The best moisture resistant tile adhesive

It is a special adhesive for installing tiles in bathrooms and stairs. It contains a hydrophobic modifier, which makes it possible to cover even fountains and swimming pools.

Litokol Litoelastic

5.0

★★★★★

editorial estimate

100%

buyers recommend this product

See overview

It is a reactive epoxy-polyurethane adhesive that does not require water to make. You only need to mix two of its components.

The agent is used for external and internal cladding of vertical and horizontal surfaces with natural stone and ceramic tiles.

Advantages:

- High adhesion;

- Frost resistance;

- Not susceptible to cracking;

- No drying shrinkage;

- Resistant to deformation.

Disadvantages:

High price - from 3000 rubles per 4 kg bucket.

Litokol Litoelastic will even glue mosaics and tiles to metal substrates. The glue is super reliable and versatile in its own way, but very expensive.

Knauf flex

4.9

★★★★★

editorial estimate

96%

buyers recommend this product

This adhesive is intended for areas of high stress, as well as for lining swimming pool bowls. The solution remains viable for 3 hours. Open time is 20 minutes, there is 10 minutes for tile adjustment.

Advantages:

- Resistant to serious dynamic loads;

- Compatible with substrates that do not absorb water;

- Water-, frost-, heat-resistant;

- Retains elasticity after hardening;

- Does not get dusty when working;

- The widest operating temperature range (-50 .. + 80 ° С).

Disadvantages:

Increased consumption.

This adhesive is used for vertical and horizontal surfaces without restrictions on the size and weight of the tiles to be laid.

Weber.Vetonit Easy Fix

4.8

★★★★★

editorial estimate

89%

buyers recommend this product

This adhesive has a cementitious base which gives a gray color. You can work with the ready-made solution for about two hours at a temperature of +5 .. + 35 degrees. For 1 sq. m. it takes about 3 kg of dry product.

Time of open use and correction of tiles - no more than 15 minutes. The composition is water-resistant, but it cannot be used for underfloor heating and other high-temperature surfaces.

Advantages:

- Adhesion over 1 MPa;

- Suitable for outdoor work;

- Frost resistance;

- No tile slippage;

- Reliable fastening.

Disadvantages:

Cannot be used with primers containing quartz sand.

This adhesive can be used for laying mosaics, as well as for indoor and outdoor installation of tiles.

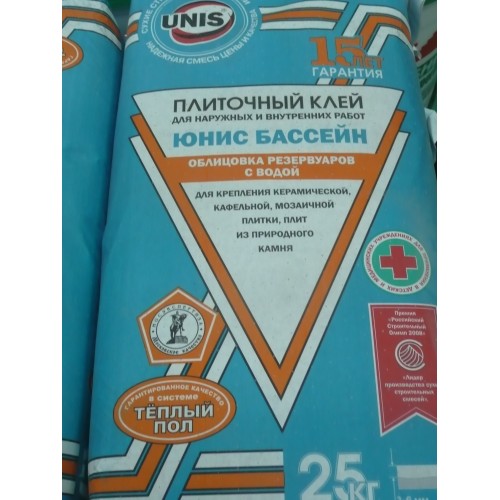

Unis "Pool Hydro"

4.8

★★★★★

editorial estimate

87%

buyers recommend this product

The composition is designed for laying tiles no larger than 60x60 cm in water tanks. It is also suitable for natural stone and mosaics. With it, you can lay tiles according to the "top-down" method.

The glue is frost-resistant and, after drying, can be used at temperatures from -50 to +70 ° C.

You can work with the solution at temperatures from +5 to +30 ° C, and its pot life is 180 minutes.

Advantages:

- Used both indoors and outdoors;

- Applicable for underfloor heating;

- Time for laying and adjusting tiles - 20 minutes;

- Strong adhesion (1.3 MPa);

- Can be used on difficult substrates.

Disadvantages:

Operation in contact with water and negative temperatures is possible only after 28 days.

It is a multipurpose compound used for areas with difficult operating conditions. However, he needs to be given enough time to build strength.

Prospectors "Lux"

4.7

★★★★★

editorial estimate

84%

buyers recommend this product

See overview

The adhesive is intended for ceramic and clinker tiles, porcelain stoneware, as well as artificial and natural stone.It is used in unheated and damp rooms, as well as outdoors.

Suitable for laying tiles in water tanks. No more than 15 minutes are allowed for correction, and the open time is 20 minutes.

Advantages:

- Suitable for underfloor heating (temperature resistance up to +70 ° C);

- Can be laid on old tiles;

- The pot life of the solution is at least 4 hours;

- Frost resistance;

- The plasticity of the solution.

Disadvantages:

The size of the tiles used should not exceed 40x40 cm.

It is convenient to work with this tool - it does not slip and is easy to apply. However, exceeding the recommended layer of 3-5 mm can lead to shrinkage of the tiles.

Things to consider when choosing a tile adhesive

When choosing a tile adhesive, the following criteria are taken into account:

- On which plane the laying will be carried out: cement, plastered, painted, drywall, etc. An important point if a warm floor system will pass under the tiles, as well as thin walls that can succumb to vibration. If you choose the wrong glue, the tile will quickly move away from the floor and wall.

- When laying large slabs, the glue must have the properties of fast setting, reliable adhesion. This will exclude the fact that, under the weight, the tile will slide off its place. As a rule, large dimensions correspond to large mass.

- Dry mix is cheaper and can be applied to any surface. And the finished one is used for prepared, smooth surfaces.

- The cement mixture dries faster. It will be difficult for beginners to get used to it right away. In addition, work is carried out at normal temperatures.

- When laying slabs on the floor, plasticizers should be included in the glue mass, it is they who allow the slabs to withstand the load and not move away.

- If the tile is laid at home on its own, even for the first time, then you should give an advantage to the mixtures, which take time to set. It will be needed to correct defects.

- For laying tiles on floors and walls, it is better to take different types of mixture, and not give preference to universal ones. Such division will save the budget, the finish will be durable in operation.

- The mass stored under unforeseen conditions, with an expired shelf life, loses its properties in a loose package. There is no guarantee that the tile will last long.

Pool cover requirements

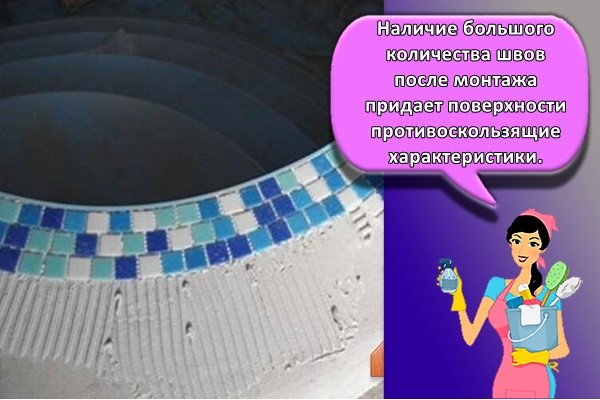

The availability of a large assortment of tiles on the market allows you to make the pool cover colorful and bright. However, ordinary tiles, which are used at home, cannot be used as a covering for a street pond. Tiles designed for outdoor pool cladding must meet certain requirements.

- Possess maximum resistance to negative natural factors (temperature extremes, frost, bright sunlight).

- Differs in durability, reliability and strength, since a large volume of water will exert strong pressure on the tile. It should also have high impact resistance.

- The indicator of water absorption is also important. Since the tile performs the function of waterproofing, the water absorption coefficient should be very low (no more than 6%). Otherwise, it is able to absorb a lot of water in a short time, which will lead to its internal damage, deformation, cracks and leakage.

- Be resistant to chemicals. Disinfection and cleaning of the pool is carried out using detergents and chemicals, often containing chlorine. These substances react with the surface of the tile, which leads to a gradual loss of the original decorative appearance.

- The tile must meet safety requirements: it must be non-slip, with embossed and rough surfaces.

- Its surface should not be porous, otherwise it will not only absorb water, but also become a source of microorganisms, bacteria and mold, which will lead to the formation of mucus and the risk of injury on slippery surfaces.

Why the choice depends

Premises

The peculiarity of the bathroom is high humidity. Choose a tile adhesive that is moisture resistant. Even if the water absorption of slabs and grout tends to zero, water can still penetrate, albeit in the form of steam, to the substrate and cementitious mixture. Therefore, it is better to play it safe. If you cover with ordinary ceramics, and even rub with a cement grout, the liquid will constantly affect the adhesive layer. No, the tile will not fall off in a year, but the guarantee of durability in the context of the situation is the moisture resistance of the composition.

Wet stains on new bathroom tiles.

Ceramics

Size matters. Or rather, the weight associated with the dimensions of the tile. The adhesive needs to withstand the pressure of the mass, which means that the adhesion requirements increase with the size of the boards. The fight against gravity is intensified when the tiles are made of porcelain stoneware. The low porosity of the material prevents the binder mixture from penetrating into the ceramics, forcing the glue to adhere to the plane of the tile. For laying large-sized ceramic granite, universal mixtures are not suitable, you need to take glue with high adhesion: 1.3-1.5 MPa.

Base

Which glue to choose if the surface is plastered with cement-sand mortar? And if sheathed with plasterboard? The type of foundation influences the choice. One thing is twenty-centimeter ceramic tiles laid on a cement screed, another is 60x60 porcelain stoneware on drywall.

All these factors combine with each other, forming the need for more or less strength of the adhesive. Affects adhesion and adhesive layer. Well, when in a "liquid", only applied form, it is equal to the thickness of the tile. With an increase in the layer, its capabilities are lost, he has to hold not only ceramics, but also himself. How can a countertop made of plywood and extruded polystyrene foam be tiled with mosaic.

Adhesive selection

The range of tile adhesives is large, but few are suitable for use in the pool. Waterproof mixtures come in the form of a ready-made solution and dry powder. The cost of the latter is lower when compared in terms of consumption. The main ingredient in them is cement, which is packed in bags, packages.

The solutions have an epoxy, latex, acrylic, polyurethane base, which are poured into cans and buckets.

When choosing products, aesthetic indicators are taken into account. They are low for compositions on cement, but where beauty is not very important, such means are suitable. If the owner follows the design, it is better to use a ready-made mixture. In this case, a predominantly white color is chosen.

Matching the pool bowl

The choice of glue is strongly influenced by the material of the base of the bowl. One of the main indicators is the degree of adhesion.

If ceramic tiles are used, compounds are used whose adhesion to the surface exceeds 1 MPa.

Concrete, stone and brick bowls are easy to lay. They have a rough surface, excellent adhesion to it, the tiles are securely fixed. Inexpensive dry mixes on a cement basis cope with the lining of such surfaces.

For the manufacture of pools, polymeric materials are often used. They have a beautiful smooth surface that works well with waterproofing and decorative functions.

It happens that the owners want to improve the design by gluing the tiles. Adhesion to plastic is provided only by polyurethane glue or epoxy resin.

Dependence on the operating mode

For the construction of summer pools, frost-resistant mixtures are used. For the winter, the water is drained, but the tiles and seams freeze.

If you use a waterproof glue designed for freezing temperatures, it will not withstand extreme conditions.

To make the composition frost-resistant, special additives are mixed into it. When the adhesive polymerizes, a structure is formed that does not react to frost by expansion. The demanded brand of frost-resistant mixture is Ivsil Aqua on a cement-sand base with polymers.

Adhesive and water treatment systems

Pools used by many people are often disinfected and disinfected with chlorine. It is a harsh chemical that can react with glue and destroy it. To prevent this from happening, formulations that are resistant to chlorine are used.

Professionals use Ardex X 77 - highly elastic, hardens quickly, which is facilitated by fiber reinforcement and Ardex E 90 additive.

Varieties and functions of adhesive for ceramic tiles

High humidity is an excellent breeding ground for fungi and bacteria. For the bathroom, you must choose an adhesive that has increased moisture resistance and contains antifungal impurities.

Types of adhesives:

- Cement;

- Dispersive;

- Epoxy.

A cement base is suitable for bathroom cladding. This glue fits well on concrete and plastered walls. You can work with this material on uneven surfaces by adjusting the level with a layer of glue. The mixture contains up to 90% cement and some sand with polymer additives, which improve its elasticity and increase adhesion to the surface.

To prepare the glue, it is necessary to dilute the dry composition with warm water to the required consistency. The cement mortar dries quickly and requires skill from the trowel. The advantage of the mixture is its environmental safety.

Dispersion or one-component adhesive is a ready-to-use material. It contains acrylic with resins and additives. Such a mixture is better suited for working with drywall, wood and metal, which has high binding qualities and does not penetrate deeply into the surface. This adhesive should not be used to repair concrete walls.

Such a composition is easy to use, easy to apply and does not dry for long. Allows to carry out the cladding without unnecessary dust and, if necessary, trim and straighten the tiles before drying. Recommended for self-styling, even for those who have no experience. It is sold in plastic buckets or a jar.

Epoxy glue consists of several components of a hardener and an activator, when combined, they form a ready-made mixture. Depending on the composition, they are divided into 3 groups: a fluid mixture, a paste with a thin and mineral filler. This solution has moisture-proof properties and is ideal for lining bathrooms.

Dealing with GOSTs

GOSTs

GOSTs

Perhaps, for the first time during the repair, you will have to turn to such a concept as GOST. Why?

Think about it - where is the highest frequency of direct contact of the body with tiles and glue? In the pool!

Neither in the kitchen, nor in the bathroom, nor in any other tiled room, do you come into contact with building materials as closely and closely as in the pool.

It is the water filling the pool bowl that can "raise to the surface" such substances from the composition of the glue or grout, the existence of which the school chemistry teacher has never even heard of! Therefore, for your safety, it is so important to find just such a tile adhesive that fully complies with GOSTs. In fairness, it should be said that almost all manufacturers of high-quality building materials comply with these very GOSTs.

Large production facilities have multi-level quality control and control systems, and before releasing products on the market, they are thoroughly studied and certified.

It is fair to say that almost all manufacturers of high-quality building materials comply with these very GOSTs. Large production facilities have multi-level systems of quality control and control, and before releasing products on the market, they are thoroughly studied and certified.

Therefore, the risk of purchasing a low-quality or inappropriate glue in a large specialized store of building materials is small.

But it is still worth paying attention to….On the label of the glue, in addition to the characteristics of the glue and recommendations for working with it, data on the conformity of the goods to the requirements of GOST, information on certification, batch number and series, as well as the date of manufacture and expiration date must be indicated.

On the glue label, in addition to the characteristics of the glue and recommendations for working with it, data on the conformity of the goods to the requirements of GOST, information on certification, the batch number and series, as well as the date of manufacture and expiration date must be indicated.

In a similar way, it is worth approaching the choice of grout (popularly referred to as a fugue). It must also meet the requirements of GOST and have appropriate marks on the packaging.

Do not forget that tile glue that does not comply with GOST can be hazardous to health and even life! If the glue contains impurities or substances not provided for by GOST, when in contact with water or other substances (for example, chlorine), they can cause various chemical reactions, causing allergic reactions in a person or leading to intoxication of the body.

Finishing technology

It is quite possible to carry out the facing of the reservoir with your own hands, if you adhere to certain rules. After completion of construction work, first remove all debris and cement laitance, clean all surfaces of the pool from contamination. After the bowl is well dried, apply 2 coats of primer with a paint roller.

After drying, the surface should be leveled using a ready-made plasticized mixture. You can also prepare it yourself using sand, cement, a special latex additive (Idrokol X20-m) and water.

The technological process is similar to working with tiles at home.

The cladding should first be applied to the walls of the bowl, laying out the coating in rows in a horizontal direction. It is recommended to apply markings on the surface with beacons or plumb lines: this will help to lay out the tiles directly and accurately.

The adhesive is applied to tiles and walls with a notched trowel sized to match the width of the tile. Then it is applied to the wall, leveling it with a rubber mallet.

Stack the next item

It is important to observe a certain distance between the tiles: for this, crosses are placed in the seam, which must correspond to the selected size of the tile seam.

They control the evenness of the laying of each element. Excess adhesive mixture around the tiles should be removed immediately: after a while it will be very difficult to do this.

Each strip laid out also needs to be checked for evenness using a building level.

Laying panel tiles begins from the central part of the picture, gradually going down to the edges. When covering the bottom of the reservoir, a different method is used. The tiles are laid out in triangles. Previously, the bottom surface of the bowl is conventionally divided into 4 triangles, drawing diagonals.

First, the first row is laid at the pool wall, the next one is placed perpendicular to the first, and it will be the guide for the next strips. The edges of the triangles have to be laid out with cut tiles.

At the end of the cladding, in a day, they begin to grout the joints. It is necessary to seal inter-tile gaps and create an aesthetic and neat look. For grouting, a special composition for wet rooms is used - a fugu. It can be white or painted in the desired shade: in tone or contrasting with the tiles.

Grouting itself is a simple process. The inter-tile gaps are filled with a trowel mixture.

Examples of well-proven adhesives

To have an idea of which adhesive material for tiling containers to choose correctly, we will consider several types of such glue and their characteristics.

Farvest - Pool C2TE-25 is a thin-layer adhesive based on a cement-sand mixture for finishing bowls with ceramic and mosaic tiles, as well as large-format finishing materials made of natural and artificial stone.Frost resistance of the glue - 50 cycles, the composition is waterproof and hydrophobic, the temperature range of its operation is from -50 to +60 degrees, with a high degree of plasticity.

Clay Farvest

Pobedit - Pool TM-16 is a waterproof multicomponent dry composition based on a mixture of cement and quartz sand with modifying components for laying ceramics. If it is necessary to cover flexible bases (HDPE bowls), the mixture is mixed with an aqueous solution of the "Tverdolit ElastoCem" dispersion. High water resistance, frost resistance, strength and adhesion of the hardened compound guarantees the durability of the ceramic lining of the container.

Waterproof glue will win

PCI Nanolight is an elastic adhesive developed on the basis of nanotechnology for laying all types of ceramic tiles on all substrates, produced in white and gray colors. Possesses a high degree of water resistance and adhesion, inert towards salts and chlorine, heat and frost resistance.

PCI Nanolight adhesive

PCI Collastic is a two-component polyurethane-based adhesive with a number of unique advantages:

- does not need preliminary priming of the base;

- has waterproofing properties;

- grouting of tile joints after it is possible after 6 hours;

- neutralizes cladding stresses from deformation of the base;

- reduces to a minimum the time for putting the pool into operation - the laid tiles can be walked on in 3–6 hours, the tank is filled with water after 12–16 hours.

PCI Collastic adhesive

Review of popular brands

After reviewing the rating of popular formulations, you can select the desired option from the list provided. The products of the manufacturers under consideration have been repeatedly tested in practice and have proven themselves in the market.

"Farvest Pool C2TE25"

A thin-layer composition from the manufacturer "Farvest" is created on the basis of a cement-sand mixture and is suitable for finishing with mosaic and ceramic tiles, as well as stone materials. The composition is resistant to moisture and does not lose its characteristics in the temperature range from -50 to +60 degrees.

"Pool TM-16 wins"

A multicomponent dry composition of the Pobedit brand based on quartz sand and a mixture contains additional modifying components for the installation of ceramic tiles. The adhesive creates a strong bond and the curing of the hardened mortar ensures the durability of the pool lining.

PCI Collastic

Two-component polyurethane-based PCI Collastic mortar has a number of comparative advantages. These include:

- the presence of waterproofing characteristics;

- no need for preliminary priming of the surface;

- grouting between tiles is allowed after 6 hours;

- neutralization of stress from deformation of the base.

PCI Nanolight

The elastic composition PCI Nanolight is developed on the basis of nanotechnology and is suitable for installing tiles on any type of substrate. The glue has an increased degree of resistance to liquids, inertness to chlorine and salts, and the ability to operate in a wide temperature range.

SM-16

CM-16 is microfibre-reinforced and suitable for all types of tiles. The adhesive is suitable for use in heated pools and is compatible with waterproofing materials. Additional benefits include environmental friendliness, deformation resistance and increased elasticity.

SM-17

It is possible to use CM-17 glue in open and closed swimming pools due to the wide operating temperature range. The mortar creates an elastic bond, prevents tiles from slipping and is suitable for lining the bowl with a large-sized coating.

SM-117

Dry building mixture SM-117 is used in indoor and outdoor pools. Before use, it is required to prepare a working mixture by mixing with a liquid. The ready-made mortar has high adhesion and reliably fixes the tiles without the risk of displacement from the original position.

"Eunice Pool"

The Eunice compound is recommended for finishing on difficult surfaces, including heated substrates and old tile coatings. After hardening, the solution is able to hold ceramic, mosaic, stone and porcelain tiles.

Ivsil Mosaik

Ivsil glue is specially designed for mosaics. The composition can be applied to the surface of a concrete base or to an old tile, which removes the need to dismantle the old coating.

CM-115

Building mixture CM-115 does not allow the tiles to move and stains on the cladding. The composition is environmentally friendly, suitable for heated pools and resistant to temperature extremes.

"Will base Maxiplix T-16"

Reinforced glue "Osnovit" is suitable for mounting any tile, regardless of the type of base. The mortar provides maximum bond strength and prevents the coating from slipping.

Tenaflex H40 ("Keracoll")

Resilient and environmentally friendly Tenaflex H40 is used for installing tiles on stable and non-absorbent substrates. In particular, the solution allows you to fix the material on the waterproofing layer or on the old coating.

Н40 Eco Flex

Mineral-based H40 Eco Flex glue is designed for high-strength tiling. The composition demonstrates high efficiency at strong deformation loads of the base.

Tile adhesive, which company is better to choose

Practicality, durability, functionality of building materials depends on the quality of the product. When choosing an adhesive for laying tiles, you need to look at the rating of the best tile adhesives from well-known manufacturers, which are:

- Knauf - produces a mixture for building materials that does not have an unpleasant odor, quickly setting on the surface. The brand was founded in 1932 and supplies products to many countries.

- Ceresit - the company was founded in 1906, annually produces new paints, glue and other products for building materials. Branches of the company are present in many countries of Europe and America.

- Mapei has been producing quality building materials since 1937. The company worked as a small family business, then grew into a single recognizable brand.

- Weber is a manufacturer of dry mixes for construction and renovation. It has been on the market for over 100 years, supplies goods to 57 countries, the product is manufactured at 200 factories.

- Sopro - manufactures products for construction work, which are composed of lightweight, cohesive materials, they are designed for tiles or ceramics. The company supplies construction chemicals to many European countries.

- Bergauf - distributor produces high-quality mixes for construction works, has been on the market since 2005. The tool is affordable, it is chosen not only in Europe, but also in many countries of Russia.

- Glims has been producing tiles since 1994. The product is of high quality, dries instantly, guarantees adhesion to any surface. It is consumed economically and does not have an unpleasant odor.

- Litokol - has been manufacturing products since 1968, using only high-quality, safe products. Available in many European countries, it guarantees maximum adhesion to ceramics.

- Unis - the company was founded in 1998, produces construction and finishing materials for ceramics or tiles. They do not have a pungent odor, adhere to the surface, do not cause allergies when working with it.

Indoor wall mixes

Before buying Litokol tile glue, you should learn to understand the types of adhesive masses. They are manufactured according to European standards, which are described in accordance with GOST EN 12004.

The main types of adhesives:

- C - cement mixtures. They are dry powders that must be diluted with water according to the parts indicated on the package. Used for laying different types of tiles.

- D - dispersion compositions. They are acrylic-based pastes. Suitable for laying boards on drywall and other types of substrates.

- R - is a two-component formulation that needs to be mixed before use. When the components are mixed, a chemical reaction begins, due to which a glue mass is formed. These are specialized adhesives that are used to fix tiles to plastic, wood, and metal substrates.

For interior decoration, Litokol has several specialized types of adhesives.

These include:

- LITOFLOOR K66.

- LITOKOL K17.

- LITOKOL X11.

- LITOFLEX K80.

There are some features of interior wall decoration. For example, large tiles should not be laid on vertical surfaces, since the glue mass may not be able to withstand the increased weight. It is best to start laying from top to bottom, so that the cutting points of the slabs remain on the lower rows.