Work rules

When carrying out facing work, the following sequence of actions should be observed:

- Preparation of the base. The surface is freed from old materials, dirt, dust and debris are removed. The base must be strong, not subject to deformation. Level the surface, seal the cracks. They are treated with a primer, for porous materials they put the soil in 2 layers. It is better to use Plitonite grade materials containing components for protection against fungus.

- An adhesive solution is prepared. Pure water is poured into a container (240 milliliters of water per kilogram of dry mixture), glue is added. All components must be at room temperature (10-30 °). Drinking water, mixing containers free of old materials. Use a construction mixer or drill for mixing (3 minutes). As a result, you should get a homogeneous composition without lumps. Readiness is checked on the wall - if it does not drain, the consistency is correct.

- After checking, let the glue settle for 5 minutes, mix again. Proceed with the facing, remembering to use the glue within 4 hours. In hot, dry rooms, in the wind, the glue loses its properties faster, you have to hurry.

Features of tile sticker:

- the composition is distributed with a spatula with a smooth or serrated edge;

- the layer is laid with a thickness corresponding to the recommendations for a particular type of "Plitonite";

- the tiles are laid on glue and pressed in with pivoting movements;

- within 15-20 minutes, the position can be corrected using a laser level;

- the excess glue from the seams and from the surface of the tile is removed immediately, not allowing it to harden.

When working, make sure that no voids are formed, fill them with an additional amount of glue (applied directly to the back of the tile), otherwise the coating will "play" when pressed.

Review of popular solutions

Several types of glue are used to work with the carpet. Professionals buy expensive imported products, the effectiveness of which is not affected by temperature jumps. The composition is sprayed with a spray gun, and one package is enough to cover a large area. You can buy an aerosol spray for upholstery, but in this case, the composition has to be applied on both surfaces, otherwise the material will not hold.

PVA does not adhere the coating in frost, loses its properties at high humidity, leaves white spots on dark fabric. Glue 88 withstands vibration and is suitable for floor cladding. It does not dry out for a long time at high temperatures, it is difficult to get rid of the smell that occurs when applied to the surface. The "moment" seizes almost instantly, you need to lubricate the coating with a paste very quickly, and not every person can work at such a pace. The tool is not cheap.

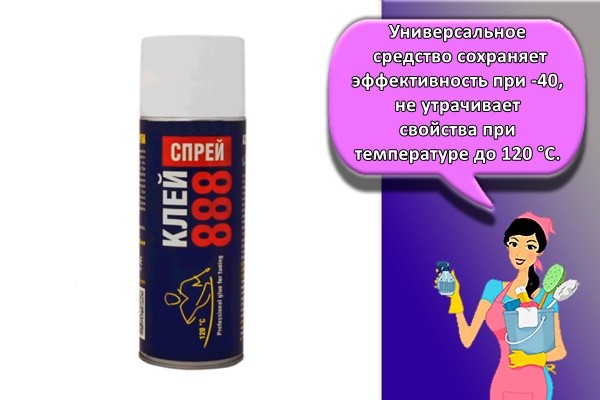

Aerosol glue 888U ltra reinforced formula

The spray, which contains synthetic rubbers, thinners, additives, combines various materials in such a way that it is impossible to tear them off. The universal product remains effective at -40, does not lose its properties at temperatures up to 120 ° C.

Aerosol glues:

- carpet;

- carpet;

- artificial leather;

- plastic;

- rubber.

The spray is applied to the surface with a brush or a spray gun in 5-6 layers, each of which dries in a quarter of an hour, they do not stick to each other, but stick together tightly. Before work, the aerosol is diluted with a cleaner in a ratio of 2 to 1. One can of a universal product is enough for application per 3 square meters. meters. To sheathe the interior of a car, not one composition is usually used, but several.

Liquid glue 88-CA

A viscous agent, which is an alcoholic ester of acetic acid, has the ability to penetrate into the deep layers of porous materials. Liquid glue sets quickly, connects:

- metal and rubber;

- fabric and leather;

- glass and wood.

The elastic seam is not damaged in 30-degree frost, tolerates +60 ° C. The product is odorless, does not contain methylbenzene, does not emit toxic substances, can be used both indoors and outdoors.

Furniture glue

Liquid pink composition, which is sold in liter bottles and is used for facing sofas, armchairs and other upholstered furniture, is suitable for covering podiums with carpet, covering acoustic shelves.

Improved blends

Profi plus

Designed for installation on walls and floors:

- ordinary tiles;

- porcelain stoneware;

- clinker;

- mosaic tiles;

- stone;

- soundproofing materials;

Already familiar surfaces can act as a base. The composition is designed mainly for internal work, but it is allowed to use it in freezing places (balconies, terraces). Frost resistance is similar to the previous one.

| Correction time, min | Life time, min | Adhesion to porcelain stoneware, MPa | Maximum thickness, mm | Application temperature, ° C | Consumption, kg / m2 |

|---|---|---|---|---|---|

| 15 | 120 | 1 | 15 | +5 — 30 | 1,35 |

Installing clinker tiles on walls with weber.vetonit profi plus:

Ultra fix

Designed for cladding facades and other places with a high level of responsibility with porcelain stoneware and natural stone of any weight and format. Weber tile adhesive is frost-resistant (more than 150 cycles) and heat-resistant - high elasticity and adhesion allow it to be used when facing heated floors.

Laying large-format porcelain stoneware on Vetonit Ultra Fix glue. The mixture is applied to walls and tiles to improve adhesion.

- GVL;

- GKL;

- concrete;

- painted bases;

- brick;

- plaster;

- waterproofing;

- cement-based putties;

| Correction period, min | Life time, min | Adhesion to porcelain stoneware, MPa | Max. layer, mm | Application temperature, ° C | Consumption, kg / m2 |

|---|---|---|---|---|---|

| 15 | 180 | 1,4 | 15 | +5 — 30 | 1,29 |

Furnace cladding with weber.vetonit ultra fix glue:

Ultra fix winter

Both the bases and the facing materials are similar to those described just above. The specificity of Weber Vetonit Ultra fix winter glue is the possibility of application at negative temperatures. Frost resistance is more than 75 cycles, operating temperature: -30 - +70. Other technical characteristics:

| Correction, min | Solution life time, min | Adhesion, MPa | Maximum thickness, mm | Application temperature, ° C | Consumption, kg / m2 |

|---|---|---|---|---|---|

| 10 | 120 | 1,4 | 15 | -10 — +20 | 3 — 3,5* |

* When working with a 6 mm notched trowel.

Mramor

The difference between this glue and other mixtures of the manufacturer Vetonit is a white color, which makes it possible to use the composition when laying transparent mosaics and slabs with veins or light shades. Suitable for porcelain stoneware, ordinary tiles and stone tiles, which can be laid even on difficult surfaces (paint and old tiles). The mixture is frost and heat resistant.

| Correction, min | Life time, min | Adhesion to porcelain stoneware, MPa | Maximum layer, mm | Application temperature, ° C | Consumption, kg / m2 |

|---|---|---|---|---|---|

| 20 | 180 | 1,8 | 15 | +5 — 30 | 1,29 |

The video shows an example of cladding a fireplace with clinker tiles using white weber.vetonit mramor glue:

Absolut

The mixture is intended for large-format slabs: ceramic, porcelain stoneware, stone, marble. In addition to traditional bases, the scope of the glue is old tiles, paint, waterproofing, linoleum. Maximum operating temperature +85.

| Correction period, min | Life time, min | Adhesion, MPa | Maximum thickness, mm | Operating temperature, ° C | Consumption, kg / m2 |

|---|---|---|---|---|---|

| 20 | 180 | 1,8 | 30 | -30 — +85 | 3 — 3,5* |

* When using a 6 mm comb.

RF

Allows facing with any ceramic and stone complex coatings: young concrete, paint, linoleum, tiles. Differs in heat resistance (withstands up to +85) and increased life in finished form.

| Allowable slab correction, min | Life time, min | Adhesion, MPa | Maximum layer, mm | operating temperature, ° C | Consumption, kg / m2 |

|---|---|---|---|---|---|

| 20 | 300 | 1 | 15 | -30 — +85 | 3 — 3,5 |

RFF

This tile adhesive from Weber has a faster setting speed - 14 times faster than conventional mixes. This allows you to use it wherever you need to finish the facing work as soon as possible. The base is traditional surfaces. Specifications in the table:

| Correction term | Life time, min | Adhesion, MPa | Maximum thickness, mm | Operating temperature, ° C | Consumption, kg / m2 |

|---|---|---|---|---|---|

| 5 | 30 | 1 | 15 | -30 — +70 | 3 — 3,5 |

Description and distinctive features of the "Plitonit" adhesive

The glue is produced in the form of a dry construction mixture in boxes or bags with a capacity of 5, 25 kilograms. Ceramic tiles and the surfaces on which they are attached differ in composition and properties, therefore the line contains products for various purposes. The correct choice of means is the basis for the reliable and durable operation of the tiled coating.

Features of Plitonit adhesives:

- pronounced adhesive properties;

- moisture resistance;

- durability;

- plastic.

The compositions reliably fix ceramics on vertical walls, hold heavy materials, and do not collapse under the influence of high temperatures and high humidity. The adhesives are intended for home and professional use during construction and renovation work.

Launched the production of 3 series "Plitonit" adhesives - "A", "B", "C". Separately produced means for porcelain stoneware, fireplaces, universal glue. Within the series there are products with enhanced adhesiveness and strength characteristics within the stated areas of application.

Manufacturers overview

There are four main manufacturers that produce quality adhesive solutions.

Dragon

This is a Polish product released by a Polish company that produces adhesives and construction chemicals. All products manufactured by Dragon are considered to be of high quality. That is why many builders use it.

"Hercules-Siberia"

This company specializes in the production of high quality dry mixes from which liquid glue is made. "Hercules-Siberia" produces universal adhesives that are resistant to low temperatures and high humidity.

Axton

Adhesives made by Axton differ from other formulations in terms of quality performance. They are used during installation work, sealing joints, as well as when fastening metal or wood structures.

Bostik

It is one of the most renowned manufacturers of polymer-based adhesives. Bostik products are often used in the construction industry when cladding exterior or interior walls.

What is the material

Carpet carpets differ in structure, thickness, and have different ductility. The cheapest fabric for upholstery is made from fiber, the density of which per square meter does not exceed 450 g. Many car owners prefer to upholster the interior of a material that is made of polypropylene. The pile length of this type of carpet reaches 6 mm.

Carpet has a lot of advantages, compared to other materials used to upholster car interiors:

- Absorbs noise.

- Does not absorb dirt, does not collect dust.

- Does not electrify, does not fade.

- Keeps you warm.

Although the fabric is made from synthetic fibers, it does not cause allergies, does not irritate the skin or the respiratory tract. Carpet sheathed the ceiling, the inside of the trunk, covered with a subwoofer, acoustic shelves. The material does not mold, does not deteriorate from moisture.

Differs in the increased flexibility of Madeleine, which is most often sheathed in the trunk. The material is liked by motorists because:

- easy to stick:

- has a beautiful smooth surface;

- keeps warm.

Carpet is inexpensive, but absorbs noise in the cabin. The floor in the car is often covered with linoleum, which adheres well, does not lag behind moisture, withstands overloads, but deforms when sand gets in, and solid particles accumulate.

Classification of glue by special properties

- Heat resistant

- Frost resistant

- Fast hardening

- Leveling

- Elastic and highly elastic

- Thick layer

- Universal

- With reinforced fixation

Heat resistant

This solution is used for facing stoves, fireplaces and underfloor heating. Must withstand temperatures in excess of 100⁰C.As a rule, prolonged heating up to 175⁰C and short-term heating up to 1200⁰C. That makes it possible to lay ceramics on a stove, fireplace or underfloor heating. In this case, a less heat-resistant solution can be used for lining the chimney.

Heat-resistant tile adhesive is indispensable for facing stoves, fireplaces and underfloor heating.

Heat-resistant tile adhesive is indispensable for facing stoves, fireplaces and underfloor heating.

Frost resistant

As a rule, it is a dispersion mixture. But frost-resistant tile adhesive must withstand not only low temperatures, but also its sudden changes. Therefore, the manufacturer is obliged to indicate on the packaging that the glue is frost-resistant. Moreover, there are mixtures that have both frost resistance and heat resistance at the same time. Which can be used for lining stoves in rooms with irregular use.

The properties of the frost-resistant adhesive make it ideal for laying ceramic tiles.

The properties of the frost-resistant adhesive make it ideal for laying ceramic tiles.

Fast hardening

This type of tile adhesive hardens in 3-4 hours. That allows you to quickly start operating it. But on the other hand, it is more difficult to work with him, since he grasps in 5-10 minutes. After that, it is no longer possible to mount the materials. Therefore, it must be placed quickly and accurately.

This quick-drying tile adhesive is a great help for people who want to finish their renovation work as soon as possible.

This quick-drying tile adhesive is a great help for people who want to finish their renovation work as soon as possible.

Leveling

This type of mortar is used when laying tiles on an uneven surface with differences of more than 1 cm. Why is it necessary to use cement mixtures. And, of course, this significantly increases the consumption of glue. Therefore, such styling will cost more. Therefore, this is rarely justified in terms of the cost of work. But in some cases it is simply necessary.

Tile leveling adhesive is a mixture of cement, fractional sand and polymers, which give it various properties.

Tile leveling adhesive is a mixture of cement, fractional sand and polymers, which give it various properties.

Elastic and highly elastic

The elasticity index of a solution determines its ability to bend under mechanical stress. Thus, two classes of elastic adhesives are distinguished: S1 and S2. S1 assumes the possibility of a deflection of at least 2.5mm. S2 - allows the mixture to bend by more than 4.9mm. Accordingly, S1 is flexible tile adhesive and S2 is highly elastic.

Elastic tile adhesives contain modified additives and plasticizers.

Elastic tile adhesives contain modified additives and plasticizers.

Thick layer

The layer thickness index refers to cement-based mixtures. Since it is these solutions that are used to correct the unevenness of the coating. Thus, for coating defects of no more than 10 mm, a thin-layer mortar is used. When the solution is used not only as a mixture for tiles, but also as a leveler, then a thick-layer mixture is used.

The thick-layer tile adhesive is used for the installation of large-format ceramic, porcelain stoneware or artificial stone floor tiles.

The thick-layer tile adhesive is used for the installation of large-format ceramic, porcelain stoneware or artificial stone floor tiles.

Universal

This type of tile adhesive is suitable for both outdoor and indoor use. But it should be borne in mind that it may not be very reliable when using ceramics larger than 30X30 cm, as well as with temperature drops and high humidity. Therefore, it is better not to put it in the bathroom. And besides, it is not recommended to use it for cladding rooms located in difficult climatic conditions.

For some tile models, a universal adhesive may also work. This applies to models 10x10, 20x20, 30x30 cm.

For some tile models, a universal adhesive may also work. This applies to models 10x10, 20x20, 30x30 cm.

Reinforced glue

Mixes of reinforced fixing include dispersion, polyurethane and epoxy solutions. As a rule, they are used for wall cladding with large materials. Since such a solution has increased adhesion properties.

The key feature of reinforced tile adhesive is its increased resistance to static and dynamic loads.

The key feature of reinforced tile adhesive is its increased resistance to static and dynamic loads.

How to choose the right tile adhesive

When purchasing adhesive for tiles in the bathroom, you need to adhere to an integrated approach. To choose the right variety, you will need to take into account a number of parameters.

Base type

Certain types of tiles are more firmly fixed on cement, brick and other substrates. To ensure good adhesion, you need to purchase an adhesive solution designed for the specific substrate.

Tile features

The reverse side of the tile can be textured or smooth, which determines the appropriate glue and the strength of adhesion to the surface. For this reason, it is recommended that you first purchase a tile and familiarize yourself with its specifics, and then look for the desired adhesive solution.

Place of laying

Bathroom decoration is often carried out not only on the walls, but also on the ceiling. For laying tiles on horizontal surfaces, an adhesive with increased adhesion is required, otherwise it will peel off from the substrate over time.

Special properties

When purchasing an adhesive solution, you need to pay attention to its special properties. These characteristics include increased adhesion, the need for preparation before application to the surface, cure rate, and others.

Availability of additional heating

If you plan to install additional heating elements in the bathroom, you need to take this into account when choosing a tile adhesive.

Colour

Since part of the solution can get into the inter-tile space, you need to choose a glue that is neutral in color. It is better to give preference to transparent glue, which can be hidden with grout.

Ease of installation

The building materials market offers several options for tile adhesive, which differ in the form of release. There are ready-to-use solutions and those that need to be dissolved in water.

Standard formulations

Classic Weber Vetonit adhesives are designed for cladding floor and wall coverings, traditional substrates, which include seasoned concrete, brickwork, cement screed.

Depending on the tasks, in the line of adhesives, you can choose a product for a specific finishing material

This condition is important to take into account in order to achieve strong adhesion of the tile to the surface.

Table 1. Features of standard Vetonit Weber adhesives

| Properties / brand | Optima | Easy Fix | Granit fix |

| Masonry correction, minutes | 8-10 | 10-12 | 10-15 |

| Vitality, hours | 2 | 2 | 2 |

| Adhesion to tiles, MPa | 0,5 | 0,6 | 0,8 |

| Limiting layer thickness, mm | 10 | Up to 15 | Up to 15 |

| Application temperature, deg. | +5 to +30 | +5+30 | +5 to +30 |

| Consumption, kg / m2 | 1,29 | 1,29 | 1,29 |

Vetonit Optima

The tool can be used for interior and exterior work. The universal adhesive is suitable for bonding ceramic tiles and glass mosaics. Before work, the dies do not need to be specially soaked. The composition is distinguished by economical consumption, uniform solidification and high strength characteristics, it is in good contact with plaster, concrete, brick bases.

It has a self-leveling effect, therefore it is suitable for correcting surfaces with slight deformations.

Easy Fix Roster

Tile adhesive Vetonit Easy Fix provides a strong bond of ceramic tiles, medium-sized porcelain stoneware fragments with various types of substrates. Due to its high resistance to the aquatic environment, the product can be used in rooms with high humidity - bathrooms, baths, saunas.

A strong mortar is suitable not only for laying on traditional substrates made of concrete, cement or brick, but also on sheets of drywall, gypsum fiber, cement-particle boards, cement plaster, gypsum plaster, cement-lime base.

Advice! To obtain a strong connection of the facing material with the base when using Vetonit Easy Fix glue, you need to maintain the same temperature of the surface, masonry and mortar for two days.

Granit fix

Granit Fix is a standard cladding agent for porcelain stoneware, double-fired ceramics, clinker and mosaics. The elastic texture of the mixture allows for laying on wall and floor surfaces from outdoors and indoors.

The glue is characterized by high frost resistance (150 cycles), lack of moisture absorption after drying, minimal shrinkage and fluidity. Granite Fix is one of the adhesives of the Vetonit line, which is suitable for underfloor heating and spot gluing of insulating materials. The gray solution has a very high strength.

On a note! Apply Vetonit tile adhesive to a clean, dry, grease-free surface. The higher the ambient temperature during the execution of work, the shorter the pot life of the prepared solution.

Which self-leveling floor to choose - weber.vetonit 3000 or weber.vetonit fast level?

The difference between weber-vetonit 3000 and weber.vetonit fast 4000 is that the first product is a superfinish self-leveling floor for eliminating differences up to 5 mm, and the second is a universal self-leveling floor for leveling from 3 to 60 mm. That is, weber.vetonit fast 4000 is suitable for both initial alignment and final alignment. In addition, weber.vetonit 3000 can be applied over weber.vetonit fast 4000 by first priming it with weber.prim multi or weber.vetonit MD 16.

Thanks to the use of modern additives in the composition, weber.vetonit fast 4000 has an increased pot life - the solution can be used within 40 minutes. Weber.vetonit 3000 self-leveling floor is made on the basis of special cements, and has increased strength and durability.

Weber.vetonit fast 4000 is a fast-curing dry flooring compound that allows you to install the flooring after 1–3 days with a layer thickness of 3–10 mm. Weber.vetonit 3000 self-leveling floor has the same drying time.

It should be noted that both products are economical to use - consumption is 1.5 kg per 1 m2 (weber.vetonit 3000), 1.5–1.7 kg per 1 m2 (weber.vetonit fast 4000).

To summarize: if the minimum floor thickness is of paramount importance, or there is a need for local repair of cracks up to 10 mm, we recommend weber.vetonit 3000.

What are the best garage floors?

The solution to this issue depends on the purpose of the garage, on the degree and intensity of its operation. For example, a parking garage must have a floor covering that is durable, water-resistant, chemical-resistant to oils.

It is also important that it does not become dusty. Today, there are 3 most common flooring options:

- Cement screed, e.g. weber.vetonit 5000 or weber.vetonit 4100, in combination with floor tiles.

- Cement-polymer coating from an industrial self-leveling floor, for example, weber.vetonit 4655.

- Epoxy polymer coating.

It is important to properly level the garage floor. It is difficult to achieve a smooth and even surface with concrete alone, Weber-Vetonit leveling levelers and self-leveling floors will help to solve this problem

Advantages of Vetonit tile adhesives

The Weber company (Weber) occupies a leading line among the manufacturers of dry building mixtures and other goods for construction and repair. Under this brand, a whole line of products for laying tiles and porcelain stoneware is produced - universal and specialized. All adhesives are divided into 2 groups - standard formulations and mixtures for solving complex problems with an improved formula.

A large assortment of tile adhesives is one of the significant advantages of the brand, because both beginners and professionals will be able to choose a tool that is really necessary for repair with the necessary characteristics. Another advantage is the high quality of Vetonit adhesives, confirmed by certificates of conformity. Weber tile adhesives also have other advantages:

- excellent level of adhesion to various surfaces (concrete, including cellular, brick, cement screed, gypsum coatings, cement-bonded particle boards, plastered and putty materials, etc.);

- the possibility of facing vertical and horizontal bases with all types of tiles - porcelain stoneware, tiles, mosaics, clinkers, blocks, natural and artificial stones;

- good elasticity - the products make it possible not to be afraid of seam cracking when applied to vibrating substrates, unstable materials and surfaces subject to shrinkage;

- frost resistance - adhesives withstand from 75 freezing and thawing cycles;

- low fluidity - the glue is easy to apply, it holds the tiles, preventing them from sliding on vertical surfaces;

- sufficient moisture resistance - the compositions can be used in rooms with high humidity.

Adhesives "Vetonit" are suitable for indoor and outdoor use (depending on the specific product). With their help, you can lay tiles in any room and on terraces, plinths, facades, balconies. The presence of such advantages determines the popularity of "Vetonit" in private and industrial construction.

Some features of gluing

The fixing technology is selected for each composition separately. Aerosols are sprayed over the surface at a distance of 15 or 20 cm, held for at least 60 seconds. Glue, not used at high temperatures, is taken on a brush, the base is lubricated, which, after 2-3 minutes, is connected to the cloth. The agent, the effectiveness of which increases with heating, is applied in several layers, each left to harden for a quarter of an hour. A cloth is glued on top, and a hairdryer is turned on. The substance melts and adheres evenly.

To plywood

The subwoofer case can also be sheathed with a Carpet. The material is laid out and cut out, leaving a fold allowance. The plywood case is treated with 88-CA liquid glue. After the composition is absorbed and dries, the same product must be taken on a brush and lubricated with a carpet, applied with a staple to the wood.

After 3 minutes, the material must be firmly pressed against the body, and the glue will harden, but it will dry for a day. After installing the speakers, the speaker system is mounted in the car.

To plastic

Before facing any part of the cabin, a piece of carpet is measured and cut off. The material is laid out on a cleaned and dried surface. A smooth plastic coating is treated with a fine-grained sandpaper, disinfected with a thinner, and anti-silicone is applied to avoid glue build-up.

Experienced craftsmen do not recommend wiping the steering wheel with a solvent containing acetone before tightening, since when the temperature rises, aggressive vapors, getting into the microfiber, destroy the upper layer of the carpet. For cleaning plastic it is better to use Molecule thinner.

If old material remains on the coating, it is not necessary to peel it off. Liquid glue 88 or Furniture is applied with a roller, brush in a thin layer, after a couple of minutes, press the carpet to the working surface. The composition finally dries up in a day. The aerosol is sprayed on the wrong side of the material, when the solvent disappears, the lining is fixed to the plastic. Thermoactive glue is applied to both surfaces to be joined in 5-6 layers, each is heated with a hairdryer. The carpet is pressed and held until the temperature of the composition decreases.