Choosing the right adhesive

Variety of construction adhesives

To fulfill all the recommendations, you need to choose the correct adhesive composition. For gluing tiles on the floor, its viscosity is not very important. For walls, you need a glue of special viscosity. In order to glue the granite surfaces, you need a transparent adhesive that does not leave marks. Adhesives can be found in retail outlets and quite a few. We should be interested in a composition at a reasonable cost and high quality. Let's take a look at some of them.

The most common option is based on cement with various additives. It has an affordable cost and ease of use. The epoxy version costs 3 times more. It is frost-resistant, white or transparent. It is used for grouting, treatment of stones, for facing fountains and pools, for laying mosaic paintings and transparent stones.

Ceresit glue is of good quality. But instead, you can get a fake. For this reason, Ceresite has now lost its popularity as an adhesive for marble and granite. Better to get Unis Granite. Its advantages:

- the life of the finished solution is measured in three hours;

- it is able to withstand slabs up to 70 kg / m²;

- possesses high moisture resistance and frost resistance.

Osnovit is a domestic product. It is frost-resistant and is used for finishing the outer surfaces of the walls. The product quality is very high.

Graniplix AC14 has a viability for 6 hours. It can be used at air temperatures from -50 to + 70 ° C. Excellent frost resistance and long service life.

Knauf marble is a time-tested substance of good quality. But it also costs a little more than other options. It is used for finishing swimming pools and balconies, stairs and terraces, walls and floors.

How to choose tile adhesive

All types of adhesives last longer and reduce rejects, if they are used for their intended purpose - the solution will not crack, the tile will not fall off, harmful substances will not be released.

Choose an adhesive based on external factors:

-

Indoor climate

- Determine the humidity and temperature. -

What will be at the bottom

: cement screed, drywall, wood, plastic, metal. -

Sudden changes in substrate temperature

- what kind of floors will be in the room: normal or warm. -

What size and type will the tiles be

: porcelain stoneware, natural stone, tiles; small or large. : whether there will be high or low cross-country ability.

Stroyholding services

Buy tile adhesive for decoration of apartments, country house construction and professional sphere from us; For interior and exterior use. We sell tile adhesive wholesale and retail, deliver in Moscow and the Moscow region.

Today, much attention is paid not only to the interior design of the house. The external facade - as a visiting card of the owners, to create a noble respectable appearance of the building, natural marble or artificial porcelain stoneware is often used

Such a tile covering is durable, it is easy to care for it, with the help of it you can achieve an amazing aesthetic effect. The tile has one drawback - the high weight of each product. Therefore, to fix it, it is necessary to purchase a stable or frost-resistant tile adhesive for outdoor use. Such materials on sale are presented in several types: a wide range can confuse any ignorant buyer, so the question of which glue is better is very relevant for many consumers. This article will focus on the advantages and disadvantages of each formulation, about the manufacturers you can trust.

So, on sale today you can find several compounds that can be used for outdoor tiles.

- Universal adhesives. They can be used both for facing the interior walls of a house and for facade work, but they can only be glued to tiles no larger than 30x30 cm.

- Reinforced adhesives. In their composition, they have components capable of providing high adhesion to the substrate. You can use reinforced mixtures for both internal and external work. It is advisable to purchase them if natural stone or any other tile material that can withstand high static and dynamic loads is used as a finishing material. The best base for such adhesives is the floor. With the help of them, it is easy to create a cladding that can withstand well both high dynamic loads and the pressure of heavy objects. Reinforced compounds perfectly tolerate temperature drops and high humidity thresholds.

- Specialized mixtures. Let's talk about them in more detail.

Inexpensive offers

On the basis of cement, another glue for stone for outdoor use is created - Ceresit cm14 extra. It costs 260 rubles. for a 25-kg bag and is able to withstand the impressive weight of finishing materials. Professional quick stone glue is in the same price category, you will have to pay 247 rubles for it. Indicators of adhesion to concrete are 0.5 MPa. Frost resistance - 75 cycles. The composition can be used in a wide temperature range - from -50 to + 70 ° C. Depending on the condition of the surface, you will use a maximum of 15 kg of ready-made adhesive per square meter.

The glue for natural stone - "Ecobond" - 310 rubles is somewhat more expensive. It has increased adhesion to concrete, which reaches 1.5 MPa, the composition can be used for wall cladding with heavy natural stones. Frost resistance is slightly lower than that of the above-described mixture, and is 50 cycles. Once prepared, the glue can be used within 4 hours.

An alternative solution will be Litokol litoelastic, which has a cost within 3274 rubles. for 5 kg. This two-component composition is intended for laying natural stone on vertical and horizontal surfaces. The mixture is created on the basis of epoxy-polyurethane resins, inert fillers and organic additives. The catalyst is an organic base with fibers. This glue is very expensive compared to others, but it is of high quality, therefore it is used for decoration of the most prestigious buildings. You can use a variety of materials for laying, and even metal can act as a basis.

If you need frost-resistant glue for stone, then you can pay attention to "Eunice Granite", which is able to withstand a stone of impressive mass. This glue is used, the price of which is 370 rubles per 25 kg, for finishing facades, fences, entrance groups and plinths

The composition can be used for finishing on concrete and brick bearing surfaces. A mixture "Knauf Marble" was created especially for marble, which costs 375 rubles. for 25 kg and is distinguished by high aggressive properties of bricks and concrete. This adhesive holds boards weighing 40 kg per square meter.

Another frost-resistant stone glue for outdoor use is Litokol x11. Its cost is 325 rubles. for 25 kg. You can also use the mixture for interior work. It can withstand about 40 freeze and thaw cycles. Consumption will depend on the condition of the surface and reaches 5 kg per square meter. Almost the cheapest on the market is the composition of "Glims Greyfix", which costs 225 rubles. for 25 kg. Concrete and brick can be used as the basis of the material for the walls. A glue is made based on water and cement. It is frost-resistant and allows you to correct the position of the tile within 20 minutes after gluing it.

Review of renowned manufacturers

Today there are many companies that make adhesives for stone and other materials used for decoration. This allows you to select the appropriate option.

Keralastic T

This substance contains 2 components. It is characterized by ease of use, high parameters of elasticity and durability. The composition does not shrink and is characterized by excellent waterproofing characteristics. It is free of water and solvents.

The tool is often used for outdoor use. It helps to lay tiles on unstable surfaces. Also, the composition helps to glue the stone to coatings that are subject to vibration and deformation.

Keraflex

The product is a dry mixture. It contains cement, sand, resins and various additives. To use the substance, water is added to it. The product is suitable for wall decoration. The adhesive composition is characterized by high elasticity and excellent adhesion.

Eunice

This dry composition is characterized by high resistance to moisture and negative temperatures. There are many types of materials in the brand's assortment. They should be chosen taking into account the operating conditions and the type of surface. The composition is suitable for laying stone on a rough surface. It is characterized by a high degree of adhesion. The substance is allowed to be used even in unfavorable conditions.

Kreps plus

This substance is dry formulated. It contains cement and sand. Also, the substance contains modified additives. After combining with water, a plastic mass is obtained, which has excellent tikstotropic characteristics.

After hardening, the composition becomes very durable. It is characterized by high resistance to moisture and low temperatures. The substance is actively used for laying tiles and stones. It can be used for indoor and outdoor work.

Elastorapid

The substance is available in the form of a dry mixture. It includes sand and artificial resins. The glue is suitable for decoration of premises with high traffic. The substance is used for vertical coatings and is able to withstand a wide temperature range.

How to perform gluing

According to the manufacturer's instructions, to obtain a neat and durable seam, you will need to do the following:

- first, the surface of the material should be cleaned from existing dirt, dust, residues of bitumen and grease. To do this, you can use rags, special chemicals and a construction vacuum cleaner. If granite or marble has too obvious cracks or other defects of a similar nature, they will need to be eliminated with a special plaster for natural stone. The material is then coated with a primer to increase adhesion. These types of work must be performed in a room with an air temperature ranging from +5 to + 25 ° С;

- in the second step, a solution of marble glue is prepared. For this, the dry mixture must be poured into a previously prepared container. For example, a construction pelvis. It is filled with water. The constituent components should be thoroughly mixed until a homogeneous mass without lumps is formed. If you use a special construction mixer, it takes about 5 minutes on average. Such a homogeneous outdoor glue solution should be used within 3 hours after preparation. Otherwise, it will lose its properties and be less effective;

- the resulting homogeneous mass is applied in a thin layer to the surface of the granite slab and combed with a notched trowel. To this layer you need to evenly apply and press down the second surface to be glued. The process will be effective if more than 80% of the surface of the bonded material is covered with glue;

- the surfaces to be glued will need to be pressed tightly against each other for some time and left until the composition is completely dry.

The video below provides detailed instructions for using marble and granite glue.

How to choose the right one

High-quality cladding can be performed provided that the correct brand of glue is selected. This will determine the strength of the adhesion of the stone to the base, which means the durability of the work done. Each option requires its own brand of glue, which must correspond to the type of cladding and the type of stone. Stone tiles have different thicknesses and sizes.

For facade work, the glue must have:

- an indicator of vertical retention of 70-80 kilograms;

- frost resistance to freezing and frosting at least 35 times;

- waterproof qualities;

- withstand low / high temperature cooling / heating;

- color matching.

The marble slabs are glued with colorless glue.

How to choose the right one

What should be guided by when choosing an adhesive for granite:

It is important to take into account that granite is heavy, so the glue for it must have excellent strength and increased adhesion.

Expansion of stone and cladding at different temperatures can have a significant difference and a high-quality adhesive composition must compensate for it so that no damage occurs.

The glue must withstand moisture and not be afraid of temperature changes, which the facades of buildings are constantly exposed to.

The pot life of the glue mixture must be long, since working with granite is not very easy due to the existing uneven edges.

The pot life of the glue after mixing must be at least 3 hours. The frost-resistant compound applied from the yard can withstand at least 35 freezing cycles.

It is also important that the product holds solid stones such as granite. Good glue does not run off vertical surfaces, because this has a bad effect on the final adhesion of dissimilar materials

When buying glue for working with granite, you need to carefully read the instructions. The packaging contains almost all the information to understand if the product is suitable for the desired purpose. It also describes the consumption of material and the optimal conditions for cladding or other work.

Varieties of glue

The mixtures with which natural stones are glued today can be divided into the following groups.

Polyester type

This category includes liquid, solid, semi-liquid glue. They have many colors and shades, so they are often used indoors, for outdoor use, for bonding porcelain stoneware.

The most famous representatives of this group:

- Tenax Solido Quarzo - they can reliably fix granite tiles on any surface, as well as laminate stone;

- Bellinzoni Mastice-2000 - perfect for interior decoration, it can be used when making mosaics.

They are not frost-resistant, therefore, in our climatic conditions, they are not intended for outdoor use.

Two-component epoxies

The two-component adhesive is highly durable. It is suitable for gluing granite tiles to concrete, for connecting concrete with iron. With this composition, it is easy to repair a stone product, to hold together marble or granite parts. Such a product will serve for many years.

Two-component formulations include two ingredients - the glue itself and the solvent to it.

The most famous representatives of this group:

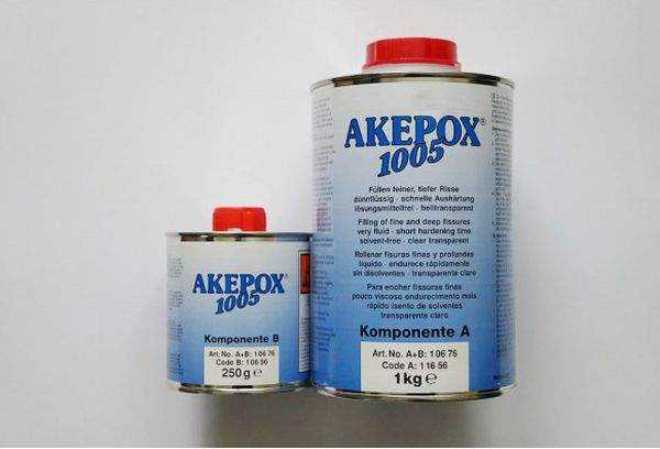

- Akepox 1005 - specially designed for bonding cracks, chips that appear on the surface of tiles or stone products;

- Bellinzoni - heavy duty, chemical resistant;

- Isomat Ak-epoxy Normal - glues stone, other surface.

Despite the high cost, such glue is in constant demand due to its qualities. It "works" in difficult climatic conditions, including frost, allows you to restore a stone that seems hopelessly damaged, is easily used in work.

Impregnants

This type of glue is ideal for outdoor use as it is frost resistant.The advantage of this product is its ability to fill the pores of the stone, cracks, joints, seams, it is easy to grind and polish after hardening.

Bellinzoni brand representatives:

- Aquapox;

- Imprepox.

Both products are characterized by high fluidity, which allows them to penetrate the smallest cracks and strengthen the stone. Very strong after hardening, do not lend themselves to chemical attack, frost-resistant.

Cement

Cement based adhesives may or may not be frost resistant. This point must be found out when buying.

The most famous of them are Ceresit, Unis Belfix, reinforced frost-resistant glue Unis Granite, Granipliks, Knauf (created for any temperature).

When deciding how to glue marble and granite, you need to proceed from the characteristics of the adhesive composition, the type of surface to be glued and the type of work.

Frost-resistant outdoor granite adhesive: which is better?

Manufacturers offer all sorts of options: some save the consumer's money, others have improved characteristics, but are significantly more expensive. We are ultimately interested in good quality for a reasonable price. We suggest starting with a market overview to avoid mistakes.

- The most common mixtures are based on cement with special bonding additives. After solidification, they form a strong monolithic connection. Affordable cost, easy to use, completely fill the voids in compliance with the technology, thereby reducing the risk of damage to the facing material or its peeling during operation.

- Epoxy compositions, or two-component glue for granite, - their cost is much more expensive, about 3-4 times, they have increased adhesion, frost resistance, usually transparent or milky white. They are used for grouting, stone treatment or in difficult operating conditions: with high humidity, in open areas (pools, fountains, facades, etc.). They are also used for laying mosaics, transparent onyx stone.

Let's take a closer look at products of different brands in order to determine what materials are needed for different conditions of use.

Cement frost resistant adhesive for marble and granite for outdoor use

Cement mixtures necessarily differ in the field of application: for indoor and outdoor work, do not forget to check with the seller for the type of glue. Among the many brands, the most popular are:

Ceresit - gaining in price, you can get good quality. However, more and more often on the market you can find low-quality products in the form of fakes, which is why many craftsmen began to refuse this brand of frost-resistant granite glue for outdoor use.

Unis - practical and reliable materials, proven over years of practice.

For outdoor use, it is worth purchasing reinforced frost-resistant glue Unis Granite:

- The life of the solution (while it is possible to carry out installation and adjustment work) is 3 hours.

- Withstands boards weighing up to 70 kg per m2, retains its properties at low temperatures, does not absorb moisture after setting, which ensures maximum adhesion for many years.

- Equally good for flooring and wall decor, the tiles do not slip on vertical surfaces.

- Frost resistance 35 cycles.

- At the same time, the price remains affordable, about 400 rubles. per bag, packing 25 kg.

Choosing a granite adhesive for outdoor use of the Unis brand, you get an excellent price / quality ratio and you can be sure of the reliability of the material.

Basite is a glue for granite for outdoor use, frost-resistant and moisture-resistant, it is a fairly high-quality domestic product, with enhanced characteristics.

You can choose Graniplix AC14 adhesive with excellent properties:

- The pot life of the finished solution is up to 6 hours.

- Withstands temperature loads during operation from -50 to +70 ° С.

- The time for adjusting the slab is up to half an hour.

- Frost resistance up to 50 cycles.

- The cost is approximately 360 rubles. per bag 25 kg.

It is used both for laying facades and in wet operating conditions: for swimming pools, dressing rooms, fountains.

Knauf is a granite glue for outdoor use of good quality, time-tested, but the cost is also slightly higher: the Knauf Flex mixture will cost about 560 rubles. per bag 25 kg.

- Frost resistance 150 cicks.

- It is used on any surfaces inside and outside the premises (including the basement): vertical and horizontal, for cladding pools, terraces, balconies, steps, stairs.

- Permissible load (slab weight) - up to 50 kg per m2.

Choosing among the considered brands of frost-resistant glue for granite for outdoor use, you can find the best option for your conditions in order to fit into the budget and not save on quality.

Rating of the best brands

Brands based on cement, polyester, epoxy resins are in demand.

Unis Granit

Composition: cement, mineral and chemical additives. We recommend for use in temperature conditions not higher than +30 and not lower than +5 degrees. Purpose: fastening large-format slabs of natural and artificial stone on the facades of buildings.

The basis can be:

- concrete;

- gypsum;

- brick;

- cement;

- asphalt.

The pot life of the solution is about 5 hours.

Litokol Litoelastic A + B

Epoxy adhesive belongs to the class of reactive, two-component, which contains resin and hardener. It is used in civil and industrial construction for cladding vertical and horizontal surfaces. Possesses increased strength, frost resistance.

Professional Quick Stone

The adhesive composition is resistant to temperature extremes from -50 to + 70 degrees, has good adhesion. Purpose: facing of facades with natural stone.

Cement-based adhesive for exterior and interior cladding of floor coverings, stairs, plinths and facades.

Tenax solido quarzo

Polyester adhesive mastic from the Italian manufacturer. White paste that can be tinted with Tenax dyes. Appointment: for facing horizontal surfaces, repair, reconstruction of compositions from natural stone.

Bellinzoni Mastice-2000

Polyester cream mastic from the Italian company Bellinzoni has a wide range of colors, applicable to temperatures of 0 degrees. Available in a liquid and thick consistency. Purpose: work with natural and artificial stone.

Akepox 1005

Liquid epoxy adhesive. It is used for laying, repairing light natural stones. Resistant to weathering, low temperatures.

Isomat Ak-epoxy Normal

2-component epoxy adhesive, solvent free. They are used for cladding floors and walls, on all types of surfaces, for external and internal work.

Aquapox

The adhesive has an ultra-high fluidity, colorless, based on resins and hardener. Recommended for outdoor pasting with granite or marble. The composition is resistant to aggressive media.

Imprepox

Liquid epoxy adhesive. Manufactured by Bellinzoni. Applications: surface restoration and gluing of all types of natural and artificial stones.

Adhesive for wild, facade stone. Features of work

Adhesive for wild, facade stone does not require preliminary soaking of products. The base must be cleaned of grease and dust, leveling is not required. Natural stone glue can also be used for leveling the surface, simultaneously with laying facing materials. For a wide range of works, we recommend buying glue for stone Plitonit B + with high indicators of adhesion to concrete.

Substrates on which stone or tiles are laid must be pre-treated with a primer to reduce water absorption. Make sure that the surfaces are free of cracks and delamination. To eliminate defects, special Plitonit leveling agents are recommended.

The "warm floor" system can be put into operation no earlier than 7 days after the completion of finishing work. For decoration of fireplaces and stoves with natural and artificial stone, a high-temperature heat resistant glue for stone Plitonit Super fireplace.

The glue for the stone is mixed with clean water at room temperature.DO NOT add water to the mixed solution! Despite the complete safety of Plitonit mixtures for the skin of hands and body, avoid splashing the solution into the eyes and mucous membranes.

Most popular brands

There are a lot of adhesives, on the packaging of which it is written that it is moisture-resistant, frost-resistant. Below is a list of adhesives that have been well appreciated by experts and users.

PC brand "Flizen" from the company "Knauf"

Knauf

Knauf is a renowned manufacturer of building materials from Germany. For outdoor tiling suitable, for example, "Knauf Flizen". Dry mix based on cement. Withstands twenty-degree subzero temperatures. The number of cycles is 50. The "Knauf Flex" mixture (100) has a large number of cycles. Unlike Flizen, Flex has no restrictions on the size and weight of tiles. "Flex" has high water-repellent qualities. It is recommended for use, in particular, for roof cladding of indoor swimming pools.

"Litestone K98 / K99"

Dry mix from the Litokol firm. K98 grade is made on the basis of gray Portland cement. It is used for laying natural stone, granite, dark marble, basalt and KP. K99 is produced on the basis of white cement. Used when working with white marble, shell rock, travertine. The glue dries quickly, withstands high loads. Operational temperature range from -30 to +80 degrees.

"Founding Graniplix"

It is used for cladding terraces, balconies, facades and plinths. The base is cement. The mixture works well in wet conditions (swimming pools, etc.). You can fix porcelain stoneware, other materials weighing up to 800 grams.

"Weber Vetonit"

The adhesive is produced by Weber. Several frost-resistant brands are known. For example, "Granite Fix" brand is used for fixing porcelain stoneware and any other tiles. It is used on almost all substrates (aerated concrete, bricks, cement-bonded particle boards, etc.). It is characterized by a very high degree of adhesion and elasticity. High frost resistance - 150 cycles.

The Ultra Fix Winter brand also has a very high frost resistance. She is able to withstand cold up to eighty degrees.

"Eunice 2000"

Russian-made product. Suitable for a variety of substrates. Operating temperature from -20 to +50 degrees. Frost resistance about 100 cycles. The glue is capable of supporting up to 50 kilograms per square meter.

White "Hardfix"

"Hardfix"

Produced by the Russian company "Perfect". "Hardfix" is used at sub-zero (up to - 10 degrees) temperatures. Very good water resistance. The base of "Hardfix" is cement. In addition, the mixture contains fractionated sand and modifying additives that allow working with the solution at negative temperatures.

"Ceresit"

"Ceresit"

A very well-known trade brand in the building materials market. The brand belongs to the Henkel company, which has been producing various building materials for over a hundred years. "Ceresit CM17 / CM117" perfectly holds not only tiles, but also other facing materials. СМ17 brand is intended for operation in the range from -50 to +70 degrees. Frost resistance reaches one hundred cycles. The SM117 has the same frost resistance. The difference between the brands is that the second glue holds the heavier material.

Facade cladding with clinker tiles

What to look for

The composition should have excellent adhesion and not change the original properties after hardening. It is not recommended to use universal mixtures, because in terms of frost and moisture resistance, they are not able to meet the requirements for mixtures that should be used in conjunction with natural stone. This is especially true in cold climates where operating conditions are most difficult.

Specialists recommend paying special attention to the manufacturer when choosing a brand of glue.Those located in the Nordic countries take into account the frost resistance factor and produce adapted adhesives

Domestic companies have now mastered the technology of making high-quality mixtures. In all respects, they are not inferior to imported counterparts. However, the cost of Russian-made products is not much lower than foreign ones. The cost is sometimes unreasonably high.

Choosing reliable glue liquid nails - an overview of proven options

When choosing the most suitable brand of adhesive, consider the following:

- What materials need to be glued;

- What kind of load will the glue line experience;

- In what conditions will the glued product be used (inside or outside the room).

Today, the most popular among professionals is liquid nails from such manufacturers as: Moment (Henkel), Titebond, Makrofix, TYTAN, Krass, Kim Tec, Liquid Nails, Kraftool, Titebond, Quadro.

The following brands enjoy a very good reputation:

Glue Moment Installation MV 50 liquid nails - universal moisture-resistant express glue based on water dispersion (polyacrylate).

Perfect for joining different surfaces (wood, styrofoam, metal, plastic, ceramics, chipboard, MDF, cork coverings, polystyrene, gypsum, etc.) when carrying out installation work inside and outside the room.

Ideal for gluing plastic and wooden skirting boards and other decorative elements, various profiles and panels indoors.

Adhesive liquid nails Titan Professional 901 - heavy-duty construction and assembly adhesive based on hydrocarbon solvents.

Provides fast and durable bonding of various types of surfaces (wood, metal, ceramics, concrete, plastic, stone, etc.). Resistant to temperature extremes, high humidity.

Suitable for outdoor use (frost resistant). Titanium Professional 901 is suitable for bonding heavy decorative elements and building materials.

Krass Extra Durable - specialized liquid nails for quick installation of plastic and tiles.

It is considered one of the best options for mounting heavy and light elements made of plastic (polystyrene, PVC), chipboard, MDF, ceramics, plaster, plywood, stone, metal.

Suitable for use in damp rooms, has excellent adhesion.

Comparison table of popular brands:

| Glue brand | Volume | Advantages | Price |

| Moment Installation MV 50 | 125 grams.; 250 grams.; 400 grams. | quick-setting, solvent-free, white. | about 300 rubles for 400 grams. |

| Titanium Professional 901 | 380 grams. | strong initial adhesion, forms an elastic seam, suitable for gluing heavy products. | about 100 rubles. |

| Krass Heavy-duty assembly | 300 grams. | convenient to apply on vertical surfaces, elastic, non-shrinking, odorless. | about 200 rubles. |

Instructions - how to properly glue with liquid nails using the example of PVC panels

Most often, liquid nails are used to attach PVC panels to walls and ceilings.

This method of installation eliminates drilling; moreover, there are no traces of fasteners on the front surface of the panels.

How to glue PVC panels on liquid nails KRASS "Extra strong installation"?

For this you need:

- Prepare the surfaces to be glued beforehand - they must be clean, dry and free from grease.

- Remove the protective cap from the tube, cut the plastic tip closer to the thread.

- Insert the glue tube into the assembly gun.

- Apply glue to the material to be glued in thin strips of the same thickness with an interval of several centimeters (depending on the weight of the product) or pointwise.

- Lean the PVC panel against the wall / ceiling, press and fix for a few seconds. To correct the position of the panel, do not peel off the material, but carefully move it. It is recommended to additionally fix heavy elements with supporting structures until the glue is completely dry (24-72 hours).

- Immediately after completion of work, the tools should be cleaned of glue with warm water.

VIDEO REVIEW

Frequently asked questions

How to use a glue gun for liquid nails?

This is not difficult. It is only necessary to insert the tube into the gun body, having previously pushed the rod outward, and cut off the tip of the tube.

When the trigger is pulled, the rod is set in motion, creating pressure on the piston inside the tube. The glue is squeezed out through the hole. The intensity of pressing regulates the supply of glue.

What is the consumption of glue liquid nails per 1m2?

Average consumption is about 200 grams of glue per square meter of decorative panels. When gluing narrow profiles and panels, the average consumption is 20-40 grams per meter.

How long does liquid nail glue dry?

The time for complete curing of the glue is usually 24-48 hours (depending on the thickness of the applied glue), the setting time is usually 20-40 minutes.

Views

Knowing the different types of adhesives will help you make the right choice.

Depending on the composition of the components, there are three main types of adhesives for CP:

- cement;

- dispersive;

- epoxy.

In addition to cement, the mixture contains sand, various additives that enhance strength and water repellency. It is used for both external and internal finishing works.

The good thing about cement glue is that it is cheap and easy to use. Laying one square meter with it will cost twenty times less than using epoxy. Even a beginner in the construction craft will be able to correctly prepare the solution and apply it to the surface.

Dispersion PC

It contains synthetic resins, organic additives and an inert filler.

It is enough to stir it before applying. It speeds up installation as the glue does not need to be prepared. It also has the advantage that it has high ductility. They are mainly used in indoor areas.

For its production, epoxy-polyurethane resins, organic additives, filler and catalyst are used. The main disadvantage is the high cost.

There are also adhesives:

- universal;

- frost-resistant;

- reinforced;

- moisture resistant;

- heat resistant.

Popular universal adhesives, as they say, for all occasions. They are suitable for indoor and outdoor use in rooms with different functionalities. However, versatility isn't always good. For example, independent experts argue that manufacturers exaggerate the moisture resistance and frost resistance of universal mixtures for advertising purposes, and do not advise using them for outdoor work.

For such work, it is better suited tile adhesive frost-resistant.

The reinforced adhesive is characterized by very high adhesion. It can be used, for example, for fixing large porcelain stoneware tiles. Since such a KP is mounted externally, the glue for porcelain stoneware must be frost-resistant.

Moisture-resistant mixtures are produced for use in rooms with high humidity (bathrooms, swimming pools, etc.).

Heat-resistant adhesives are used when the tiles are operated at elevated temperatures, from underfloor heating to facing fireplaces and stoves.

Adhesive mixture - what is it

Usually, experts prefer to use dry construction adhesives, which are mixed with water to a solution state and then used for gluing tiles. The mixtures are sold in durable paper bags with protection, do not contain lumps inside, but are a homogeneous fine fraction of gray or white color.

The exact composition of the glue differs depending on the manufacturer, brand, and specific purpose. It usually contains:

- organic, mineral substances - limestone, cement, quartz sand, cobalt vitriol, dolomite (give strength to the connection);

- polystyrene and other polymer additives (act as a frost-resistant component, serve to restore properties after diluting the mixture with water);

- thickeners and plasticizers (provide plasticity, elasticity of the seam);

- synthetic additives and some minerals, for example, magnesium, aluminum, calcium (necessary to increase moisture resistance, adhesion of the adhesive mixture);

- cellulose ether (gives the desired viscosity).