Beneficial features

Transparent glue for glass is a thick and viscous mass that has a specific odor. This composition contains polymers that allow it to be applied to any surface and make it possible to quickly solidify at room temperature

It is also important to remember that it can be used to glue parts that are subject to light loads.

How to use

It will not be difficult to choose the finished product that suits you and how to glue glass surfaces with it after you read all the recommendations and tips in this article. Its use, in principle, is no different from the rules for working with any other glue, they are standard and well known. But it's better to repeat it again just in case. Transparent glue for glass and plexiglass does not burn and is not explosive, even metal or wood can be glued to the glass surface. You should work with him in a ventilated area and it is advisable not to allow children to this process.

It will not be difficult to choose the finished product that suits you and how to glue glass surfaces with it after you read all the recommendations and tips in this article. Its use, in principle, is no different from the rules for working with any other glue, they are standard and well known. But it's better to repeat it again just in case. Transparent glue for glass and plexiglass does not burn and is not explosive, even metal or wood can be glued to the glass surface. You should work with him in a ventilated area and it is advisable not to allow children to this process.

I would like to note that this glue is practically harmless to humans. But on one condition that you do not use it inside the body! It is better to glue in rubber gloves and in clothes that you will not be sorry to throw away later. In the event that a drop of a substance, despite all your efforts, has fallen on the surface of the skin, it is necessary to wash it off with soapy water or any weak solvent.

How to choose a glue for glass

Glass has low adhesion properties. Therefore, the connection of such surfaces is difficult. The fragility of the material further complicates the task. For gluing glass objects, you need a special substance that has certain qualities:

Glass has low adhesion properties. Therefore, the connection of such surfaces is difficult. The fragility of the material further complicates the task. For gluing glass objects, you need a special substance that has certain qualities:

- High adhesion for connecting objects that experience significant mechanical stress in everyday life.

- Transparency so that the resulting joint becomes invisible. When joining parts of small size, this quality is even more important than strength.

- The ability to dry in a short time.

- Increased density so that the resulting joint acquires elasticity.

- The ability to withstand significant temperatures, as well as frost and heat.

- The ability to repel moisture when in a humid environment or when operating products in atmospheric conditions.

- Environmental friendliness and safety for nature.

It is optimal to choose transparent means for work. They can be used to easily neatly connect small pieces of decor. It is also worth considering the physical parameters: transparent compositions are suitable for combining smooth objects, but if the surface is corrugated, a stronger formula is required. When you need to connect parts of the aquarium, choose a product that does not contain antibacterial components that will not harm the fish. For the connection of painted surfaces, strong compounds are chosen.

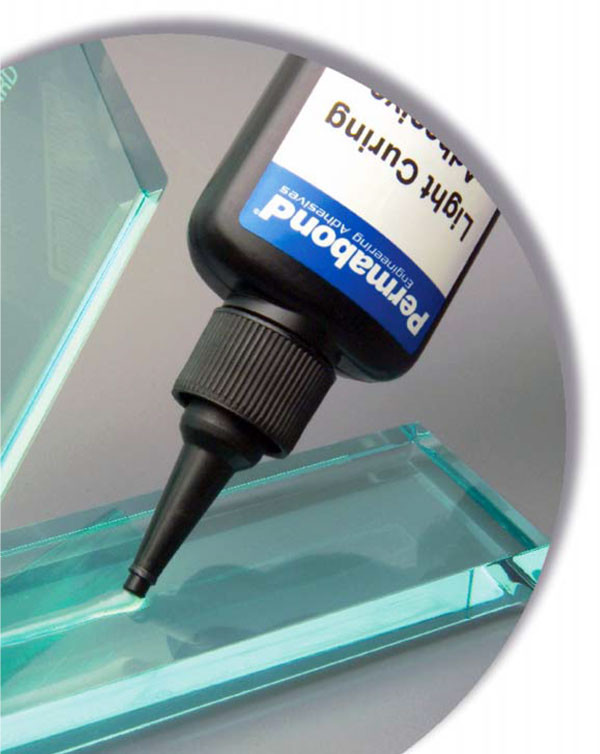

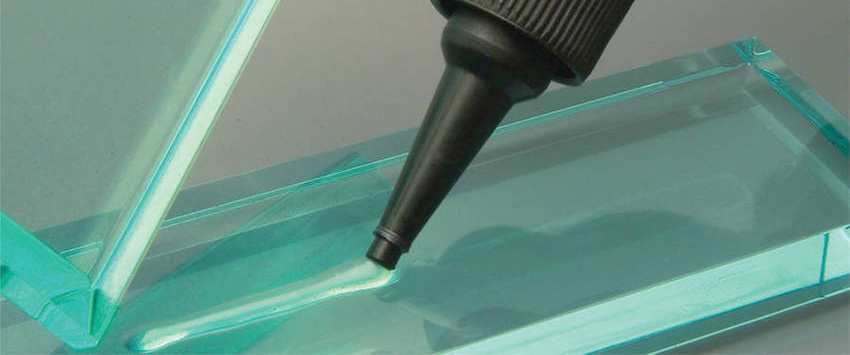

Polymer glue

The hardening of such a composition is carried out by exposure to ultraviolet radiation. In this case, gluing is possible only if at least one of the parts to be joined transmits light. To improve the process, a special lamp is applied to the aligned planes until the seam hardens. When glued with this substance, a transparent joint is obtained that can withstand temperature changes, moisture and mechanical stress.

The hardening of such a composition is carried out by exposure to ultraviolet radiation. In this case, gluing is possible only if at least one of the parts to be joined transmits light. To improve the process, a special lamp is applied to the aligned planes until the seam hardens. When glued with this substance, a transparent joint is obtained that can withstand temperature changes, moisture and mechanical stress.

Important!

Such a substance is used to work with jewelry, shop windows and stained glass windows. The connection is very strong. The only drawback of the glue is the slow hardening rate.

Silicate glue

The main ingredients of this substance are sealants and silicones. It is often used in construction.Due to the large number of shades, the connecting joint is made invisible or, on the contrary, emphasizes its decorative effect. This composition is often used in needlework. In this case, for a high-quality connection, you need to apply a larger layer.

Cyanoacrylate glue

This composition is also called cold welding. It has excellent adhesion and fast drying speed. The result is a strong and very durable seam. Cyanoacrylate glue is used to bond painted objects or to glue glass to other surfaces: metal, wood or plastic. The disadvantage of glue is that it breaks down when exposed to water.

Household adhesives

This group of adhesives includes PVA, "Moment", BF-2 or BF-4. In this case, the bond will be the stronger, the more the surfaces are squeezed after applying the adhesive. It is difficult to connect objects with BF glue, since this product requires a high temperature, and the glass may not withstand it.

This group of adhesives includes PVA, "Moment", BF-2 or BF-4. In this case, the bond will be the stronger, the more the surfaces are squeezed after applying the adhesive. It is difficult to connect objects with BF glue, since this product requires a high temperature, and the glass may not withstand it.

Important!

When using "Moment" glue, you must first withstand the lubricated surfaces for about 20 minutes and only then connect. If there is no time to wait, use the "Super Moment" tool.

Heat Resistant Glass Adhesive

I use a similar tool if the parts after connection will be regularly exposed to high temperatures. Such connections can be in an oven, electric kettle, or kitchen stove. To prevent the destruction of the glue seam, special reinforcing additives are included in the composition.

Peculiarities

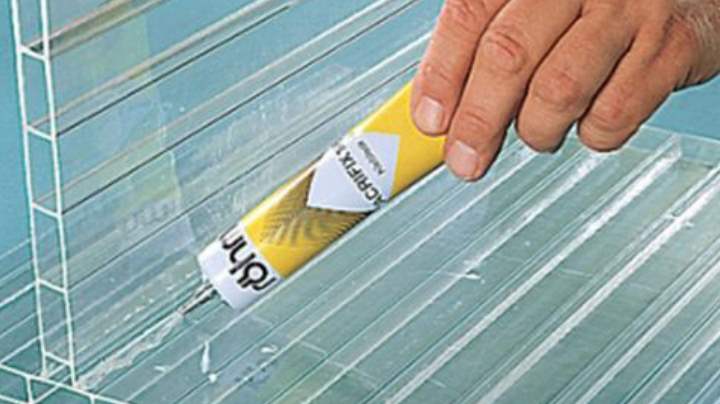

Plexiglass, which is usually called plexiglass, is flexible, so it is very pleasant and easy to work with it. This material is used for the manufacture of various containers and products, while special compounds are required to connect the elements. The result of gluing should not only be positive, but also strong, while it would be desirable that no muddy traces remain on the plexiglass, and the integrity was ensured. Experts recommend using different adhesives, which are offered in a wide range.

Working with plexiglass and glue can give different results, which depends on the method of application, the characteristics of the composition, components and other factors.

Here it is important to name two groups into which the products for joining plexiglass structures are divided. The first includes strong organic solvents, which include an acrylic filler

Their main advantage is that the fusion is not just strong, but homogeneous, since the seams are created by dissolving the plexiglass itself. This option is used in cases where you want to get the perfect result without disturbing the presentability of the plexiglass product.

The second group includes adhesives made from epoxy resins, which are often used to seal cracks and crevices. Such compositions are quite in demand in case of repair. However, a small drawback is the duration of the drying process, but this is covered by increased resistance to stress.

How to glue correctly - technology

For work, you will need the glue itself, carefully prepared parts, means for degreasing and washing them, rags. To heat the surface and irradiate it, you may need a UV lamp, to fix the parts - a press, a vice.

Preparation of the base

It is important to clean the surface before starting work, since the presence of even a small amount of rust, dust, dirt greatly reduces adhesion. If the metal is not covered with anything, it is simply wiped with a solvent (acetone, white spirit), you can also use alcohol or vodka

Do the same with glass or wash it with any detergent, thoroughly wash off the foam.

After washing, it is worthwhile to wipe the part with alcohol again, because any household chemicals leave a film on the surface.Paint, varnish applied to metal must be cleaned by hand (sandpaper) or a grinder, then degreased. All surfaces are well dried immediately before work.

Bonding steps

The parts to be glued must be heated to a temperature of + 40 ... + 50 degrees - this will make adhesion even more reliable

Care should be taken when heating the glass, it can crack when the temperature rises sharply. You can not use an open flame, it is better to use the hot air of a regular or construction hair dryer

Heating will also help to completely dry the parts, remove invisible condensation. After cooling, the risk of internal stress in the material will be minimal.

Further recommendations for work are as follows:

- gently apply glue to both parts to be glued;

- grind the product, forming a thin layer;

- carefully work out the edges of the products;

- relate the details to each other, add them;

- place the products under the press, ensuring uniform pressure.

The press should not be heavy, otherwise there is a risk of damage to the product. It is advisable to remove all the drops that have come out right away, because not every glue can be rolled up and removed after drying.

Using UV Lamp for Bonding

To form an even stronger seam, it is recommended to use ultraviolet lamps. It is imperative to preheat the parts to a temperature of +60 degrees. Then you should apply a thin layer of adhesive, attach the products to each other. Next, you need to irradiate the junction with a UV lamp twice. This is done to achieve the maximum strength of the seam (after a single irradiation, the degree of adhesion will be 70% of the possible, after the second - 100%).

The duration of the lamp will depend on its wattage. For the first stage, usually 10-120 seconds are enough, for the second - 60-300 seconds. Compliance with the technology without skipping stages will help to securely fix the parts and get the most durable joint that will be impossible to break or break.

Bonding parts of kitchen appliances

Sometimes there are situations when you need to repair the oven or microwave oven door. If you decide to do this at home, the question arises: with what glue to glue the metal to the glass?

When choosing a connection tool, you need to pay attention to the following indicators:

- high degree of adhesion;

- elasticity;

- neutrality and exclusion of toxic emissions;

- heat resistance.

In specialized stores, they sell sealants for the repair of kitchen appliances or silicone glue. Dow Corning can be purchased for these purposes, but it is not available everywhere.

To glue the glass in the oven or hob, clean the joints and dry them. Then glue is applied to the metal according to the attached instructions. When repairing the oven, you have to coat the metal joints carefully, removing excess glue immediately, otherwise, after it has hardened, it will be possible to remove the smudges only with a special tool.

Other craftsmen have found more ways to glue metal to glass:

- glue HC-1 and HC-2,

- glue BK-4,

- silicate glue,

- car sealants.

Auto glass

Car drivers are often faced with the problem of replacing broken glass in a car. Of course, it is better to use the services of workshops, but every car owner should know the principle of replacement.

To glue the glass to the metal, the gluing sites are treated with a pneumo knife, removing fragments and old glue. They clean and degrease the body at the junction. The glass is treated with some kind of activator and automotive glue is applied.

It is not difficult to glue glass to metal on your own if you use the types of glue appropriate for the work and follow the instructions. You can repair glass tables, oven and other items at home.

Plexiglass gluing with vinegar

Not many novice craftsmen know how to glue plexiglass with vinegar essence.Ordinary table acetic acid is not capable of making a strong bond.

The liquid is applied to the edges of the parts to be bonded. Further, the master squeezes them together. It turns out a one-piece product. The top layer softens, unlike EDC, diffusion is slow. The seam itself will be finally ready only in a day.

Disadvantages of using vinegar essence:

- Low bond strength.

- The seam quickly deteriorates.

- Cracks appear at the places of the bends.

In order to glue Plexiglas products for a short period of time, it is recommended to use vinegar essence with a strength of 30 ... 70%. Do not add plexiglass shavings, their essence will not dissolve, as it contains up to 30% water. By the way, the concentrate can be replaced with solvents, keep in mind that they can evaporate quickly.

Work rules

Before starting work, it is necessary to clean the surface from dirt and remnants of old glue. It is also recommended to degrease glass and wood using alcohol or other solvents. These products are also suitable for removing glue.

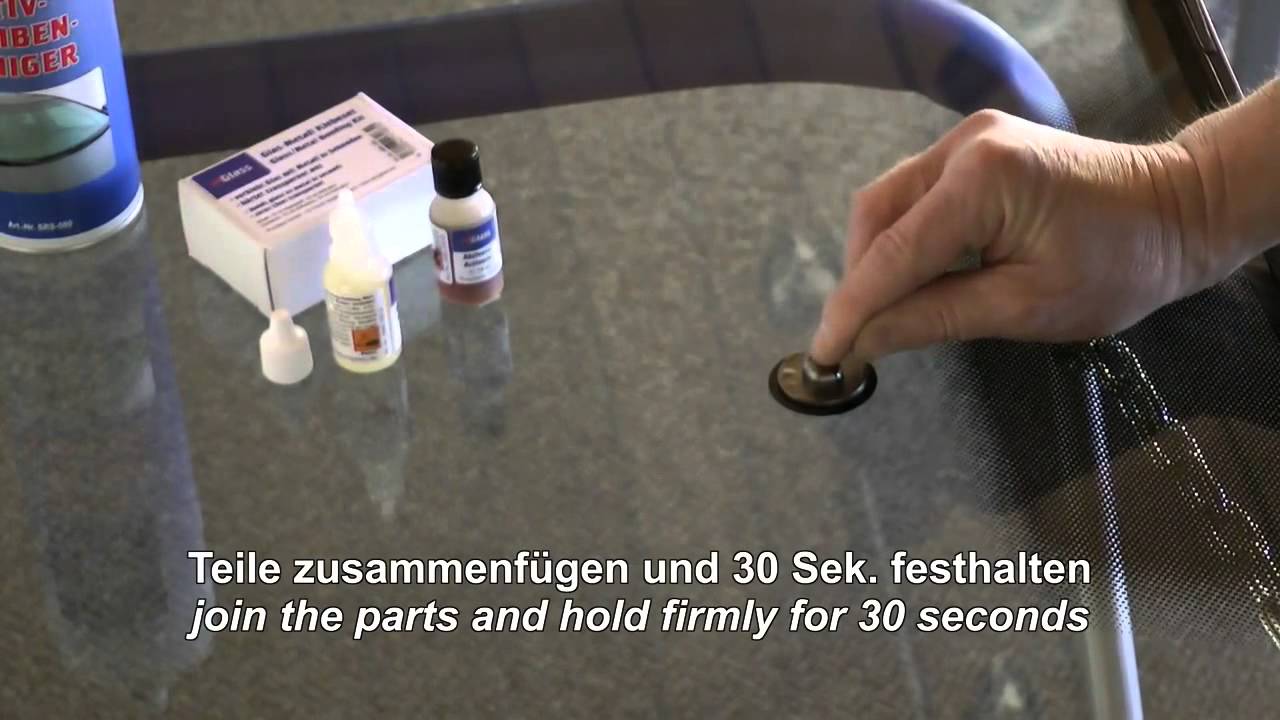

Glass and wood are glued together according to the following algorithm:

- Both materials are pre-treated with putty or other means that eliminate visible defects (chips, cracks, and so on).

- In places where the glue is applied, glass and wood are processed with fine sandpaper. This increases the degree of adhesion. That is, the glue will more reliably connect materials to each other.

- The adhesive is applied and the surfaces are pressed.

The procedure for applying the glue depends on the type of the selected composition:

- PVA. The adhesive should only be applied to one surface, avoiding the formation of bubbles. After that, the materials must be kept under load for half an hour.

- "Moment-Crystal". After applying glue, the created connection must be dried with a hairdryer for 15 minutes. During this time, the composition only has time to dry. The tool is gaining strength after a day.

- "BF2" and "BF4". Both products must be dried after application. In this case, a building hair dryer is recommended, since this glue gains strength when exposed to a temperature of 140 degrees. Then you need to connect the glass and wood and squeeze, applying maximum effort.

If liquid nails or PVA are used to connect wood and glass, then the agent should be applied only to one surface with a thin layer. If the latter requirement is not met, the adhesive remains visible after curing.

> Two-component products are applied using a different algorithm. In this case, one surface must be treated with glue, and the other with an activator. After that, you need to tightly squeeze the materials together and stand for five minutes.

Share link:

How dichloroethane (EDC) glues

It is effective when there is no target adhesive to work with. It can be purchased where electronics components are sold. Dichloroethane dissolves the material to be glued rather quickly, but it also evaporates quickly.

There are two methods for applying dichloroethane:

- If the surfaces are even, the substance is taken with a medical syringe from a vial of EDC, poured along the contour of the joint so that it gets to the full depth. The result is a transparent seam without bubbles.

- When surfaces are uneven, the gluing technique changes. A small amount of sawdust or plexiglass powder is added to a container with dichloroethane. Powder is enough for 5 grams per 100 grams of liquid. After a short period of time, EDC becomes a thick mass. Apply the mixture to the bonded surfaces with a metal wire.

The bonding procedure must be carried out using high-quality ventilation, with goggles, gloves. Keep away from children, do not work near open flames. Anyone can glue two parts of plexiglass with dichloroethane without additional skills.

Technological process

The technology for gluing acrylic has its own technological features and differs from gluing ordinary glass, it is important to take this into account. The latter can be glued using silicone glue, but special adhesives must be chosen to connect plexigas.

First of all, it is worth paying attention to the very "delicate" surface of the material, we are talking about the fact that it is vulnerable to the effects of various solvents, chemical compounds. When using some even organic compounds, unwanted cracks may appear on the surface of the plexiglass.

Today, gluing technology is often used using glue made on the basis of organic solvents. Plexiglass gluing of manufactured products is possible with a 2-5% solution of polymethyl methacrylate in dichloroethane. It is made on the basis of dichloroethane, into which fine acrylic shavings are mixed. The resulting solution must be stirred for 20 minutes, the room temperature must be room temperature. After that, the solution must be kept for about 3 days, this is necessary in order for all the chips to dissolve. The result is a homogeneous and high quality adhesive. Its shelf life is one month. After applying the glue and completely drying it, you will have a securely connected part, it will be like a monolithic one. A small amount of bubbles may form in the thickness of the adhesive solution.

Gluing glass to metal - the choice of glue

Usually, transparent glue is selected for gluing metal to glass, because it will provide the most aesthetic seam, which will be almost invisible from the outside.

This glue quality is especially important if you plan to glue the glass decor to a metal base. But the absence of color, invisibility is not the only requirement for the material.

The best adhesive also has the following properties:

- Strength. If the product will withstand high loads, you should buy only glue with increased adhesion, for example, compounds that become even stronger under the influence of UV radiation and stick the parts almost forever.

- Tightness and moisture resistance. Some products act as a sealant. They are indispensable for gluing glass to metal if the joint is exposed to moisture. Most often, sealants are used when inserting auto glass, self-gluing an aquarium. There are even black sealants that make the future product stylish, with expressive contours.

- Solidification rate. Some products dry in just a few seconds, while others polymerize for a long time under the influence of ultraviolet light.

If the transparency of the composition is not critical, you can use your own glue. Its components are as follows: 2.5 parts of gypsum, lead litharge, chalk, 3.5 parts of rosin. This mass is diluted with linseed oil to get a mixture with the consistency of putty. It will firmly adhere metal and glass, as well as rubber and metal. Among the purchased adhesives, there are different products that have different composition and properties.

Cyanoacrylate

How to firmly glue dissimilar parts to each other? It is worth using cyanoacrylate or superglue. The tool is better, faster than others, it gives a reliable pairing, it can be one-component, two-component. Drying time for superglue rarely exceeds 5-10 seconds. When buying, you need to immediately clarify whether the glue is moisture resistant, since some cyanoacrylates cannot be used in a humid environment. Most adhesives are very easy to use: the parts need to be lubricated, pressed against each other. If the composition contains epoxy resin, the two components of the glue must be mixed together before work.

Sealant

How to glue glass to metal if the seam will be exposed to regular moisture or even be in water? A transparent sealant will help here, which gives a high degree of isolation from moisture, withstands the action of aggressive factors and temperature interruptions. The sealant has two drawbacks: the degree of its adhesion may be lower than that of superglue, and it takes an order of magnitude longer to dry. But there are special heat-resistant sealants that can be used to repair stoves and ovens. They don't respond to action:

- high temperatures (up to +300 degrees and above);

- fat and oils;

- household chemicals;

- frost.

You can use the item after gluing one day after the repair

Before applying the sealant, it is very important to degrease the base well, dry it, otherwise the bond will not be strong

Moment-Crystal

This product is absolutely transparent, leaves no residue. It is ideal for non-ferrous materials and has a minimal evaporation time. Moment-Kristall can glue not only metal, glass, but also porcelain, ceramics, cork, wood, plexiglass, PVC in various combinations. If excess adhesive remains on the surface, no solvent is required. You need to wait for the product to dry, then gently roll it into a small ball, remove. The downside is the unsuitability of "Moment" for products in contact with food.

"Moment-Kristall" is suitable for substrates subject to stress, because the glue line will be sufficiently elastic. After the termination of the impact, the interlayer returns to its original state without deformation. The glue is one-component, it is convenient to use it, because there is no need to dilute, mix the components together.

Car glue

What glue should a car owner use when repairing a car? There are transparent and black car adhesives, you can choose the color based on the task and the required degree of invisibility of the seam. All auto adhesives have increased adhesion and are resistant to aggressive environments. Before gluing the parts, it is usually recommended to warm them up well so that the joint is more reliable.

How to make adhesives for porcelain, glass and ceramics:

Recipe one:

Stir and grind in a mortar:

- 170 g of tripoli powder,

- 300 g of barium sulfate,

- 160 g of asbestos,

- 110 g of fine sieved sand,

- 260 g of concentrated liquid glass.

The adhesive hardens at normal temperature. The resulting compound can withstand temperatures up to 100 ° C and has significant chemical resistance to a wide variety of chemical agents.

Second recipe:

Grind in a mortar:

- 160 g of powdered glass,

- 250 g of asbestos,

- 500 g of concentrated liquid glass.

The adhesive hardens at normal temperature. The compound can withstand temperatures up to 150 ° C and the action of chemical agents.

Types and their composition

Structures that include many parts cannot be assembled without the use of adhesives

In this case, it is important to make sure of the strength of the seams of the glued elements, taking into account the strength of the material

When choosing such products, it is necessary to pay attention to all indicators, as well as to study the composition of the product in order to find something that will meet all the requirements.

Physical adhesion is achieved with products that are offered as solutions. With the gradual evaporation of the solvents, the glue mass will become solid, which indicates the connection of the plexiglass parts.

With regard to chemical action, this includes all two-component formulations. The components are mixed, after which they begin to act and quickly harden. To obtain the desired effect, several factors must be taken into account - high temperature, combination of ingredients, introduction of catalysts or activating components, without which the reaction is impossible.

If you need to repair a plexiglass structure at home, the question immediately arises of which means to choose so that the result is of high quality, and the seams are strong and resistant to possible damage. Previously, dichloroethane was in great demand, which was applied to the surface of the material and dissolved it. When dry, the parts turned into a solid structure, and the seam was barely noticeable, and if necessary, it could be removed and the surface polished.

It is worth noting that dichloroethane-based products are highly toxic and volatile, but at the same time they are considered one of the best for working with plexiglass. Today, the market offers mixtures with innovative components in the composition that are safe, so they can be safely used even at home.

Ordinary Moment glue is suitable for simple joining of plexiglass parts. Its main advantage is that it responds quickly and can connect surfaces of a wide variety of materials. Of course, it is necessary to work with this tool carefully, precisely gluing the elements, because it will no longer be possible to separate them, since the integrity will be violated.

If adjustments are required, you can choose the waterproof 88 glue, which has increased strength. Liquid nails are considered a versatile tool that is suitable for home repairs. The only drawback is that the seam will not be transparent, so this factor must be taken into account in advance.

Dichloroethane is often used to make an adhesive at home. The components should be not only this chemical, but also plexiglass shavings, which are mixed to a state of medium density. After a couple of days, the shavings dissolve, and the mass can be used to glue the parts together. Such a dichloroethane composition is able to tightly combine the elements of plexiglass by the accretion of molecules with each other. As a result, the seam will be strong, uniform and transparent.

UV glue contains methacrylate, the hardener is ultraviolet light, which emits a special flashlight. You can use such a substance for gluing not only plexiglass, but also metal, wood, plastic and much more.