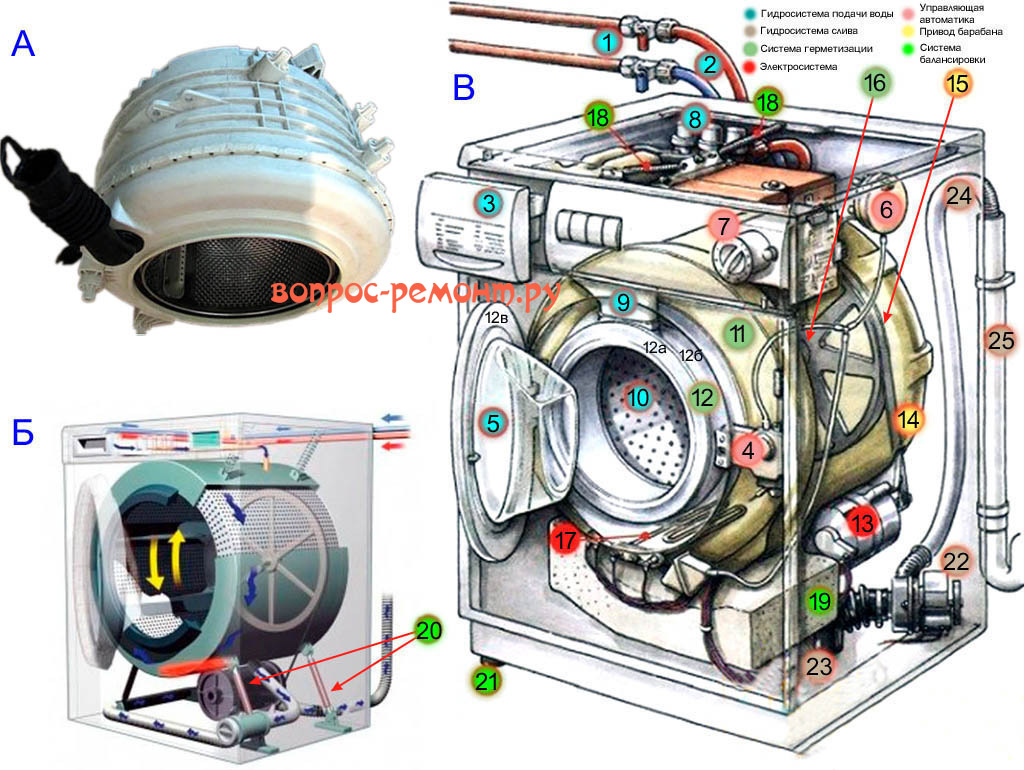

The electronic module of modern washing machines is a small computer with a processor, memory and software. It is he who controls all the nodes, and gives commands or supplies voltage.

In the event of a breakdown, two options are possible:

- Purchase of a new module corresponding to the CMA model with subsequent firmware.

- Repair.

The second option is more preferable from the point of view of money, but for its implementation you need an experienced electronics engineer who, at the same time, understands the principle of operation of washing machines. In addition, it is not always possible to find a new block, due to the lack of the nearest suppliers or the discontinuation of the model.

Wrong position or rupture of the hose

The reason why the machine fills and drains water at the same time is the wrong location of the hose, its rupture or too low position. In this case, the display shows an error code: LE, LC, E9, or LE1.

Such codes are deciphered as "self-draining", "leakage". If the machine is not equipped with a display, all wash indicators light up red, except for the cold mode. In Samsung devices equipped with aquastop, a special “float” in the pallet reacts to a leak, which immediately gives a signal to stop work.

Perhaps the connection point of the hose to the sewer is not sufficiently secured, especially if it has recently been unscrewed. The gasket is likely to be worn and needs to be replaced.

If a similar problem occurs, it is necessary to inspect the floor for the presence of puddles, as well as the hose itself and the place where it is attached to the drain point.

Advice! Before washing, you should carefully inspect things for sharp objects. A small nail or pin in the pocket could fall out and damage the hose when draining.

Errors also occur when too much foam forms in the drum. The reasons are as follows:

- low-quality washing powder;

- overdose of detergent;

- powder not suitable for automatic machine.

The pressure switch reacts to this by displaying an error code.

Attention! If erroneous codes are displayed on the display of a newly connected machine, the issue is often resolved by a simple reboot.

The washing machine does not collect water at all - reasons

If you started the washing machine by choosing a washing program, and water does not enter the washing machine at all, then any of the following breakdowns is possible. Check the machine on them in order to pinpoint the exact cause.

The water supply to the washing machine is turned off

The first thing to check is to see if the water supply to the washing machine is open. Usually it is placed in the place where the rubber hose from the washing machine is connected to the pipeline. This is how it looks:

In the photo, the tap is in the open position, make sure you have it open as well. To do this, the lever that opens the tap must be located in the direction of water movement, i.e.along the hose.

No water or low pressure

The first and most commonplace situation is when there is simply no water in the tap. Unfortunately, this happens very often in our country. Therefore, if you notice that water does not flow into the washer, then in order to exclude this reason, open the tap with water. If there is no water, or the head is too small, then consider that the cause is established.

To solve it, you need to call your ZhEK and find out the reasons and terms for eliminating the malfunction. In any case, you will have to wait for them to fix everything and only then continue washing.

The door of the loading door is not closed.

The washing machine has a lot of different protections, one of them is that when the door for loading laundry is open, water will not be supplied and the washing program will not start. First, make sure the door is tightly closed and not loose. To do this, close it tightly with your hand.

If the door does not lock when manually closed, then you have a broken locking tab on it, or the latch that is located in the lock of the washing machine body. The tongue may simply be skewed, this is because the stem falls out of it, which serves as a fastener.

This happens due to the fact that over time, the door hinges loosen, and the hatch warps. In any case, you will need to align the door or disassemble it to insert the stem. Also, if the lock itself is broken, then its replacement is necessary. Watch the video, which clearly demonstrates the repair of the door lock:

The second problem that may arise with not closing the hatch. This is not a working door lock. The fact is that in any washing machine, the hatch is blocked before washing in order to protect you. If the machine cannot block the door, it will not start the washing program, which means that no water will be drawn into the machine.

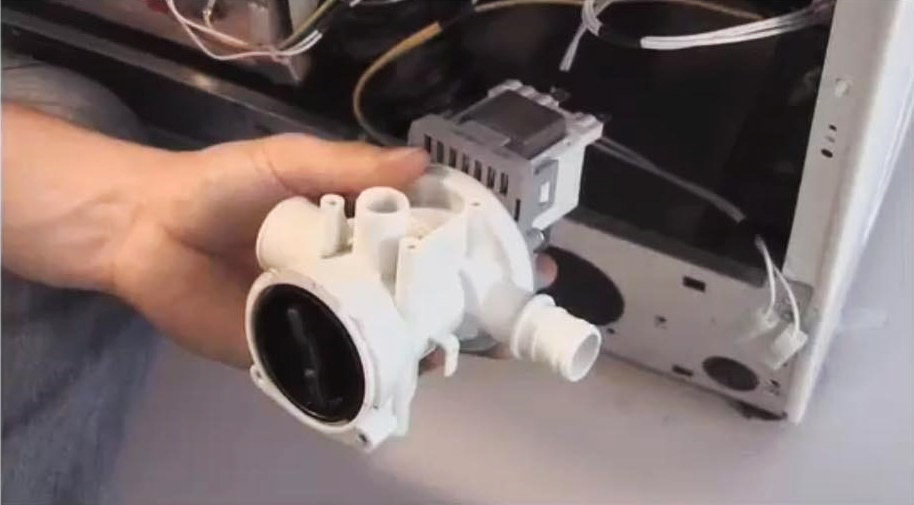

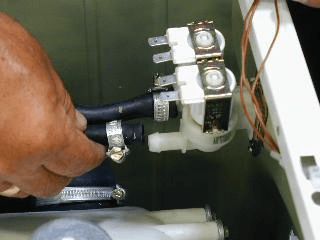

Broken water inlet valve

The inlet valve is responsible for supplying water to the washing machine. When the programmer sends a signal to it, the valve opens and water is supplied to the machine. When a signal comes that there is already enough water, the valve shuts off the water. A kind of electronic faucet. It turns out that if the valve is not working, then it will not be able to open itself and we will not see water in the washing machine. The easiest way is to ring it, because most often the coil at the valve burns out. It is located behind the washing machine, and the inlet hose is screwed to it.

If the water supply valve is broken, it should be replaced.

Broken software module

The software module is the central "computer" of the washing machine, which performs all the intelligent actions. It contains all the time data, washing programs and, in general, it controls all sensors.

If it is the programmer that breaks down, then this is a rather serious breakdown, and you cannot do without calling the wizard. Perhaps it can be repaired, if not, then it will have to be changed completely. In any case, before checking and changing the software module, first check all of the above, because in 99% of cases the problem lies either in a clogged filter, or in a closed tap, or in a broken door.

Typical causes of malfunction

If the washing machine system constantly draws water into the tank, this is an “alarming symptom” that should prompt you to take action. First you need to figure out the question, and what could potentially cause such a problem? First, you need to highlight a wide range of problems, and then gradually, as a result of systematic actions, narrow this range. So, the typical causes of a malfunction:

- the new washing machine is incorrectly connected;

- the washing machine tank is leaking;

- the water level sensor (pressure switch) is out of order;

- the inlet valve has broken;

- problem with the electronic control unit.

Description of the causes of malfunctions and ways to eliminate them

If a completely new, just connected washing machine constantly draws water into the tank, most likely the reason is the wrong connection of the drain hose. This begs the question: why exactly the drain hose, where is it? In fact, he is directly related to this problem.

If the drain system of the washing machine is not properly arranged, a "siphon effect" may occur. It can lead to both the fact that all the dirty water from the sewer will rush back into the tank, and the fact that the water from the tank will constantly pour into the sewer by gravity. In the latter case, no matter how much water is pumped into the washing tank by the machine, it will immediately pour out through the drain hose. Bottom line: high water consumption, constant operation of the heating element, poor-quality washing of things (if the wash will start at all). What to do in this case?

There are two ways to eliminate the siphon effect. First, you can correctly connect the washing machine to the sewer by lifting the sewer pipe at least half a meter from the floor. Secondly, you can install an anti-siphon valve on the drain hose or pipe.

A leaky tank can cause the process of constant pumping of water into the washing machine. This reason is hard to miss, unless of course your car is equipped with an aqua-stop protection system. Water from a leaky tank will flow to the floor, under the bottom of the car, and if you watch this moment, it will lead to flooding, since the system will again and again give the command to fill the tank to the desired level.

A leaky tank can cause the process of constant pumping of water into the washing machine. This reason is hard to miss, unless of course your car is equipped with an aqua-stop protection system. Water from a leaky tank will flow to the floor, under the bottom of the car, and if you watch this moment, it will lead to flooding, since the system will again and again give the command to fill the tank to the desired level.

This does not threaten washing machines that are protected from leaks, since in this case the protection system will work, which blocks the flowing out water and at the same time blocks its supply. We see the elimination of such a problem either in replacing the tank or in repairing it, and it is not always possible to solder a leaky tank. Everything will depend on the material from which it is made.

If the machine constantly draws water, the reason may be a broken water level sensor. This sensor performs a very important task - it detects the water level in the tank and reports this to the electronic system of the machine. If the sensor is broken, it means that the system will think all the time that there is not enough water in the tank and it needs to be collected. A broken sensor is best completely replaced, but you can try and fix it. Usually it breaks down on the pressure switch:

- membrane - the gum loses its tightness and needs to be replaced with a new one;

- sensor contacts - you need to clean it well, and it is better to replace the contacts;

- sensor tube - if the water level sensor tube is cracked, then you will have to change the entire device, fill the cracks with sealant, it does not make much sense.

To replace the pressure switch, you need to get to it. Read more about this in the article on checking the pressure switch of the washing machine.

Another reason that the "washing machine" constantly draws water can be the inlet valve

If this is the case, then the water will flow round the clock into the tank of the washing machine and no matter what state the machine will be in on or off. Accordingly, the water consumption will greatly increase, even more water will be spent than if the cause of the breakdown was a pressure switch, a tank or a "siphon effect"

The intake valve cannot be repaired - you need to buy and install a new one.

What to do if the reason for the constant filling of water into the tank lies in the control unit of the washing machine. Experts on this account give unequivocal advice - contact the professionals. Self inspection, repair and testing of the control unit can lead to its breakdown. In this case, expensive repairs cannot be avoided, so if you are not a good master electronics engineer, do not engage in amateur activities.

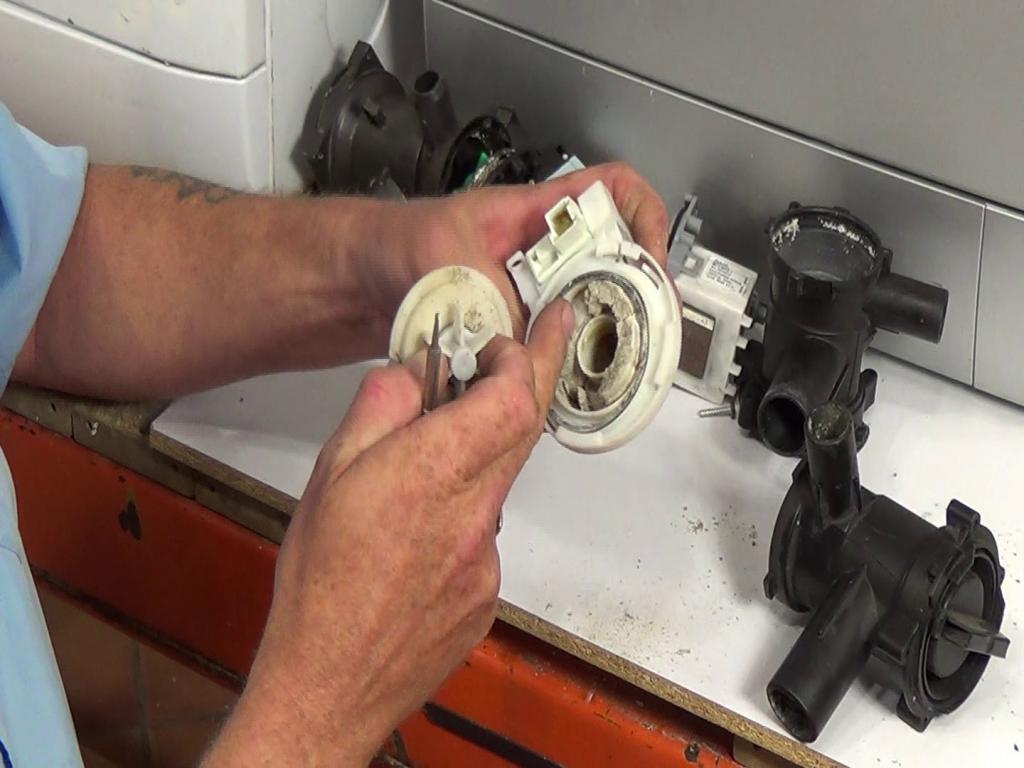

How to check and replace your pump?

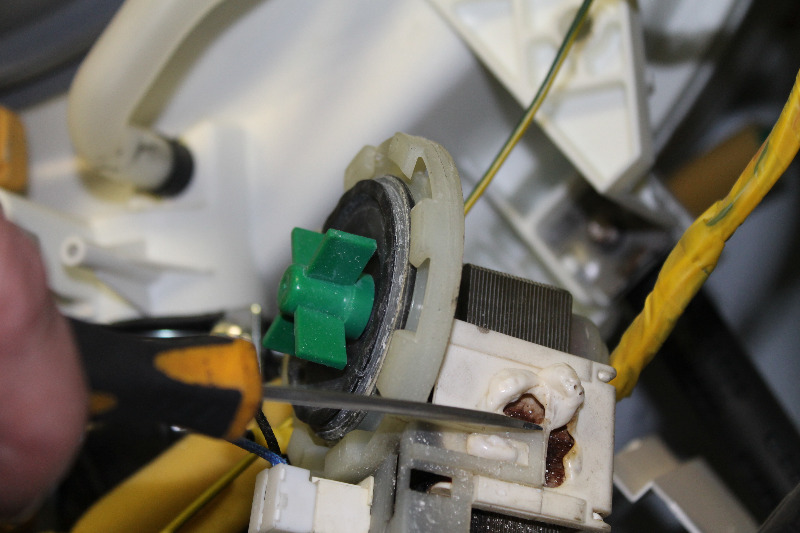

In order to check the serviceability of the drain pump, we will remove the filter, as you have already done this before.After that, we will install the program for spinning. And highlight the filter hole. The easiest way to do this is to use a regular pocket flashlight. If the pump impeller does not move, then the pump (drain pump) is broken. After all, we have already checked it for foreign objects. And this is the only explanation that the impeller does not rotate. And since we have established the malfunction, then we proceed to the next stage - replacing the broken part.

But before that, we need to purchase this very part. Most washing machines are assembled using standard parts. Therefore, we can easily find the new pump we need without any problems. If you do not know where you can buy it, then the easiest way is to use the Internet to find a seller. Namely, search engines Yandex, Google, or others. Type in the search line: "buy a pump for a washing machine in Moscow", "in Moscow" you need to change to your city, if you are not a Muscovite. Then find sellers in the search results, call them and buy a new pump.

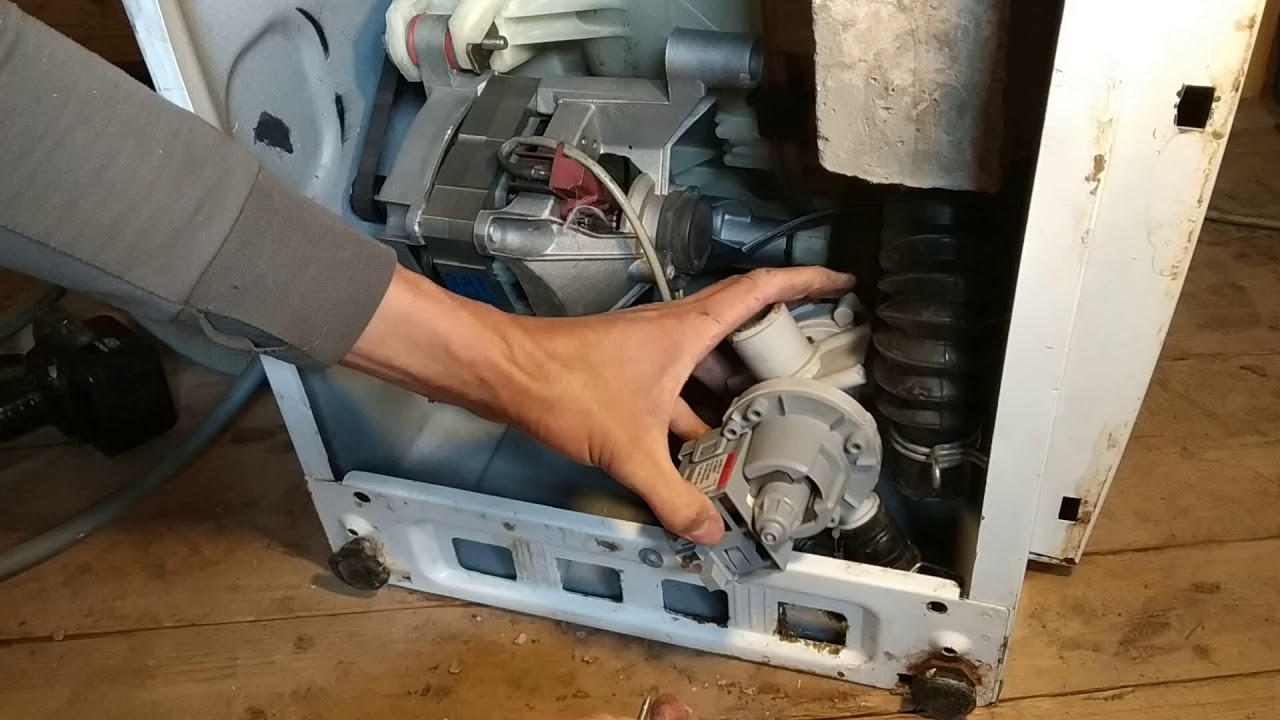

And so, we have already bought the pump. Now let's remove the broken one and replace it with a working one. To do this, we need to remove the washing machine drain unit. And detach the drain pump from this unit. Then he carefully removes the wires from it. Then we take out a working drain pump and install it in place of the old one. We attach wires to it and so on. And we collect the machine in its original state.

To facilitate the whole process, we have selected a video that shows the entire process of removing and replacing the drain pump. See:

Assembling the washing machine

After that, we will check the performance of the machine by carrying out a test wash. Be careful when washing. If there is a leak somewhere, it means that some connection was not properly secured. In this case, correct this defect and check the operation of the washing machine again.

We hope this article helped you solve the problem. Have a good day!

We open the case

Repairing a washing machine very often costs a lot of money, so many users try to cope with the problem with their own hands. For example, a filler valve, with an application for Italian quality, will cost 500 rubles. In the workshop, about 5 thousand rubles will be charged for its replacement.

In most cases, the reason that the machine does not fill is a failed water supply valve. The procedure for replacing the inlet element will be as follows:

- de-energize the MCA, close the shut-off valve;

- disconnect the hoses from the valves (they are located on the back of the housing). Remember that water accumulates in the hoses, which will have to be drained into a separate container;

- remove the top cover of the washing machine by unscrewing the fixing bolts;

- take a picture of the valve wiring diagram. The location can be remembered as the wire connectors from the coil are usually brightly colored. Then disconnect the wiring;

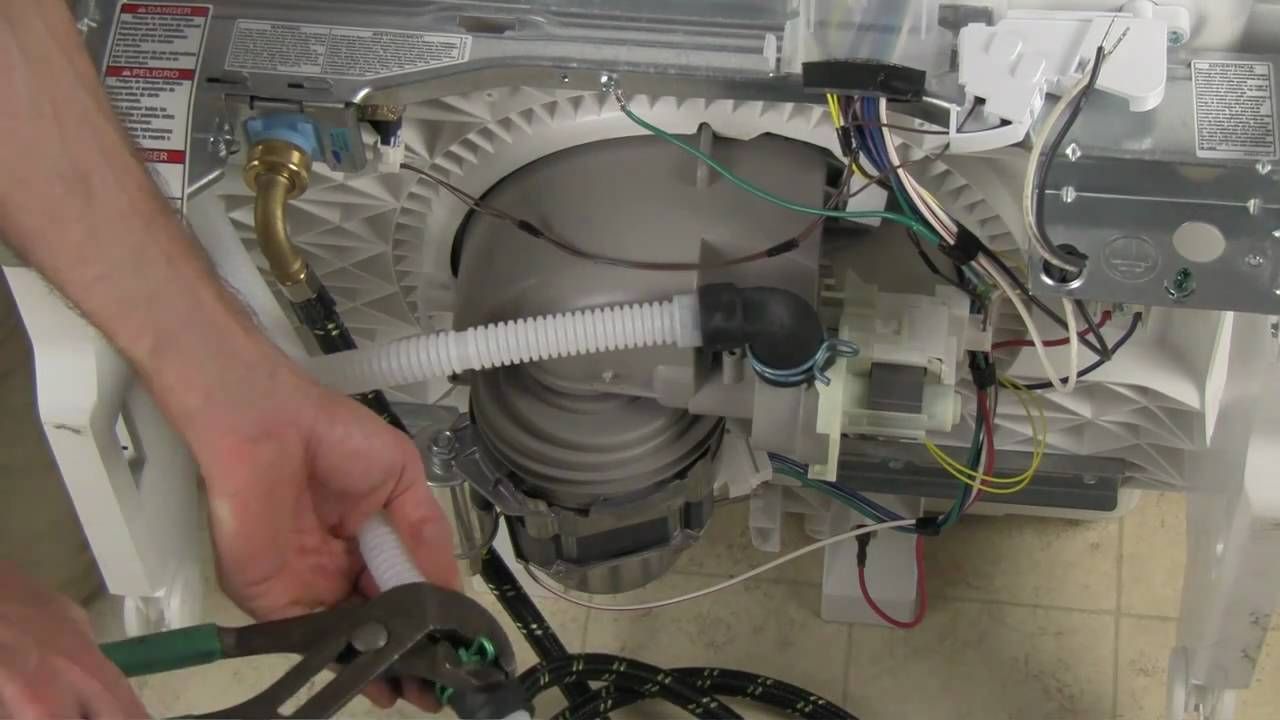

- using pliers, remove the fasteners from each of the 4 hoses. Be sure to remember how they are located. It should be understood that water can also accumulate in them, so it is better to prepare a dry cloth in advance;

- unscrew the screw that secures the valve;

- remove the inoperative solenoid valve from the body;

- install a new part in the bracket and secure with a bolt;

- reconnect the previously removed hoses, fix them with clamps;

- connect the coil wiring;

- put the "top" of the automatic machine, fix the cover with self-tapping screws;

- connect the hoses to the new water supply valve.

After the washing machine is connected to the network, the shut-off valve opens. The test wash is then started. If you do everything according to the instructions, then the machine should work properly.

Inlet valve or heating element

More often, water does not enter the tank due to problems with the valves. The problem is that these parts cannot be twisted or blown out, so they will need to be replaced.

- We turn off the water tap and disconnect the washer from the mains.

- We disconnect the inlet hose from the valves located in the upper part of the back cover, and drain the water from them into a prepared container or sink.

- We remove the fasteners from the top panel of the case.

- Fix the location of the connectors on the spool to the camera and release the wiring.

- With the help of pliers, we disconnect the hoses from the terminals, not forgetting that liquid always accumulates in them.

- We release the screw holding the valve.

- We take out the inlet valve.

- We install a new valve on the seat and fix it on the fasteners.

- We return hoses and wiring.

- We check the reliability of the fixed elements.

- We install the cover on the washing machine, tighten it with bolts.

- We connect the inlet hose.

- We connect to the water supply and power supply, after which we run a test wash to check.

A faulty heating element also gives a "hang-up" to the machine for water intake. If the scale layer is not removed manually or the multimeter indicates a breakdown, the heater will have to be replaced. We will now give the instruction.

- We unscrew the back panel of the machine body.

- We find the heating element in the lower part behind the drive belt.

- Armed with pliers, pull out the temperature sensor and ground wires from the connectors.

We loosen the nut holding the heating element with a key.

Gently swing the heater up and down and pull it out together with the cuff.

Lubricate the gum with dishwashing gel and insert into place.

We install a new heating element in the vacant space.

We connect the previously removed fasteners, wiring and temperature sensor to the part.

If the check showed that the heating element and valves are in perfect order, but water is still poorly poured into the tank, we pay attention to the machine door. Probably, the hatch blocking device or UBL does not work, and the control board does not give a command to the drum set

Therefore, we disconnect the machine from communications, and begin to test the locking mechanism, "ring" with a multimeter "and clean up the contacts.

Rules of operation and prevention

Modern technology is quite reliable, and most of the troubles can be avoided by observing the operating rules.

In the case of a washing machine, these are:

- Clean pockets before washing. Cleaning up small items, documents, and so on is a very useful habit. It will save not only the "washing machine", but also many necessary little things.

- Observe weight criteria when loading.

- Fill the unit with the correct detergent. That is, if there is no liquid or dry powder, postpone washing or wash by hand. Incorrect household chemicals in the tray can adversely affect the integrity of the entire system, for example, corrode some of the connections.

- If voltage drops occur, connect the washing machine through a stabilizer.

- Regular - once a year - cleaning the filter from debris and the entire system from scale. This is enough for the excellent performance of the technique.

Any technique loves cleaning, prophylaxis, maintenance, this seriously affects its service life and the quality of the operations performed.

In fact, there are three solutions to the problem of not having a drain, not two. In addition to calling the master and self-diagnostics, you can instruct someone from the family to conduct an inspection and repair work. Suddenly there are technology lovers among them who have long dreamed of getting to know the device of the washing machine.

Finding the cause of the breakdown, fixing minor problems

The culprits of the failure:

- The connecting pipe between the pump and the tank is clogged with debris or small change from the pockets and does not allow water to pass through well.

- The pump has broken (or something is stuck in it). The unit hums a lot and water does not drain out of the washing machine.

- The pump filter is clogged. This may be after washing very dirty things or an abundance of loose small parts in the bookmark.

- The drain hose is pinched. If there is no direct discharge into the sewer, the hose is thrown into the bathroom manually, perhaps the "washing machine" was moved or something was put behind it.The hose can be squeezed by a heavy object, or folded into kinks. It is corrected instantly - you just need to straighten it.

- The hose supplying water to the pump is clogged.

- The siphon is clogged.

- The sewer is clogged. With direct draining, this can affect the operation of the machine - the water has nowhere to go. They quickly stop washing and flush the drain before additional water flows into the apartment.

- Broken control module.

- Overload. Washing machines are designed for a certain weight of laundry. If you put in a lot more, but tamp it well, she not only does not stretch clothes, but also faces problems with draining water. For normal operation, you will have to pull out some of the laundry, leaving it for the next bookmark.

The algorithm for diagnosing problems is simple - you should not immediately disassemble the machine and, sorting out the parts, try to understand why the washing machine does not drain the water. It is more convenient to check for possible malfunctions as the complexity increases.

1. Disconnect the device from the mains. This is a prerequisite for any equipment repair. 2. Clean the filter of the drain pump. 3. Drain the water from the machine. 4. Unscrew and inspect the drain pipe. 5. Assess the ease of rotation of the impeller. 6. Check the pump performance.

1. Disconnect the device from the mains. This is a prerequisite for any equipment repair. 2. Clean the filter of the drain pump. 3. Drain the water from the machine. 4. Unscrew and inspect the drain pipe. 5. Assess the ease of rotation of the impeller. 6. Check the pump performance.

If a malfunction is found at a certain stage, it should be eliminated and the unit's operability checked. It works - there is no point in continuing to disassemble the equipment. If the problem persists, go to the next item. The situation is quite real when one breakdown pulls another.

Reasons why water does not flow into the washer

If there is a lack of water, which is drawn into the machine during rinsing, the automatic system is triggered, and an error indicator is displayed on the electronic display of the control unit, signaling an insufficient liquid level, due to which the process stops. The user's task is to find the reason why the washing machine does not pump water, to eliminate the breakdowns on his own, if possible.

Feeding problems

The reasons, as a consequence of which the washing machine does not fill with water, are elementary, for example, the intake tap is closed. Then the wash is not even started by the triggered protective automatics of the equipment. It is necessary to open the tap and start the washer again. But perhaps repair work is underway, so the water or low pressure is turned off in the house. In this case, you need to wait for the completion of the repair, and then continue washing. It is also recommended to inspect the supply hose - it may be damaged or clogged.

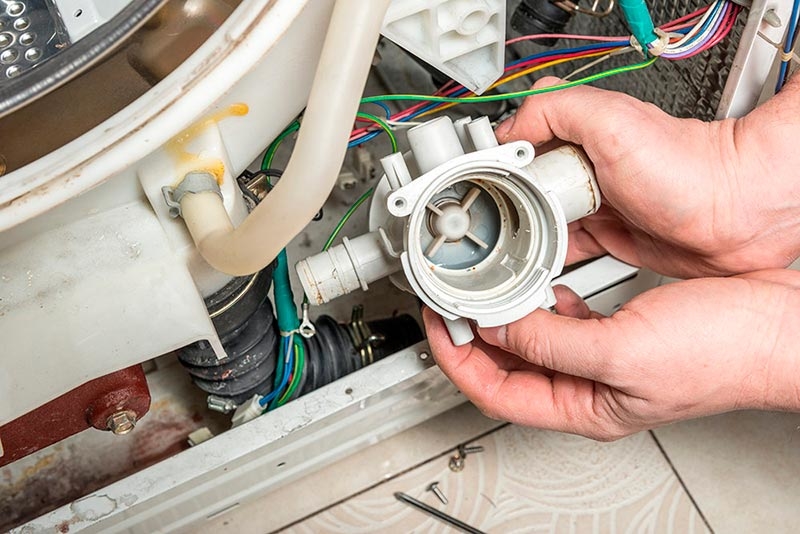

The pump has broken

If their pump fails, the washing machine does not rinse things well and does not drain the waste water.

If their pump fails, the washing machine does not rinse things well and does not drain the waste water.

If the drain pump breaks down during the rinsing mode, at a certain moment, water does not enter the drum of the machine, it does not rinse well or does not rinse clothes at all. At the same time, the synthetic detergent for preliminary washing does not pass from the loading box, and the spent liquid leaves for a long time or does not drain into the sewer at all. If this pump burns out, you must contact the service department - it cannot be repaired on its own.

Door problem

Failure of the door lock-blocker or loose closing of it leads to the fact that the electronic system will pause the washing process. When using washing equipment, the metal hinges of the door and the plastic guide are worn out, which prevents the hatch from being fixed in the “Closed” position. The blocking system from unintended opening of the hatch breaks down during the operation of the washing machine. This is the reason for the start of the protective mechanism, which blocks the access of water to the drum.

Pressure sensor does not work

A breakdown of the pressure switch does not allow the machine to pour water into the system, the sensor will signal a full tank, due to which the filling is not performed (the inlet valve stops opening), or the drain into the sewer will begin. If this unit does not work, it also does not spin the laundry. Also, a malfunction of this sensor leads to the destruction of the heating element of the machine.

Broken intake valve

The inlet valve is responsible for filling the equipment with liquid and is located on the back of the body.

The inlet valve is responsible for filling the equipment with liquid and is located on the back of the body.

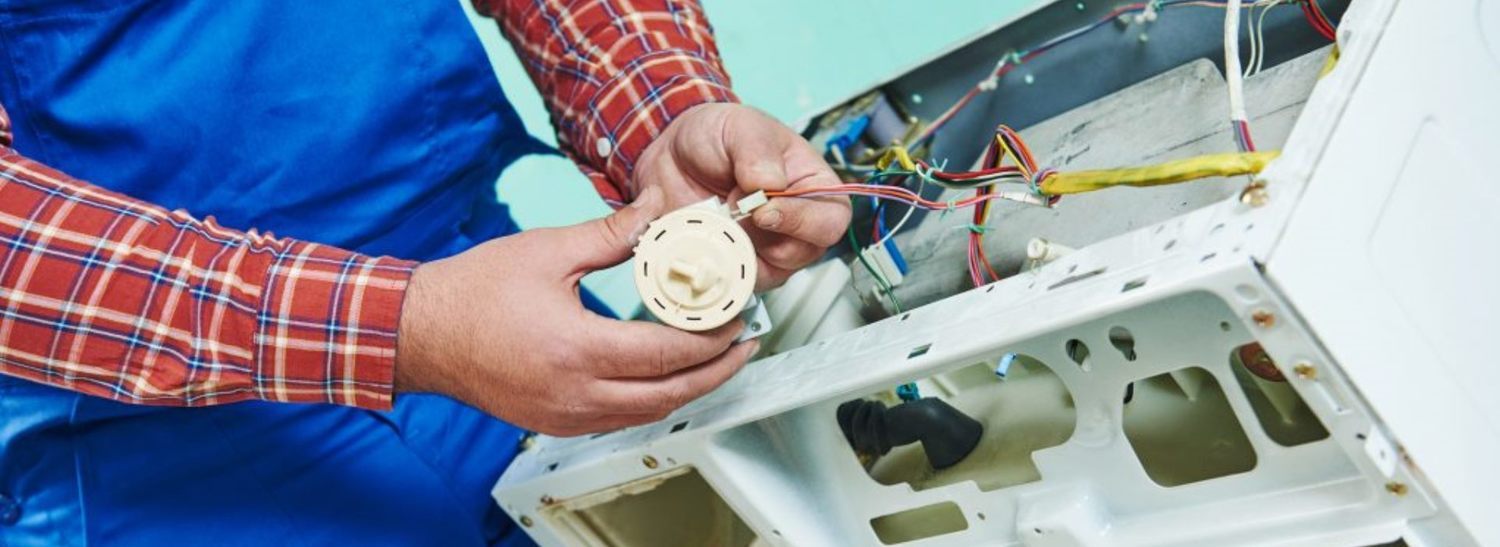

To check this part, you need to remove the upper part of the body from the machine - the valve is at the back. It is recommended to conduct an inspection to identify mechanical damage, then check its performance by applying voltage to the coils. If he is a worker, the device turns on and opens. When this is not observed, the part is replaced.

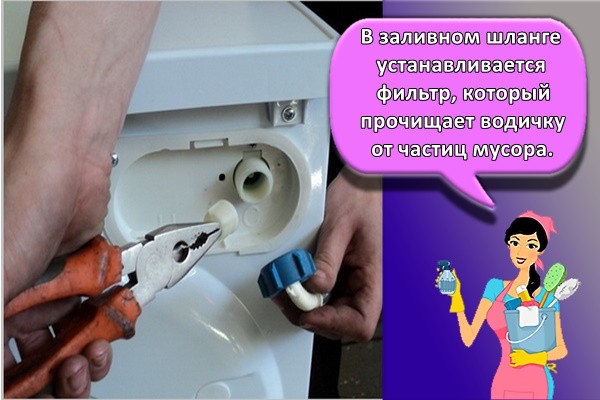

Cleaning filter clogged

Most modern types of automatic machines are equipped with an additional cleaning filter on the filling sleeve, which protects the inlet valve from debris from the water supply. Debris clogs the filter mesh, after which the washing machine's automatics are triggered and the work stops. The filter element is cleaned and washed.

Malfunction of the programmer

A faulty electronic control unit of the machine does not issue commands to start the washing program, therefore water does not enter the machine's tank. This breakdown occurs due to voltage surges in the electrical network, only a master can eliminate it. It is impossible to solve this problem on your own. Service centers try not to repair the module, but replace it with a new one.

Main reasons

Not always the cause of the breakdown lies in the washing machine itself. Sometimes external factors are to blame, for example, improper care or communication problems. All the reasons why the washing machine suddenly stops picking up water can be divided into two groups: external, not related to the machine itself, and internal, which relate to damage and malfunctions of mechanisms or other parts of the machine.

The first group includes:

- Lack of water supply or electricity. In these cases, you just have to wait for the water or electricity supply to be resumed. Calling the housing office can speed up the process.

- Insufficient water pressure. Typically, this is due to a drop in pressure or blockage in the pipes. Here, again, a plumber from the housing office will come to your aid.

- Errors made when connecting the drain. In this case, you need to check whether the connection of the drain hose is made in accordance with the instructions and, if necessary, reinstall everything again.

- Failure to comply with the rules for operating the washing machine. This point includes many very different reasons. Just re-read the instructions: you may be doing something wrong.

The second group, in turn, can be divided into two large subgroups. The first subgroup is the causes associated with the malfunction of mechanisms:

- Intake valve filter clogged. If so, then we can say that you are lucky: you can solve this problem on your own, without involving a master. Simply pull the filter out gently with pliers, rinse it under running water and replace it.

- Other inlet valve malfunctions are much more difficult to fix; most likely, it will need to be replaced.

- The door does not close. Perhaps some foreign object just got into the lock, or perhaps the element responsible for blocking the hatch has failed.

- The drain pump has broken. Here you will need the advice of an experienced master: he will tell you whether the unit can be repaired or whether you will have to buy a new one.

The second subgroup is the causes associated with electronics malfunction.

- Malfunctions in the electronic control unit. There can be a great many reasons, but in any case, without having special knowledge, it is better not to try to fix the breakdown on your own, but you need to seek help from a professional. Sometimes it is enough to just clean the contacts, and sometimes you have to order a new part.

- The pressure sensor and water supply does not work. As in the previous case, an experienced technician will help identify the problem. But it will be possible to solve it, most likely, only by replacing the element.

Causes of malfunction

Poor water supply to the washing machine can indicate a variety of problems.Some of them can be eliminated by hand:

- The supply hose is kinked. First of all, inspect the inlet hose from the pipe to the device: it should lie freely and not be squeezed by anything. If even a small area is clamped, the tank will take much longer to fill.

- Weak water supply pressure. To ensure fluid is delivered at the correct flow rate, fully open the cold tap in the sink or bathtub and evaluate the flow. If the flow is such that drops fly away from the surface more than 5 cm, then this is not the problem. If the pressure is small, we recommend stopping the wash and waiting for the normal operation of the water supply. Masters say that the cycle can not be interrupted, it just will last longer, but washing with a poor pressure can overheat the heating element and break the control board. Owners of AEG, Ardo, Whirlpool devices need to be especially careful.

- The stopcock is not fully open. Sometimes users do not pay attention to the supply valve and do not tighten it to the open position. In no case should you do this. This leads not only to the fact that the water does not flow well into the tank, but can also deform the faucet itself, the hinge will erode over time and may break.

If you have checked all the available zones, but still have not figured out why the water is poorly flowing, then the problem was caused by a broken part. We will consider possible failures in more detail.

Clogged filter

Before the liquid is poured into the tank, it passes through a small mesh filter that keeps rust particles, salt sludge and other debris from entering the system. Over time, this filter can become clogged with debris and interfere with the free flow of water. More often than others, owners of LG, Samsung, Bosch appliances face this problem. If you have experience in equipment repair, you need:

- Disconnect the inlet hose.

- Gently pull out the filter mesh with pliers.

- Clean it from plaque, perhaps soak it in a solution of lemon or acetic acid to remove the sediment.

- Replace the filter and reconnect the appliance to the water supply.

If you are not sure that you can properly clean the blockage, it is better to contact a professional.

Intake valve breakage

After the filtration mesh, there is a filling valve in the machine body, which is responsible for when and how quickly the drum is filled. Depending on the program, a signal from the control module is sent to the solenoid coil and the dampers inside the valve open or close. If one or more coils are shorted, the information signal will not be received or reproduced, and the damper will remain closed. Water will not be able to enter the tank with the normal pressure.

Also, if the protective filter is broken, all debris from the water supply will flow to the valve diaphragm and accumulate there. This also lowers the head and can damage the parts.

Some experts suggest repairing the intake block, replacing coils, or removing a blockage, but any defect will wear out the element, so we recommend installing a new one. Manufacturers Candy, Ariston, Indesit and Hansa also advise against using parts after a problem.

Control module failure

The control block is the brain of the entire system. It contains all the operations that your equipment can perform, therefore, if the washing machine does not pick up water well, it is probably the control unit that is to blame.

Usually this part is carefully closed from access. But if the contacts are short-circuited or moisture gets on the surface of the board, a failure could occur. In this case, a command is sent to the serviceable inlet block to reduce the feed rate. This is a serious control box failure that can cause parts overheating, shorts and other damage to the system.

The control board cannot be repaired; a spare part must be installed. It is advisable to use original components, for Zanussi and Miele brands this is a prerequisite for restoration. To call a specialist, dial 8 (495) 777-19-19 or use the feedback form on the website.If you create an application earlier than 12 o'clock, it is possible for the master to leave on the day of the request.

Blockages

Clogging is one of the most common causes of washing machine breakdowns. Over time, the filters become clogged and scale build up. Filters are divided into two types: drain and inlet.

Note. Particularly often, inlet filters break in Zanussi machines.

Signs of filter clogging:

- unpleasant smell emanating from the device;

- slow set of water and its drain.

Step-by-step cleaning plan:

- input filter:

- turn off the water supply tap to the washer;

- disconnect and pull out the hose;

- pull out the filter;

- rinse the filter under a strong pressure of water;

- put the clean filter mesh back and press on the edges;

- assemble the system and check for leaks.

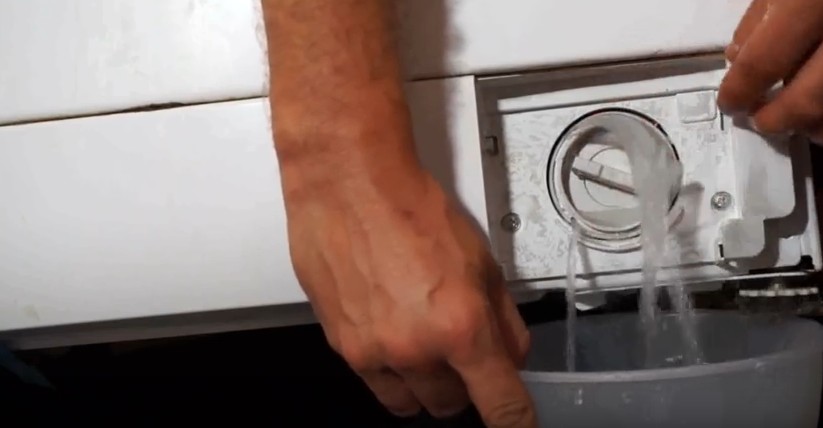

- drain filter:

- open the lower hatch on the front panel;

- disconnect the hose;

- substitute the container and drain the remaining water;

- pull out the filter in a circular motion;

- rinse the filter under running water;

- install the part back;

- turn on the machine to the "drain" mode and check for leaks.

To prevent blockages, the filters should be cleaned at least once every 2-3 months. The socket of the dirt trap and the place where the filters are installed are also subject to cleaning. Such simple maintenance can extend the service life of the machine for many years.