Additional tips and tricks

Cold welding is used anywhere, but more often it is used by motorists. When the muffler burns out, the crankcase or radiator drips, a tube of glue is irreplaceable.

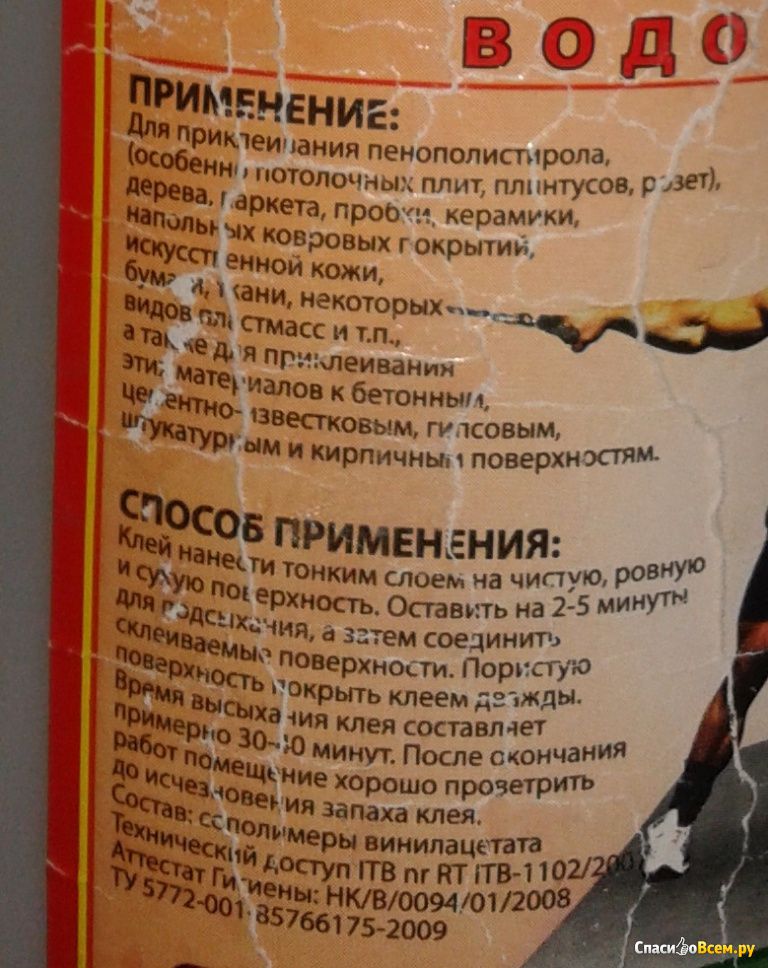

In order for the choice of the composition to meet expectations and not make you disappointed, they carefully study the operating conditions of the unit or part, as well as the instructions on the package with glue. For high temperature environments, a suitable product is needed. The same applies to parts in contact with liquids.

Oil-resistant adhesives deserve special mention, there are also such adhesives. The metal is better connected by compounds with additives that enhance adhesion and strength of the seam. Cold welding does not tolerate pressurized media poorly. Universal adhesives, in fact, have a narrow scope: if special working conditions are required, it is better not to save money, but to buy a specialized product with the required properties.

The quality of the seam and the durability of the restored product largely depend on the preparation of the surfaces for bonding. These are cleaning, degreasing, dedusting, removing traces of moisture and roughening with fine sandpaper. And you can use a ready-made knot, a glued part, not earlier than the seam is finally polymerized. The setting time of the composition can be found in the instructions.

Share link:

Storage and transportation conditions

People who have purchased an adhesive solution should be familiar with how to store it properly. First you need to figure out in which containers it is better to keep the adhesive composition. Experts advise leaving it in metal barrels or jars. At the same time, they must be hermetically sealed so that the liquid does not spill out.

It is recommended to store the adhesive in rooms that are reliably protected from sunlight. In this case, the temperature inside should not exceed thirty degrees Celsius and fall below five degrees. These temperature values are considered optimal, since with them the composition will not deteriorate within six months.

Any type of transport is used to transport glue over long distances.

However, people who are going to transport KH-3 should do it very carefully and adhere to all recommendations for transporting flammable substances.

Features of epoxy adhesive

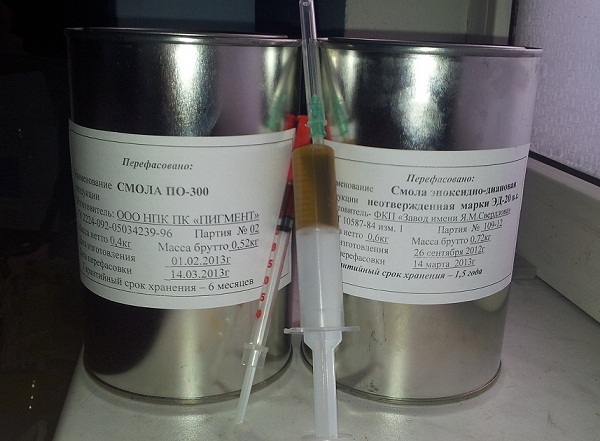

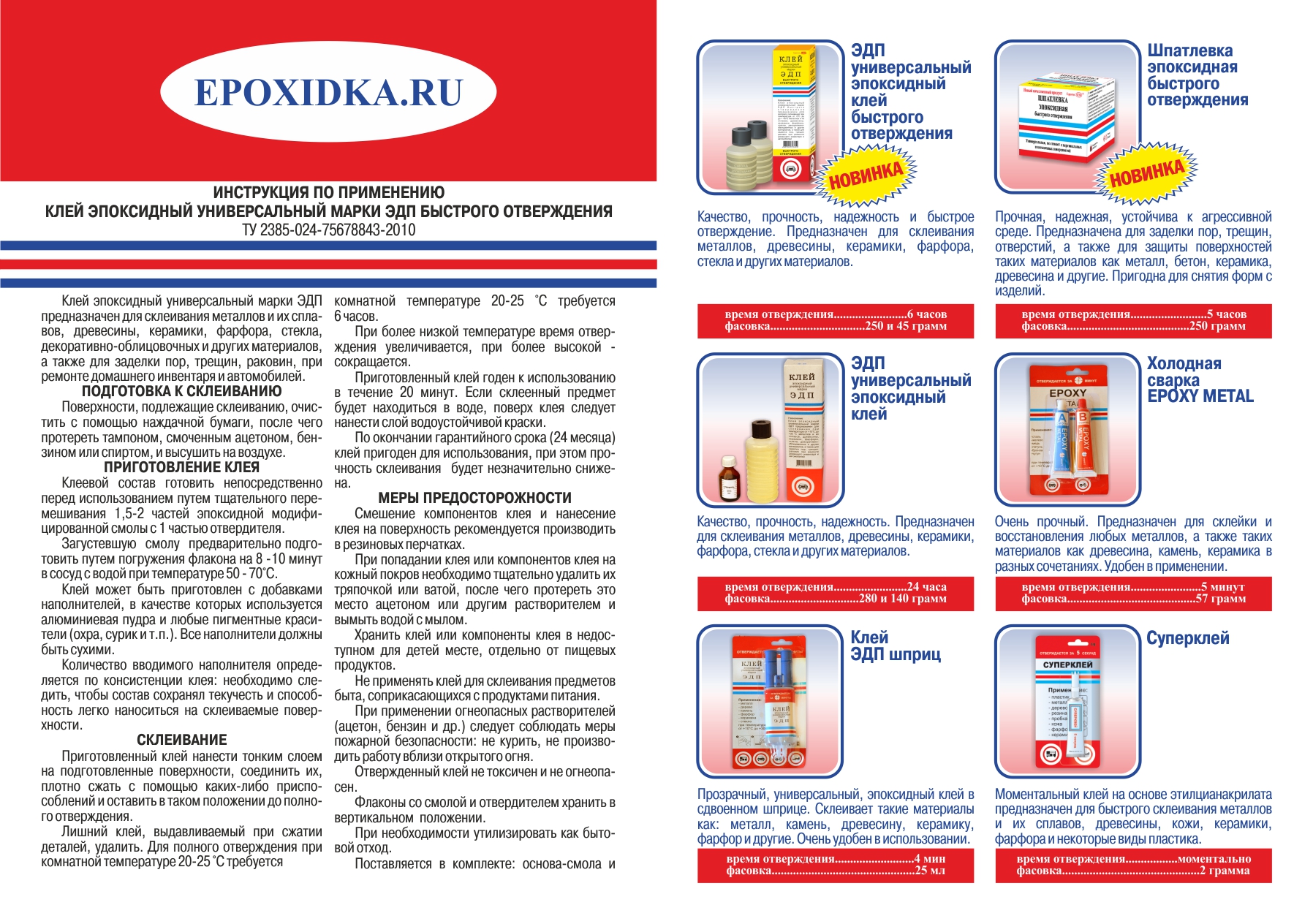

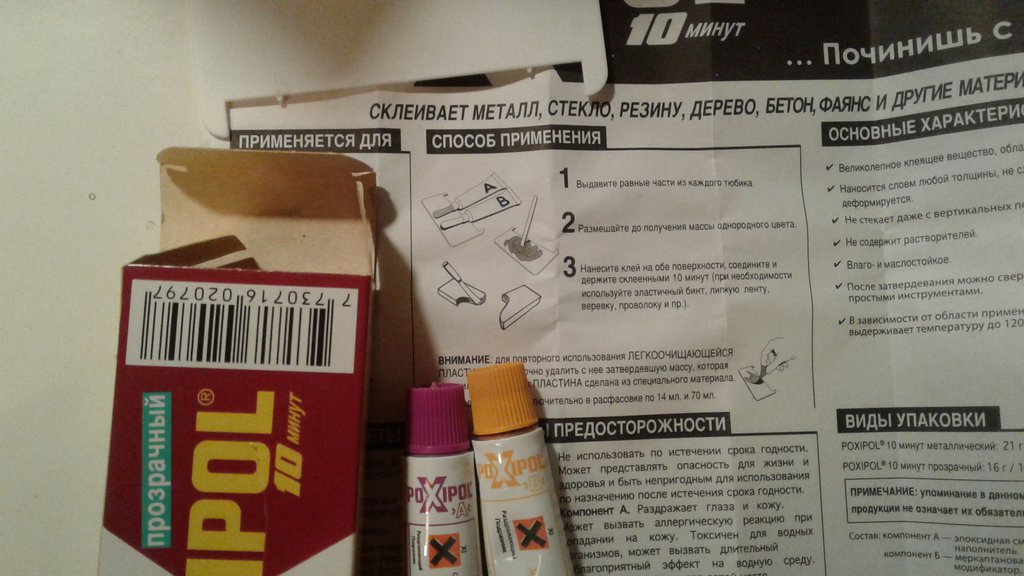

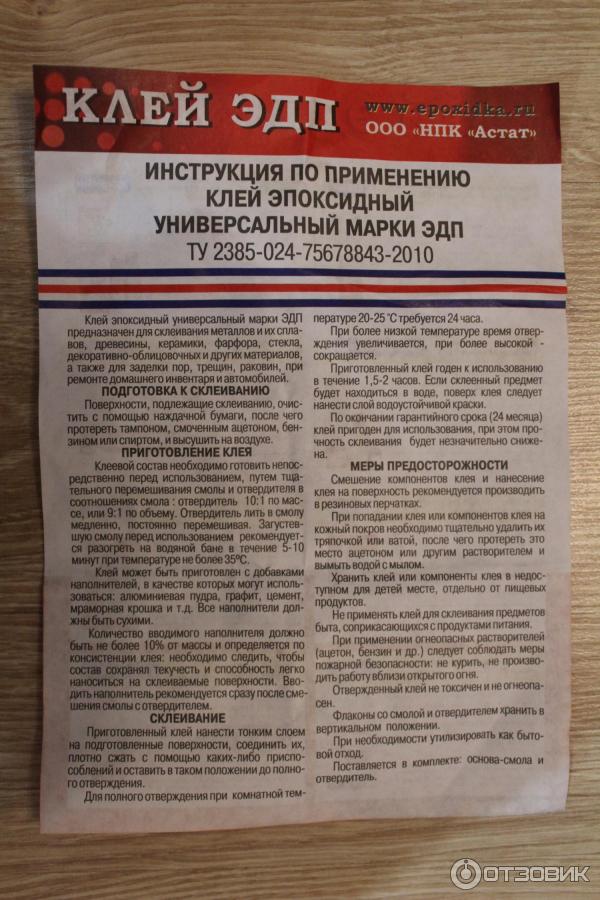

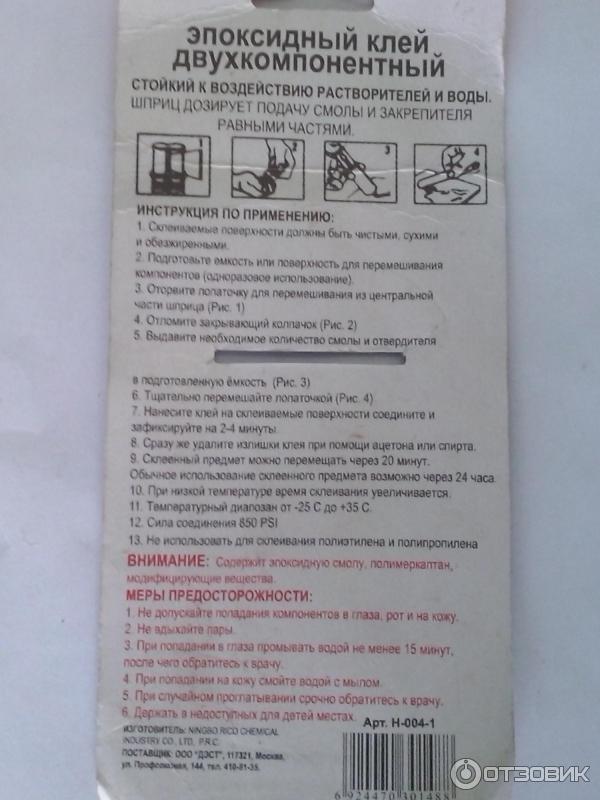

EDP glue consists of two components: epoxy resin and modifiers. The package includes a hardener required for the composition to harden. When used, it must be diluted correctly, in accordance with the instructions. The mixture will cure only after adding the hardener.

The glue has technical characteristics:

- In appearance, it is a viscous solution with a yellow or brownish tint, which does not have solidified particles.

- Very durable under favorable conditions.

- Full hardening requires room temperature and 1.5 hours of time.

- Provides adhesion to almost all surfaces.

- Not exposed to chemical compounds.

- Withstands external mechanical stress.

Pros when using:

- The glue has practically no shrinkage.

- Resistant to cracking.

- Waterproof.

- Frost resistance.

- High degree of strength.

- The dried adhesive does not conduct electricity.

- Suitable for all liquids.

- After complete hardening, any kind of processing is allowed: washing, polishing, sawing, grinding, drilling, painting.

Minuses:

- This glue is not used for Teflon, silicone, polyethylene surfaces.

- Fast curing does not give time for long-term adjustments.

- EPP affects the surface of the skin and the respiratory tract.

Ecology

environmental friendliness of KIILTO products

Each of the submitted materials has passed rigorous tests for compliance with technical

and sanitary and hygienic standards, as well as safety standards

The company KIILTO (Kiilto) strives for harmony of functionality and environmental issues in solving the problems posed by our customers.

In 1993, the Finnish Standards Association (SFS) confirms Kiilto's high level of performance with the ISO 9001 quality certificate. The ISO 14001 environmental program, the OHSAS 18001 occupational health and safety management system are also integrated with this quality system.

The high quality assurance system covers all stages of the product life cycle: development, production, marketing and sales, customer service, warehousing and delivery of products, and also takes into account environmental protection, health and safety.

KIILTO pays special attention to environmental and safety issues. The company strives to organize its production in such a way that all activities, from the development stage, the manufacturing process to the recommendations for final use, are carried out without harming the environment.

In 1992, KIILTO joined the international chemical industry program "Responsible Care - Responsibility for Tomorrow", which includes environmental protection, health and safety.

By putting his signature on the program, Kiilto made a commitment on his part to actively contribute to the protection of a favorable environment and openly provide information about his products, production process and plans for the future.

The development department of KIILTO is constantly researching more reliable and environmentally friendly alternative raw materials, developing products that are harmless to health and the environment.

All Kiilto product packaging has a guide for the disposal and use of empty packaging.

When choosing packaging materials, the company prefers to use recycled materials.

Choosing the best glue

Not only the comfort of passengers, but also, most importantly, their safety on the water depends on competently carried out repair work on an inflatable craft. With the wrong approach, the patch may depressurize, the boat will begin to deflate or fill with water, which will lead to negative consequences.

A high-quality adhesive must meet the following requirements:

Drying time of the repaired joint is especially important in field conditions.

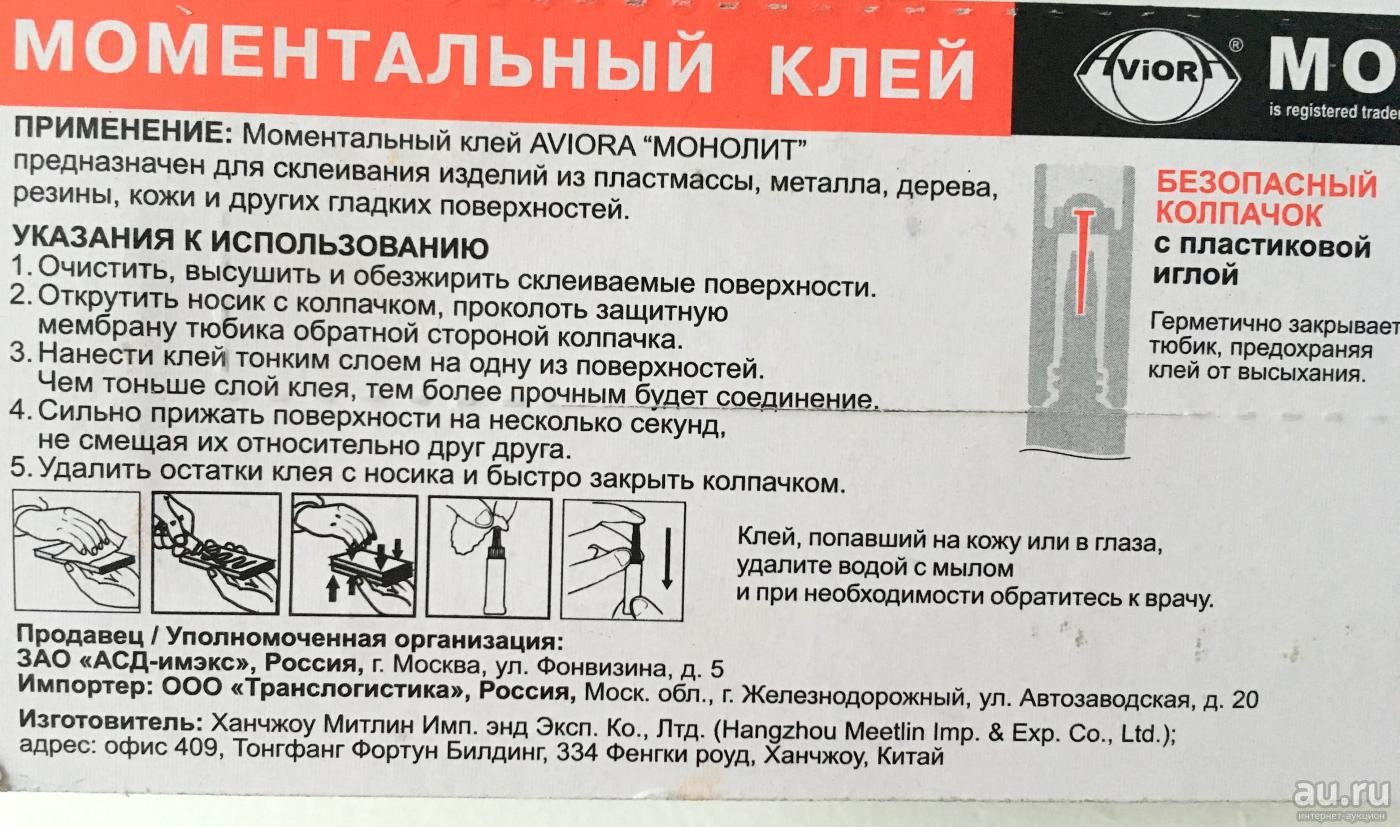

The adhesive should not be cyanoacrylate based. Super glue is not allowed. Despite all its advantages (instantly and firmly glues surfaces), the product does not have the necessary elasticity, which leads to the destruction of the seam.

The adhesive must be of good quality. To check this parameter, you can use the following technique: apply a thin layer of glue to any surface and leave for 5 - 7 minutes, then check it for stickiness. A poor quality product will stick to your fingers. The use of Moment glue is also not advisable.

The versatility of the adhesive is not always justified; it is better to use special-purpose products (for PVC boats).

One of the important parameters is the thermal stability of the composition. For swimming equipment made of polyvinyl chloride, it is recommended to choose products that can withstand sudden temperature changes (-40 to +70 degrees).

It is not effective to use formulations based on polyurethane or chloropropylene, given the sensitivity of the components to moisture. The quality of the seam will be poor and unreliable.

Freeze quickly.Drying time of the repaired joint is especially important in field conditions.

High-quality glue cannot be cheap, it is not advisable to save money here.

Advantages and disadvantages

CMC is diluted only with water at room temperature. You do not need to add any other substances to prepare the solution. The adhesive mixture is easy and quick to prepare. There are no toxic additives in it. The mass is homogeneous, colorless, without lumps and sediment. The adhesive mixture can be used in any room, even in the children's room. When dry, the solution does not emit any toxic substances to the body.

The adhesive mixture itself, prepared from white powder and water, is colorless. It has no smell. Some manufacturers tint the powder pink to show where the glue is applied to the canvas or wall. The adhesive solution ensures the adhesion of the wallpaper to all types of surfaces. The main thing is to clean the wall from crumbling particles before repairing. CMC can be used even in rooms with high humidity.

Insecticidal and antifungal additives are added to the glue. For example, boric acid salt, aluminum-potassium sulfate, carbolic acid. Such substances improve the quality of the adhesive mixture, prevent fungi, mold, and insects from multiplying under the wallpaper.

The CMC has disadvantages. This glue takes time to swell. Usually about 2-3 hours. Modern formulations have a shorter swelling period of only 15-20 minutes. True, the price of such products will be higher. After pasting the walls, you need to wait at least 3 days for the glue to dry completely. While the substance dries, there should be no drafts in the room. The repair itself is best done in the summer, so that the wallpaper dries naturally, without turning on electrical appliances.

p> Share link:

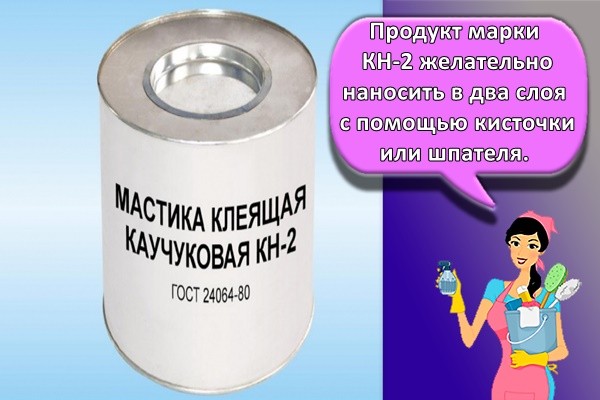

Work instructions

In the purchased packaging (or on it), there is a manual - instructions for the use of BF-4 glue

It is important not only to choose a high-quality composition, but also to be able to work with it:

The working surfaces must be initially cleaned of dirt, then degreased and sanded with sandpaper.

Using a brush, an even layer of liquid is applied to the surfaces to be joined

It is important not to leave empty spaces and smudges.

After applying the first layer, you need to wait 60 minutes, then proceed with the application of the second layer. After applying the second layer, it is required to dry within 55 minutes.

Parts are connected using a special clamp

Then they go to the oven heated to 180 degrees.

After 60 minutes, turn off the oven and leave the product to cool naturally.

There is also a cold connection method. It is enough to apply two layers of BF-4 glue with an interval of 20 minutes, squeeze the parts in the clamps and wait a day.

Safety engineering

It is necessary to work with the BF-4 adhesive with gloves. For respiratory safety, a respirator is required. The room in which the work is done must have a good ventilation system.

How to clean the glue

Often during operation, the bonding mixture falls on the wrong surfaces. The adhesive can be removed from clothing and human skin with alcohol. After 20 minutes after the first wiping, you need to treat the surface again. Vodka is used as a last resort

Do not use solvent with care to clean the fabric.

Possible analogues of this brand

It is difficult in hardware stores

epoxy resin

BF-4 is considered one of the best adhesives on the market. In this series there is a line of proven products that are suitable for use in various areas of everyday life.

Application rules and precautions

To use the KN-3 rubber adhesive mixture correctly, you need to familiarize yourself with the basic rules for its use. There are several guidelines to follow when using such a tool. These include the following:

- Preliminary preparation of coatings. The surface to be treated with an adhesive solution must first be cleaned of debris and dust particles. It is also wiped with alcohol for degreasing. This is done so that the adhesive layer is more securely fixed on the coating.

- Leveling surfaces. It is recommended to pre-align the coatings to be treated with adhesive. For this, a special primer is used, which will help get rid of roughness and irregularities.

- Maintaining optimal temperature. It is necessary to apply the agent to the surface at suitable temperature values so that the glue sets better. Optimal temperature values are considered to be 15-25 degrees above zero.

- Application of the adhesive in a thin layer. Some people think that the glue should be applied in a thicker layer, but this is not the case. Its thickness should not exceed one millimeter.

This rubber adhesive is classified as a third hazard class, and therefore, before using it, you need to understand the precautions. In the room where the work is carried out, fumes gradually accumulate, which must be disposed of.

To do this, the windows are regularly opened for 5-10 minutes so that fresh air can enter. When carrying out work, it is recommended to use portable lamps that are connected to the mains in another room. This reduces the likelihood of fires occurring. For added safety, it's best to keep your fire suppression equipment with you.

In the room where the work is carried out, fumes gradually accumulate, which must be disposed of. To do this, the windows are regularly opened for 5-10 minutes so that fresh air can enter. When carrying out work, it is recommended to use portable lamps that are connected to the mains in another room. This reduces the likelihood of fires occurring. For added safety, it is best to keep your fire suppression equipment with you.

Instruction for VS-10t glue

The specific composition of the VS-10 t requires special handling. The instructions for it include a detailed description of the necessary actions, as well as all recommendations for use. The composition is heat-resistant, which means that when using it, the requirements for temperature conditions must also be met. In the photo - VS-10t.

Store and transport adhesives in sealed packaging. If transportation is carried out at a low temperature, then before use, the composition must be kept at 25–35 C or warmed up in an oven at 35–40 C. The container is not cut off at the same time. If the composition is warm enough, it becomes transparent and homogeneous.

The surfaces to be glued - pads, heat-resistant plastics, fiberglass, metals, etc., are cleaned from rust, scale, ordinary dirt before gluing in order to obtain a uniform roughness. To do this, use sandpaper 4-6 or corundum. Then the surface is degreased with acetone or gasoline.

It is allowed to glue after no more than 6 hours, otherwise the surface loses its properties. Dry materials after cleaning for at least 15–20 minutes.

Brake pads

Heat-resistant glue VS-10t is applied to brake pads or other parts with a brush. With a small size of the elements, they can be dipped in an adhesive solution. The brush moves in one direction. If the material is dipped, then after that it is necessary to stand for up to 1 minute so that the excess glue can drain.

The smudges at the ends of the products are cleaned with a scalpel.

The surface lubricated with the first layer, according to the instructions, is kept for up to 1 hour so that the solvent evaporates.

Then a second layer is applied and also kept for 1 hour.

The pads to be joined are placed in a press, the minimum pressure is 1–5 kgf / sq. cm. Then the press, together with the parts to be connected, are placed in an oven with a temperature of 180 C. The products are kept for 2 hours.

It is allowed to use the product after gluing after 12 hours.Recommendations for the use of analogs include the same principles.

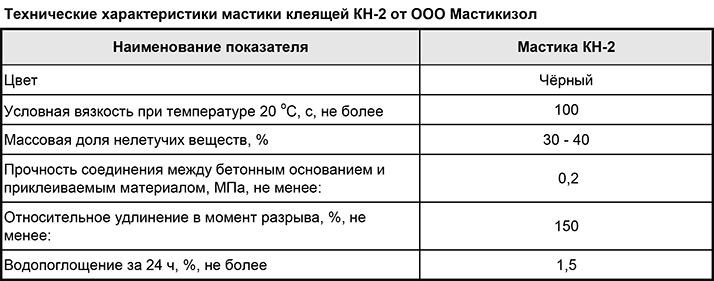

Specifications

Experts recommend that you familiarize yourself with its main technical characteristics in more detail before using rubber mastic.

The characteristics that must be considered before using such an adhesive include the following:

- Duration of hardening. Every person who is going to use KH-3 in the future should know the gluing time of the mixture at room temperature. At temperatures above twenty degrees, the adhesive begins to set within twenty-four hours. However, complete hardening occurs much later - three days after application.

- Consumption of working solution. Adhesive compositions may differ from each other in the amount of agent used to process one square meter. To process a surface with a volume of one square meter, you will need about 750-800 grams of rubber glue. However, if the surface is rough, the flow rate may increase slightly.

- The amount of volatile components in the composition. Some adhesives contain volatile substances. The KN-3 adhesive contains about fifty-five percent of these microelements.

What does the glue consist of?

The ability of a reliable connection of various materials is explained by the composition of this substance. BF-4 glue is made in accordance with GOST 12172-74, as well as other varieties of this line. The main component in the composition is polyvinyl butyral.

In addition to the main component, there are additional substances in the composition. Additional components improve elasticity, however, deteriorate its strength. These include:

- Ethyl alcohol as a solvent.

- Phenol-polyvinyl acetate resin.

The liquid is a thick mass that can have yellow, brown, red and brown hues. Technical characteristics of BF-4 glue depend on its composition.

Applications and characteristics

It is used for joining various materials. These include wood, glass, ceramics, metals (non-ferrous and ferrous), leather and various polymers.

Due to this characteristic and properties, BF-4 glue has a wide range of applications. This can be the repair of clothing, furniture, electronics, various household appliances and industrial equipment.

Resistance of the adhesive to aggressive environments

BF-4 glue is resistant to acids, alkalis and low temperatures. Due to this, it is used when repairing containers for storing reagents, they are connected to parts at low ambient temperatures.

Specifications and properties of various varieties

There are several brands of KS glue. All of them are used for indoor and outdoor renovation. Each type of product differs in both general and inherent properties only.

"Artel"

The main properties of the Artel brand KS construction adhesive is that it:

- heat and frost resistant;

- environmentally friendly;

- has no smell;

- elastic.

It is not for nothing that the Artel brand of glue is used for gluing block parquet, wooden flooring, ceramic tiles, and linoleum to the floor. Use a beige-brown mass in order to clad the exterior and interior walls of houses with natural and artificial stone. Suitable for lining stoves and fireplaces. The optimum air temperature during the period of repairs using a pasty construction agent should vary between 5-35 degrees above zero. The finished composition can be purchased in specialized stores with a volume of 9 kilograms.

"Optimist"

This type of KS glue is more suitable for floor coverings. It holds well linoleum based on jute, fabric and felt, while the glue seam will be strong. Use an adhesive mass for pasting stoves and fireplaces. Seams and cracks can be sealed with glue.By adding the composition to cement mortars, the heat resistance of the building material is increased. The glue line reaches its maximum strength after 3 days. They offer a ready-to-use composition in 18 kg buckets.

KS-3 "Malva"

White moisture-resistant adhesive mass is considered ideal when laying parquet, linoleum of various types on the floor. The paste is easily applied to the surface and sets after 24 hours. Before use, the composition is thoroughly mixed and applied with a spatula to both glued surfaces. Then you need to roll it in with a roller. Excess paste coming out of the seams is immediately removed.

Farvest

KS glue is heat-resistant and suitable for gluing tiles. With the help of an adhesive mass, she is lined with not only the floor, walls, but also stoves, fireplaces. Thanks to high-tech additives to liquid soda glass, the glue is used for surfaces inside the building, as well as outside. Withstands the composition even of natural and artificial stones of a large size.

"Pulse"

The improved adhesive properties of the glue allow it to be used widely during renovation and construction. The pasty composition of the composition allows you to quickly and reliably glue surfaces of different structure.

You can stick tiles on surfaces that are slightly heated. The glue begins to harden after 25 minutes. Therefore, it is possible to correct the incorrect masonry after the surfaces are smeared with a building compound. After all, the tool belongs to heat-resistant. It is used for ennobling warm floors.

"Universal"

Construction universal adhesive KS with mineral fillers is necessary when working on wall cladding, both internal and external. With it, you can easily and firmly glue the floor with tiles, linoleum, parquet. The adhesion strength does not depend on whether there are residues of old paint or other coating on the surfaces. The adhesive is resistant to alkaline solutions. Hence the use of funds for the repair of canteens, kitchens in children's institutions, hospitals, and catering establishments.

The coating is firmly glued to fibrous, chipboard, concrete and aerated concrete. Suitable for underfloor heating installation. Cladding is securely held on stoves and fireplaces, if you use the universal KS. When laying stoves, sealing cracks, seams, it is an irreplaceable material. It can be added to grout using slab masonry material.

Instructions for use

The use of Loctite products may differ depending on the composition and purpose of the substance.

Loctite 243

It is a one-piece sealant that is used to seal threaded elements. It is characterized by high resistance to vibration or unscrewing. The substance is produced in the form of a spray equipped with a spray.

401

This universal product can be used for paper or cardboard. It is also suitable for vulcanized rubber, suede, leather. With the help of this glue, it is possible to hold textile elements together. The substance is released in the form of a one-component liquid.

It is recommended to degrease and dry the surface before using the substance. Wooden elements should be cleaned and primed. It is recommended to apply glue on both surfaces. It should be done with a thin layer of 2-3 millimeters. Then the elements should be connected and left for 24 hours at a temperature of + 20-23 degrees.

406

It is a cyanoacrylate adhesive that cures quickly. It is used when it is necessary to quickly fix elements made of plastic, rubber, metal. Also, the composition is used for adhesion of alloys or polymers. It is recommended to apply the product to a cleaned and degreased surface. The layer thickness should not exceed 2-4 millimeters. Excessive adhesive will not affect the bond quality, but will increase the drying time.

The maximum strength can be achieved after a day.

Loctite 638 shaft-sleeve retainer

This seal is used for cylindrical elements.It also helps to locate the bearings. It is recommended to apply the substance to cleaned and dried elements.

496

This product is intended for metal. It has a long setting period - it takes 10-30 seconds.

3421

It is a two-component epoxy adhesive that has a slow cure rate at room temperature.

480

It is a one-component adhesive that is fast acting. It is characterized by reduced vapor emission.

Alternative uses

CMC glue is used not only for wallpapering walls. Due to its high adhesive characteristics, this product is used in various sectors of the national economy.

Construction

CMC is added to tile mortar, gypsum or cement putty. This glue is mixed into the mortar used for laying foam blocks or aerated concrete.

Manufacturing of finishing and building materials

Glue is mixed into clay or cement, gypsum mixture in the manufacture of finishing building materials. CMC increases the strength of the finished product and improves its performance.

Chemical industry

In the paint and varnish industry, CMC is used as a thickener. Carboxymethyl cellulose is the basis for the manufacture of facade and various water-based paints. This substance is used in the production of various synthetic detergents.

Mining of oil and gas

Carboxymethyl cellulose is used as a stabilizer for highly mineralized clay suspensions. This substance is used as a regulator of the properties of drilling fluids when drilling oil and gas wells.

Varieties, composition and technical characteristics of wallpaper adhesives

Chemical enterprises produce their own type of CMC for different types of wallpaper. The characteristics of each are indicated on the label or packaging. In any composition of the base substance, there must be at least 50 percent, and the proportion of sodium chloride must be 21 percent. The moisture content of the mixture is up to 12 percent. The solubility of the powder is 96 percent.

CMC differ in composition and percentage of carboxymethyl cellulose. Almost all manufacturers produce universal glue that can be used to glue all types of wallpaper. For each finishing material, its own solution is prepared, in which water is taken in more or less quantity.

For light thin wallpaper

For the thinnest paper wallpaper, it is recommended to use KMTs Burny, KMTs-N, KMTs-1 (Shaving). In shape, the glue is a powdery substance of white or pink color, without any smell. Before use, the powder is diluted in water according to the instructions for use. The adhesive solution applied to the surface dries for a long time. During the period of the repair, they make sure that there are no drafts in the room.

Middle weight

Non-woven wallpaper is considered slightly heavier than paper. For their gluing, KMTs-N or KMTs-N Super-Max, Mini-Max, Extra Fast are used. This product is a fine granular powder. The packaging must indicate the type of wallpaper for which the adhesive is used. Any glue is diluted with water according to the instructions.

Thick heavy wallpaper

The inil wallpaper is considered the heaviest. For pasting the surface with thick wallpaper, KMTs Super strong is used. For pasting the surface with thick wallpaper, KMTs Super strong is used. leaving the adhesive, sometimes PVA glue is added. Externally, glue for heavy wallpaper looks like a white pulp. Before use, the product is diluted with water at the dosage indicated in the instructions.

Glue BMK-5K in accordance with GOST

The industrial adhesive has a very long shelf life, and not only in sealed packaging, but also in a form prepared for work. You can save the composition for several days, and before the next use, you don't even need to stir it.

Industrial adhesive

Due to its quality composition. According to GOST, the glue includes:

- acrylic resin - 180 parts by weight;

- filler kaolin - 400 parts by weight;

- acetone as a solvent - 420 parts.

For fixing parts, as indicated by the manufacturer, acrylic resin is "responsible". Under proper conditions, this substance polymerizes, forming the strongest bond between objects and surfaces with any technical characteristics.

installation of electrical structures

Kaolin serves as a filler for the mixture and strengthens the resulting bond. Its presence ensures the retention of objects of large mass. In addition, kaolin reduces shrinkage and reduces the setting time of the commercial formulation to a minimum.

The technical characteristics of the BMK-5K glue will comply with GOST only if the composition is prepared according to the manufacturer's instructions.

Powder glue

To do this, follow 3 recommendations:

it is better to prepare the composition right before the start of construction work

It is imperative to keep the exact proportion of the components;

if the volume of the hardener is insufficient, the polymerization process is much slower. That is, seizure is carried out, but at a much lower speed, which can significantly slow down the installation of equipment and cables;

with a small amount of filler, the finished mixture loses a number of characteristics, for example, resistance to heat loads decreases

Considering that power cables heat up significantly when current flows, this can lead to line accidents.

adhesive tube

Application

Industrial glue is most often used for installation work, as it guarantees a strong fixation of objects with different weights. The instructions for using it are simple:

- before work, it is necessary to clean the surfaces of dirt, oil, grease, old paint;

- the work area should be dried, if necessary, degreased;

- glue is applied on a flat surface that does not contain depressions, cracks and chips. The layer thickness ranges from 0.5 to 1 mm. An excessive amount of it in the composition only interferes with the hardening process;

- the parts to be connected must be pressed against each other and held for 30 s;

- the connection reaches its maximum strength in a day, as indicated by the manufacturer.

The shelf life of BMK-5K is 9 months. After this time, you can use the adhesive solution only after checking the tear strength.