Additional tips and tricks

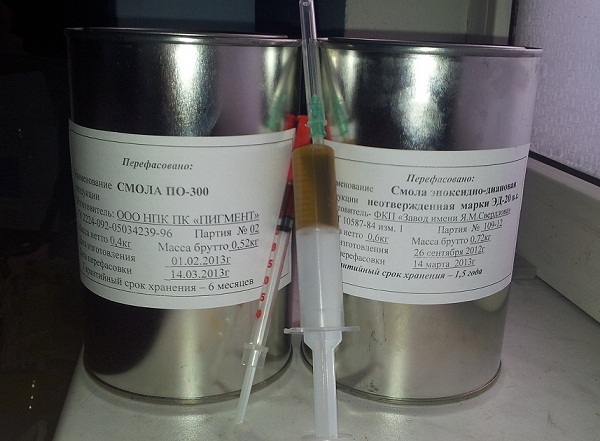

To obtain the finished composition, disposable dishes are required, which cannot be cleaned after using the glue. Mixing the components is required with a metal or glass rod. The use of wooden sticks is impractical due to the high porosity.

Polyamide resin is poured into epoxy, constantly stirring for uniformity of the composition. To speed up the polymerization, the parts to be bonded must be heated. At +50 degrees, final hardening will occur within one hour. In a room where the temperature is + 15 ... + 18 degrees, bonding will end in 1.5-2 days.

Share link:

Instructions for use

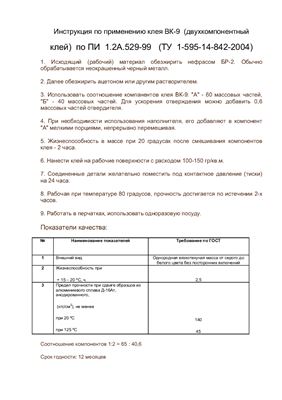

Working with VK-9 consists of 3 stages:

- preparatory;

- worker;

- final.

At the first stage, before applying the glue, it is required to prepare the surfaces. Metal, in the presence of rust, are cleaned with sandpaper. To avoid corrosion, the joints are treated with kerosene or gasoline, which are then removed with a solvent. Glass, ceramics, concrete are washed with water, if there is contamination, after drying, they are wiped with a degreaser.

The meaning of the final stage is to create a strong connection. For this, the treated areas must be pressed against each other with effort and left in this position until completely solidified.

Instructions for use

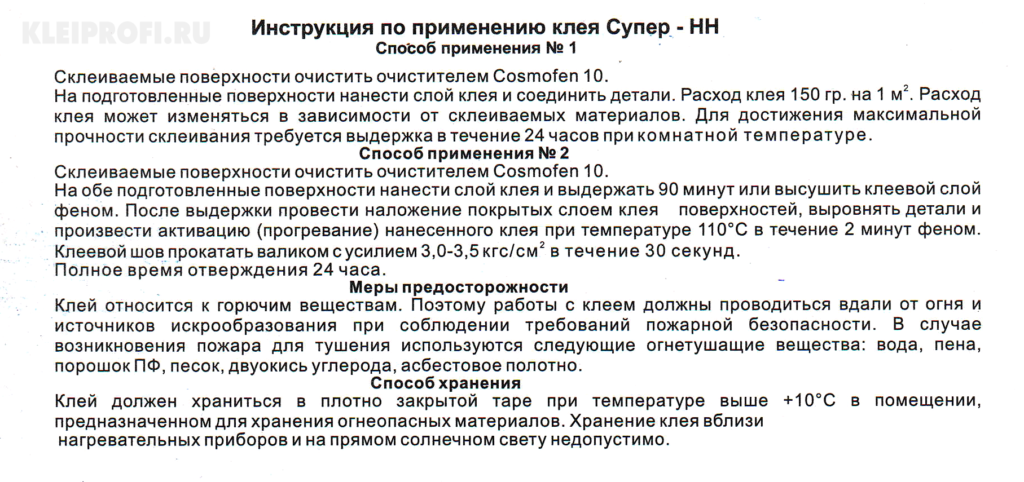

Desmocoll glue is universal, it is intended not only for repairing shoes, but also for bonding PVC elements, polyurethane, rubber products, glass surfaces, etc.

In the process of manufacturing, repairing shoes, they attach polyurethane or PVC soles to fabric bases.

When repairing shoes, you must follow the instructions:

- Surface preparation. Thorough cleaning of dust and dirt is carried out. If there are old glue residues, they are completely removed. To ensure better adhesion, it is recommended to clean the glued sides with fine-grained sandpaper. After mechanical preparation, the surface is degreased.

- The adhesive mass is applied to both glued surfaces, evenly distributed. It is left in this position for five minutes. If the composition is completely absorbed into the plane, then reapplication is performed. The second time is waiting up to three minutes.

- After the formation of a glossy film, the surfaces are pressed tightly, warming up to 80 degrees.

- You can use the product after a day.

The use of this glue frees from the need to use a load, a vice to increase adhesion.

We recommend a video on the topic:

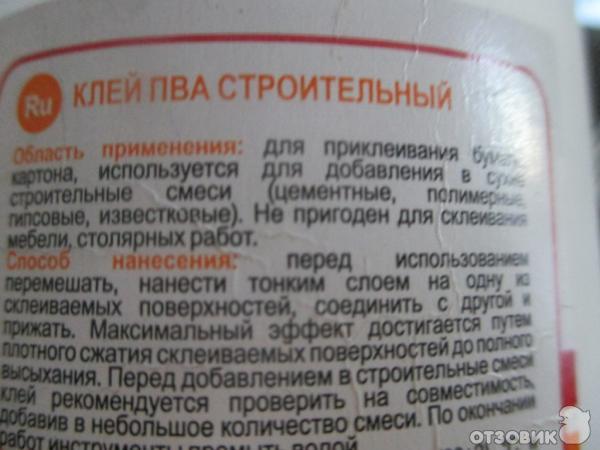

Features of the popular Elmer adhesive

Elmers' adhesive composition is produced by Elmer's School Glue, which develops special compositions for creativity. This glue specializes as a school glue, but is often used to create slimes, sticky toys. Outwardly, the mass is similar to PVA glue, since it is also a white mass of thick consistency. When glued, it is easily distributed over the plane.

It goes on sale in packages of large volumes, buckets, tubes. Colored materials with glitters are produced.

This material glues paper, cardboard, fabric bases, wallpaper. The clutch is fast. But excess or stained areas are easily washed off with water.

When making slimes, it is better to buy a transparent color composition. This material does not contain toxic compounds, therefore it is permissible for small children to use.

Found use for cleaning nails. For this, elmer's glue is applied to the nail and the area around it. Adhesive tape is applied on top. After hardening, the tape is removed along with the dirt that has been absorbed into the glue mass.

Brand overview K Flex

The K-FLEX company has been successfully present on the market for 20 years with its range of products, which are environmentally friendly, easy to use. It is the world leader in elastomeric insulation for energy conservation.

The production of goods is carried out at modern production facilities of subsidiaries located around the world. The range of products is large and satisfies the sectors of the markets for the construction, transport industry, etc.

The technological departments of the company are constantly focused on research and development of new products, which are aimed at increasing the efficiency of the used, produced energy at various facilities. At the same time, the quality remains at the highest level, meets all the requirements.

Seam properties

- vacuum resistance;

- heat resistance;

- chemical and weather resistance;

- high electrical insulation;

- resistance to solvents;

- over time, glass transition occurs in the seam.

Precautionary measures

- Epoxy-polyamide resin is highly toxic. Therefore, it should not glue objects that are used in cooking or serving food.

- Children under 18 must not be allowed to work with VK 9 glue.

- It is necessary to work in a well-ventilated area with gloves. Hands should be lubricated with a protective cream before work.

- If the glue gets on the skin or mucous membranes, they should be washed with an aqueous solution of sodium chloride and consult a doctor.

- After finishing work, treat hands with acetone or other solvent.

Forbidden:

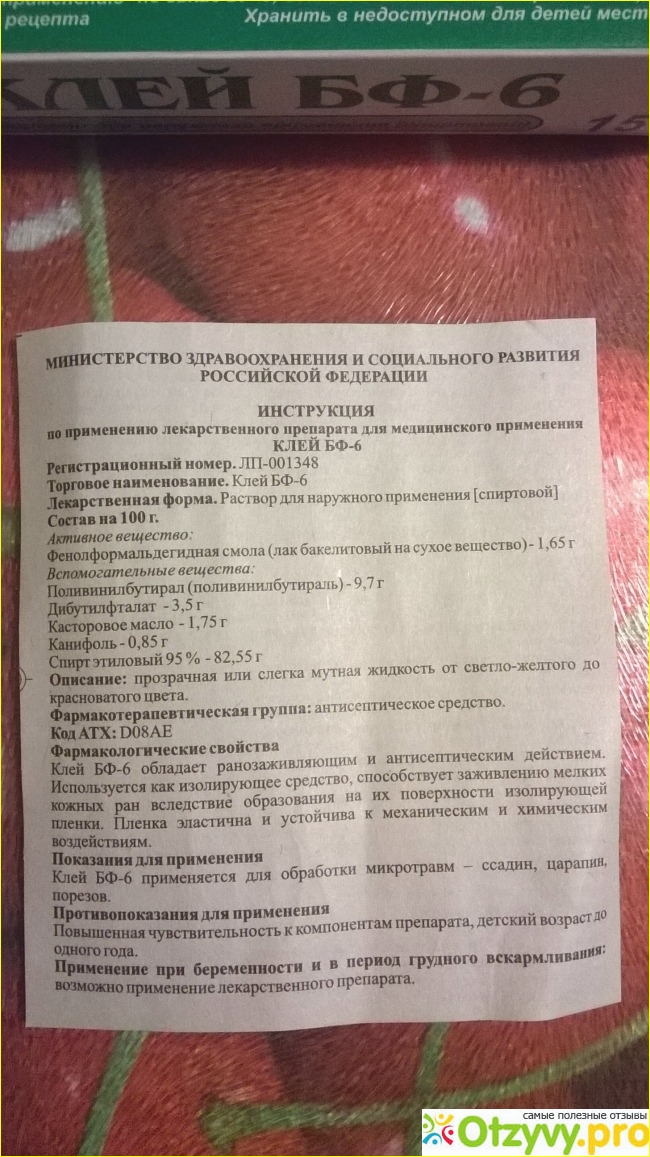

Composition and characteristics of Desmokol glue

Desmokol glue is produced on the basis of polyurethane resins with the addition of modifier ingredients. The characteristics possessed by this adhesive composition:

- Transparency. This feature allows you to use the mass for gluing different colored surfaces. In this case, the seam after drying remains invisible.

- Moisture resistance. This is a big plus when repairing products that are used in wet conditions, in contact with water (rubber shoes, boats, fishing equipment, etc.).

- Resistant to temperatures. The formed seam can withstand low temperatures, while resisting cracking.

- Ease of use. Easy to apply, spread, there is time to correct defects.

- Seam strength. The connection, made in compliance with all application standards, ensures reliable, durable use of the product.