Materials and tools for assembling a wooden structure

A person who starts assembling furniture with his own hands needs to prepare the following basic tools and materials:

A person who starts assembling furniture with his own hands needs to prepare the following basic tools and materials:

- Curly and ordinary screwdriver (ideally if it is a screwdriver with many attachments), screwdriver.

- Normal hammer - small or medium in size.

- Reversible key.

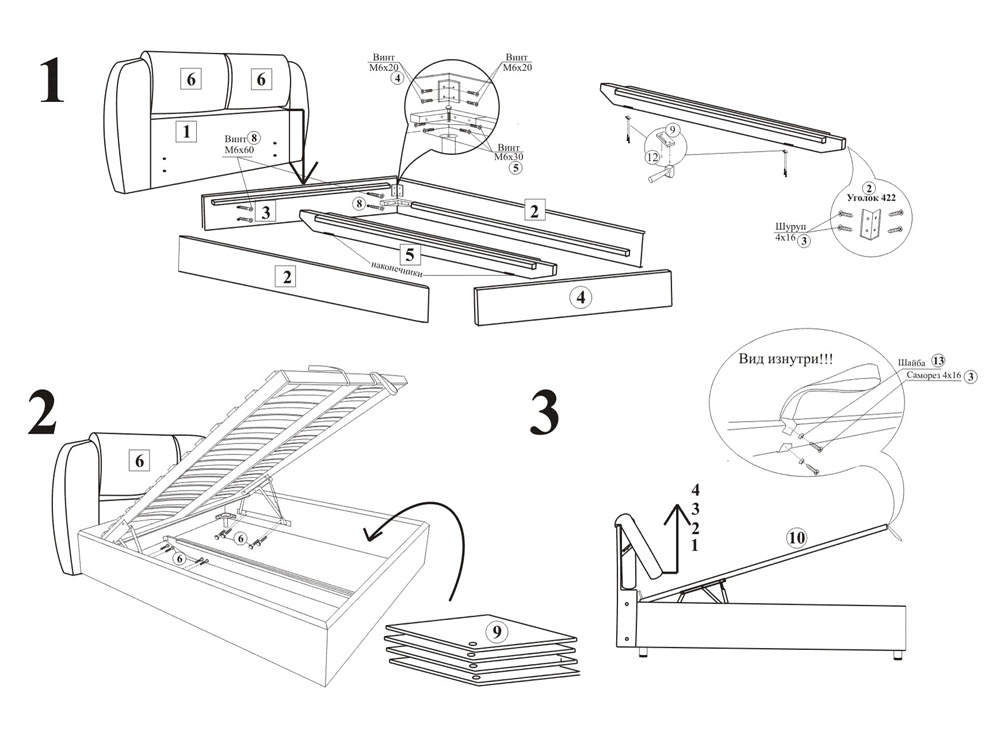

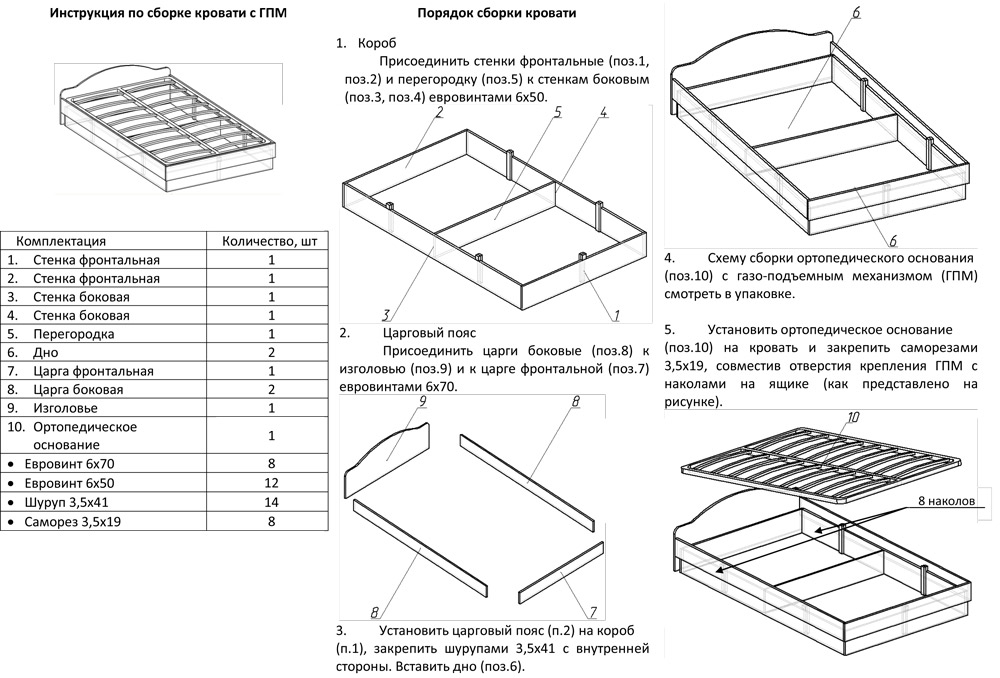

- Manufacturer's manual with assembly diagram. It should be included with the kit you purchased.

Before you start assembling the bed, you need to carefully consider the instructions.

Please note that this information must correspond to the configuration, include all those elements that come with the bed. The instructions should be clear, not vague, with numbered details.

Transfer all the sealed parts of your bed to the room where you plan to assemble. After checking all the components and main parts, comparing them with the quantity according to the instructions, you can get down to business.

Advice

All actions must be performed not alone, but together. You can involve household members in work.

Step-by-step description of making a bed with a lifting mechanism

Having prepared everything you need, you can proceed directly to the manufacture of the lifting bed. Let's consider all the stages in detail.

Manufacturing of a lifting frame

The lifting frame is the basis for the main function of such a structure - the ability to lift. Let's take a closer look.

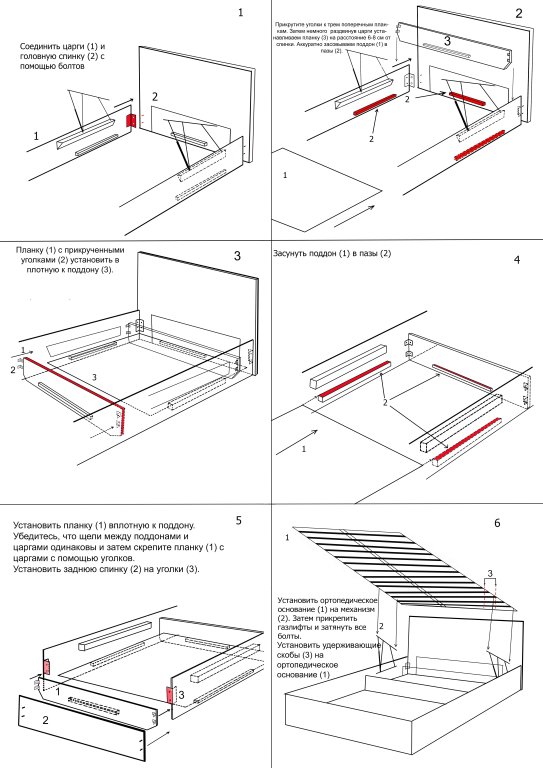

First, you need to make a lifting frame.

First, you need to make a lifting frame.

The work includes two stages: manufacturing and processing. The first means:

- Prepare the frame parts.

- Assemble the bases with calibrated boards. This is best done on a flat surface.

- Screed the resulting structure with metal corners and furniture glue. All cuts need to be processed with sandpaper, make sure that the caps of the screws are slightly buried in the tree.

- If you intend to make a large bed, then you need to make a central partition for greater strength.

- Attach the strips with self-tapping screws on the inside of the sidewall and align them with the bottom edge. Reiki should be approximately 20 * 80 centimeters.

- In the role of slats, you can use slats, the length of which should be equal to the width of the future bed. Attach them to the support rails about 15 centimeters apart.

The frame is ready, now it needs to be processed. To do this, it is necessary to process the boards with sandpaper, and then cover with wood varnish.

Installation of an inset frame under the mattress

After making the lifting frame, you need to start installing the insert under the mattress. It will increase the reliability of the structure and extend its life, so this stage cannot be skipped when making a double bed.

For installation, you will need wooden strips and a steel profile.

For installation, you will need wooden strips and a steel profile.

Headboard manufacturing process

Any material can serve as a basis: plywood or natural wood. Apply the markings, and then use a jigsaw to carefully cut out the shape of the back. This element can be given any shape you like.

The headboard can be shaped to any shape you like.

The headboard can be shaped to any shape you like.

Get a furniture stapler, trim material, and a foam sheet. The sheathing should be soft and airy; for this, lay two sheets of foam rubber between the plywood.

Making the main frame

An integral part of any bed is its main frame, which consists of:

- side drawers, front and rear backrest, bottom of boxes;

- mattress flooring created from slats or planks.

Be sure to place emphasis on ensuring that all elements are securely fastened.

Making the main frame

Let's take as a basis the standard dimensions 2 * 1.8 meters. Take 2 boards of 2 meters for the side edges. For the end, take two boards of 1.8 meters each, connect them with self-tapping screws and corners. All boards should be fastened at right angles.

When assembling the main frame, it is important that all boards are fastened strictly at right angles.

We install lifting mechanisms and supports

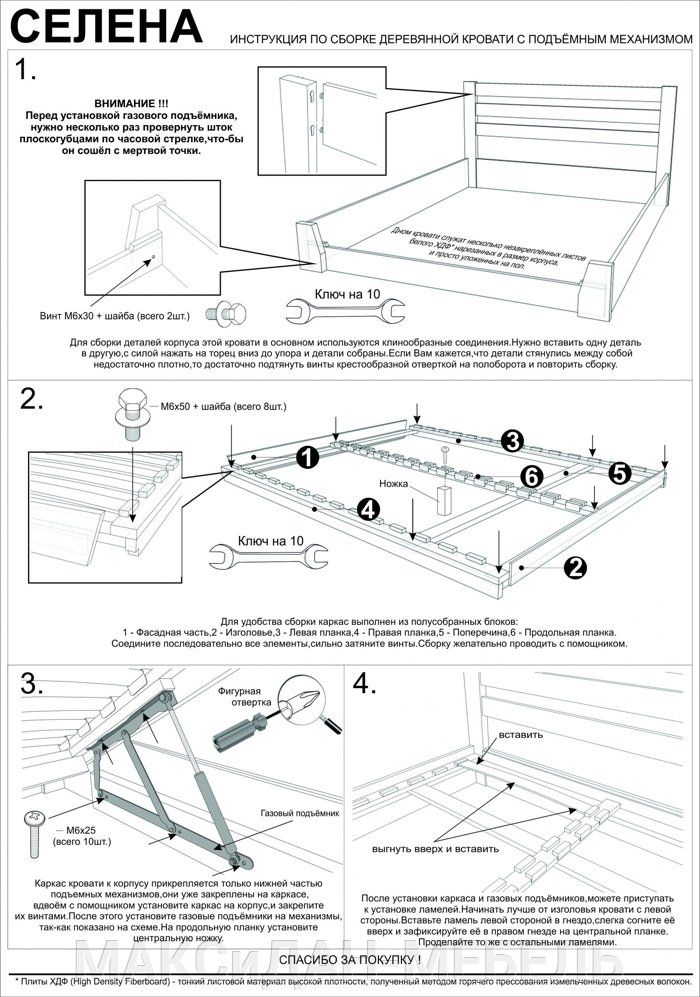

To install the lifting mechanism, you should fix the upper bar and the bed grate with rolled steel, then attach the two bases of the mechanism to the bar to lift the structure. Fix the bottom bar so that it is located on the main box and check the strength of the structure and its function. Installing the mechanism is the easiest step, so even a beginner can handle it.

Sheathing and finishing

The last and final step in making a lifting bed is decoration. You can do without it altogether and just varnish the wood, but if you want to finish, then you need to choose a material for this. The most commonly used are the following:

- the cloth;

- leather or leather substitute.

Cover the frame and headboard with the material of your choice. In order for the upholstery to be airy and soft, it is worth using foam rubber. A stapler and glue will help to carry out all operations.

The final stage is the upholstery and decoration of the bed.

The final stage is the upholstery and decoration of the bed.

To make a double bed with a lifting mechanism with your own hands, you must strictly follow the instructions, carefully measure and be patient. As a result, you will get a chic homemade bed that will help you successfully save space in a small room.

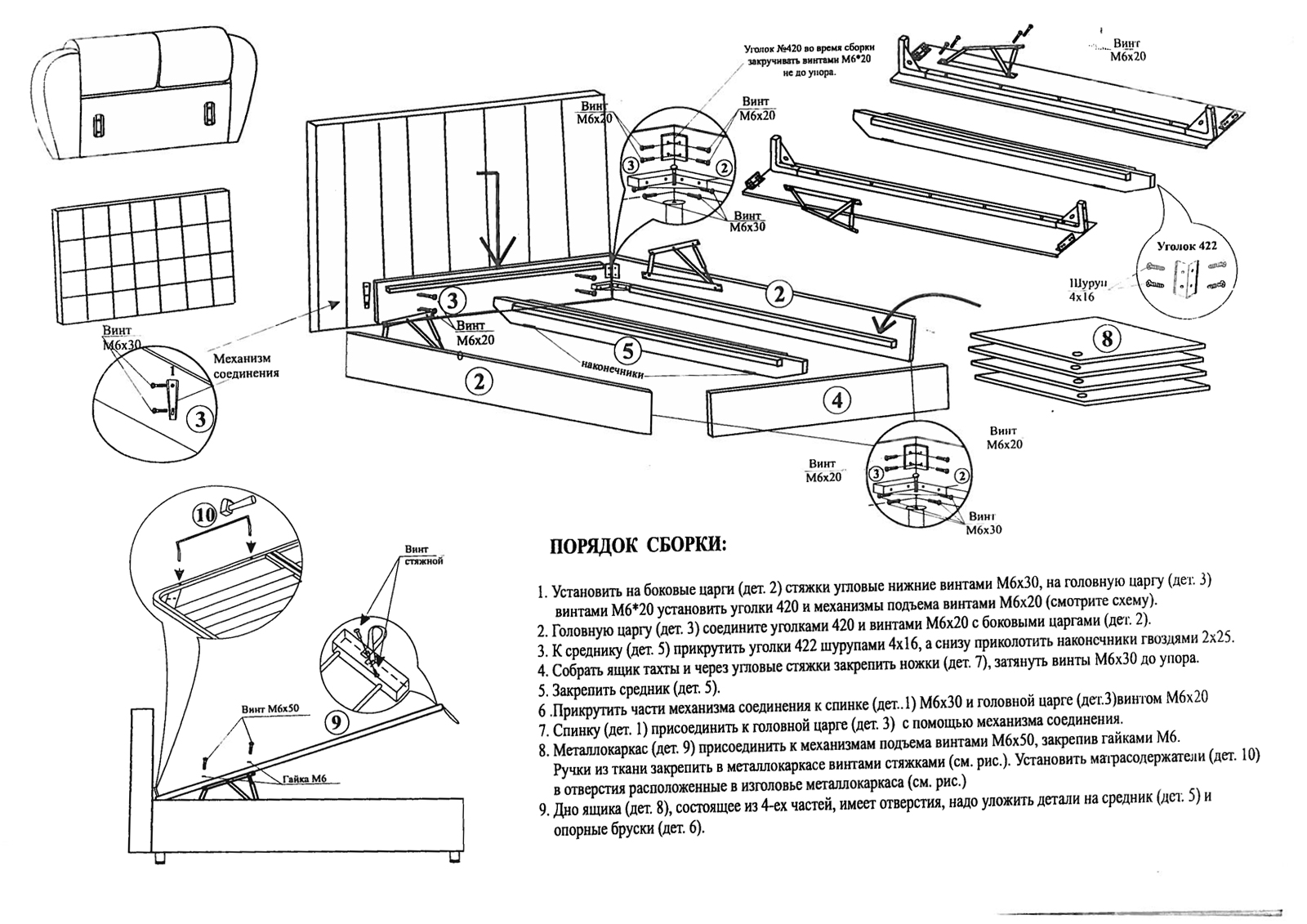

Manufacturing steps

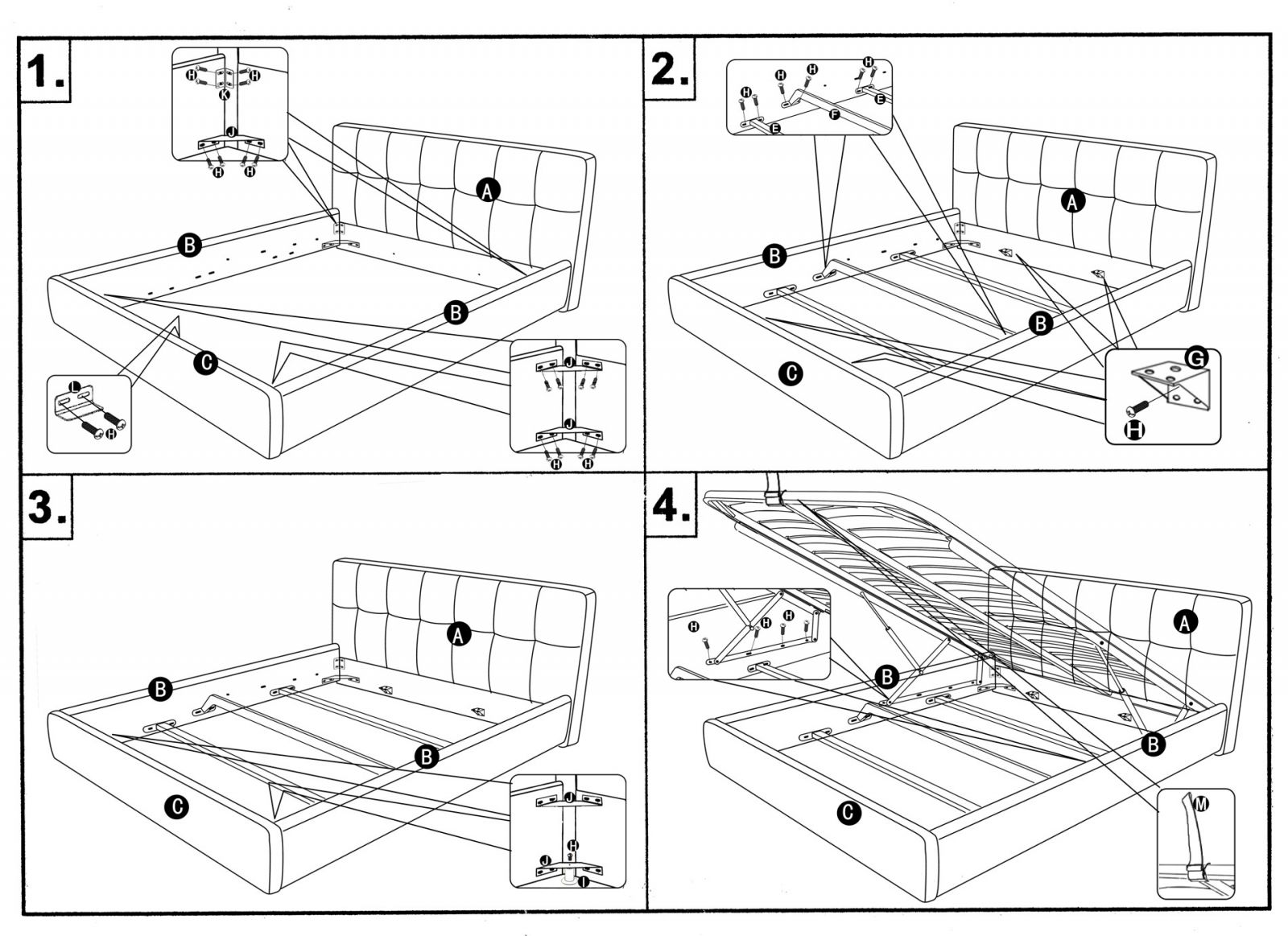

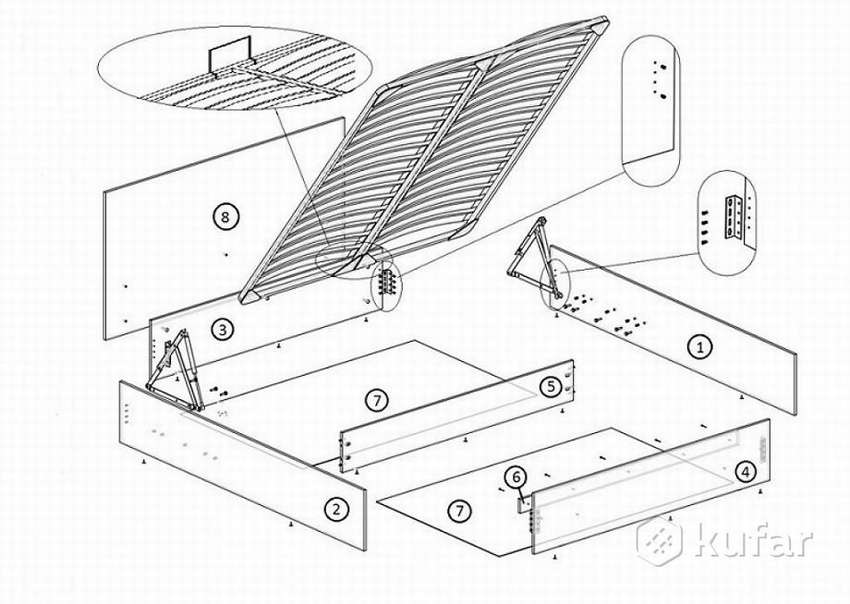

After the end of the preparatory stage, you can safely start assembling the bed with a lifting mechanism. The elements are mounted in the following sequence:

- main frame;

- lifting structure;

- directly the lifting mechanism.

At the final stage, sheathing and decoration are performed. The process must take place strictly in the agreed order, otherwise it will not work to complete the assembly correctly.

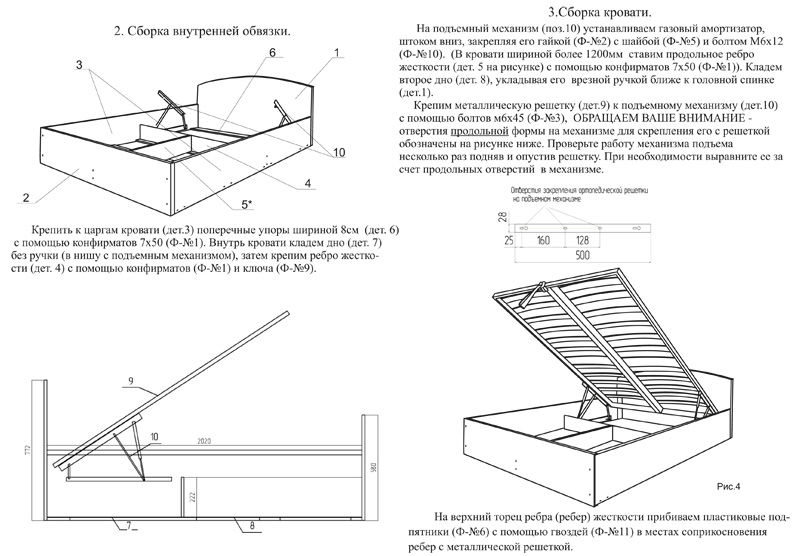

Main frame

Any lifting bed should be based on a reliable frame. It consists of several elements:

- side drawers, back and front edges, bottom for the installation of boxes;

- mattress flooring, which is created from slats or wooden boards.

To make the main frame of a regular bed with side ratios of 2 to 1.8 m, you will need a lot of details. On the side faces, you will need a pair of boards 2 meters long. For the end parts, it is better to take also two boards, but 1.8 meters each. Next, you need to connect them using self-tapping screws and several corners. This stage of assembly is the most critical, so you need to make sure that the formed corners exactly correspond to 90 degrees. If glue was used, its protruding excess must be removed immediately, otherwise difficulties may arise during further surface treatment.

When making a large bed, a stiffener must be installed through the longitudinal axis. If the project includes legs, they should be fixed at the very end. The easiest option is to use four wooden blocks. To strengthen the structure, you can make an additional leg in the center. In conclusion, it is recommended to varnish the resulting frame.

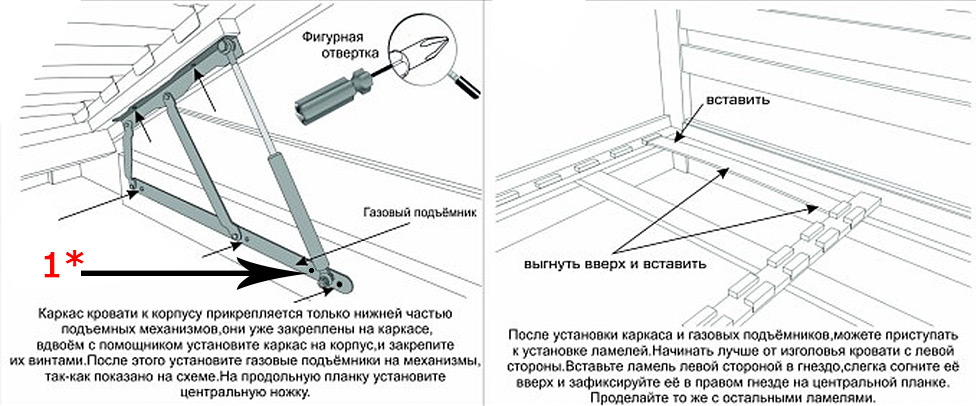

Lifting structure

The process of creating and assembling a lifting frame consists of two points: joinery and carpentry operations and processing. The first stage begins with the manufacture of a box from calibrated boards. It is best to do the work on the floor to avoid distortions. Further, using corners, all the elements are combined. The joints can be additionally reinforced with furniture glue

It is important to pay attention to the caps of the screws - it is necessary that they go under the wood, but only slightly.When creating a large bed along the frame, you will need to lay an auxiliary partition

Now you need to fasten the slats. Fasten them with self-tapping screws inside the side surfaces. Previously, the parts must be aligned parallel to the lower edge of the box. Elements are required for fixing the lamellas. The dimensions of the slats should not exceed 9 cm in width. For slats, you can take the same blanks, but only with a length equal to the width of the future bed. Plywood is also suitable for this purpose, but you will have to make a central partition.

It remains to process the lift. The structure can be ennobled with sandpaper or varnished. One of the significant nuances in the preparation of the frame is the quality of the plywood, which is laid on the lamellas in order to evenly distribute the load.

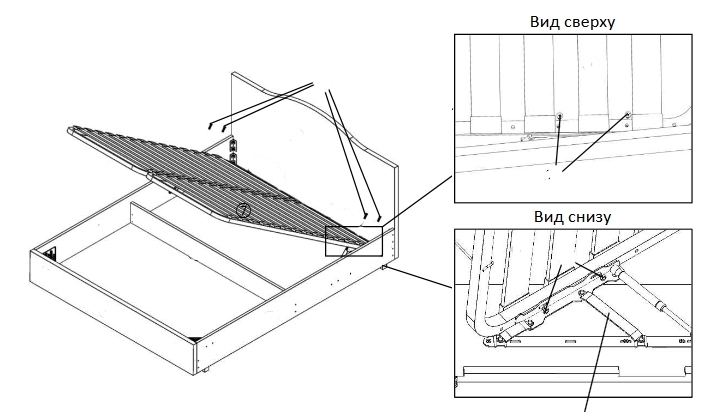

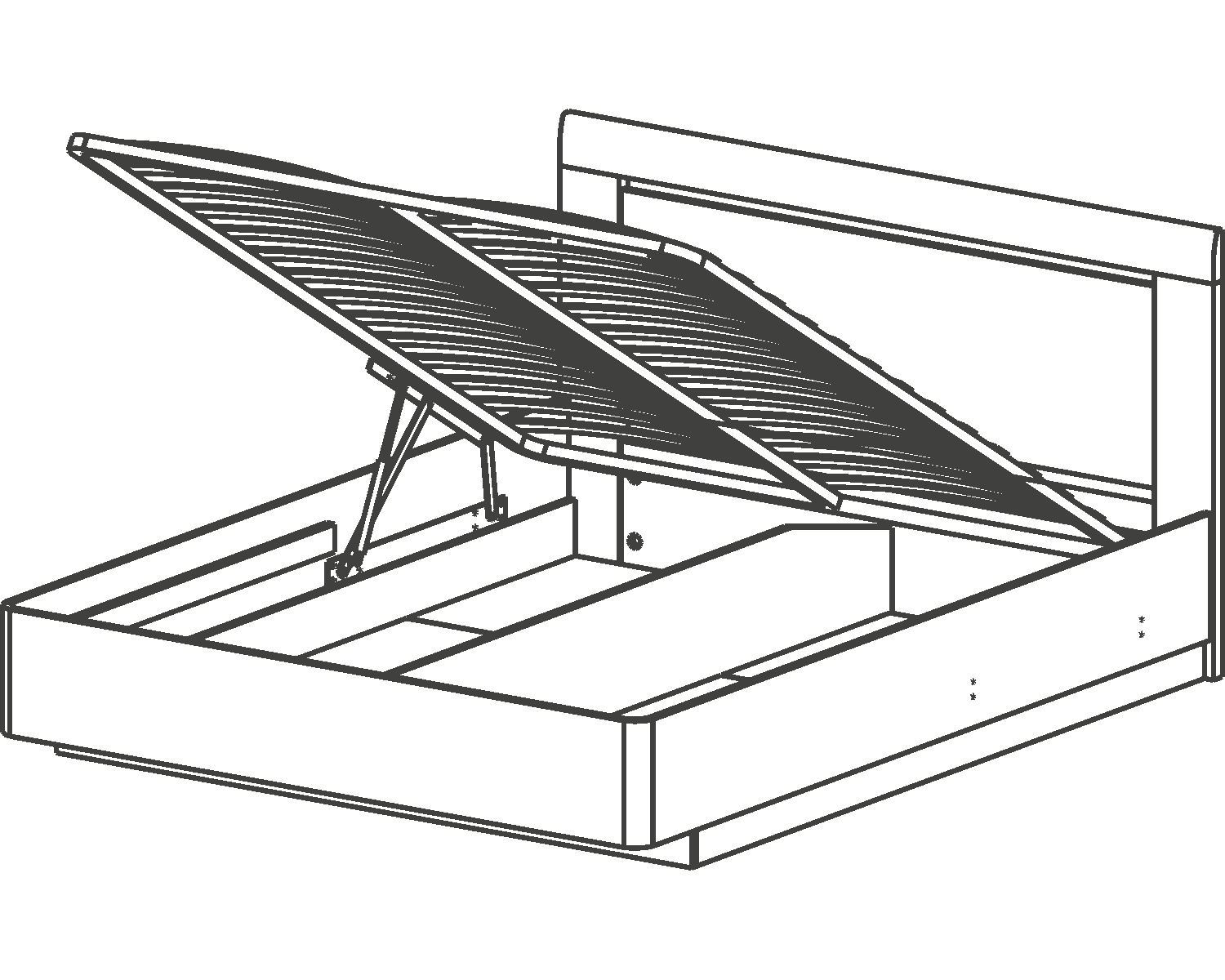

Installation of the lifting mechanism

Installing the hoist is the easiest assembly step. First, its upper part is attached to the bed frame using a special steel bar. Further, the remaining parts of the lifting mechanism are attached, which provide control over the highest lifting height of the bed grate and mattress. The lower bar is attached to the main frame. The installation is complete, it remains only to check the strength of the fixation and test the mechanism in action.

Sheathing and decoration

The final stage in the creation of any furniture product is considered to be upholstery and subsequent decoration, which should correspond to the style of decoration of the room. To do this, use:

- fabrics;

- skin or its artificial analogs.

The selected material must be used to cover the main frame and the head of the bed. To give the upholstery volume and airiness, a sheet of foam rubber is placed under the fabric. An ordinary construction stapler is suitable for securing textiles - its staples pierce even wood, due to which they tightly hold the material. If desired, the cladding can be performed at intermediate stages of work.

It is not easy for novice craftsmen to figure out how to make a bed with a lifting mechanism correctly. However, with a careful study of the process in the video and the further observance of all recommendations, it will definitely work out to make furniture. One has only to make a little effort during assembly and show imagination in the decorating process.

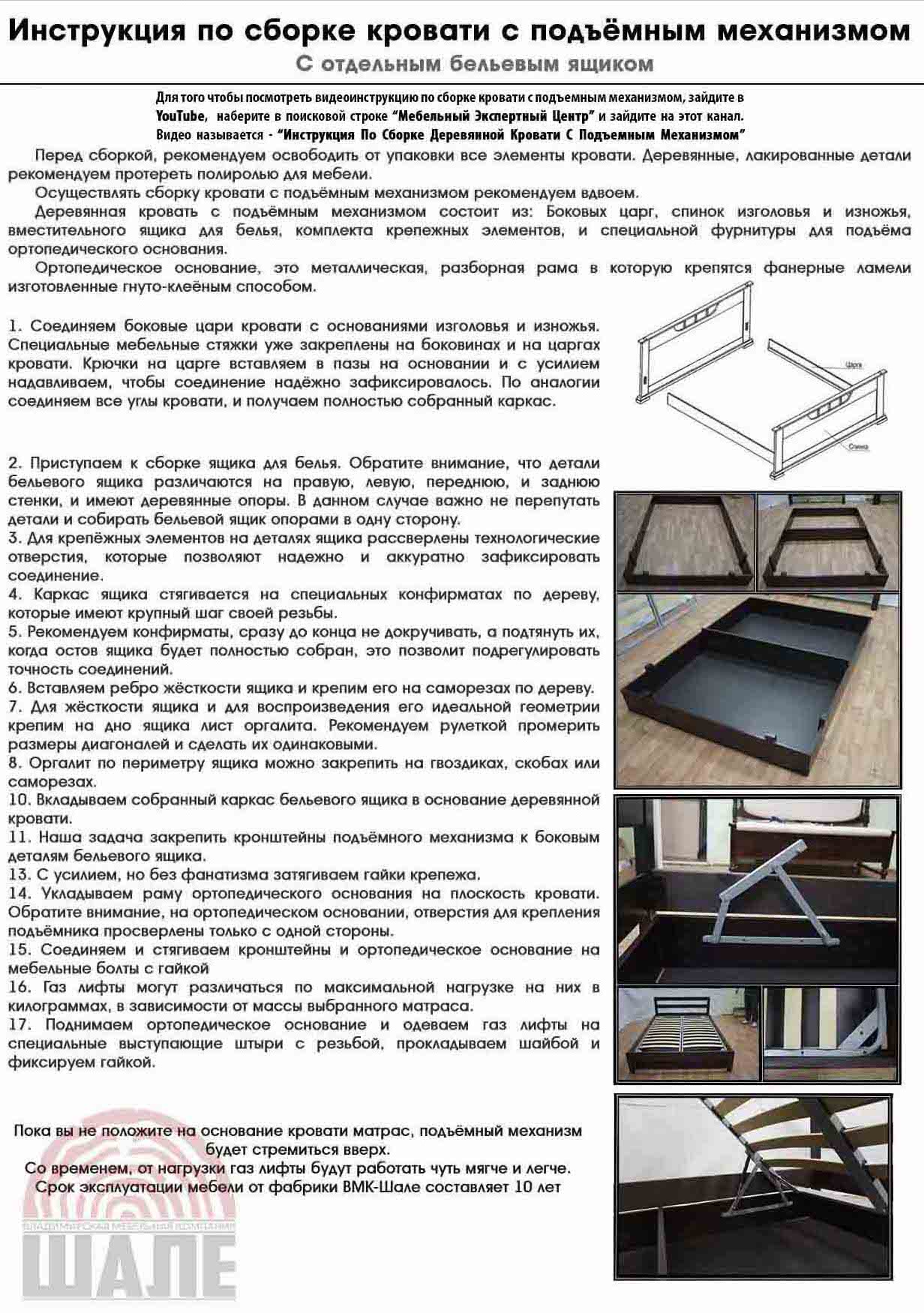

Assembling the bed with a lifting mechanism

For quality work, prepare tools that are used at home.

Required tools and materials

- screwdriver or screwdriver with a set of nozzles;

- medium hammer;

- reversible key;

- assembly instructions included with the product.

Assembly nuances

Before starting the assembly, carefully study the manufacturer's instructions, it should be clear. Then transfer the details of the future bed to the room where you plan to place it.

All steps can be written down like a checklist for assembling a bed, and the actions themselves are best performed together, so involve your family.

Usually the frame is wooden or metal, the lifting mechanism is always made of metal

Usually the frame is wooden or metal, the lifting mechanism is always made of metal

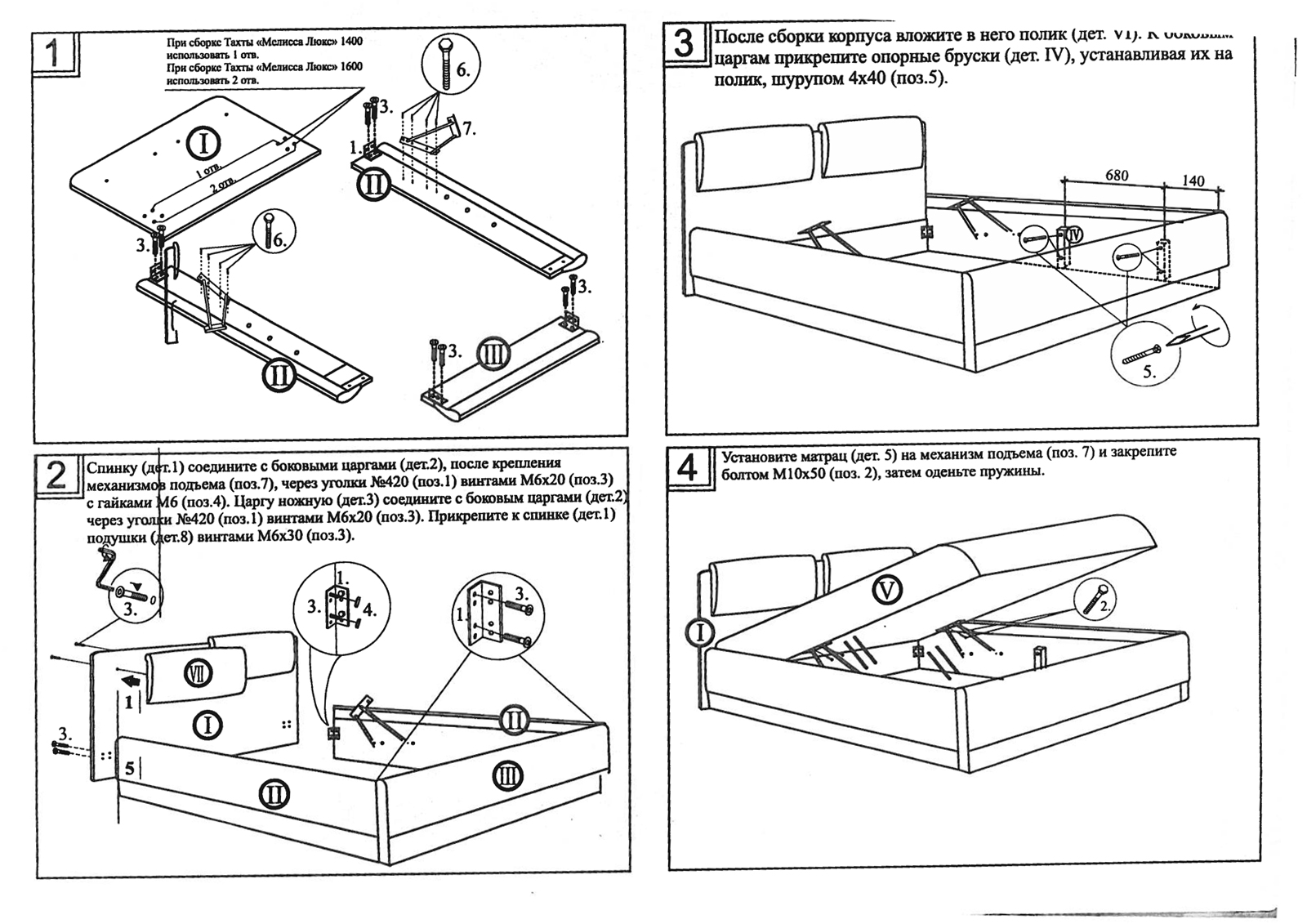

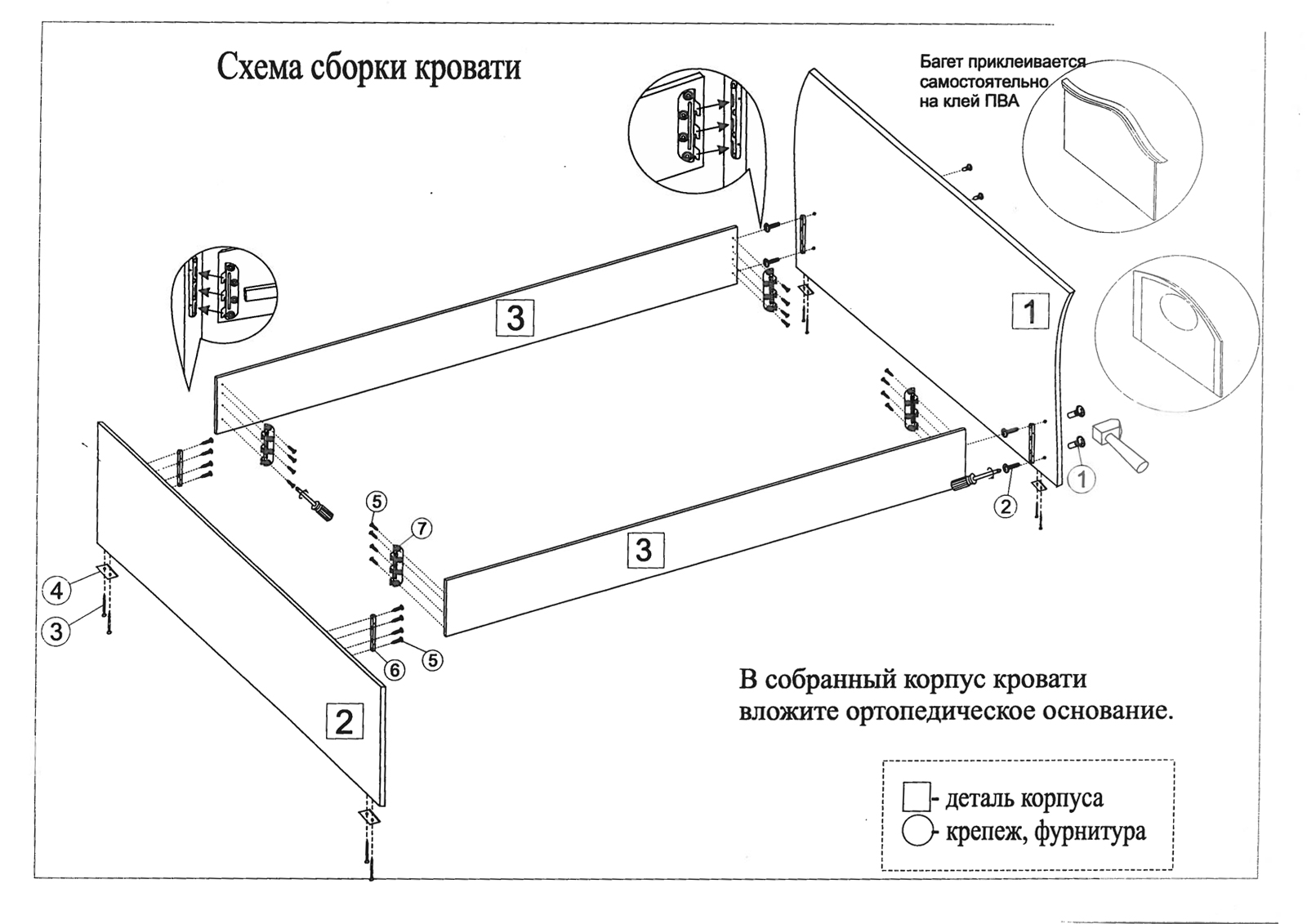

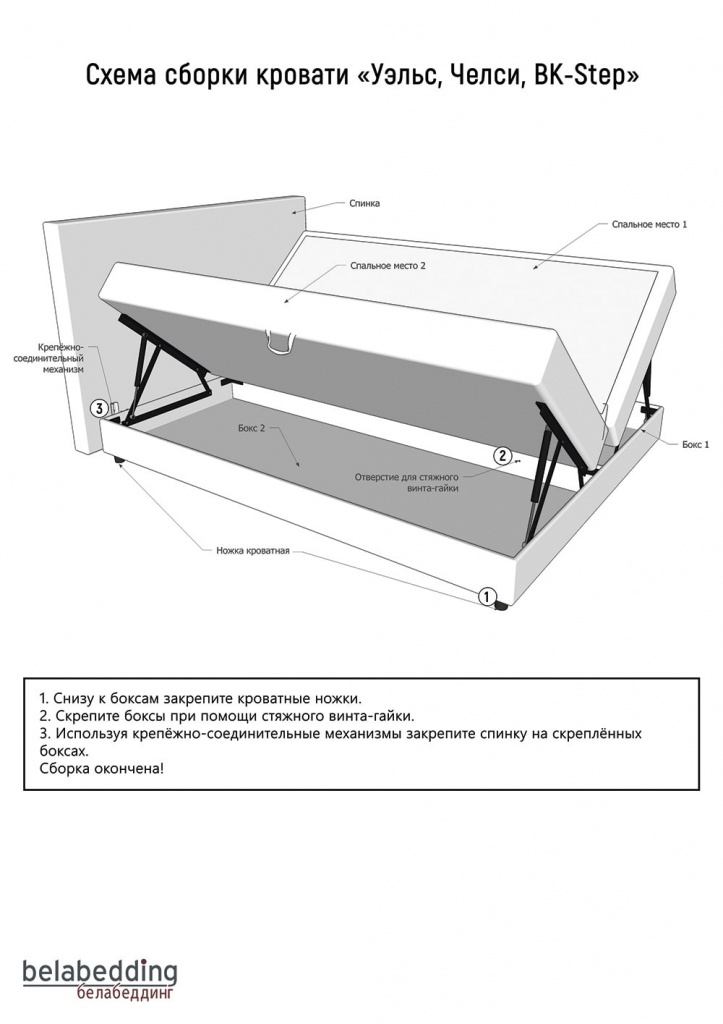

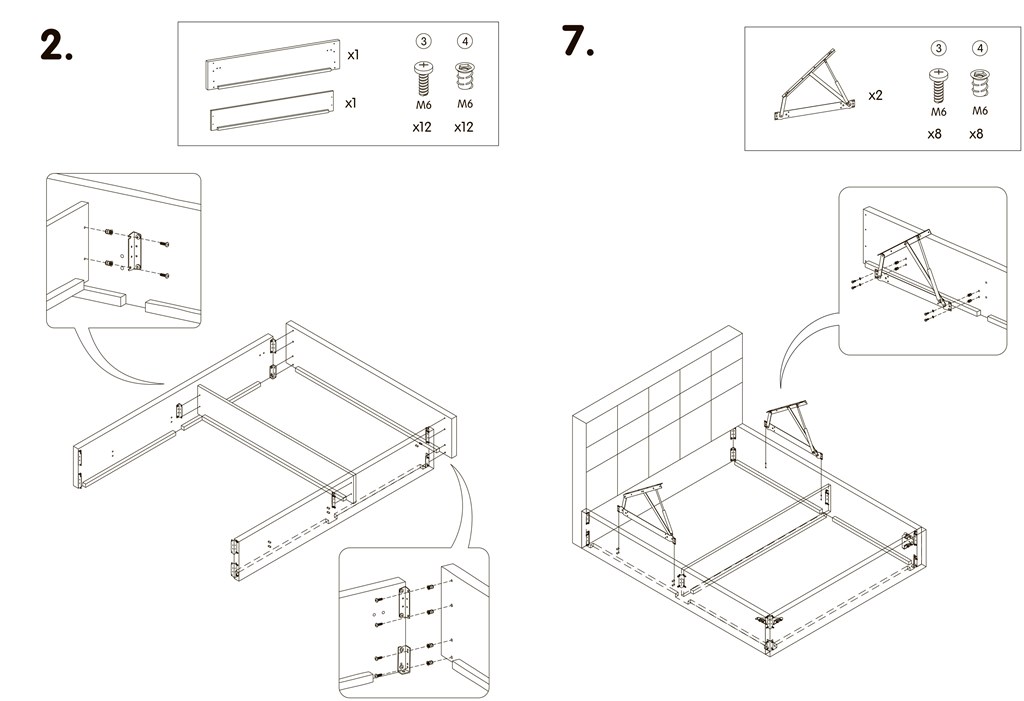

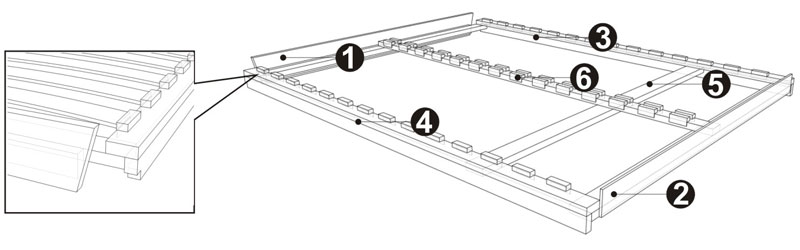

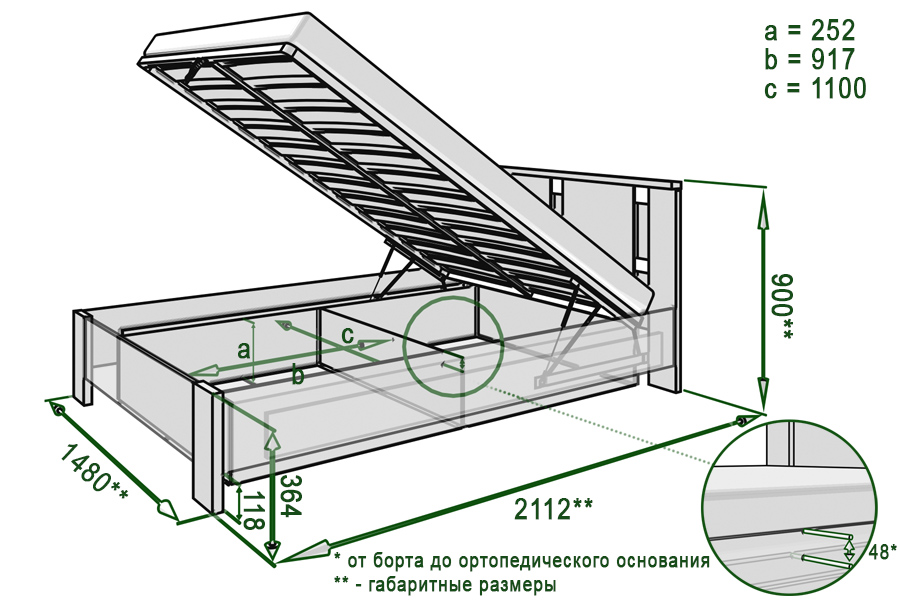

Base

You should start assembling the bed from the base, which consists of three frames and a headboard. To connect these parts into a single structure, you will need to take corners, small brackets or ties. For fastening, you must use the screws supplied with the model.

Then we attach the legs, if any, or install soft seals so that the structure does not damage the floor covering.

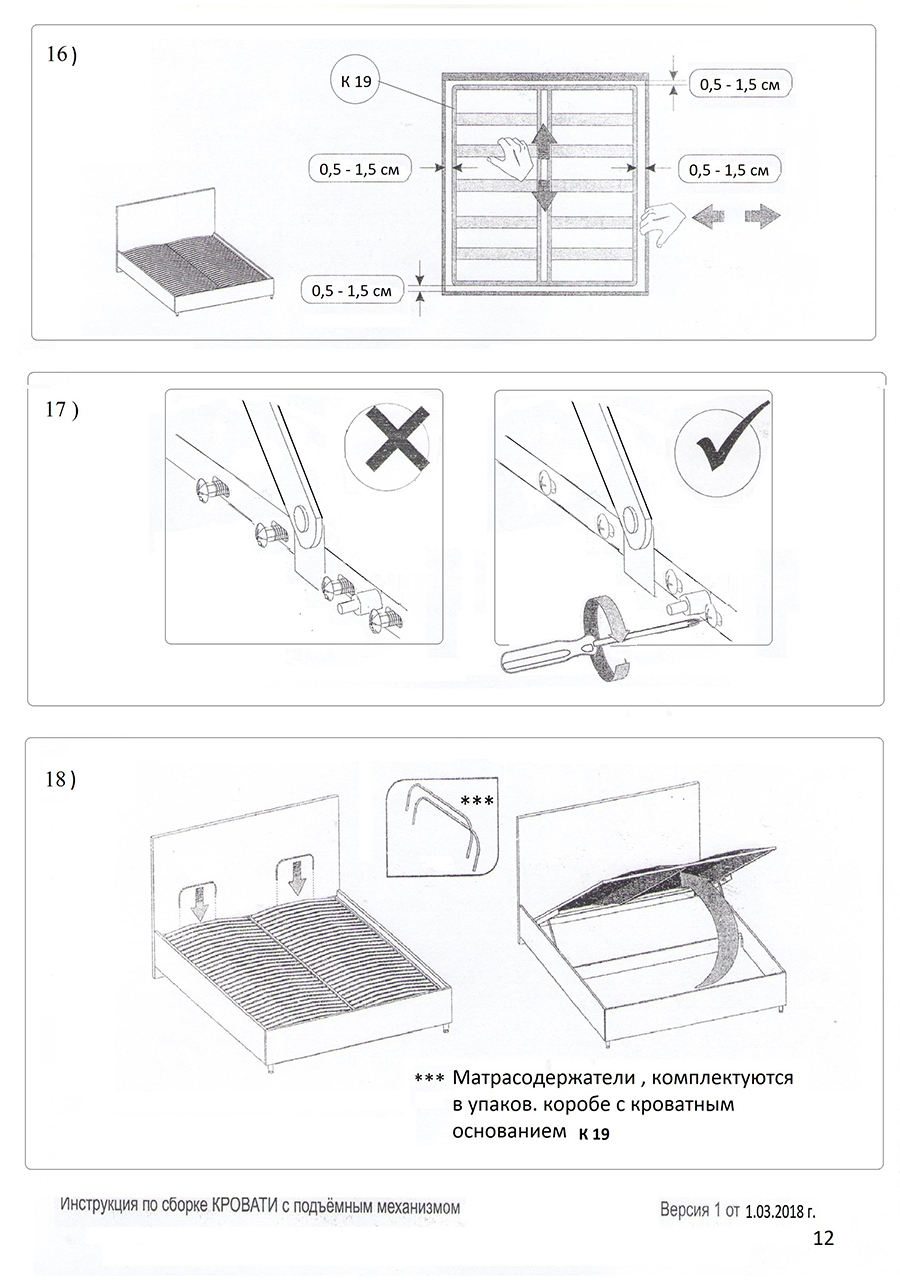

The next step should be installed to the upper part of the sidewall, if the model provides for a lifting mechanism, then we install it with a slight backlash (the gap between the parts is necessary to prevent the mechanism from jamming).

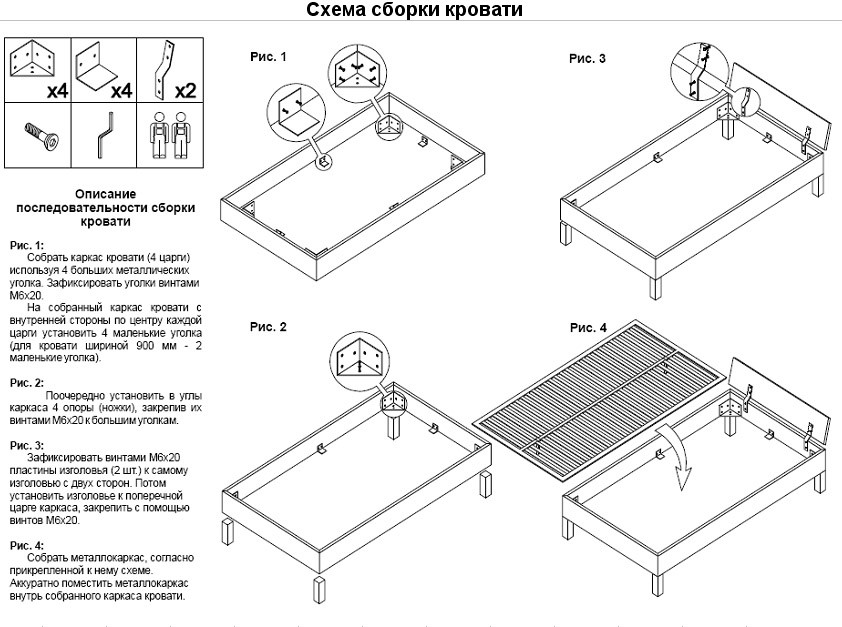

Frame

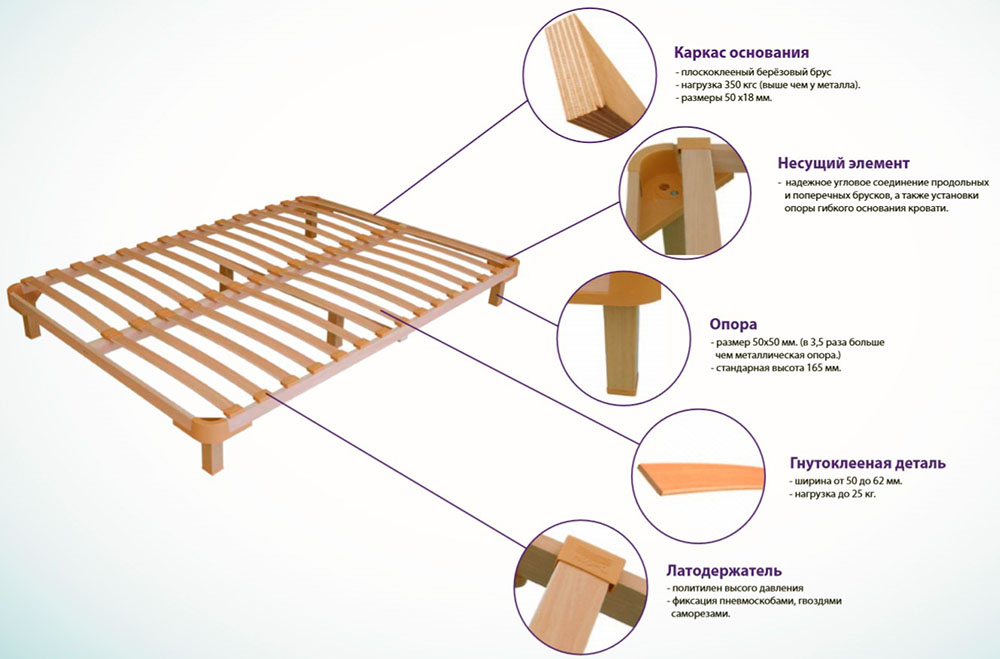

The main element of any bed is a frame, which is a metal frame with lamellas fixed to it.

Thanks to the lamellas, the mattress is supported for the most comfortable sleep.

The slats provide support for the mattress, which contributes to the most comfortable sleep

The slats provide support for the mattress, which contributes to the most comfortable sleep

Standard model

- Using the corners, we connect the side frames at a height of about 20 cm;

- We fix the footrests at the same height;

- We collect the ribs, they should be 5 centimeters above the frame;

- We strengthen the central frame with special corners.

With orthopedic base

Today, the orthopedic base is considered the most popular, since a large number of people have problems with the spine. The orthopedic construction consists of a frame and special adjustable lamellas. It is further completed with a mattress with specially designed padding and springs to provide restful sleep for people with posture problems.

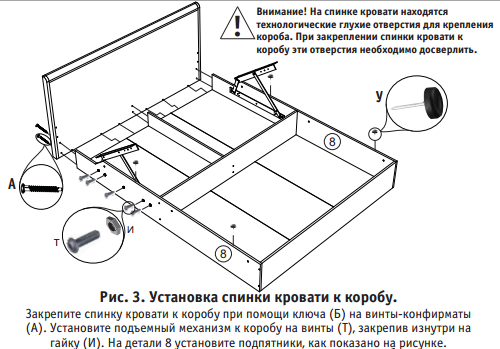

Headboard

The bed as a full-fledged piece of furniture is not only intended for sleeping, but also contains the main aesthetic component of the bedroom design.

The headboard can be carved, upholstered, covered in fabric or leather, and can also be the centerpiece of an eye-catching bedroom. Your task is to connect the sides of the frame with the headboard with the help of fixing elements

If the places for attaching the headboard are not marked, then it is necessary to outline them with a simple pencil and make holes with a drill

If the places for attaching the headboard are not marked, then it is necessary to outline them with a simple pencil and make holes with a drill

Take a drill intended for wood. As a rule, the headboard is attached at a right angle; there are exceptions in designer models. The parts are connected to each other with confirmations, and the recesses are covered with special stickers in the color of the furniture.

Installation of the lifting mechanism

The lifting mechanism can be installed both on the sidewalls and on the headboard and depends on the specific model.

It is worth installing exactly in accordance with the instructions so that the gap between the components is minimal. Next, we connect the lifting mechanism to the upper part of the base and check the operation of the lift. After checking, you can tighten the screws tighter. The mattress can now be placed on the lifting bed.

Additional equipment

In order to increase the functionality of the bed, it is necessary to consider additional equipment. These can be drawers, a mechanism for raising the mattress at the head, various restraints, and more.

Having assembled the bed, with your own hands, you should check all the fasteners, the lifting mechanism and the legs. Tighten and adjust all components if necessary.

Having assembled the bed with your own hands, you should check all the fasteners, the lifting mechanism and the legs

Having assembled the bed with your own hands, you should check all the fasteners, the lifting mechanism and the legs

How to make a double bed?

Basically, people, regardless of whether they live with a soul mate or on their own, prefer double beds. Moreover, its design is not very different from a single bed. Beds have always been considered not a cheap pleasure, so making it yourself is much more economical and practical. Before starting work, you need to understand a few important points:

- In order for the bed to meet your requirements, and its price was minimal, you need to limit yourself only on your own.

- Furniture material should be easy to process and affordable. In other words, it is best to purchase ready-made material and cut it according to templates, rather than purchase an entire furniture workshop.

- Special and inexpensive tools must be purchased. In the future, they will be needed for other purposes.

If you have never come across the manufacture of furniture, then for a double bed it is better to choose a podium made of laminated chipboard. Even a beginner can assemble it on his own. There is no need to bother with the manufacture of moving parts and lifting materials, as this podium is designed with a special interior space. Do not forget about the design of the bed, because it should harmoniously fit into the room and match other furniture. Decide exactly what kind of bed you need, look at the photos on the Internet or in magazines.

Furniture assembly tools

- Electric screwdriver.Indispensable when screwing in screws and attaching fittings.

The screwdriver will help you speed up the assembly process

Drill for drilling holes in chipboard, it is desirable that the drill has a reverse

Drills for wood and metal of different diameters

A jigsaw is needed to saw off parts

A rubber hammer may be needed if something needs to be tapped and put into place

Confirmation hex key for assembling cabinet furniture

Building hair dryer for edge glueing

Furniture clamps for fixing, gluing, joining parts

A stapler will be very useful for stuffing the back wall of fiberboard

Remember to be vigilant and cautious when using these tools. Don't be hasty

It is best to invite an assistant.

Fixing tools play an important role in the twisting of furniture, and also as important "helpers". These and other tackles perform the function of installing fragile parts (mirrors and handles). They help to attach and adjust doors.

Major build problems

Modern beds have many complex mechanisms, and not all buyers can understand the principle of their operation and installation rules. Even though the beds come with step-by-step instructions. Why does this situation arise? There are three reasons.

- Most urban dwellers, especially the younger generation, do not have the skills to work with construction and carpentry tools. Accordingly, assembling a bed on their own is almost an impossible task for them.

- Assembly instructions are written by qualified personnel. This is correct and logical, but the presence of specialized terms in the text significantly complicates the task of an ordinary consumer. In addition, some operations are skipped in the instructions, as a matter of course, which is another obstacle for an unprepared person. As a result, the buyer can read the instructions several times, but still cannot understand them.

- Making beds is not considered a complex production and there are a large number of semi-handicraft companies operating in the furniture industry. They produce rather low-quality products, many elements and parts have to be adjusted on their own during assembly.

Not every furniture company is responsible for the production of its products.

And one more problem. Budget bed options are made of laminated chipboard, and the only real advantage of this material is its low cost. In terms of physical properties and performance, they do not quite meet the requirements of strict buyers. Especially great difficulties arise in the loaded joints of the individual elements. They do not withstand cyclic multidirectional loads, and it is these that mostly act on double beds. At the slightest violation of the assembly technology, the nodes weaken, then the plates quickly collapse, and the bed frame can completely lose stability. In addition, all threaded joints in chipboard are considered disposable. This means that re-screwing the screws into the old holes will no longer provide the initial strength.

Laminated chipboard has an attractive appearance and low cost, but does not differ in strength

How to assemble a single bed?

Often a model assembly diagram is supplied in the kit. However, the general design is the same for all metal or wooden beds. You can make the frame alone, but it is better to involve an assistant who will hold the side elements.

Before starting work, you need to check the number of parts and the presence of fasteners that are supplied in the kit. There should be enough free space so that you can turn the bed.

To assemble a single bed, you need to prepare the following tools:

- a set of screwdrivers or screwdriver;

- rubber hammer;

- hexagon.

Metal wrenches and pliers may be needed.

Headboard and drawers

Self-assembly of the bed begins with the connection of the headboard and side walls, which are also called drawers. In most cases, holes for the fixing elements have already been made at the attachment points. However, if they are not there, it is imperative to do it with a drill and drill of the required diameter.

Attach the drawers to the headboard at an angle of 90 ° and fix with Euro screws, confirmations or dowels. If wooden pins are used, the joints should be coated with PVA glue for secure attachment. The euro screws should be tightened with a hexagon, and the confirmations with a screwdriver or screwdriver.

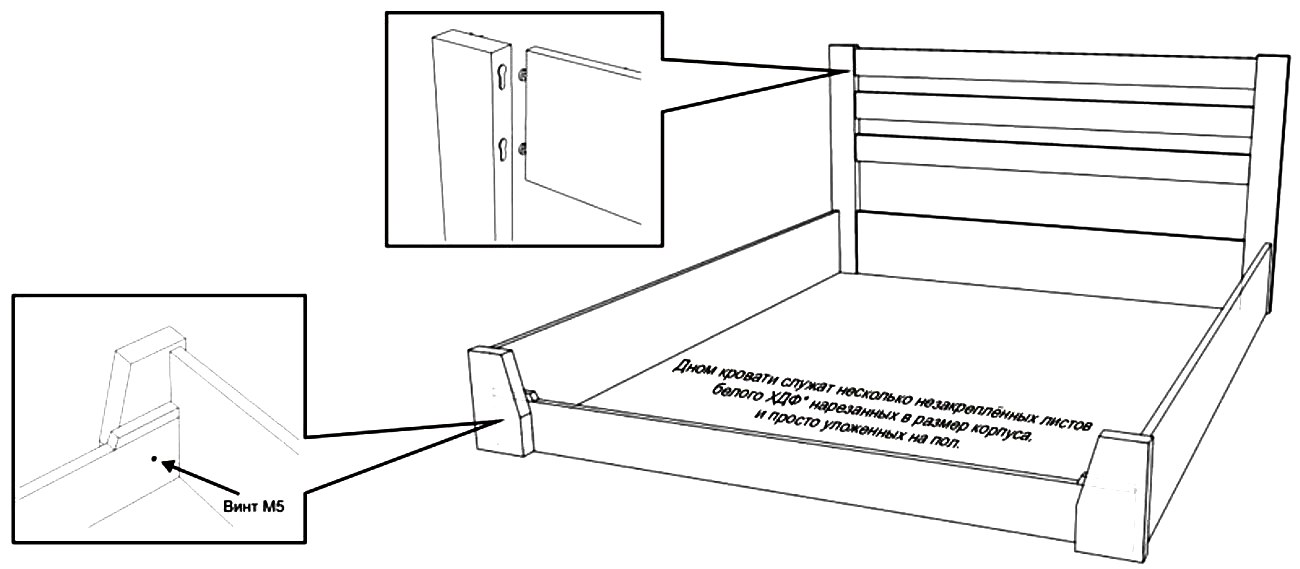

Then the tsars of the single bed are attached to the back. If the product includes legs, they are placed on the bed base at this stage. When PVA glue is used during assembly, remove its excess with a dry cloth before further work.

Base

The installation of the base of a single bed is started when the frame is ready. To do this, you need to fix the transverse bars or lamellas to the longitudinal ones. The slats can be wooden or metal, depending on the model of the bed. They are fixed with self-tapping screws or screws to the tsars in several places. The longitudinal parts of the bed are attached to them. Cross bars are inserted into special grooves.

Sometimes there are no grooves and holes may be in their place. Fastening can be done with self-tapping screws or screws.

Assembly

Now you need to put everything together correctly. The box is installed in the place where the bed will be. Then the base is carefully laid on top. Everything is fixed with fittings. Caps are installed on the screws to hide the caps.

Varieties of lifting mechanisms, their principles of work in bed

Today the furniture market offers several types of lifts that are installed in beds of various sizes and designs. They differ in price, design, durability, and the physical effort required to lift them. According to the principle of work, they are divided into three groups:

- Manual mechanism with hinges. The simplest, cheapest option was very popular in the 90s. Now there are relatively few beds with such a lift, because it requires significant physical effort (the weight of the base is completely on the hands of a person), it can provoke deformation of the case (most often, the hinges are installed in inexpensive models made of chipboard, which, with frequent use, cannot withstand the weight of the base and deteriorate). For the sake of fairness, it should be noted that the lift itself is quite durable, rarely breaks down.

- Spring lifting system. Convenient, easy-to-use mechanism. It is considered a budget option, therefore, it is installed in inexpensive beds. It does not require much effort to lift, but still, the child cannot cope with it. The springs only partially compensate for the weight of the base. A significant drawback is a short service life, about 5 years, after which the springs stretch and require replacement.

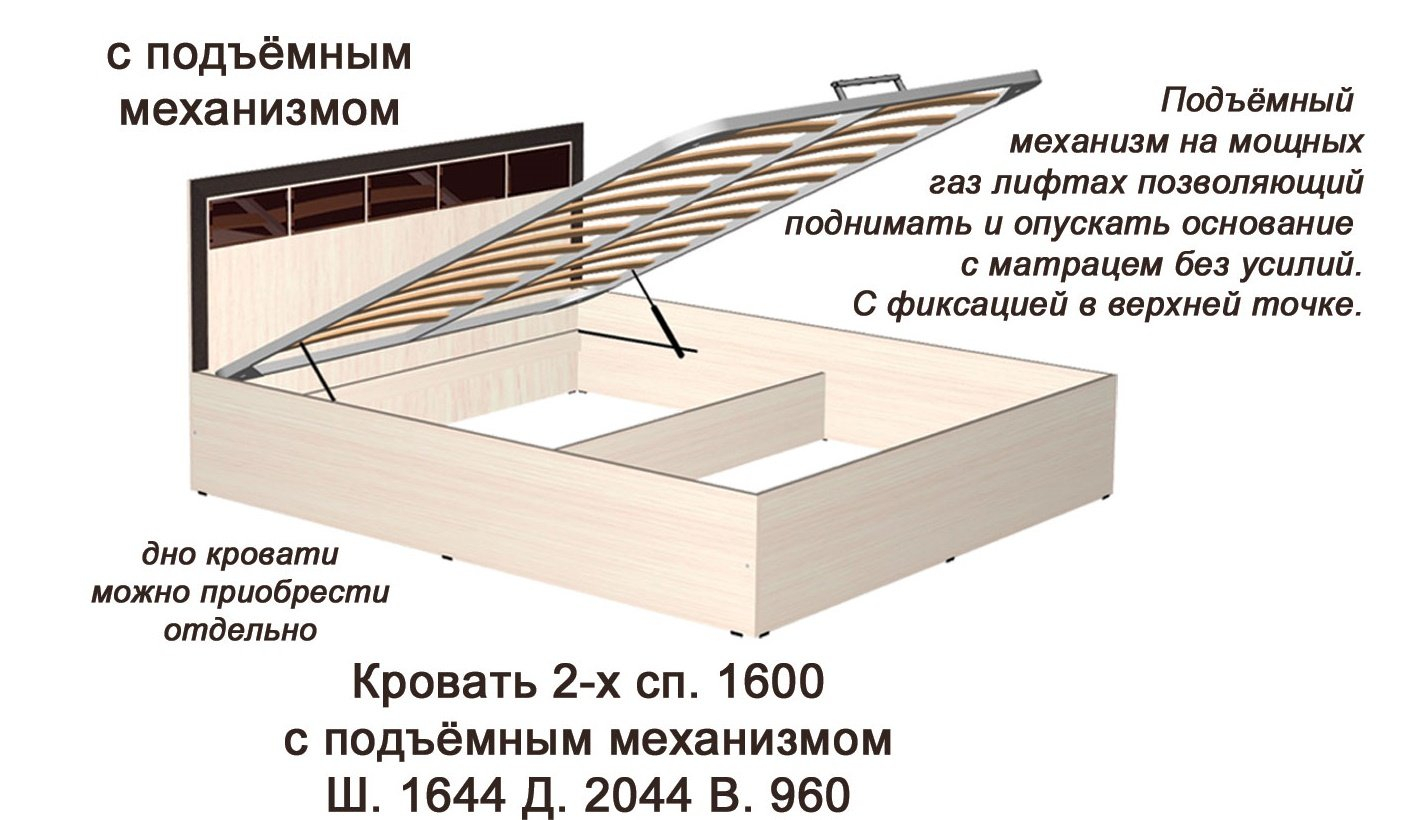

- Mechanism on gas shock absorbers, or gas lift. Today it is the most advanced, easy to use. Requires little or no human effort. Works smoothly, without noise, securely fixes the raised base. The system is considered reliable and can be installed on any bedroom furniture, even children's furniture. With properly selected shock absorbers, it can last for more than ten years. Its cost is higher than that of other mechanisms, but is fully justified by the comfort and safety of use.

Manufacturing process: step by step instructions

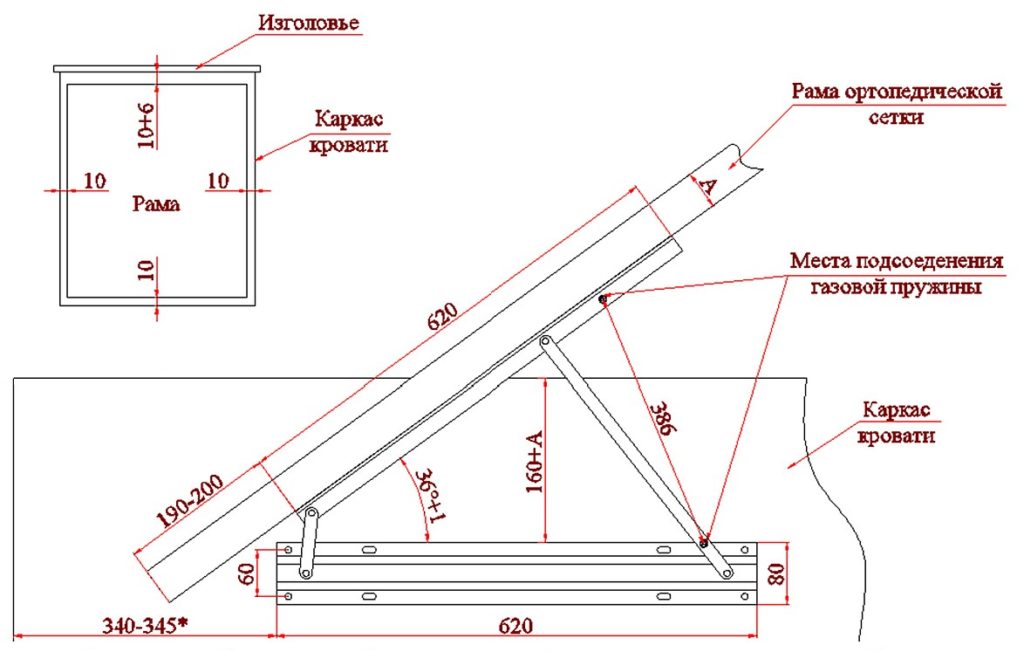

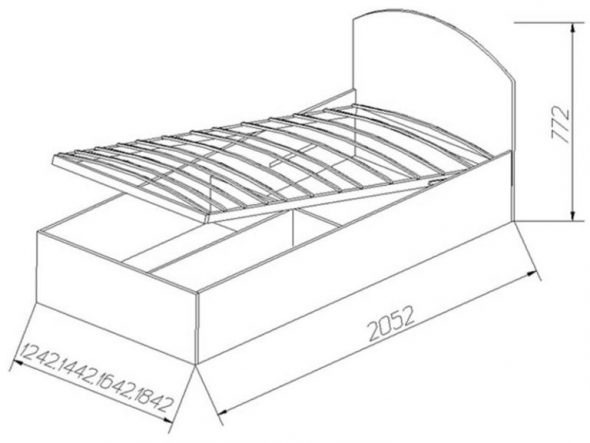

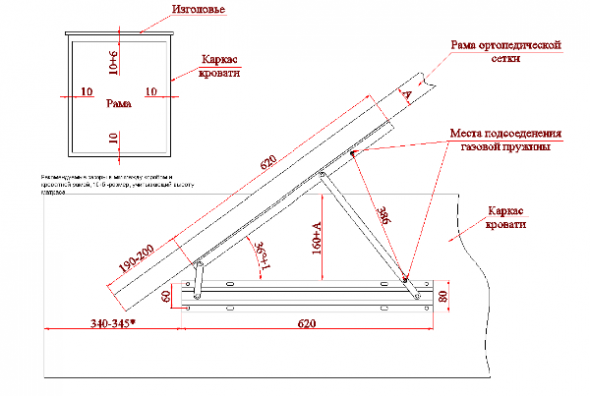

Bed frame diagram with lifting mechanism

To make a universal lifting mechanism for a bed with your own hands, you need to prepare detailed drawings of the future model. In order to avoid making irreparable mistakes when installing the bed, you can focus on the finished schematic drawing of the frame assembly.

Detailed assembly diagram of a bed with a lifting mechanism

You can get information on how to make a bed with a lifting mechanism with your own hands by examining the prepared drawings.

Drawing of a lifting mechanism for a bed

First, a solid, reliable base of the conceived bed is built. To make the base of the stock, you need to prepare:

-

bottom, side parts of the bed, drawers and headboard made of MDF or chipboard - all elements of the appropriate size;

- a frame formed from wooden blocks;

- mattress walkways made of slats and boards.

After the completion of the preparatory work for installation, the bed base is mounted from the finished elements.

-

On a frame made of bars, the bottom for the prepared niche is fixed with self-tapping screws.

-

After the steps taken, they are mounted on the frame of the drawers and sidewalls.

-

We attach the headboard to the prepared structure using a screwdriver and self-tapping screws.

- After the end of the base assembly process, the bed lift is installed. It is sold ready-to-use, so the lifting structure is mounted on nuts.

Elevator transformation system

The lower steel bar is immediately fixed to the base frame, then the upper element is fixed to the side part.

Gas lift is mounted on a rack base

Installing Gas Shock Absorbers for Lift Bed

To create a reliable bed, a steel base is installed, made of a metal profile, sawn into parts by a grinder, of the required dimensions and connected to each other into an integral structure by welding, which is an important working step. After the completion of welding, a frame made of timber is fixed to the base.

Installation of the lifting mechanism

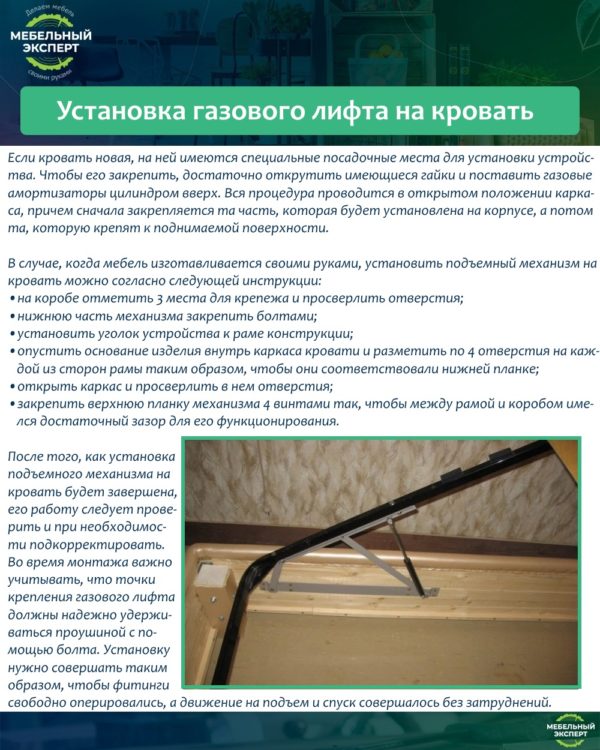

When planning to assemble a Suspa device, you should familiarize yourself with the main recommendations of the manufacturer of these accessories. The gas lift installation process can be divided into several sequential steps:

First, the bed frame is assembled. Observe the manufacturer's instructions when performing all operations. Metal corners are used to connect the boards. This will strengthen the entire structure and make it more resistant to external influences.

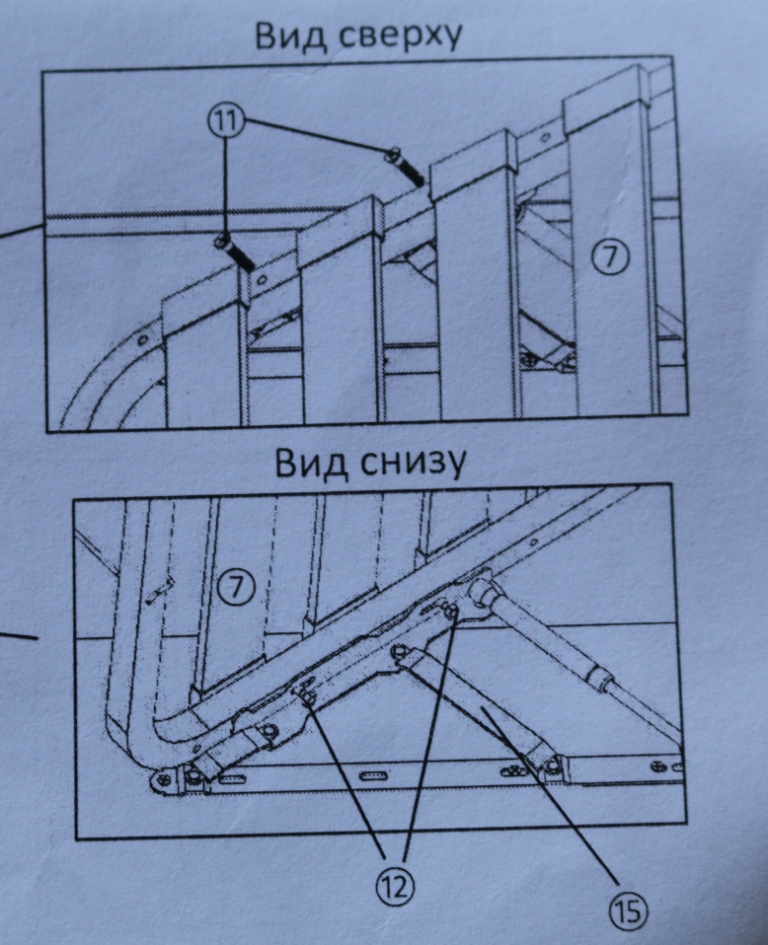

When the frame is assembled, they begin to mount the gas lift. The structure is fixed using special self-tapping screws, which are often included in the kit

Please note that some gas lifts are one-way

Therefore, it is important not to mix them up.

In some cases, the cylinder side also plays an important role. This characteristic should be checked with the manufacturer.

At this stage, the folding frame is being assembled. In some cases, it is metallic and solid. If the structure is made of wood, then it is built in accordance with the manufacturer's instructions.

The procedure is completed by attaching the gas lift to the upper element

It is important to screw on the mechanism only when the cover is open. This will eliminate the likelihood of breakage if the arm length is incorrectly calculated.

When the entire structure is assembled, the system should be started several times to check its operability. If the system does not work properly, the mechanism should be reinstalled.

Installing gas lifts on a bed can differ in many nuances. If you are not sure that you can perform the operation efficiently, you should entrust it to an experienced specialist. The best option would be to manufacture such furniture to order. This will allow not only to select the size and style of the structure, but also to determine the optimal characteristics of the lifting mechanism.

If you still want to handle all the work yourself, consider the important nuances.This way you can get the best results. For how the gas lift is installed, see the next video.

Bed types with a lifting mechanism

Lifting beds are available with different types of opening devices, different sizes, configurations, transformation methods.

The classification by the type of lifting device is represented by 3 types: with manual lifting, on coil springs, on gas shock absorbers.

Fastening with coil springs is easy to install, reliable in operation. The cost of the fastening system is affordable. However, the springs will wear out and stretch if the rules of use are violated. If several elements are damaged, the system will need to be changed completely. The warranty period for the mechanism is no more than 5 years.

The lifting device on gas shock absorbers does not require physical effort during operation, providing easy access to the unit for things and bedding at the bottom of the bed. Gas devices allow you to move the bed to the open position quietly and smoothly. When choosing a system, the dimensions and weight of the surface of the sleeping bed are taken into account. The devices are designed to lift voluminous mattresses. Manufacturers issue a guarantee for the operation of the mechanism for a period of up to 10 years.

Manual lifting of the sleeping bed (on the hinges), due to the lack of auxiliary elements, requires physical effort when transforming the bed. However, the strength and durability of the device is great. Manual mechanisms are not equipped with systems for smooth lifting and spring devices, therefore they have a low price. In order to access the bedding unit, you will need to remove the mattress. The mechanism is not used in furnishing children's rooms.

According to the number of beds, there are single and double models.

Single-bed designs are compact, versatile, suitable for small spaces, allowing you to organize an additional resting place. Models are often made in the form of an ottoman and placed in the corner of the room. Single beds with a lifting device are used in the design of children's and teenage rooms. For the complete set, a spring mechanism or gas shock absorbers is used. The lifting system in narrow beds is mounted along short parts.

The mechanism in double models depends on the weight of the bed and mattress. For massive structures, gas shock absorbers are needed, for light ones - spring blocks.

In accordance with the number of combined furniture elements, there are lifting beds with a sofa, an ottoman, a resting place that can be transformed into a cabinet, etc. The sleeping bed can be built into a wardrobe. The latest model is the easiest to design and assemble a lifting bed with your own hands.

Beds also differ in the way the sleeping bed is raised: vertical or horizontal.

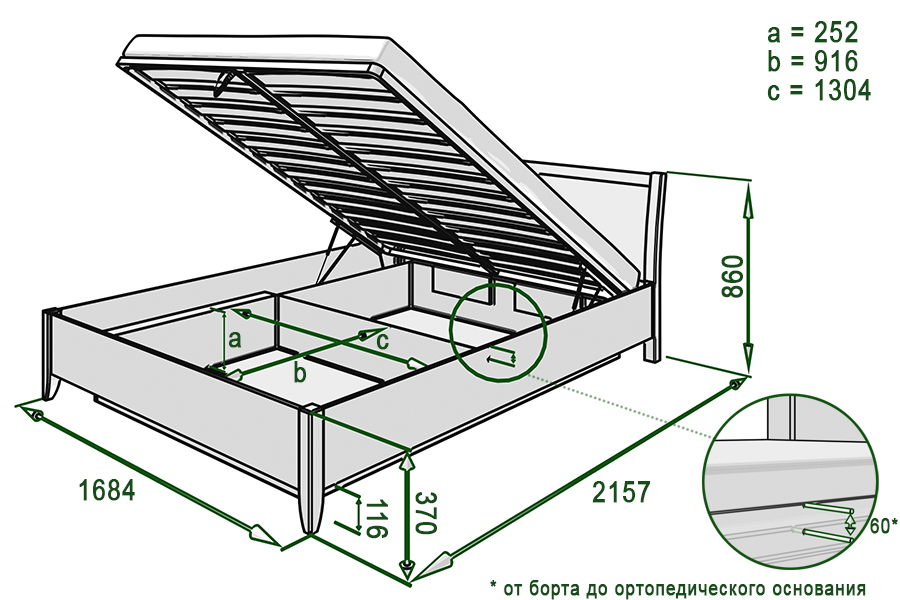

Do-it-yourself double bed. Dimensions, drawings, assembly instructions

Walking through furniture stores and salons, you can very often be horrified by the price tags presented there. The most annoying thing is that a simple bed made of the cheapest material (not wood at all, but an ordinary chipboard or MDF with an ordinary mattress board made of rough chipboard, i.e. even without slats) has an exorbitant price for such a product. Having seen enough of this, we begin to work out other options: some are looking for used furniture on bulletin boards, others take a simpler one and are content with a cheap analogue, and someone simply postpones the purchase of the product for an unlimited period.

But in this article we will go the other way. We will make a double bed with our own hands.

The advantage of this approach is that the furniture salon that you - will pay almost the same for materials. And, having assembled this double bed yourself, you will save at least half of the cost of the structure (that is, this is exactly the markup on the cost price for the design, design and assembly of this piece of furniture).

Photo of a double bed, which we will make with our own hands:

This article presents a master class on the manufacture and assembly of a double bed made of chipboard + MDF overlays on the stakes, the overall dimensions are 2032 * 1692 * 800 (length / width / height), the size of the bed for the mattress is 1600 * 2000 mm, i.e. quite a standard bed for two people.

At the very bottom of the article, you can download a file with assembly drawings for a double bed, as well as its configuration.

How to disassemble the lifting mechanism and in what cases it is necessary

Disassembling the bed lifter is a painstaking task. If you are planning to transport furniture, then the mechanism itself should not be disassembled, it is better to leave it on the side slats, remove the mattress, orthopedic base, and carefully pack all the elements in a protective film.

Disconnection of the lift by parts is only necessary in the event of a breakdown. The following symptoms may indicate a gas lift malfunction:

- the orthopedic base spontaneously descends;

- the mechanism periodically jams, does not perform its lifting functions;

- during operation of the mechanism, squeaks or other unpleasant sounds are heard.

If it is not possible to call a furniture master at home, you can independently disassemble the bed, remove the lifting device and take it for repair. The algorithm of actions is the reverse of the assembly, i.e. first, the mattress is removed, the orthopedic base is disconnected, and then the lift is dismantled. It is advisable to film this process, or take step-by-step photos, so that in the future there will be no problems with the installation of a repaired or new device.

Assembly of non-standard models

Beginners in this business often do not understand how to assemble a modern bed according to the instructions. Honestly, even professionals sometimes have problems. This is not surprising, since the construction itself is not ordinary. The problem is that the durability of a product is directly related to its assembly. In the case when you simply do not have any thoughts on how to properly assemble the original double bed, you need to contact the specialists in their field. Check with your store to see if they can help you. Thus, you will save a lot of time and be completely confident in the quality.

Beginners in this business often do not understand how to assemble a modern bed according to the instructions. Honestly, even professionals sometimes have problems. This is not surprising, since the construction itself is not ordinary. The problem is that the durability of a product is directly related to its assembly. In the case when you simply do not have any thoughts on how to properly assemble the original double bed, you need to contact the specialists in their field. Check with your store to see if they can help you. Thus, you will save a lot of time and be completely confident in the quality.

Such rules should not be neglected, otherwise you will waste your money, and the bed will not serve you for ten years.

In general, the work on assembling a double bed is not hard work. Following the recommendations and schemes, furniture is assembled in less than an hour.

How to assemble a double structure

There are slight differences in the design of the double bed over the single bed. This model is much wider, especially the king-size options, therefore there is a crossbar in the frame that reinforces the structure for the lamellas. Make sure all parts are included before starting work. Prepare tools and materials, and need an assistant.

First, the base is mounted, which consists of three metal frames. Then we attach the legs, remembering not to tighten the screws tightly. The headboard of a double bed can be made of wood, metal, chipboard covered with eco-leather or tapestry. Whatever the decorative element of the headboard, it is attached to the base in the same way, using corners and screws.

A wide double bed is assembled in the same way, starting from the base. First, the drawers are fastened together with the help of corners, special ties or brackets. We attach shelves to the upper part of the sidewalls, if this model has them.

Now it is necessary to check the geometry of the structure, install the lifting mechanism and fix the central backrest to the frames. The bottom of the base can be solid or orthopedic.

Once the center rib has been installed, the bed is almost complete. It remains to lay the mattress, fix the fittings, check all the nodes.

Assembling a self-purchased bed is not at all difficult.It is enough to carefully read the instructions, prepare the tools and use the tips from the article. Cozy and comfortable sleep will ensure complete rest and good mood.