How to make a DIY air purifier for a room with high humidity

Filters can be made from dense, porous fabric

Filters can be made from dense, porous fabric

To complete the project, materials are required:

- a plastic container with a depth of at least 20 cm;

- a low-power fan, the impeller of which rotates slowly;

- sea or table salt;

- porous material: a multi-layer pillow like a cotton-gauze bandage, foam rubber;

- power supply for fan operation;

- fasteners;

- reliable glue of hasty action;

- sharpened knife for performing the assembly process.

You can make your own air purifier by following the instructions:

- make two holes of different sizes in a plastic container on different walls: the hole for installing the fan should be the same size as the air exchange device. Place it slightly higher than the second hole on the opposite side;

- fix the fan;

- make a filter, the size of which will be slightly larger than the size of the second hole. The filter can be made in a multi-ball way: gauze + cotton wool;

- fix the filter on the box with quick-drying glue;

- pour dry salt in such a way that the substance covers the hole with the filter installed, but does not reach the fan;

- connect the structure to a power source, and start the mechanism.

This purifier has 2 levels of filtration: a porous material in the form of gauze will eliminate dust particles; salt that absorbs excess moisture, bacteria and fine dust. A homemade electrostatic air purifier of this type will saturate the air in the room with chlorine and sodium ions, making the air in the room more beneficial for humans and indoor plants.

The do-it-yourself cleaner is made taking into account the humidity in the room. To measure it, a special device is used - a hygrometer. The optimum humidity in the room in accordance with GOST 30494-96 is 40-60%. If the hygrometer readings are more than 70%, a dry cleaner should be used. With rates less than 30%, a device with air humidification is required.

Filters in air purifiers

The following types of filters are used in air purifiers:

- Pre-cleaning. Conventional mesh filters, which are used in the first stage of cleaning, trap large dust particles, animal hair.

- HEPA filters. They are an accordion assembled on both sides with micro-holes. Cope with spores of mold and fungi, animal hair, dust mites.

- Coal. Fight dust and absorb odors with activated carbon.

- Electrostatic (ionic). They work on the principle of ionization, provide a high degree of purification, cope with microorganisms.

- Photocatalytic. Purify the air with UV radiation. Absolutely disinfect the room from pathogenic bacteria and carcinogenic substances.

Accessories for the device

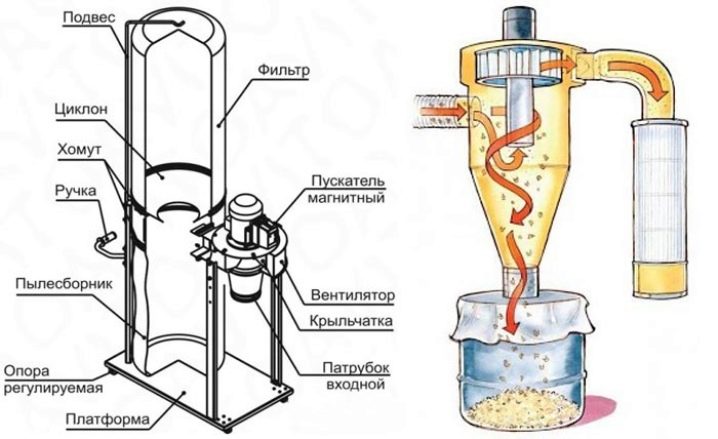

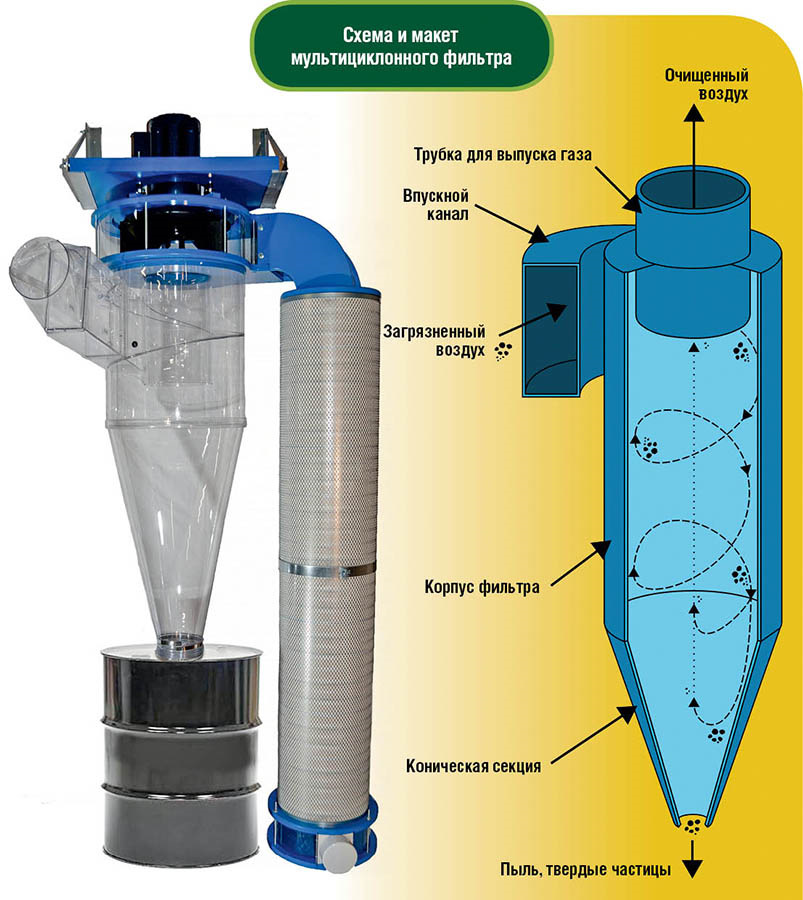

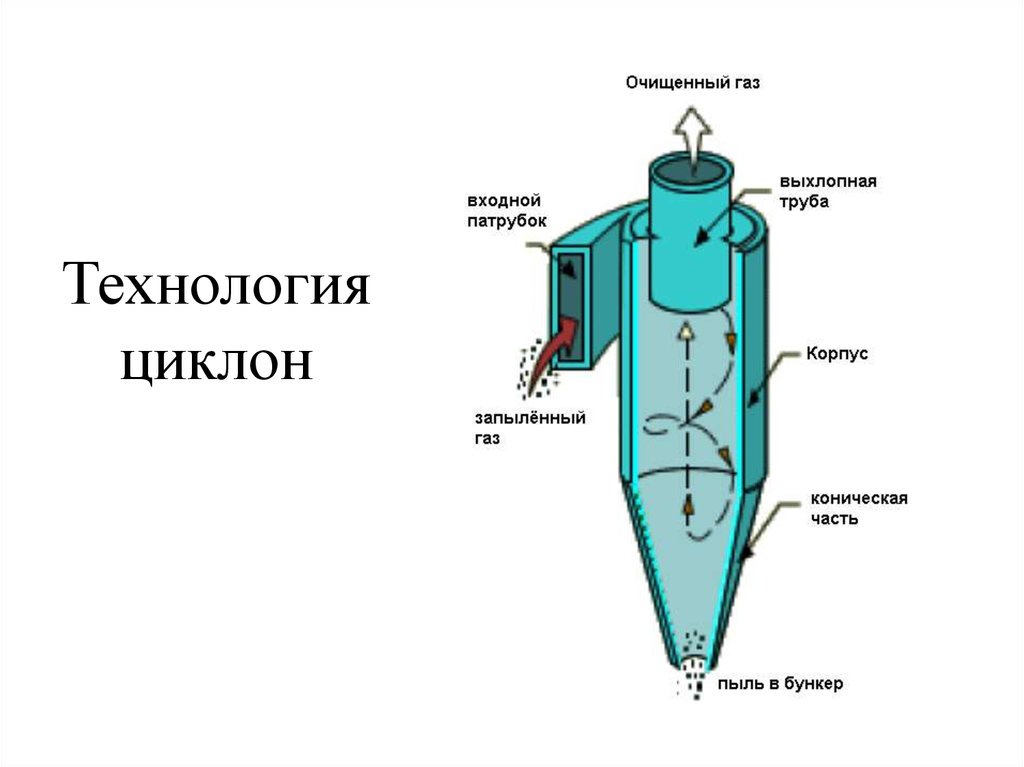

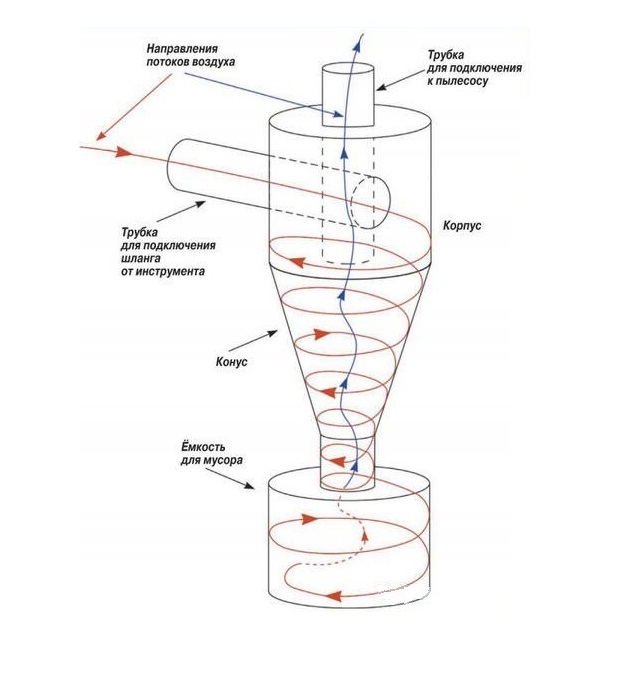

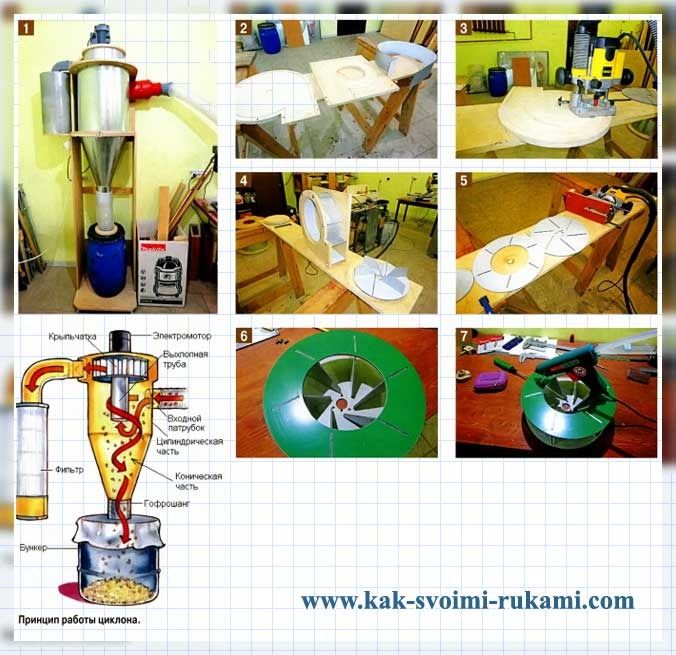

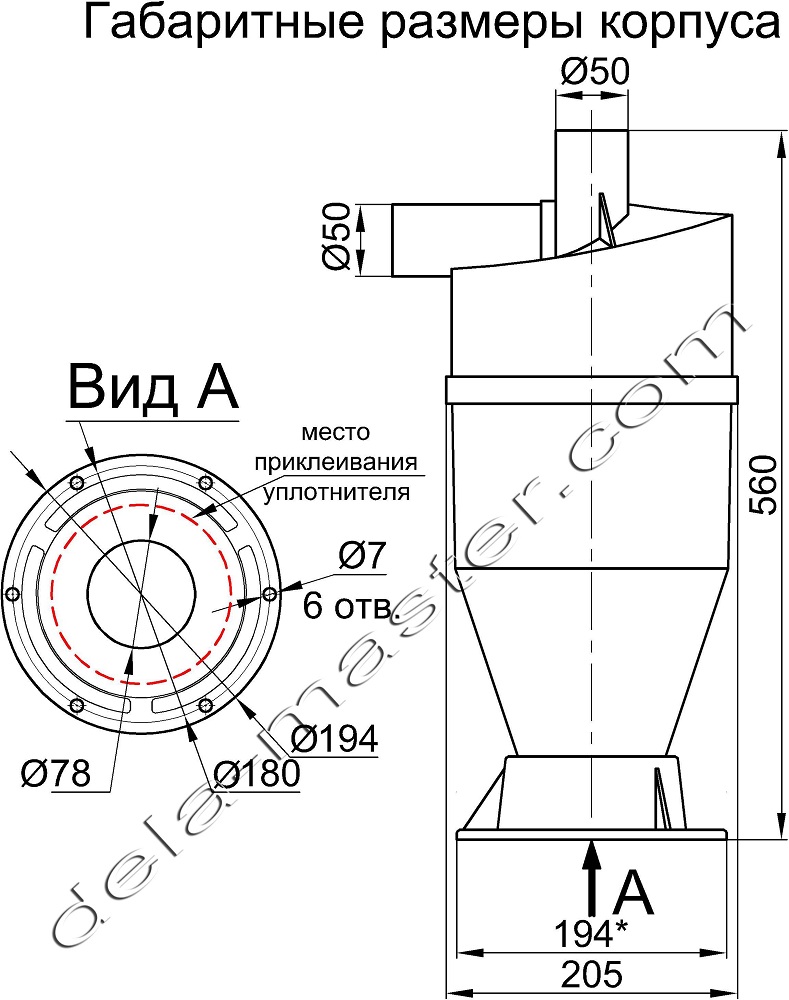

Making a cyclone for a construction vacuum cleaner with your own hands is quite simple, but for this you need to have a number of component parts. To do this, it is enough to disassemble the old device, which has not been used for its intended purpose for a long time. From it you need to get the power regulator and power cord. If the vacuum cleaner was large enough and "strong", its motor will also come in handy. Next you will need:

- plastic or tin cone;

- pipe with a cross section of 5 cm;

- corrugated hose;

- bolts with nuts;

- plywood and zinc sheet;

- you should also prepare consumables such as sealant, skins, fillers for the glue gun.

You will need a regular tool - a drill, a glue gun, a set of keys and screwdrivers, side cutters and a hacksaw, preferably a jigsaw. Next, consider the manufacturing procedure for a cyclone vacuum cleaner.

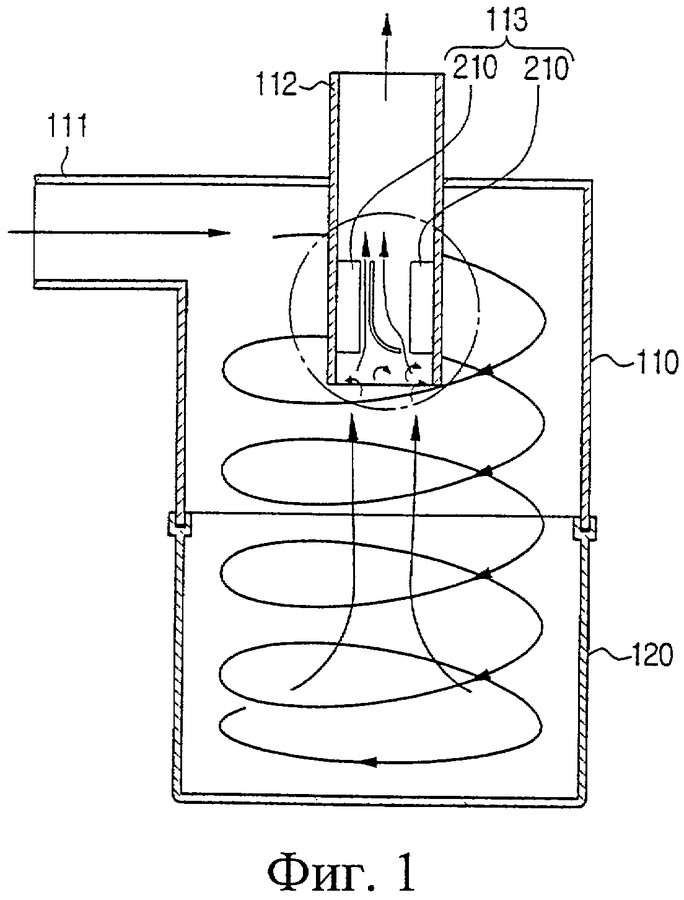

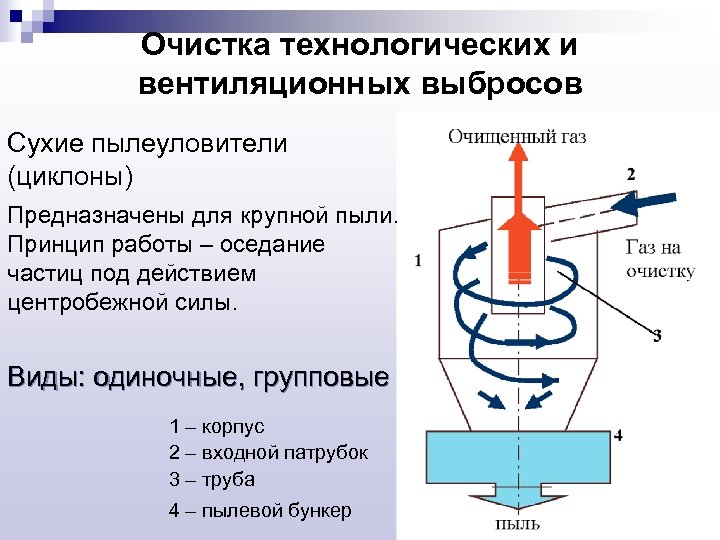

The principle of operation and design of the cleaner

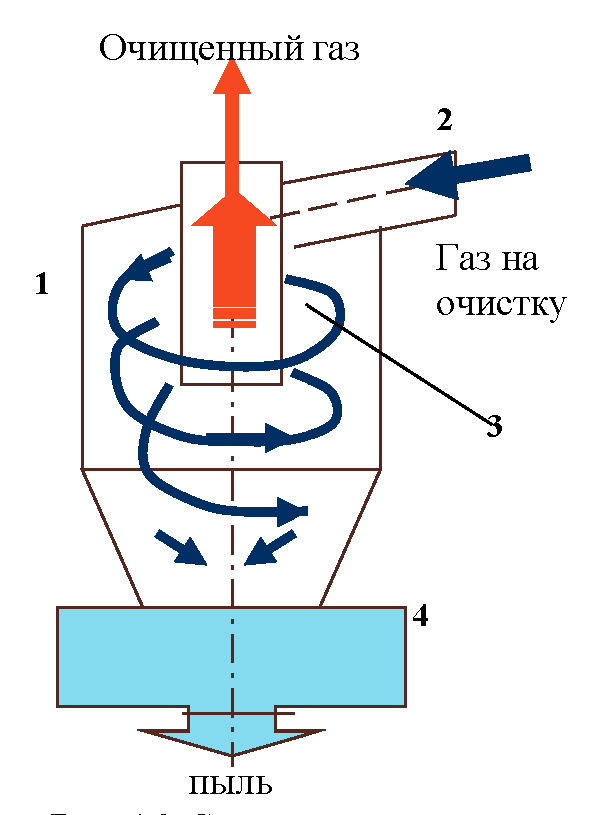

The principle of operation of an electrostatic air purifier is quite simple: a corona charge is created on the electrode, which produces ions with a certain charge. Charged ions begin to move towards the oppositely charged electrode, capturing air molecules, dust, bacteria, etc. along the way. After that, all ions and impurities that have received a charge are deposited on the electrode, and the purified air enters the room.

Structurally, such cleaners consist of:

- The case, in which openings are made for the intake of contaminated and outlet of cleaned air.

- A filter, cartridge or cartridge, in which air is ionized, falling into a high voltage field.

- Dust collector containing oppositely charged electrodes.

- Control and power supply boards.

In some models of electrostatic air purifiers, a fan is installed to increase productivity and to pump the air mixture through additional filtration stages, if any.

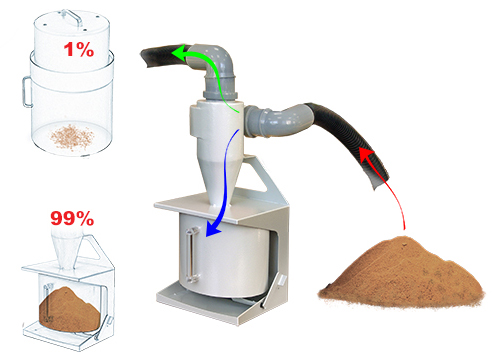

Homemade cyclone from a household vacuum cleaner

The first method has been presented on the Internet and on YouTube for quite some time. You can easily find many videos with similar homemade cyclones.

However, they cause quite natural questions and skepticism among professional builders. Therefore, you should immediately make a reservation that they are mostly suitable for cleaning wood shavings.

But it is better not to work with cement dust with such devices. The second option is more "sharpened" for it.

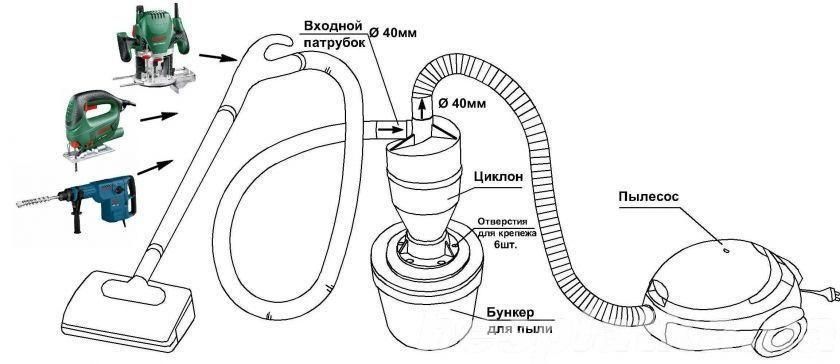

The main "trick" that will allow you to calmly suck in kilograms of garbage, wood, metal sawdust and at the same time not worry about the frequent change of filter bags is a homemade "separator".

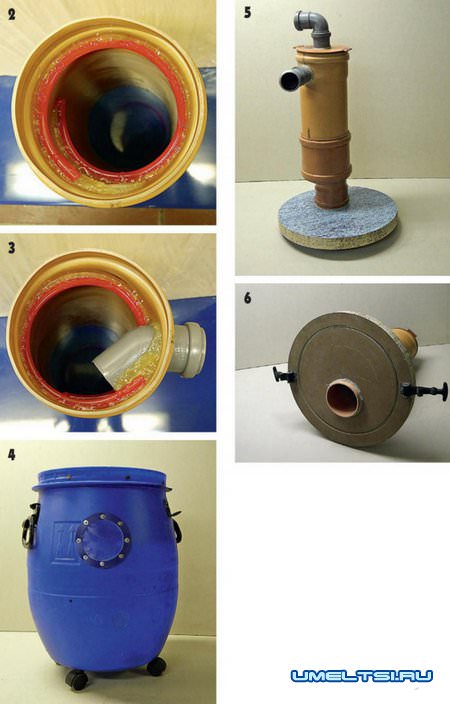

It will then need to be constructed from several components. For the entire assembly you will need:

regular vacuum cleaner

thick plastic bucket with a lid

A bucket from Shitrok putty is best suited here. It is harder to flatten it with a vacuum.

plastic sewer pipe d-40mm

polypropylene sewer outlet at 90 degrees with a diameter of 40mm

40mm crown or clerical knife

First of all, drill or carefully cut a through hole for the tube in the center of the bucket lid.

Mark the third hole closer to the edges of the lid, where the stiffener is.

If you do not have a special crown, then first pierce the marked circle with an awl and carefully cut it with a clerical knife.

The edges will be uneven, but they can be cut with a round file.

Two sewer outlets are inserted into these holes. So that they are securely held and there is no additional air leak, it is better to glue them.

To do this, first sand the edges of the tube with sandpaper or a file to create a rough surface.

Do the same operation with the lid.

After that, insert the tubes into the inside of the lid and apply a thick layer of glue with a heat gun.

Do not spare glue. This will help create a good seal in these places and tightly close all the cracks.

There is, however, another option in which you can do without glue and fan pipes at all. To do this, purchase rubber transition couplings from Leroy Merlin.

They come in different diameters. Match your hose size.

For example, a tube from a 35mm hose is tightly inserted into the 40/32 coupling. But in a 40mm pipe, it will dangle. We'll have to wind up and farm something.

On the tube that is located on the edge of the lid, put on a 90-degree sewer outlet.

On this, the design of the separator can be said to be almost ready. Install the lid with taps on the bucket.

The air intake hose from the vacuum cleaner is inserted into the center hole.

And the piece with which you will collect all the debris and dust is stuck into the corner joint.

It is desirable that the tubes contain O-rings to the size of the vacuum cleaner's corrugated hoses.

This completes the entire assembly. You can plug in the vacuum cleaner and use it.

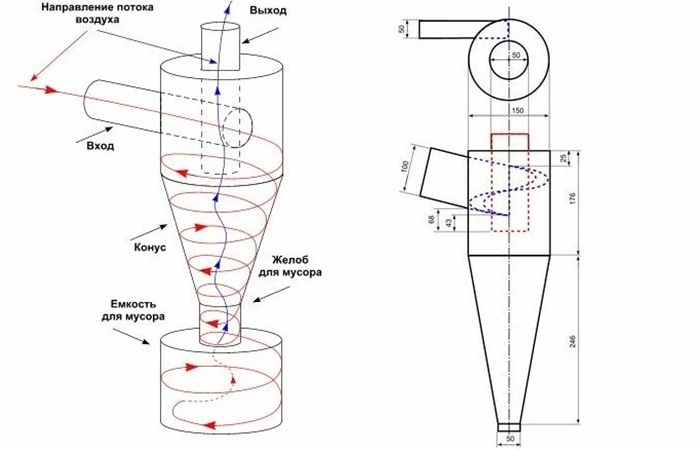

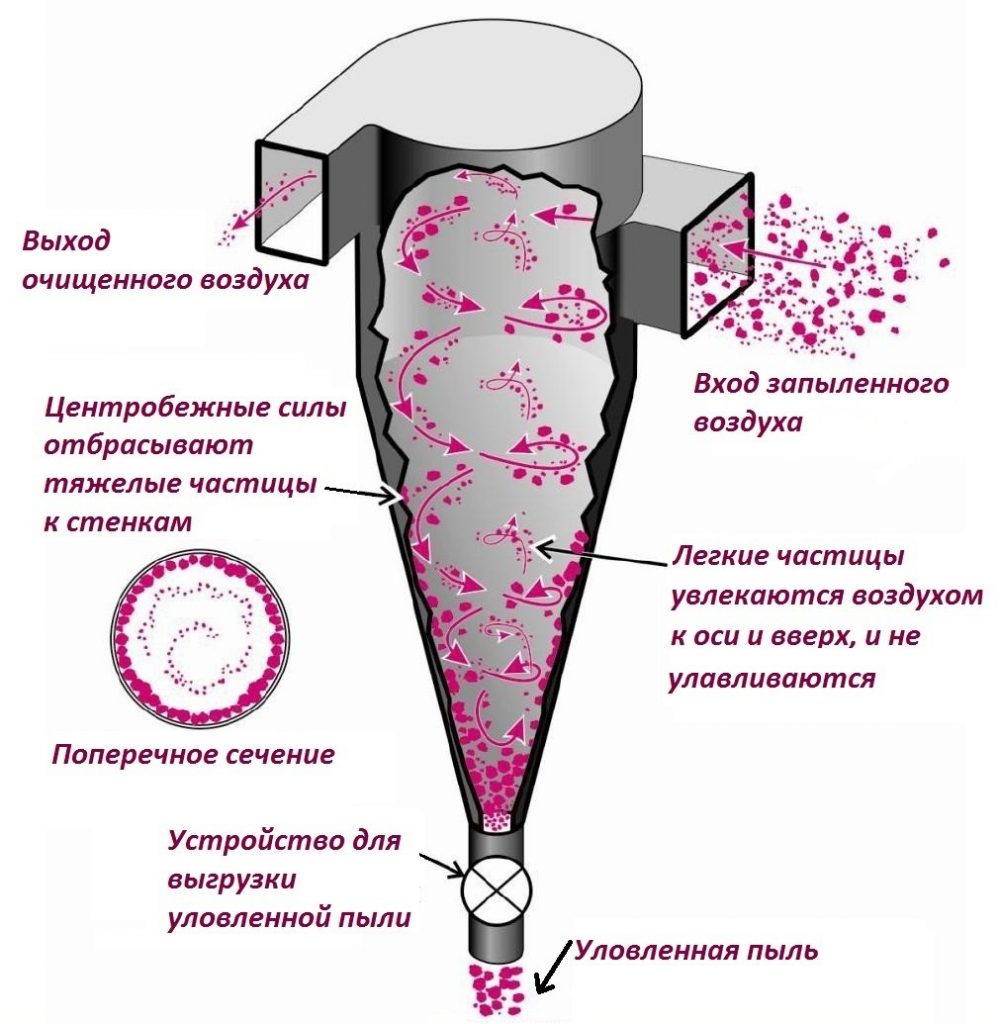

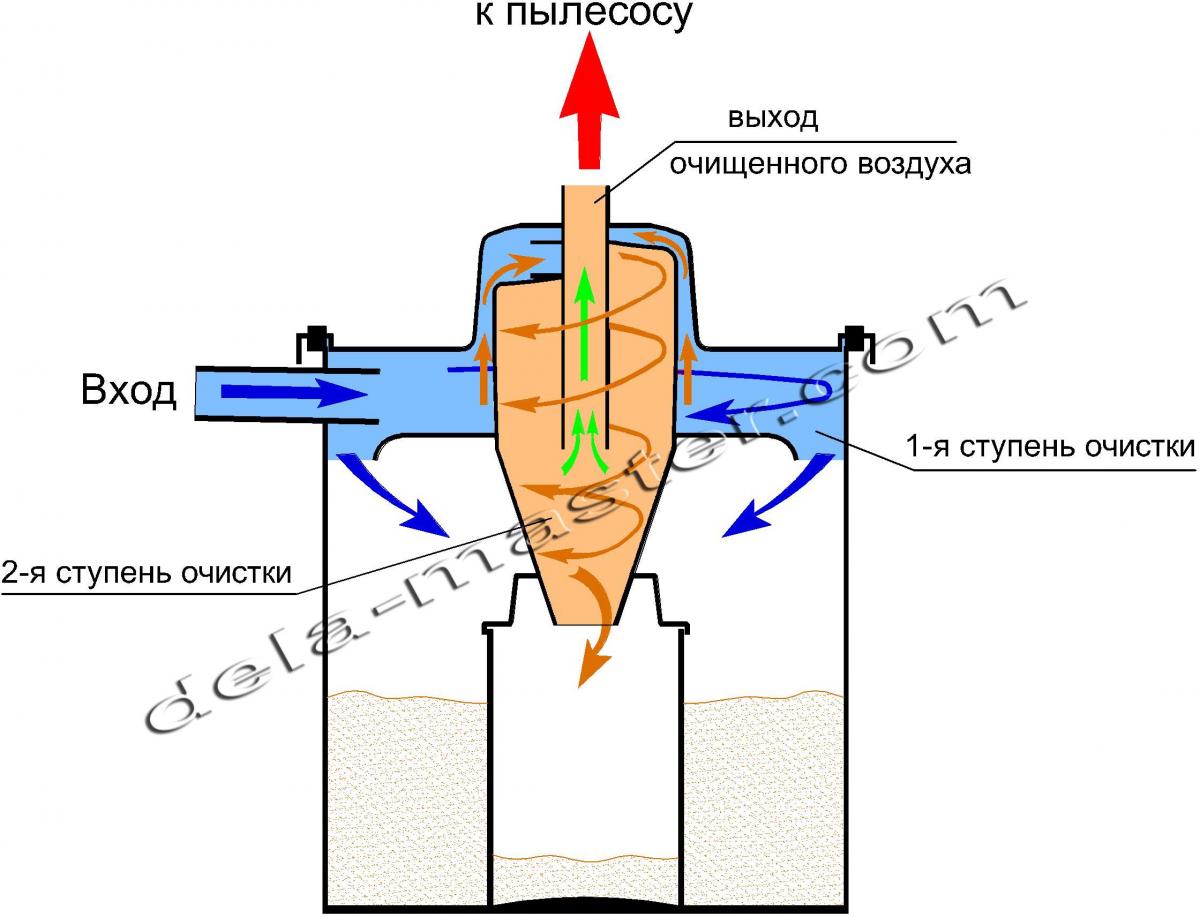

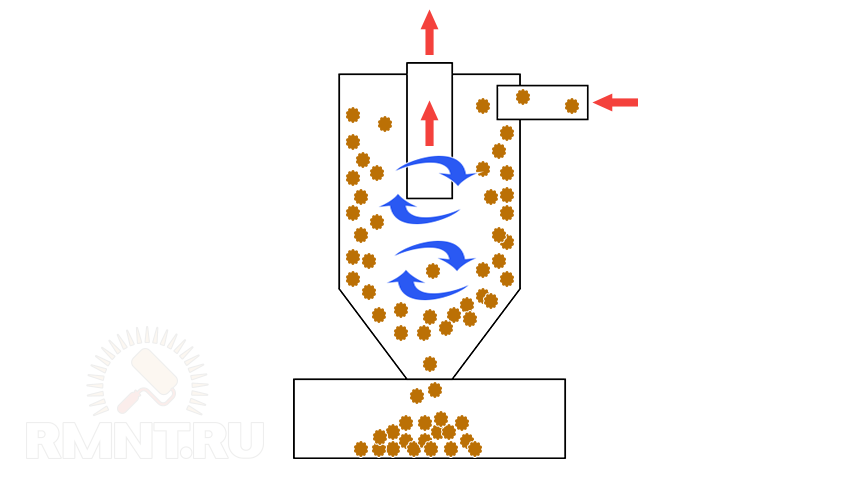

The principle of operation is as follows. The coarse dust sucked into the container falls to the bottom of the container. At the same time, it does not fall into the zone where air is pumped out directly.

Three factors help in this matter:

gravity

friction

centrifugal force

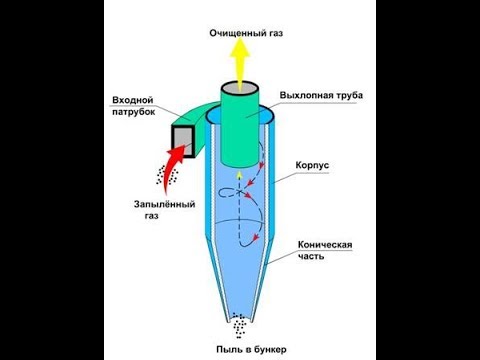

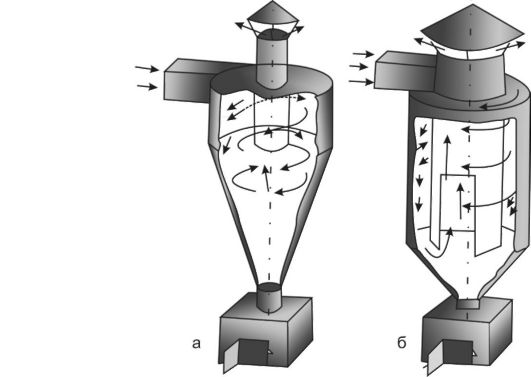

Typically, such a cyclone in factory designs has the shape of a cone, but cylindrical specimens also often do a good job with this task.

True, the higher the bucket is, the better the installation will work. Much here depends on the correct pairing of the container design and the power of the vacuum cleaner. Here is a plate from Chinese cyclones on the correct selection of the diameter of the hoses and the power of the units.

In cylindrical buckets, the tangential air flow is entered not through a curved side wall, but through a flat lid. It is much easier to assemble such a device.

Also, if you have more than one bucket, you can use them one at a time. Just remove the cover from one and move it to the other. Moreover, this is even easier to do than in bulky cyclones.

Then, at the very end of the work, simply take out the filled containers at once. This is a great time saver.

If you have a powerful vacuum cleaner, instead of a plastic bucket from under the emulsion paint, it is better to use a metal tank of the same shape. Otherwise, the bucket will collapse and flatten it.

The power regulator helps out in this matter. If it is of course present in your model.

Rules for choosing an electrostatic air cleaner

The device should be chosen based on its power, that is, for the volume of which room it is designed for.

Noise level

Pay attention to devices with a noise level of no more than 40 dB.

The presence of additional stages of cleaning.

Security. When choosing an air cleaner with an electrostatic filter, pay attention to the amount of ozone it produces.

We remind you that the maximum daily average ozone concentration should not exceed 0.03 mg / m3.

Execution. On the modern market of climatic technology there are air cleaners of this type, wall, ceiling, floor and tabletop. The choice of a purifier depends solely on your preferences.

Due to the relatively high cost of this device, many of our compatriots ask the question of how to make it with their own hands. An electrostatic air purifier with your own hands, of course, can be made and there is nothing complicated about it: if you dig a little, you can find a lot of diagrams, instructions and even books on the net. (One of them is called "Home Practice", issue 7)

Despite the high voltage, you can avoid electric shock by following basic safety requirements. But, it is very difficult or even almost impossible to control the production of ozone at home. Due to the high toxicity of ozone, we do not recommend assembling the electrostatic air cleaner on your own.

Advantages of the device

A vacuum cleaner with a cyclone not only cleans the air from dust, it has a number of undoubted advantages compared to conventional ventilation or using a commercial filter:

- First of all, this is the absence of a dust bag or filter in the device that requires cleaning or replacement. Dirt and small debris can simply be shaken out of the dust container after cleaning.

- This type of device is very compact in contrast to an industrial installation.

- Since there are no moving parts inside the cyclone, it works absolutely silently.

- If the filter is made of transparent material, then it will be possible to visually monitor the degree of its clogging in order to clean it in time.

- With a comparatively low cost of the device, its efficiency and usefulness for human lungs are very high. Purifying the air with a cyclone is much more effective than using respirators or simply gauze bandages.

All this makes it necessary to make a cyclone for a vacuum cleaner with your own hands, because it is cheap and necessary. The low cost of this device is extremely important, since this device is needed only during repair or reconstruction, then it is simply thrown away. That is, it should be simple and not expensive.

Air purifier operating rules

The air purifier should be installed in areas with the greatest accumulation of dust for effective operation.

The device should not be close to the wall, but at a distance of at least 10 cm from it. For the cleaner to work, you must plug it in and set the cleaning mode in accordance with the instructions.

Almost all modern models have electronic controls and filter replacement indicators. Replaceable filters of the device must be replaced every 2 months. The ionizer plates should be wiped with a damp cloth at least once a week.

An air purifier for the home is a useful thing, as it cleans the air space as much as possible. When choosing a device, you should take into account the area of the room and the factors of its pollution.

The best option is a combined air purifier from dust, carcinogens, allergens and bacteria, which includes a multi-stage cleaning system.

What are they?

Nowadays, people are increasingly using dust collectors not only in production, but also in their own apartment. On the market, you can purchase gas cleaning units for grinders, perforators, as well as centrifugal, vortex, diffusion, rotary, each of which has certain characteristics and capabilities.

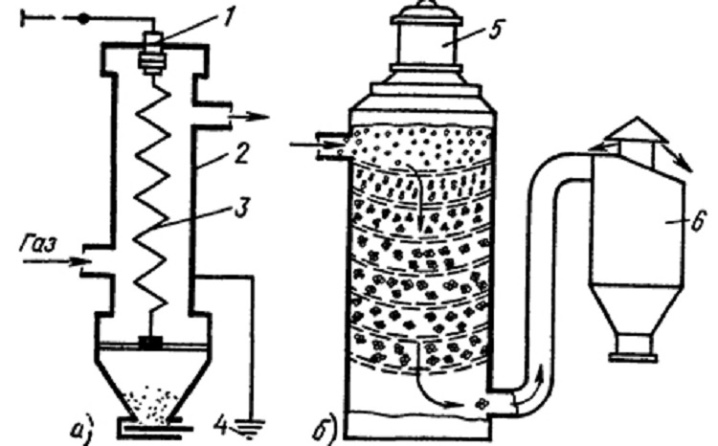

Gravitational

The gravity-based dust collecting device is designed by gravity. Due to the influence of the device, dust particles and other contaminants are deposited from the cleaned air. Such dust cleaners include dust-collecting chambers that are located in the interior of the ventilation systems of industrial workshops and devices for gas cleaning.

Dust deposition chambers include the following types of devices:

- straight-through;

- ceiling;

- labyrinthine.

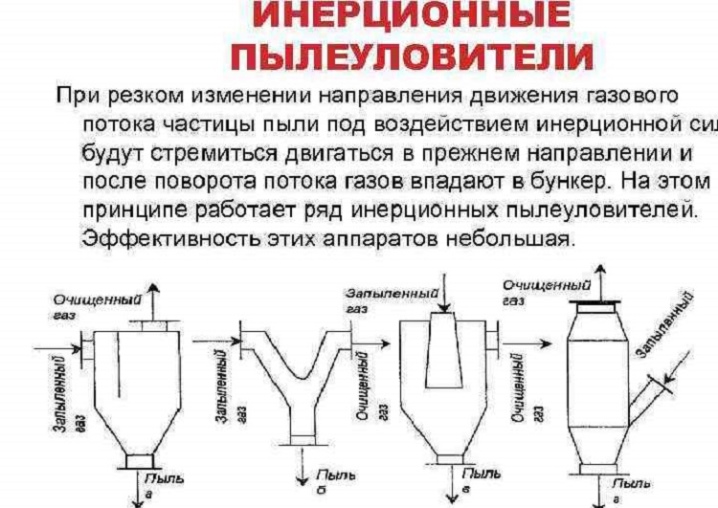

Inertial

The inertial type of dust collectors has such a classification.

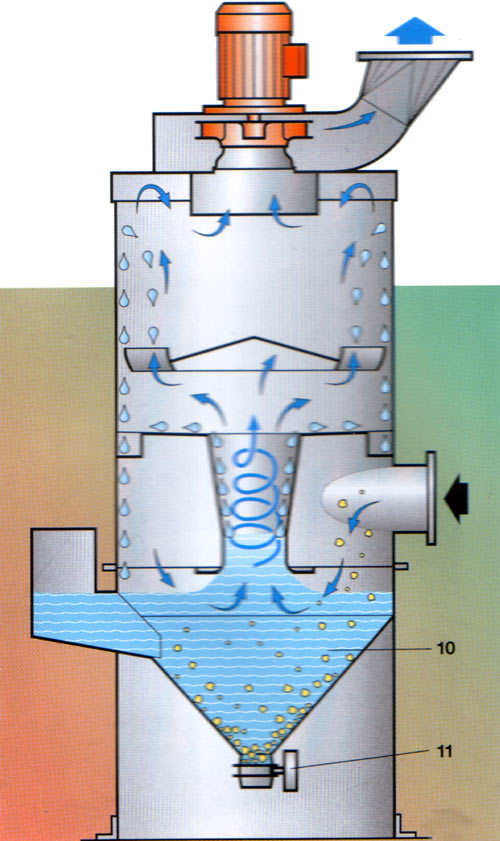

Wet

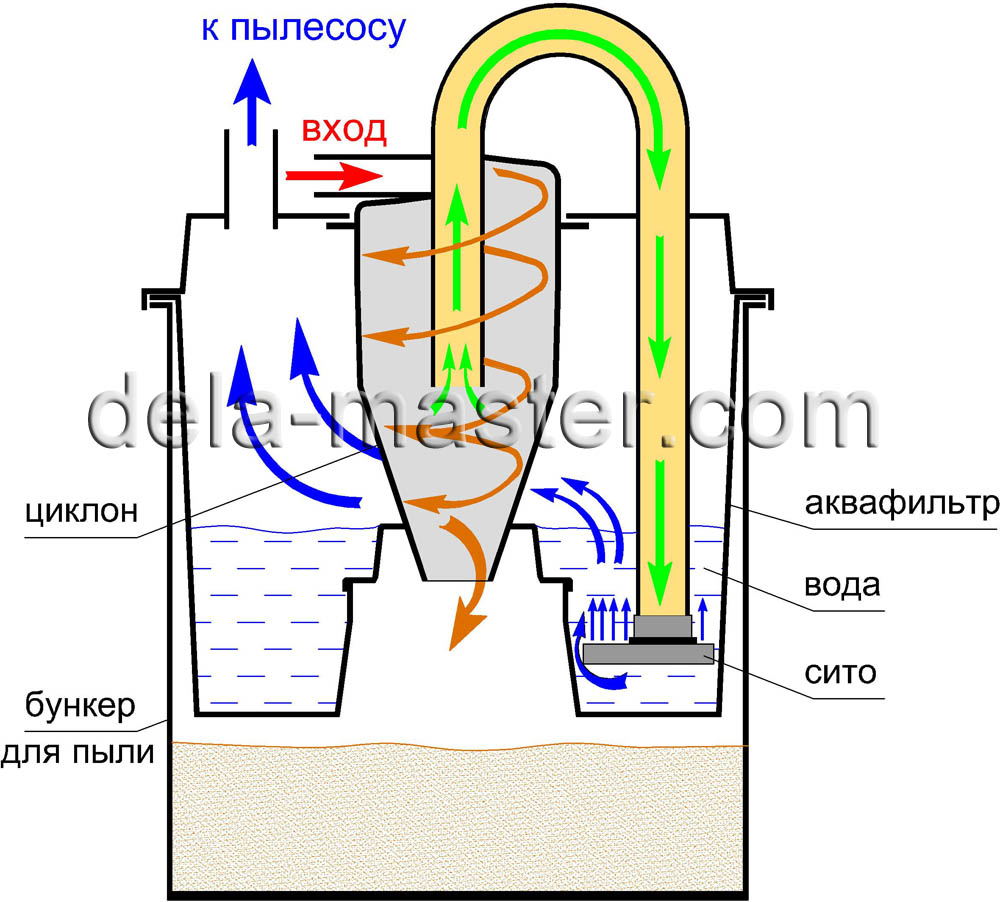

The functionality of the scrubbers is due to centrifugal forces. The air, loaded with dust fractions, enters the dust collector, where it is moistened with a liquid film. After that, the heavy dirt particles are directed to the sludge receiver. Another type of wet dust collecting unit is a cyclone with a washing action. In it, dust and dirt are captured by humidification, which occurs by atomizing an air stream.

The operation of the turbulent scrubber is due to the energy of the gas stream on the principle of water atomization.

Dry

The dry type dust collector works by centrifugal force and functions as a fan. When the air is shaken, it is freed from dust and dirt. Foam aggregates are often found among wet dust collectors. They have the form of one or more louvered tiers, which can be filled regularly or irregularly laid nozzles. The large contact area contributes to deep interaction and high-quality deposition of the dusty fraction on the film from the liquid. The clean air stream then passes through the mist eliminators, where it is dehydrated and sent to the room.

Some drops under the influence of gravitational force fall downward, the rest rise upward.Final cleaning together with dehumidification of air jets takes place at the final stage.

Contact action

Dust collectors, as well as filtering installations, which are based on contact action, are able to retain dust fractions during the passage of air through dry or wet materials of a porous structure. This device may include fabric, a layer of synthetic fiber, paper, wire mesh, granular material, as well as ceramic or metal rings.

Contact action filters have found their application in various fields. Currently, more than 70% of devices for the elimination of dust in a room fall on this type of dust collectors. Almost every ventilation device in a public or residential building uses such a filter. It is considered a good option for an apartment.

Electrical action

Models of dust collectors of an electrostatic type are considered the most popular due to their affordable price and good quality. In them, air purification occurs due to the ionization process. After turning on the device, the ionized air moves and thereby attracts dust particles with a negative charge. In this case, the plates of the device itself have a positive charge, due to which dust is attracted and remains on the filter.

In addition, these units do not need special care, they only need to remove dust residues weekly with wet wipes. The presence of an ionizer is an additional advantage of the device, since it is characterized by a high efficiency in eliminating viruses, bacteria, and unpleasant odors in the room.

The oil dust collector has also found its place in people's lives; it is often used on main pipelines and compressor shops. It looks like a vessel consisting of 3 sections. Due to the flushing, settling and bumping level, oil dust collectors clean air masses of high quality.

Methods of work

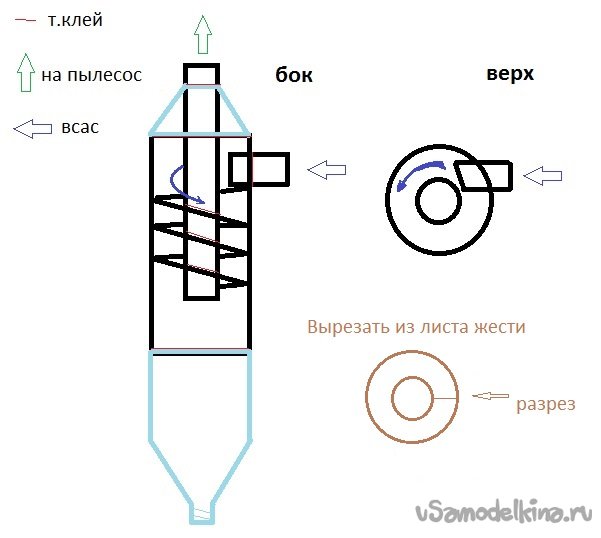

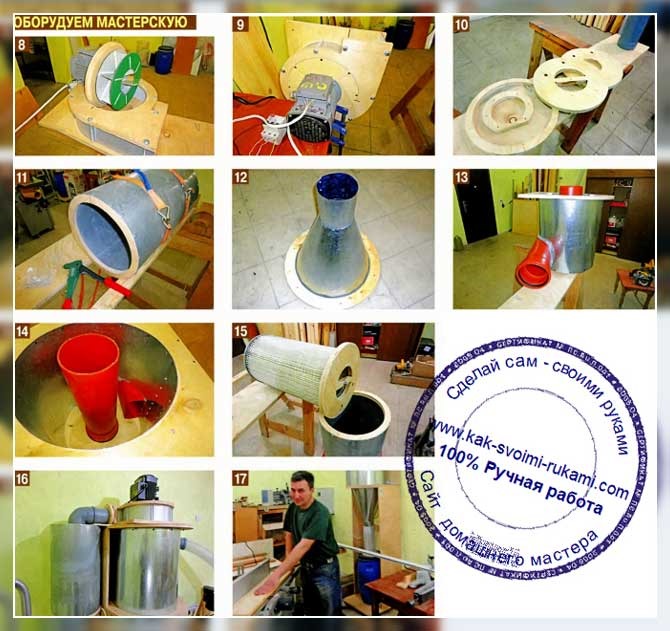

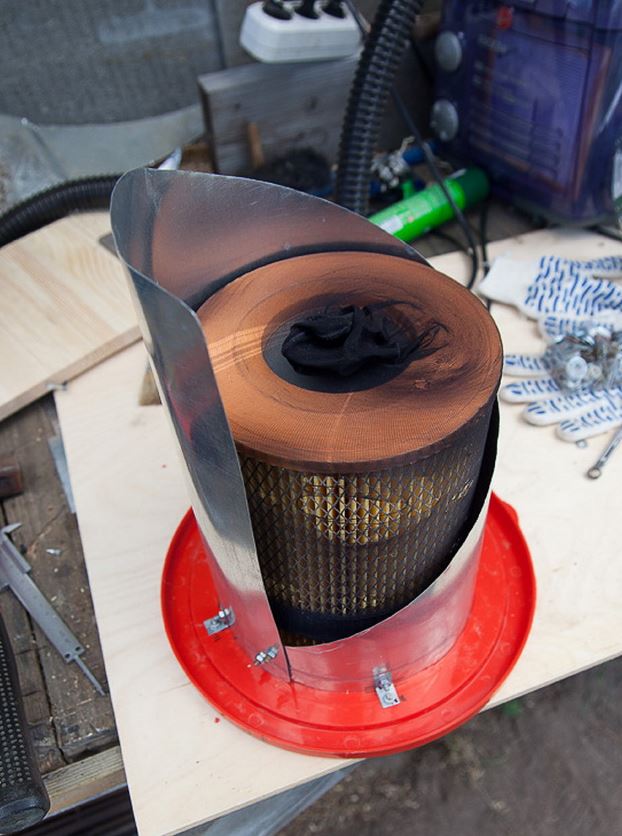

The production of a cyclone at the next stage involves the installation of polypropylene pipes into the cylinder. They should be glued with hot melt glue. The suction pipe must be rectangular on the inside of the cylinder. For this, it is heated with a hairdryer, and then a wooden frame is inserted into it, after which it is cooled. The air filter housing folds in the same way. The filter can be borrowed from KamAZ, because it has an impressive filter curtain area.

Now you can connect the lower body and the upper cylinder by screwing the snail on top. The air filter is fixed with polypropylene bends. The whole structure is assembled, and a plastic barrel is installed for the sawdust. A transparent corrugated pipe must be used to connect to the lower cone, this will allow the technician to see the fill level. In the last step, the unit must be tested by connecting it, for example, to a planer. After all, this equipment generates the most shavings.

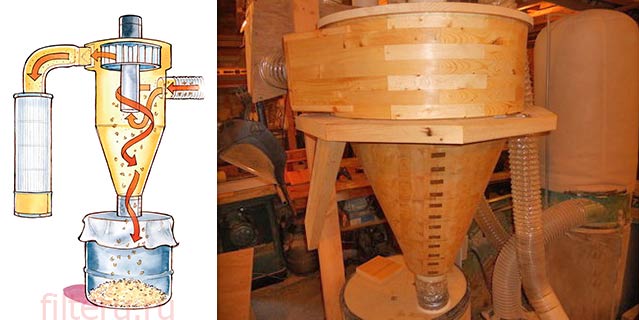

Making a cyclone with your own hands

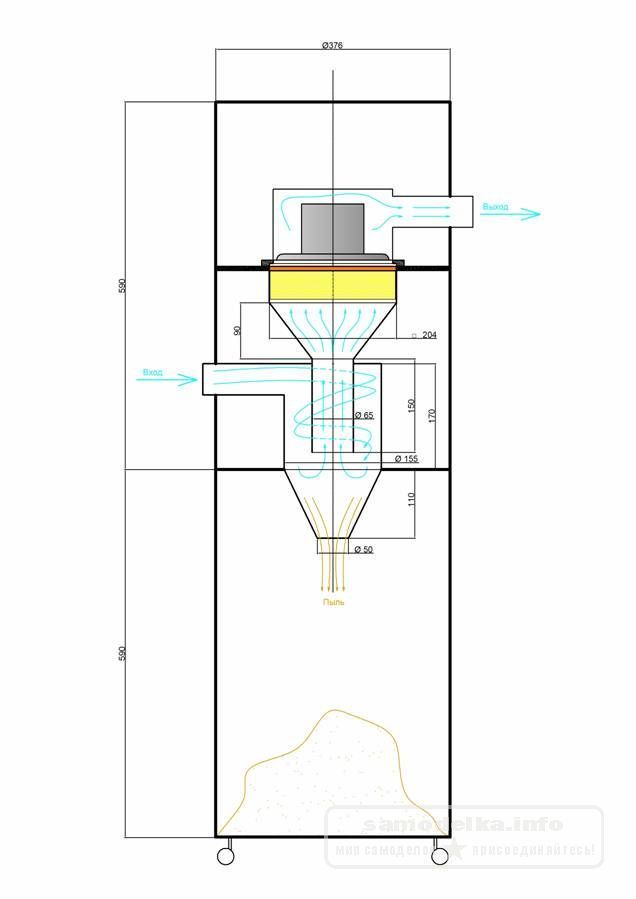

You can easily make a cyclone for cleaning air from dust with your own hands. This will allow setting up furniture manufacturing in our own workshop. At the same time, workers will not be exposed to the dangerous effects of the smallest wood dust, which they would have to inhale. At the first stage, a centrifugal fan in the form of a volute is manufactured. The body can be made of alucobond, and the body covers can be made of 20 mm plywood.

With the help of a hand mill, grooves are made in the covers, the diameter of which is 3 mm. The volute body is installed in the groove, the whole structure is tightened with bolts. At the next stage, a fan for the snail is made from alucobond, for this two circles are cut with a milling cutter, grooves are made into them, into which the blades are installed.They are glued with a hot glue gun. This will create a drum that looks like a squirrel wheel.

A cyclone for cleaning air from dust, the production of which can be carried out independently, will have a fairly strong and lightweight impeller with an accurate geometry. It is put on the engine axle. One with a power of 0.55 kW will do. For the manufacture of the case, you will need 20 mm plywood, on the surface of which, using a compass, it is necessary to depict the circumferences of the base. The upper body in the form of a cylinder is folded from the roofing sheet. On the base, fastening is carried out with self-tapping screws, the joints are glued with double-sided tape. The sheet is pulled together with blind rivets. The lower conical part is manufactured according to the same principle.

Operating tips

Before starting operation, you should carefully read the instructions in order to know what kind of care the device will need, at what time and what needs to be changed. Fundamental rules:

- The device is placed in places of maximum dust accumulation, not too close to the wall (at least 10 centimeters).

- All devices work from the mains, they are connected to an outlet, set the desired mode.

- The sensors for the indication of filter clogging are monitored. The replacement is carried out within the prescribed time frame.

- Plates of electrostatic models during daily use are wiped from dirt once a week.

If there are active small children in the house, place the dust collector so that the baby cannot reach it and dump it. By using any kind of dust collector, you can improve the air quality in your home and make your life more comfortable. A clean atmosphere in the apartment helps to avoid breathing problems, to sleep well and relax. With a lack of funds, you can make the device yourself.

Share link:

Technical characteristics of the model and some of its positive features

The above cyclone model consumes 36 m3 / min of air. The set comes with one dust bag. The diameter of the nozzle of the vacuum cleaner is 100 mm. Equipment dimensions are equal to 1200х700х1800 mm. The power of the device is equivalent to 2600 W. The unit has two suction openings.

Dust bags are designed for 105 liters of volume. Such cyclones for air purification of wood dust weigh a lot. For example, the mass of the described model is 88 kg

Before purchasing such a device, it is important to pay attention to some features, among them:

- long service life;

- convenient transportation;

- emergency turn-off;

- thoughtful design;

- mobility.

As for the long service life, it is provided by many stiffeners, which contribute to effective cooling of the motor during operation. This increases the service life and prevents overheating. The unit is equipped with transport loops that allow you to move the equipment using a lifting mechanism.

Varieties

Thinking about purchasing a dust collector for your home, it is useful to familiarize yourself with the types of devices, since each design has its own strengths and weaknesses, it copes with certain types of cleaning in the best way.

Electrostatic

In devices of this type, the property of dust particles to acquire an electric charge and be attracted to surfaces with the opposite sign is realized. In the dust collector, metal plates are installed, on which impurities from the air ionized in the device are deposited. The device catches dust, smoke, soot. In the presence of an ozonizer, it kills germs, eliminates odors.

Electrostatic models are almost silent, consume a minimum of energy, and belong to the budget segment. The main advantage of the devices is the absence of replaceable elements, which simplifies and reduces the cost of operation. Dust accumulates on the plates, they are washed once a week.

Photocatalytic

Photocatalytic dust collectors work on the disinfecting effect of ultraviolet radiation, which is directed to titanium dioxide plates, which act as a catalyst. Contaminants do not accumulate on the surface of the catalyst, but immediately decompose, turning into tiny particles (comparable to the size of molecules) that are harmless to humans.

The photocatalytic device removes toxins, biological contamination, odors. The disadvantages of the device include the need to replace the UV lamp (after 1-3 years), the price, a significant level of noise, as well as the death, along with the harmful and useful flora of the air.

With replaceable filters

Air purification in these devices is provided by HEPA filters. They trap dust particles as small as 0.34 micrometers. Most devices implement multi-stage filtration through materials of varying density, which also have antibacterial impregnations.

A great option for homes with children and people with allergies. A significant drawback of this type of dust collector is the replacement of expensive filters, which is necessary for the device 1-2 times a year.

Combined devices

The greatest demand is for combined-action dust collectors, which clean the air in several ways at once. They are equipped as follows:

- filters that cut off large (wool, dust particles) fractions from the air - preliminary cleaning;

- coal - eliminate odors, air impurities;

- HEPA filters are leaders in removing biological components from the air;

- electrostatic filtration;

- photocatalytic filter - disinfects.

Combined cleaning is more expensive, the device needs maintenance and replacement of elements, but the result is worth it.