Advantages and disadvantages

It is convenient to work with EC 3000 glue:

- 1 square meter requires 2.5-3 kilograms of glue. Layer thickness during application - 5 millimeters. For dense walls, this is a low consumption. But for porous surfaces, it needs to be increased. On average, 25 kilograms of powder requires 6 liters of water, and the mixture is enough for 6 square meters of surface.

- The mixture is suitable for work for a long time. In 4 hours you can have time to arrange a bathroom or an apron in the kitchen.

- Within 15 minutes, the master can correct the position of the tile after fixing it, which also makes the work easier.

- Plastic glue is easy to apply, does not crumble, does not break.

The disadvantages include packaging and technical features of the work:

Large volume of glue packed in 25 kg paper bags

During transportation, the packaging may tear, therefore, carry the bags with care. In damaged packaging, the adhesive loses its adhesive properties and absorbs moisture.

Powder spilled on the floor must be removed immediately.

The particles are embedded in the surface and are not cleaned.

The consumption of glue increases when laying underfloor heating. If electric mats are placed in the glue layer, its thickness increases to 10 millimeters against the standard 5-6 millimeters.

The EC 3000 glue holds the facade cladding well. Stone slabs do not lag behind the vertical base in frost -25

It is important to thoroughly clean the surface of dust before work, otherwise the strength of the glue will significantly decrease.

Craftsmen appreciate EC 3000 cement glue for its ease of preparation, ease of use, durable coating and savings on minor repairs. The result is a high-quality cladding that will withstand frost and moisture inside or outside the room.

p> Share link:

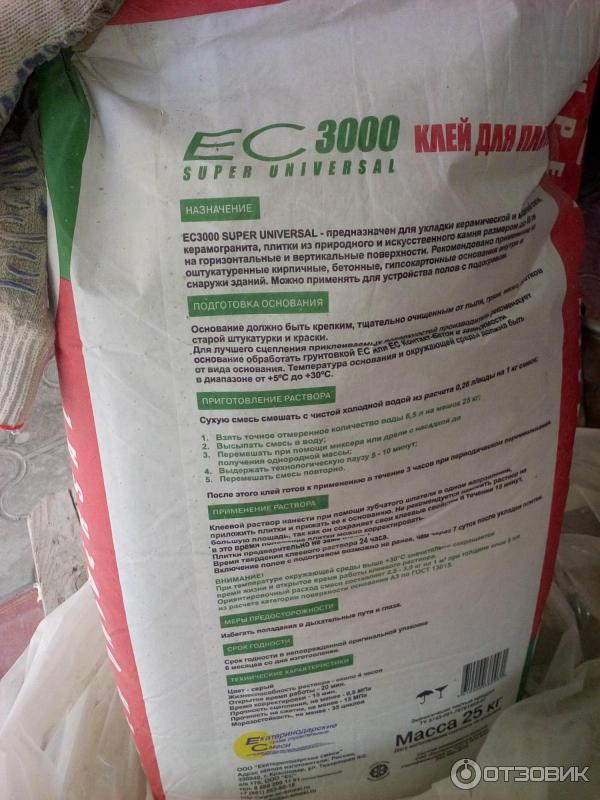

Product characteristics

EK 3000 glue compares favorably with analogues in its properties. It has a high level of adhesion to the surface, due to which the tiles will not stray down when glued to vertical substrates. With the help of this material, you can glue the plates using the "top-down" technique, there will be no problems with the quality of work.

Main technical characteristics of the material:

- the shade of the glue is gray;

- the size of the grains in the powder fraction is less than 1.25 mm;

- the readiness of the solution - 4 hours;

- open time - 15 minutes;

- the possibility of correcting defects after applying the product - 20 minutes;

- consumption per 1 m2 - 2.8 kg / sq. m, provided that a 6 * 6 mm spatula is used with an angle of 60 degrees;

- thickness of the glue layer - 3–6 mm;

- adhesion - 1.0 MPa;

- operating temperature + 5 ... + 30 degrees;

- drying period - 24 hours.

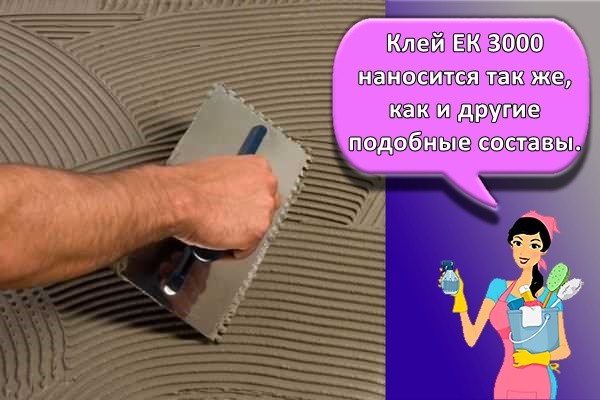

Application of EK 3000 glue

Tile adhesive EK 3000 Universal looks like a dry powder for preparation of working solution. The composition of this construction product contains fractional sand, cement of special preparation. Also, modifiers and special fillers have been added to the EK 3000 mixture.

With this tool, you can glue ceramic tiles of medium and small size. The material is best suited for stone slabs with a water absorption of up to 1%. Also in the description of this universal glue it is indicated that it is suitable for gluing tiles to such bases:

- plastered surfaces;

- concrete;

- brick coverings;

- aerated concrete;

- other minerals.

In addition to ceramics, the tool is used for working with artificial stone, with its help, a warm floor is installed in rooms. Glue helps to level out small irregularities in walls, floors, but no more than 15 millimeters. A feature of operation is the need to use a starting profile if the tile is applied to walls and other vertical foundations.

Specifications

Glue EC 3000 is sold in cans and bags, with a volume of 5 or 25 kilograms and is valid for six months from the date of issue.

Pot life of the solution

The mixture retains its plasticity and softness for 4 hours. Then the mass hardens, it is difficult to pick it up with a spatula and spread it.

Working time with tiles

The position of the slab can be corrected within 15 minutes after laying.

Extra time is important when working with uneven surfaces and tiles with complex patterns

Degree of adhesion

The adhesive is highly adhesive - 1 MPa. It is used for laying heavy tiles using top-down technology. Good adhesion between the wall, glue and cladding prevents the coating from sliding under its own weight.

Compressive strength

The indicator of 15 MPa determines the high strength of the coating. The cladding will not fall off from strong impact or pressure, constant load from furniture, loads or steps.

Frost-resistant glue withstands 35 thawing and freezing cycles.

Ambient temperature

The glue can be used in moderate heat. The temperature range in which the properties of the mixture are preserved is from +5 to +30 degrees. At sub-zero temperatures, the water in the mixture will freeze. High temperatures are detrimental to the adhesive properties.

Consumption by brands

| Name | How much tile adhesive is needed per 1m2 (comb size 6 * 6 mm) | Recommended layer thickness, mm |

|---|---|---|

| Eunice Plus | 3,5 | 3-15 |

| Eunice 2000 | ||

| UNIS XXI | ||

| Unis HiTech | ||

| Eunice Granite | 3-10 | |

| Eunice Belfix | ||

| Unis Fix | 3,5-5 | 3-15 |

| Eunice Pool | 3,1 | 3-6 |

Ceresite

| Name | Max. tile side length, cm | Comb teeth size, mm | Consumption, kg per sq. m |

|---|---|---|---|

| Ceresit CM 9 (for ceramic tiles) | 10 | 4 | 2 |

| 15 | 6 | 2,7 | |

| 20 | 8 | 3,2 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 11 Plus (for tiles and porcelain stoneware) | 5 | 3 | 1,7 |

| 10 | 4 | 2 | |

| 15 | 6 | 2,7 | |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 12 (for porcelain stoneware and large tiles) | 30 | 10 | 4,2 |

| 60 | 12 | 6 | |

| Ceresit CM 14 Extra | 15 | 6 | 2,7 |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| 45 | 12 | 6 | |

| Ceresit CM 16 (elastic) | 10 | 4 | 2 |

| 15 | 6 | 2,7 | |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 17 (super elastic) | 10 | 4 | 1,5 |

| 15 | 6 | 2,1 | |

| 25 | 8 | 2,7 | |

| 30 | 10 | 3,2 | |

| 40 | 12 | 4,1 | |

| Ceresit CM 115 (marble and mosaic) | 10 | 4 | 2,5 |

| 15 | 6 | 3,4 | |

| 25 | 8 | 3,9 | |

| 30 | 10 | 4,4 | |

| Ceresit CM 117 (flexible adhesive for facade tiles, stone and porcelain stoneware cladding) | 10 | 4 | 1,8 |

| 15 | 6 | 2,5 | |

| 25 | 8 | 3,2 | |

| 30 | 10 | 3,6 | |

| 40 | 12 | 4,7 |

Kreps

| Name | Consumption, kg / m2 | How long will the package last 25 kg, m2 |

|---|---|---|

| A plus | 2-4 | 8 |

| Aqua | ||

| Base | ||

| Standard | ||

| Super | ||

| Kreps Prostoklei | ||

| Reinforced | 2-3 | |

| Express | ||

| White Reinforced |

Bolars

| Name | Average consumption (comb size 6 mm), kg / m2 | Max. layer thickness, mm | One 25 kg bag is enough for m2 |

|---|---|---|---|

| Base | 3-3,5 | 10 | 8 |

| Standard | 3-3,5 | 10 | 8 |

| Elastite | 3-3,5 | 6 | 8 |

| A plus | 2,7-3,2 | 6 | 8 |

| Granite | 2,7-3,2 | 6 | 8 |

| Aqua plus, for pools | 2,5-3 | 6 | 9 |

| Elite | 2,5-2,8 | 6 | 10 |

| Express | 3 | 6 | 8 |

Hercules

| Name | With a word of 1 mm, kg / sq. m | Maximum layer thickness, mm |

|---|---|---|

| Universal GM-35 | 1,53 | 20 |

| Superpolymer GM-45 | 1,53 | |

| For porcelain stoneware GM-55 | 1,53 | 20 |

| Elastic GM-195 | 1,43 | |

| For underfloor heating GM-125 | 1,49 | |

| Heat resistant GM-215 | 1,81 | 20 |

| Strong GM-115 | 1,53 | 20 |

| For GM-165 mosaic | 1,33 | |

| Aqua-stop GM-145 | 1,49 | |

| Base GM-25 | 1,53 | 10 |

Vetonite

| Name | With a layer of 1 mm, consumption, kg / sq. m | Maximum layer, mm |

|---|---|---|

| Optima | 1,29 | 10 |

| Easy fix | 1,29 | 15 |

| Granit fix | 1,29 | 15 |

| Profi plus | 1,35 | 15 |

| Ultra fix | 1,29 | 15 |

| Ultra fix winter | *3-3,5 | 15 |

| Mramor | 1,29 | 15 |

| Absolut | *3-3,5 | 30 |

| weber.vetonit RF | *3-3,5 | 15 |

| weber.vetonit RFF | *3-3,5 | 15 |

| Name | Dry mix consumption (teeth size 6 * 6 mm), kg / m2 |

|---|---|

| EK 1000 WIDE | 3,4 |

| EK 2000 KERAMIK | 3,3 |

| ЕК 2000 KERAMIK ECO | 3,3 |

| EK 3000 UNIVERSAL | 2,8 |

| ЕК 3000 UNIVERSAL ECO | 2,8 |

| EK 4000 TITAN | 2,7 |

| ЕК FAST FIX | 2,7 |

| EK 5000 AQUA | 2,7 |

| EK 6000 MOZAIK | 2,8 |

| EK 8000 KAMIN | 2,7-2,8 |

Plitonite

| Name | Maximum length of a side of a tile, mm | Teeth height, mm | Dry glue consumption, kg / m2 | How long is 15 kg, m2 |

|---|---|---|---|---|

| Plitonite A | 301 | 12 | 5,1 | 5 |

| Plitonite B profi | 301 | 12 | 5,1 | 5 |

| Plitonite C light | 51-108 | 4 | 1 | 15 |

| 109-200 | 6 | 1,5 | 10 | |

| 201-250 | 8 | 2,1 | 7,1 | |

| 251-300 | 10 | 2,6 | 5,8 | |

| > 301 | 12 | 3,1 | 4,8 | |

| Plitonite Bb | 51-108 | 4 | 1,8 | 14 |

| 109-200 | 6 | 2,6 | 9 | |

| 201-250 | 8 | 3,5 | 7 | |

| 251-300 | 10 | 4,4 | 6 | |

| > 301 | 12 | 5,3 | 5 | |

| Plitonite B super floor | 109-200 | 6 | 2,9 | 9 |

| 201-250 | 8 | 3,9 | 6 | |

| 251-300 | 10 | 4,9 | 5 | |

| > 301 | 12 | 5,9 | 4 | |

| >401 | 15 | 7,3 | 3 | |

| Plitonite SuperFireplace ThermoGlue (W) | — | — | 1,4-4,5 | 25 kg per 9 m2 with 6 mm notches |

| Plitonite -AquaBarrier HydroGlue | Prospectors |

| Name | Approximate consumption, kg / m2 |

|---|---|

| Standard | 3-5 |

| A plus | |

| Suite | |

| Premium | |

| Quick |

About the manufacturer

The Prospector company appeared on the Russian market in 1992. Initially, the company specialized in the production of putty. Over time, it was decided that it was necessary to expand the range of goods by producing ready-made building mixtures.

Having adopted the relevant European experience, the organization's specialists quickly managed to establish a full-fledged production cycle for products that are very popular with builders.

The main advantages of the Prospector company are as follows:

- production of more than 80 types of products for various construction tasks;

- fully automated production;

- significant development dynamics, which allowed the brand to become the market leader;

- introduction of modern technologies in the process of manufacturing goods;

- the presence of 15 high-tech production lines;

- constant checks of product quality at various stages of its manufacture.

The company Prospectors has established a process for certifying its own products in the GOST system.Additionally, all types of products constantly undergo an appropriate sanitary and epidemiological examination, confirming their full compliance with the requirements of Rospotrebnadzor.

Ceresit CM 17

The main feature of Ceresit CM17 is its high elasticity and good adhesion. Due to this, it can be used for laying deforming bases: warm floor, drywall, chipboard. It is not afraid of moisture or frost, it can be used for lining swimming pools, for interior and exterior works, tiles and large-format porcelain stoneware (except for marble).

Ceresit 17 is available in two versions: regular and low-dust (marked "Stop Dust").

Specifications

| Mixing ratio | When laying on walls: 8.5-9 liters of water per 25 kg of dry mix.

When laying on the floor: 9-9.5 liters of water per 25 kg. |

| Time of using the mixture after mixing | Minimum 2 hours |

| Terms of use | Base and air temperature from +5 to +30, air humidity less than 80% |

| Open hours | From 30 minutes |

| Tile adjustment time | From 30 minutes |

| Sliding tiles | No more than 0.5 mm |

| Grouting | After 24 hours |

| Adhesion to concrete after 28 days | More than 1.3 MPa |

| Frost resistance | At least 100 cycles |

| Operating temperature | -50 to +70 |

| Package | 5 and 25 kg bags |

Properties

The popularity of Prospector tile adhesives is due to their respective performance properties, such as:

Versatility

The company's dry mixes can be used with almost all types of tiles, both for walls and floors.

They are allowed to be used indoors and outdoors - both in normal conditions and in conditions of high humidity.

Plastic

When properly prepared, Prospector glue can be easily applied to absolutely any substrate. Working with it does not require significant labor costs, so it can be carried out not only by professionals, but also by inexperienced workers.

Water resistance

Almost all dry mixes can be used in rooms with high humidity levels. These include, among other things, a bathroom and toilet.

Good adhesion

It is allowed to apply glue to almost any surface, regardless of the material, whether it is brick or concrete base.

Standard pour point and humidity

Thus, tile adhesives from the Prospector company are currently in significant demand among professional builders.

Preparation of the base

The temperature regime should not go beyond the above range, this applies to the base on which the glue is applied, and the material itself. Before starting work, the base should be thoroughly cleaned from dirt, dust, grease, enamel residues and other substances that can negatively affect the adhesion rate.

If there are craters on the base, pits deeper than 5 mm, they must be filled by plastering with a suitable agent. If the base is made of a porous material that absorbs a lot of moisture, it is pre-primed. It is recommended to use a deep penetration primer such as EK GS300 Deep.

EK 3000: features of preparatory work before use

EK 3000 tile adhesive is used for construction work outside and inside. This solution has a wide range of applications. It perfectly fills the tile joints and smoothes the surface. If you follow the instructions, you can get a high-quality work result.

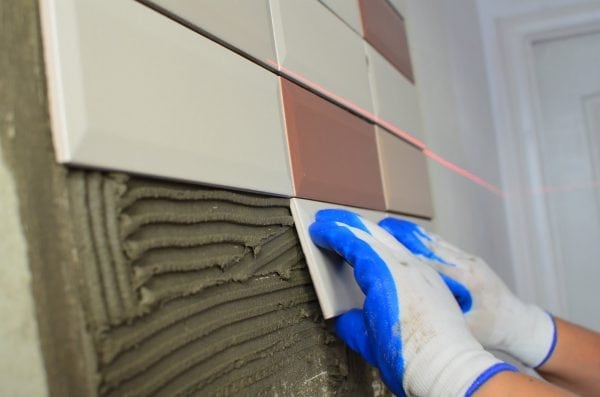

Laying tiles on glue

To calculate the correct amount of EK 3000 that will be needed for construction or renovation work, you need to measure the cubic capacity of the surface area where you plan to lay the tiles.

- Using this glue, tiles can be laid starting from the top. EK 3000 tile adhesive is characterized by high adhesion up to 1 MPa. By choosing it, you can forget about such a common problem as tile slipping. To take advantage of all the positive characteristics of the glue, you must strictly follow the instructions.

- Tile adhesive 3000 must be used under certain conditions. The temperature of the environment and the base can vary between + 5 ... + 30 degrees.

- The surface that is being prepared for cladding must be solid. It should be well cleaned of all dirt, as they will weaken the adhesion of the adhesive to the base. Unevenness deeper than 5 mm is pre-leveled with plaster mixtures. If the substrates strongly absorb moisture, then it is recommended to process them before starting work with the EK 3000. For this, the primer EKANTISEPTIC / EKG300DEEP is used.

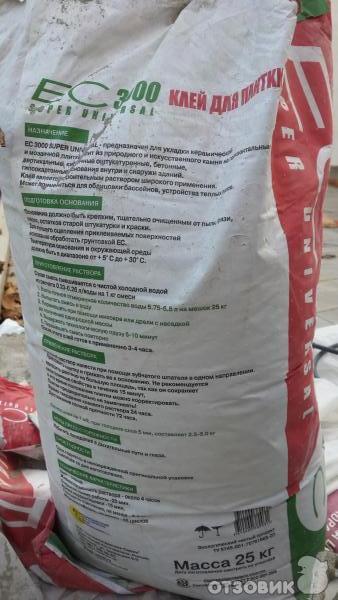

How to prepare a solution

The glue is stirred in water. An average of 250 milliliters of liquid is required per kilogram of dry powder. Water can be added while stirring, but the finished mixture should not be liquid. The normal consistency is similar in thickness to fatty sour cream.

Mixing instructions:

- measure the minimum volume of water;

- pour liquid into a plastic container;

- pour powder;

- stir with a construction mixer to thicken the mass;

- let it stand for 5-10 minutes;

- stir again, if the mass is too thick - add water;

- the mixture is ready.

It is better to stir the powder with a special tool, since it is difficult to obtain a uniform consistency manually. To get the finished mixture without lumps, it can be stirred with a drill by installing a special nozzle.

Certificates

Create innovative finishing materials solutions to provide consumers with products that anticipate their needs in terms of functionality and quality, make their work simple and efficient.

EC Chemical 2008—2019. All rights reserved.

607630, Nizhny Novgorod region, Bogorodsky district, Kudma village, street Kudminskaya industrial zone No. 1, building 4, room 1

Adhesive 3000 is available on the market as a powder mixture. It consists of a cement binder, fractional sand, special fillers, modifying additives. This composition has good performance characteristics.

Tile adhesive Kreps

When deciding on which glue to strengthen porcelain stoneware, you can choose Kreps glue, which costs 280 rubles. Kreps is a bathroom tile adhesive designed for exterior or interior decoration. It has excellent adhesion to concrete, cement, plasterboard and gypsum surfaces. The composition containing the hardening accelerator significantly reduces the commissioning time for construction facilities.

The main advantages of the adhesive include:

- plastic;

- water resistance;

- frost resistance;

- high tenacity (0.7 MPa);

- the possibility of using in the arrangement of the "warm floor" system.

After diluting the mixture with water, an elastic mass is formed, which is able to maintain its qualities even in severe frosts. The product contains fractional sand and cement.

Tile adhesive is a good bonding material that can be used when laying tiles with an area of 400x400 mm. The thickness of the tile can be 8 mm, and the height is 1 m.

The use of this compound is permitted for laying tiles on surfaces with a high level of heat transfer, for example, finishing a fireplace. If you choose Kreps, which contains antifreeze, then you can lay the tiles at temperatures down to -10 °.

General requirements for tile adhesive

All types of adhesive mixtures for laying tiles must have a certain set of necessary technical characteristics, which, depending on the type of glue, may differ in value. Let's list these properties.

During operation (until the solution solidifies):

- ease of preparation;

- elasticity (should fit well on the surfaces to be glued);

- a sufficient life (the ability to work out the prepared amount of the mixture, fix the displaced tile until the glue hardens);

- high adhesion (adhesion of the solution to the surfaces of the material and base);

- low fluidity and resistance to slipping (holding the tile in place of installation on a vertical surface).

First of all, the glue should have an increased indicator of water and frost resistance.

After the tile adhesive has cured:

- compressive and shear strength;

- water resistance;

- heat resistance;

- frost resistance;

- resistance to chemicals;

- elasticity (the ability to take on the stresses of the cladding material arising from temperature changes).

Instructions

Preparation of the base

The temperature of the base and the environment must be in the range from +5 ° C to +30 ° C. The base must be strong, thoroughly free of dust, dirt, oil, grease, loose paint residues and other substances that can weaken the adhesion of the filler layer to the base. Irregularities with a depth of more than 4 mm must be leveled beforehand with plaster mixtures EK TG20, EK TG40 or EK TG40 WHITE. Uneven or highly absorbent substrates are recommended to be primed with a deep penetration primer EK GS300 DEEP, EK GS300 TIEFENGRUND or EK GS400 ANTISEPTIC.

Preparation of the solution

To prepare the EK K300 solution, you must:

- Take a precisely measured amount of water (1.32-1.74 liters per 3 kg bag, 8.8-11.6 liters per 20 kg bag)

- Pour the mixture into the water

- Stir with a construction mixer or a drill with a special attachment until a homogeneous mass is obtained.

- Maintain a technological pause for 5-10 minutes to ripen the solution

- Stir again

After that, the putty is ready for use within 60 minutes with occasional stirring.

The order of work

The filler is applied to the substrate with a smooth steel trowel. For leveling small areas, a 30 cm wide spatula is used. The permissible thickness of one layer with continuous filling is no more than 3 mm, with partial leveling and filling of irregularities no more than 15 mm. If it is necessary to apply a thicker layer, the solution is applied in several passes at time intervals necessary for the previous layer to harden. Drying time for one layer is from 5 to 9 hours (depends on the thickness of the applied layer, temperature and humidity of the environment). After drying, the surface is sanded with fine emery paper or a sanding mesh.

Sealing the joints of plasterboard sheets. The first main layer of putty is applied into the joint, into which the reinforcing tape (serpyanka) is pressed. A covering layer of putty is applied with a wide spatula. After drying, the surface is sanded with fine sandpaper. Uncured material can be washed off the instruments with water. Once hardened, it is scraped off mechanically.

Calculation example

It is easiest to calculate the consumption of the mixture when the required brand of composition is precisely known.

If the brand of the mixture has not yet been selected, but you need to estimate the costs of purchasing it, you can use the average value.

For example, we can take the most common cement-based composition, the consumption of which per 1 mm of layer is 1300 g. This amount is multiplied by the layer thickness.

- If a tile measuring 20x30 cm is glued, then the solution is applied in a layer of 3 mm, which means that 3.9 kg of glue will go per 1 m2 (1.3 kg * per 3 mm).

- On a base with an area of 30 m2, 30x3.9 = 117 kg of tile glue will go.

- When a small tile is laid on the same area, then the glue seam will be thinner, which means less consumption: 1.3x2x30 = 78 kg will go for a size of 10x10 cm.

- With large slabs, the volume of the solution increases: for a size of 60x60 cm, 1.3x6x30 = 234 kg is needed.

Calculation by any of the methods will be approximate. In practice, the required amount of glue depends not only on the brand of glue, but also on the other factors listed above.

Tile adhesive EK 2000 and 3000

Thinking about which tile adhesive is better to use in the bathroom, you can choose the product EK 3000 or EK 2000. After complete drying, this adhesive gains strength and can no longer shrink. Dry mix EK 3000 is produced with the content of cement, fractional sand, modifying additives and special fillers.This set of key components in an adhesive provides excellent performance.

According to the instructions for use of EK 3000 tile adhesive, ceramic tiles should be of medium or small size. The composition has a water absorption level of no more than 1%. It can be applied to concrete, brick, aerated concrete or plaster. Its price is 230 rubles.

EK 2000 glue is often used to create porcelain stoneware flooring. With the help of this product, you can make underfloor heating, wall cladding inside and outside the house. The material is a composition of widespread use, it can be used to level surfaces. The applied layer must be no more than 5 mm thick. The cost of the product is 205 rubles. per packing.