How to connect the washing machine correctly

To ensure trouble-free operation of the washing machine, it is necessary to install it correctly, choosing the optimal place. Before the first use, be sure to read the instructions to use the device safely. The rules for connecting equipment consist of the following stages:

- choosing a place where the washing machine will stand;

- preparation for operation;

- connection to the water supply;

- connection to the sewerage;

- electrical connection;

- installation of equipment.

First of all, you need to choose a location for the device. If the bathroom is small, then the car can be put in the kitchen or bathroom. The main thing is that the floor in this place is even, so that it is possible to bring sewer and water pipes, as well as to throw the device to electricity. As for the bathroom, excessive humidity can negatively affect the details, thereby shortening the period of operation of the equipment. It is not very convenient to use the machine in the bathroom, considering that washing can last for hours. If the washing machine is installed in the kitchen, splashes and stains can disturb the beautiful appearance of the shiny front panel.

The preparation phase of the instrument includes the removal of packing materials and other shipping parts such as staples and blocks.

Important: do not turn on the washing machine before you have removed the transit bolts, as this may lead to an out of operation. If the kit contains plastic plugs, then they should be installed in place of the bolts

It is important to understand that connecting equipment to the water supply system is a responsible matter, since improper implementation of this point can lead to water leakage. Typically, the kit includes a water supply hose and the necessary fittings, but its length may not be long enough to lead to the pipe in the required place

There are two ways to solve this problem: buy a longer hose or run the pipe directly to the machine. If you decide to go the first way, then when buying a part, you should take the length with a margin, so that the tube does not turn out tight and, moreover, does not twist, stopping the water supply.

Connecting the washing machine to the sewer is possible in two ways: fixing the pipe to the drain of the bathtub or washbasin, or bringing the pipe to the sewer pipe. The first option does not provide reliability, since the hose can be accidentally touched and water will spill onto the floor. It is optimal to connect the device permanently, in which case the reliability of the connections will be guaranteed. When connecting household appliances at this stage, it is necessary to take into account the length of the drain hose and the presence of a special siphon, which will prevent the ingress of impurities and unpleasant odors into the device.

When connecting the device to the mains, keep in mind that the machine consumes quite a lot of energy. Therefore, this procedure must be carried out carefully, taking into account the factor that the machine is in contact with water and current. To ensure the safety of operation, it is recommended not to use extension cords, but to supply electricity using special plastic boxes. The use of sockets with an appropriate degree of electrical safety is considered the best option.

After you have connected all the required hoses and removed the shipping bolts, you need to level the washing machine using the adjustable feet. It is recommended to place the device on a concrete surface to ensure a stable position. Do not place various objects under the legs in an attempt to place the equipment evenly.

Remember that vibration during spinning can indicate a serious malfunction of the device.

Why does the washing machine jump when spinning

The so-called washing machine jumping is a strong vibration that makes the appliance jerk and move out of place. Such a phenomenon causes a lot of problems, at least it is accompanied by loud noise, which disturbs not only residents, but also their neighbors. There are several possible reasons for this behavior of the technique.

Unsuitable installation location

The wrong place for the washing machine is one of the most common reasons for jumping. Taking into account the strength of vibration that occurs during spinning, the technique is often called capricious - it requires an even and solid floor. There are two possible options:

- unstable flooring, soft floor (for example, wooden) - in this case, the very place on which the machine is installed will be mobile, which means that it will jump significantly with strong vibration;

- uneven floor. Even if there is a tile at the installation site, this does not guarantee a stable position of the equipment. Inexpensive tile itself may be a little crooked, flaws during installation are not excluded. Thus, different levels of the floor under the feet of the washing machine will intensify vibrations and provoke jumping.

There is only one method of solving the problem - to eliminate floor defects. So, if it is soft or wobbly, it is better to move the equipment to another place, and if the floor is curved, then it will be enough to adjust the height of the machine's legs. This is easy to do:

-

First you need to determine which legs are to be adjusted. To do this, you just need to shake it - that leg, on which the machine falls when swinging, needs to be lengthened.

-

Use a wrench to turn the adjustable foot counterclockwise. Sometimes this can be done without raising the car, but if this is inconvenient, then the equipment will still have to be tilted.

-

When the swing is gone, you need to check whether the machine has become even - for this it is worth using a building level.

Incorrect preparation for operation

If the jump appears on a car that was recently purchased, the first thing to check is the shipping bolts. They are fasteners that hold the drum during transportation and must be removed before starting the device - then the drum will drop into place and the vibration damping system will work at full strength. Often, temporary mounts are simply forgotten, and then the device begins to vibrate and jump violently. In this case, it is necessary to urgently pull out the forgotten bolts - their number depends on the specific model and manufacturer, you can do this yourself, following the instructions for commissioning.

Before using the machine, be sure to remove the shipping bolts.

Machine breakdown

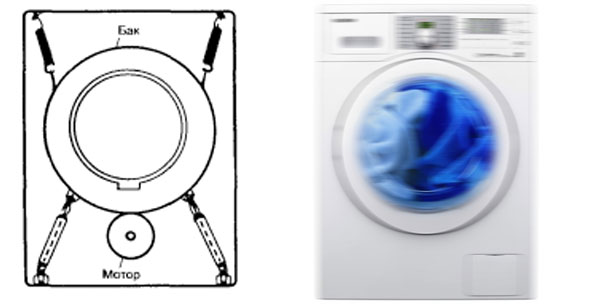

If a breakdown occurs in the vibration damping system of the washing machine, it begins to behave extremely actively and bounce strongly during the spin cycle. If the device is correctly installed, then perhaps one of the parts is out of order:

- shock absorbers, which are located at the bottom of the sides of the tank and absorb vibrations by the resistance of the piston;

- springs on which the tank is attached from above (they stretch over time);

-

counterweight (a large weighting agent, which is located on top of the tank and ensures the stability of the washing machine, may crumble or loose on the mountings over time).

The solution to such a problem is one - to call a competent repairman for washing machines, who will diagnose and make the necessary replacement of parts.

Incorrect loading

Strong vibration and jumping with a characteristic drum rumble often occur due to non-compliance with the rules for using the washing machine. The things in the drum, knotted into one big ball, simply do not allow it to rotate evenly, creating vibrations that are dangerous for the safety of the technique. To avoid such a problem, you must take into account a number of rules:

- do not exceed the weight of the loaded items indicated in the instructions for a specific model of the washing machine;

- when loading things into the drum, you need to lay out, you cannot throw them in one lump;

- the problem often arises when washing one large item - in this case, you need to stop the cycle and redistribute the item in the drum.

Severe vibration and, as a result, jumping during the operation of the washing machine is a common problem that can be triggered by both improper operation and serious breakdowns. If the elimination of simple violations does not give results, then it is worth contacting a specialist.

How to troubleshoot

The first thing to do if the washing machine jumps during spinning is to check if the setting is correct. The unit must stand on a flat, solid surface, preferably a solid floor. If you place the device on a wooden surface, then vibrations and noise during spinning cannot be avoided.

You also need to check the adjustment of the legs, which during operation of the machine can unwind, from which, in turn, the equipment will lose stability. In order not to face such a problem in the future, it is necessary to secure each support with a locknut.

When installing a new washing machine, users often make the following mistake: they forget to remove the shipping bolts. They are located on the rear panel and serve to secure the tank when transporting equipment. If they are not dismantled, the machine will vibrate and make a lot of noise during washing, and soon it will completely fail. You can unscrew the fasteners with a wrench.

Be sure to remove the transit bolts before use.

Be sure to remove the transit bolts before use.

When the installation issue has been resolved, it is important to check the load volume of the laundry. If the clothes are unevenly distributed in the drum, they are clumped or too much of them, this can lead to increased shaking of the washing machine.

In this case, stop the machine during the spin phase, distribute the clothes by hand or remove a few unnecessary items, and then restart the unit.

If you are still wondering why the washing machine jumps when spinning, remove the top case cover and inspect the special springs that hold the tank on top. They wear out quickly and lose their elasticity, which affects the operation of the unit. Within a few months after purchasing the equipment, the springs may fail. If you have the necessary spare parts, it is not difficult to replace parts at home.

To get to the springs, just remove the top cover of the washing machine

To get to the springs, just remove the top cover of the washing machine

In typewriters Indesit, Bosch, Samsung and models of other brands, shock absorbers designed to damp the vibration of the tank often fail. These can be accessed through the rear or front panel of the instrument (depending on the model). The shock absorbers are attached with bolts or plastic clips: one side to the tank, the other to the bottom of the body. With wear, they weaken, as a result of which the washing machine vibrates strongly during spinning. To replace parts, it is necessary to disconnect the mountings of the old shock absorbers and install new ones, securely fixing them in place. Replacement is not difficult if you have at least minimal knowledge about the device of the washing machine.

Serviceable shock absorbers hold tank and reduce vibration

Serviceable shock absorbers hold tank and reduce vibration

Often times, the washing machine rumbles and jumps due to the destruction of the counterweights - plastic or concrete blocks that are bolted to the tank and balance it. Over time, fasteners can loosen, resulting in increased vibration and noise. The material for the manufacture of counterweights is also important. For example, the LG typewriter has concrete parts that often crack or crumble. Plastic blocks are considered to be more durable and reliable.Despite this, they also need regular inspection, especially if the clipper constantly rattles during spinning. Timely checking the counterweights for damage or loosening of fasteners will avoid strong vibration and prevent damage to other parts.

With prolonged operation, the attachments of the counterweights weaken

With prolonged operation, the attachments of the counterweights weaken

Answering the question why the washing machine shakes during the spin cycle, one cannot but mention the bearings. These parts wear out over time and become a source of noise, namely: squeaks or rattles during the rotation of the drum. If left unattended, the bearings will permanently collapse, which will lead to free movement of the drum shaft on which they are installed. At the first symptoms of a malfunction, it is worth replacing the support part, otherwise the cost of repairs may increase significantly. It is difficult to replace bearings at home, so entrust the work to a specialist.

Only a professional can replace worn bearings

Only a professional can replace worn bearings

When the washing machine jumps and knocks, it creates discomfort for others and can end in failure for technology.

In order not to bring the unit to a serious breakdown, it is important at the first symptoms to establish the cause of the malfunction and eliminate it as soon as possible. We hope our recommendations will be useful for those looking for ways to cope with the constant rumble and vibration of the device.

Troubleshooting yourself

To fix some malfunctions, it is not necessary to take the device to a service center, you can do everything yourself. To do this, you need to do the following:

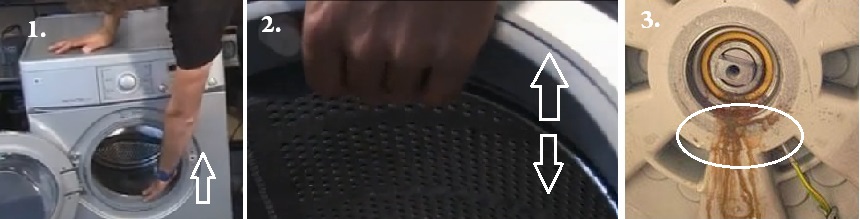

- If foreign objects get into the drum, bend the rubber seal of the hatch on the front panel, while fixing the drum. After that, you should hook the thing with a hook and pull it out. If you cannot do this, only removing the heating element and disassembling the automatic machine will help, which is better to entrust to a professional.

- If the distribution of the laundry is uneven, an emergency drain must be performed and the door unlocked. Next, take out the laundry, separate it from each other and carefully lay it out in the drum. If an overload was observed, then remove some of the things from the car.

- If there is a problem with the installation, you need to determine the correct height using a level and adjust the legs of the washer. You can also level the floor or put a sheet of chipboard, fiberboard, or anti-vibration pads. Using a rubberized mat will also help if the unit slides over a surface.

- If there are transport bolts, you need to turn the machine with the back wall towards you and unscrew 3 or 4 fasteners with a wrench or pliers. In some cases, there are more fasteners, and they are located under the top cover, so it is better to first check the instructions. In their place, plastic plugs from the delivery set are installed. The removed bolts should not be thrown away, they will come in handy when moving or rearranging for the duration of the repair.

- If you have problems with the shock absorbers, you need to unscrew them and try to compress them. Since their task is to extinguish vibrations, the movement should be given with difficulty. If it turns out to be easy to do this, then both structures need to be replaced. If only one is corrected, the stiffness will be different and the load will be unevenly distributed.

- In case of difficulties with counterweights, you need to remove the machine panel (using pliers, screwdriver, wrench) and inspect the counterweights. If they crumbled, then buy and install new ones. If not on sale, you can tighten the parts with metal plates or glue them, although this is a rather difficult option. When the counterweights look intact, consider their mountings as well as the springs. In the event of a breakdown, they are changed, but if they are intact, the bolts are tightened.

- To resolve the issue with the electric motor, you need to remove the back panel and try to tighten the fasteners.Also, removing the far cover will allow you to determine the condition of the belt leading from the engine to the drum. Other actions with the motor and the programmable part of the apparatus cannot be carried out independently.

- Bearing breakage can only be repaired within the framework of a service center.

How to fix a washing machine if it jumps

Having dealt with the reasons that make the automatic machine vibrate and bounce unnecessarily, we will proceed directly to eliminating them.

We eliminate the reasons ourselves

Often, the problem of increased vibration occurs when the device is not installed correctly or when a lot of things are overloaded. Such problems can be eliminated without assistance. This will be discussed further.

Correct installation of equipment

The proper operation of the technique depends on how correctly it is installed. How to set up the washer so that it doesn't jump? Read the recommendations below.

- If your washing machine bounces when spinning or washing, check to see if the shipping bolts have been removed and must be removed after installation. Otherwise, you cannot avoid jumps of the machine, and the wear of its important components is guaranteed.

- The placement of the automatic machine is an important point to be taken seriously. The technique must be level, without any distortions. For this, special legs are provided, which just need to be correctly adjusted.

- The surface on which the washer is installed must not be slippery. If jumping and movement occur, use additional anti-vibration pads.

Correct operation

If you have aligned the clipper as expected, and the problem persists, the cause must be looked for elsewhere. The drum may be overloaded or an imbalance occurred during the wash.

To prevent this situation, it is important to adhere to certain rules:

- follow the maximum permissible load weight of the laundry, which is provided for the automatic machine;

- do not exceed the drum loading by volume - if the drum is 2/3 full, this is already an excess;

- do not allow a situation where the laundry gets knotted. Therefore, before loading it into the washing machine, it should be straightened and evenly spread over the drum (you can use special bags for washing).

Small objects falling into the gap between the tub and drum are common. To remove a foreign object, follow the guidelines below.

- Equip yourself with a flashlight and illuminate the tank from all sides.

- If you find a foreign object, try pulling it out with a hook-shaped wire at the end.

- If the attempt was unsuccessful, you will have to partially disassemble the machine.

Operate the washing machine according to the rules set out in the instructions and install it taking into account all the recommendations. This will save it from premature breakdowns, and you - from unnecessary hassle in search of the cause of the malfunction.

When you can't do without calling a specialist

In case of serious technical breakdowns, it is better to call a repairman. But if you have certain skills and are confident in your abilities, you can try to fix the breakdown yourself. The malfunction should be eliminated immediately so that it does not lead to more serious consequences.

Damage to shock absorbers or springs

Shock absorbers and springs are elements of the device that prevent excessive vibrations when spinning at high speeds. Strong vibrations and characteristic knocks may indicate a malfunction of the shock-absorbing system. In other words, the shock absorbing elements are simply worn out and need to be replaced.

If one shock absorber has become unusable, change both at once. You will definitely not save money, because over time you will still have to change another one. With springs that have worn out, having lost their elasticity, do the same.

Counterweight attachment problems

The counterweight is a concrete or plastic weight that is placed on the top and bottom of the chassis, sometimes on the sides. Its task is to "block" unnecessary vibrations of the automatic machine. Counterweight problems are of two types:

- deformation of the counterweight itself. In this case, you need to replace the worn out part with a new one;

- fixing problems. Here you will need to adjust or replace them.

Bearing wear

A common cause of noise and vibration is bearing failure. Under the influence of moisture, over time, they begin to rust and collapse.

The defective part should be replaced immediately. Entrust this procedure to a service center specialist.

Use household appliances correctly, adhere to the manufacturer's recommendations, then you definitely won't have to look for the cause of the breakdown.

Badly

Interesting

2

Super

1

Incorrect installation and operation of the device

The reasons why the machine rumbles and jumps during the spinning process are very diverse - from improper installation of the unit to the failure of its important components. And if some of the causes can be eliminated on their own, the help of a qualified specialist will be required to eliminate others. To begin with, we propose to figure out in which cases it is possible to cope with the problem without outside help.

Shipping bolts not removed

If the problem was discovered immediately after the delivery of new equipment, it may not be a device breakdown at all. Often, during the installation of the unit, customers forget to unscrew the shipping bolts located on the rear panel of the unit. These bolts firmly fix the washing machine tank to protect the appliance from damage during transportation.

When installing a new washing machine, it is imperative to unscrew the transit bolts

When installing a new washing machine, it is imperative to unscrew the transit bolts

After removing the parts, the drum hangs freely on the springs, which dampen the vibrations of the device during washing. If the bolts are not removed, the rigidly mounted drum will vibrate violently, causing rapid wear on many internal components. The number of shipping bolts may vary from model to vehicle, so we advise you to check the instructions before removing them. In order to remove the parts, you need a wrench of the appropriate size. For washing machines from Indesit or Zanussi, its size is 10 mm, for devices of the brands Samsung, LG or Bosch - 12 mm.

The appliance is unstable on the base

Another reason for the strong vibration of the washing machine during spinning can be its incorrect installation.

First of all, pay attention to the surface on which the device stands: it must be solid and monolithic (ideally, a concrete floor or tiles). Most often, cars jump on a plank floor: at high speeds, it bends under the weight of the device, amplifying the vibrations created by the drum

On rare occasions, the machine may jump due to the floor in the room being too smooth and slippery. In this case, you can cope with the rumble by placing a rubber mat under the device or sticking special anti-slip stickers on its legs. If you cannot find similar stickers in the store, use double-sided construction tape.

You can restore stability to the washing machine by adjusting the height of its legs.

You can restore stability to the washing machine by adjusting the height of its legs.

We also advise you to pay attention to how tightly the legs of the device are twisted. Sometimes during operation, their fasteners loosen, which leads to the instability of the machine

To check the fixation of the legs, simply shake the clipper with your hands. If it is "limp", then the supports should be adjusted and fixed in the correct position with a locknut. You can also shorten the legs by screwing them deeper into the base of the device. In this way, you will achieve greater stability of the unit against vibrations.

The laundry is unevenly distributed throughout the drum

In order to avoid many problems during the operation of the device, the developers advise to always follow the recommendations for the weight of the loaded laundry. Uneven distribution of items can overload the drum and cause the machine to rattle during spinning. If you suspect that an imbalance is responsible for the rumble, follow these instructions: stop spinning, remove some of the clothes from the machine, spread the remaining laundry evenly over the drum, and then restart the spin program.

Do not overload the washing machine with laundry.

Do not overload the washing machine with laundry.

Wear of springs and shock absorbers (dampers)

The longer the life of the washing machine, the less the elasticity of the springs fixing the tank becomes, their ability to control vibrations is lost. To correct the problem with the worn springs, all of them must be replaced with new ones.

Another reason why washing equipment jumps a lot is faulty shock absorbers. They, like the springs, dampen the rocking of the drum during intensive rotation. Their failure leads to tank subsidence. You can check the condition of the shock absorbers yourself: open the machine door and pull the tank a little towards you, and then release it. If it starts to move to the sides and does not fit clearly into place, then the shock absorbers will need to be replaced with new ones. In addition to shaking, spinning can be accompanied by tapping - these are faulty elements hitting the body.

Damper problems are usually manifested by the breakage of the plastic covers that fit the tubes or plates extending from the tank. Replacing broken covers also requires experience and dexterity. In addition, there is a problem with the selection of a suitable lining; it is more expedient to replace the dampers with new ones.

Damper problems are usually manifested by the breakage of the plastic covers that fit the tubes or plates extending from the tank. Replacing broken covers also requires experience and dexterity. In addition, there is a problem with the selection of a suitable lining; it is more expedient to replace the dampers with new ones.